|

|

市場調査レポート

商品コード

1701815

MAP包装(ガス置換包装)市場:材料別、技術別、包装ガス別、用途別、地域別、2025-2033年Modified Atmosphere Packaging Market Report by Material, Technology, Packaging Gases, Application, and Region 2025-2033 |

||||||

カスタマイズ可能

|

|||||||

| MAP包装(ガス置換包装)市場:材料別、技術別、包装ガス別、用途別、地域別、2025-2033年 |

|

出版日: 2025年04月01日

発行: IMARC

ページ情報: 英文 139 Pages

納期: 2~3営業日

|

全表示

- 概要

- 図表

- 目次

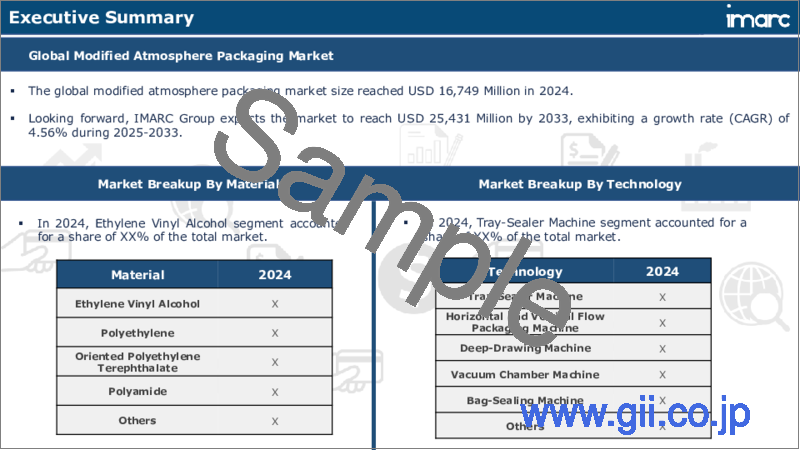

MAP包装(ガス置換包装)市場の世界市場規模は2024年に167億米ドルに達しました。IMARC Groupは、2025年から2033年にかけての成長率(CAGR)は4.56%で、2033年には254億米ドルに達すると予測しています。製品が提供する保存期間の延長、食品安全性の向上、新鮮な包装食品に対する消費者需要の増加、持続可能性に対する関心の高まり、食品サプライチェーンの急速な世界化、食品包装技術の進歩などが市場を推進している主な要因です。

MAP包装は、密封パッケージ内のガス組成を変化させ、腐敗しやすい製品の賞味期限を延ばす食品包装技術です。この方法は、果物、野菜、肉、魚介類など様々な食品の鮮度と品質を保持するために食品業界で広く使われています。包装内の酸素、二酸化炭素、窒素のレベルを調整することで、MAPは微生物の増殖や酸化など、自然に起こる劣化プロセスを遅らせる。その結果、MAPを使って包装された製品は鮮度を長く保つことができ、食品廃棄物を減らし、消費者に高品質の商品を確実に届けることができます。この技術は、製品の安全性を高め、流通距離を延ばし、最終的には消費者により便利で持続可能な食品体験を提供しようとする食品メーカーや小売業者にとって、効果的で信頼できるソリューションであることが証明されています。

MAPは、最適なガス環境を作り出すことで、生鮮食品の賞味期限を大幅に延長します。これにより、食品廃棄物が減少し、流通期間の延長が可能になります。これは、今日の世界化したサプライ・チェーンでは特に重要です。さらに、MAPは病原菌や腐敗微生物の増殖を抑制しながら、食品の鮮度と品質を維持するのに役立ちます。これは食品安全基準の向上に貢献し、食中毒のリスクを低減します。この他にも、消費者はますます新鮮で加工度の低い、保存期間の長い食品を求めるようになっています。MAPは、製品の自然な味、色、食感を保つことで、この需要に応えています。これに加えて、MAPは食品廃棄物を減らし、持続可能性を重視する世界の流れに沿うものです。食品の廃棄や輸送に伴う環境への影響を最小限に抑えることができます。これに加えて、食品流通ネットワークが国境を越えて拡大する中、MAPは鮮度を保ったまま長時間の輸送に耐えることを可能にします。これは、生鮮品の世界の取引をサポートします。これに伴い、企業は賞味期限の延長によるロスの減少から恩恵を受け、MAPは長期的には費用対効果の高いソリューションとなります。

MAP包装市場傾向/促進要因:

賞味期限の延長

MAP包装は、包装内の酸素、二酸化炭素、窒素のレベルを制御することで、生鮮食品の賞味期限を延長します。この精密な制御は、腐敗微生物の増殖を抑制し、酸化反応を遅らせる。その結果、生鮮食品、肉類、乳製品などの製品は、従来の包装方法と比較して鮮度を大幅に長く保つことができます。

食品安全性の向上

MAPは、有害な病原菌の増殖を抑制する包装内環境を作り出すことで、食品の安全性向上に貢献します。酸素レベルを下げ、ガス組成を変化させることで、MAPは細菌増殖のリスクを最小限に抑え、食中毒の可能性を低下させる。この技術は、消費者が購入する製品の安全性を確実に信頼できるようにし、ブランドの評判を高め、消費者の信頼を醸成します。

鮮度に対する消費者の要求の高まり

食品業界では、消費者は鮮度を重視します。消費者は、自然な味、色、食感を保つ製品を求めています。MAPは食品の官能的品質を保持することで、この需要に応えています。シャキシャキの野菜、ジューシーな果物、柔らかい肉など、MAPはこれらの製品が長期間魅力を維持することを保証します。これは、最小限の加工で自然な食品を求める消費者の嗜好と一致し、最終的に購買決定とブランド・ロイヤルティを促進します。

目次

第1章 序文

第2章 調査範囲と調査手法

- 調査の目的

- ステークホルダー

- データソース

- 一次情報

- 二次情報

- 市場推定

- ボトムアップアプローチ

- トップダウンアプローチ

- 調査手法

第3章 エグゼクティブサマリー

第4章 イントロダクション

- 概要

- 主要業界動向

第5章 世界のMAP包装市場

- 市場概要

- 市場実績

- COVID-19の影響

- 市場予測

第6章 市場内訳:材料別

- エチレンビニルアルコール

- ポリエチレン

- 延伸ポリエチレンテレフタレート

- ポリアミド

- その他

第7章 市場内訳:技術別

- トレイシーラー機

- 水平・垂直フロー包装機

- 深絞り機

- 真空チャンバーマシン

- バッグシーリングマシン

- その他

第8章 市場内訳:包装ガス別

- 窒素

- 酸素

- 二酸化炭素

- その他

第9章 市場内訳:用途別

- 乳製品

- 家禽

- ベーカリー・菓子店

- 魚介類・肉製品

- インスタント食品

- 果物・野菜

- その他

第10章 市場内訳:地域別

- 北米

- 米国

- カナダ

- アジア太平洋地域

- 中国

- 日本

- インド

- 韓国

- オーストラリア

- インドネシア

- その他

- 欧州

- ドイツ

- フランス

- 英国

- イタリア

- スペイン

- ロシア

- その他

- ラテンアメリカ

- ブラジル

- メキシコ

- その他

- 中東・アフリカ

- 市場内訳:国別

第11章 SWOT分析

- 概要

- 強み

- 弱み

- 機会

- 脅威

第12章 バリューチェーン分析

第13章 ポーターのファイブフォース分析

- 概要

- 買い手の交渉力

- 供給企業の交渉力

- 競合の程度

- 新規参入業者の脅威

- 代替品の脅威

第14章 価格分析

第15章 競合情勢

- 市場構造

- 主要企業

- 主要企業のプロファイル

- Air Products & Chemicals Inc.

- Amcor plc

- Barry-Wehmiller Companies

- Berry Global Inc

- Ilapak International S.A.

- Linde plc

- Multisorb Technologies Inc.(Filtration Group Corporation)

- Orics Industries Inc.

- Robert Reiser & Co. Inc.

- Sealed Air Corporation

- The Middleby Corporation

List of Figures

- Figure 1: Global: Modified Atmosphere Packaging Market: Major Drivers and Challenges

- Figure 2: Global: Modified Atmosphere Packaging Market: Sales Value (in Billion USD), 2019-2024

- Figure 3: Global: Modified Atmosphere Packaging Market Forecast: Sales Value (in Billion USD), 2025-2033

- Figure 4: Global: Modified Atmosphere Packaging Market: Breakup by Material (in %), 2024

- Figure 5: Global: Modified Atmosphere Packaging Market: Breakup by Technology (in %), 2024

- Figure 6: Global: Modified Atmosphere Packaging Market: Breakup by Packaging Gases (in %), 2024

- Figure 7: Global: Modified Atmosphere Packaging Market: Breakup by Application (in %), 2024

- Figure 8: Global: Modified Atmosphere Packaging Market: Breakup by Region (in %), 2024

- Figure 9: Global: Modified Atmosphere Packaging (Ethylene Vinyl Alcohol) Market: Sales Value (in Million USD), 2019 & 2024

- Figure 10: Global: Modified Atmosphere Packaging (Ethylene Vinyl Alcohol) Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 11: Global: Modified Atmosphere Packaging (Polyethylene) Market: Sales Value (in Million USD), 2019 & 2024

- Figure 12: Global: Modified Atmosphere Packaging (Polyethylene) Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 13: Global: Modified Atmosphere Packaging (Oriented Polyethylene Terephthalate) Market: Sales Value (in Million USD), 2019 & 2024

- Figure 14: Global: Modified Atmosphere Packaging (Oriented Polyethylene Terephthalate) Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 15: Global: Modified Atmosphere Packaging (Polyamide) Market: Sales Value (in Million USD), 2019 & 2024

- Figure 16: Global: Modified Atmosphere Packaging (Polyamide) Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 17: Global: Modified Atmosphere Packaging (Other Materials) Market: Sales Value (in Million USD), 2019 & 2024

- Figure 18: Global: Modified Atmosphere Packaging (Other Materials) Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 19: Global: Modified Atmosphere Packaging (Tray-Sealer Machine) Market: Sales Value (in Million USD), 2019 & 2024

- Figure 20: Global: Modified Atmosphere Packaging (Tray-Sealer Machine) Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 21: Global: Modified Atmosphere Packaging (Horizontal and Vertical Flow Packaging Machine) Market: Sales Value (in Million USD), 2019 & 2024

- Figure 22: Global: Modified Atmosphere Packaging (Horizontal and Vertical Flow Packaging Machine) Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 23: Global: Modified Atmosphere Packaging (Deep-Drawing Machine) Market: Sales Value (in Million USD), 2019 & 2024

- Figure 24: Global: Modified Atmosphere Packaging (Deep-Drawing Machine) Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 25: Global: Modified Atmosphere Packaging (Vacuum Chamber Machine) Market: Sales Value (in Million USD), 2019 & 2024

- Figure 26: Global: Modified Atmosphere Packaging (Vacuum Chamber Machine) Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 27: Global: Modified Atmosphere Packaging (Bag-Sealing Machine) Market: Sales Value (in Million USD), 2019 & 2024

- Figure 28: Global: Modified Atmosphere Packaging (Bag-Sealing Machine) Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 29: Global: Modified Atmosphere Packaging (Other Technologies) Market: Sales Value (in Million USD), 2019 & 2024

- Figure 30: Global: Modified Atmosphere Packaging (Other Technologies) Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 31: Global: Modified Atmosphere Packaging (Nitrogen) Market: Sales Value (in Million USD), 2019 & 2024

- Figure 32: Global: Modified Atmosphere Packaging (Nitrogen) Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 33: Global: Modified Atmosphere Packaging (Oxygen) Market: Sales Value (in Million USD), 2019 & 2024

- Figure 34: Global: Modified Atmosphere Packaging (Oxygen) Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 35: Global: Modified Atmosphere Packaging (Carbon Dioxide) Market: Sales Value (in Million USD), 2019 & 2024

- Figure 36: Global: Modified Atmosphere Packaging (Carbon Dioxide) Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 37: Global: Modified Atmosphere Packaging (Other Packaging Gases) Market: Sales Value (in Million USD), 2019 & 2024

- Figure 38: Global: Modified Atmosphere Packaging (Other Packaging Gases) Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 39: Global: Modified Atmosphere Packaging (Dairy Products) Market: Sales Value (in Million USD), 2019 & 2024

- Figure 40: Global: Modified Atmosphere Packaging (Dairy Products) Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 41: Global: Modified Atmosphere Packaging (Poultry) Market: Sales Value (in Million USD), 2019 & 2024

- Figure 42: Global: Modified Atmosphere Packaging (Poultry) Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 43: Global: Modified Atmosphere Packaging (Bakery and Confectionary) Market: Sales Value (in Million USD), 2019 & 2024

- Figure 44: Global: Modified Atmosphere Packaging (Bakery and Confectionary) Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 45: Global: Modified Atmosphere Packaging (Seafood and Meat Products) Market: Sales Value (in Million USD), 2019 & 2024

- Figure 46: Global: Modified Atmosphere Packaging (Seafood and Meat Products) Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 47: Global: Modified Atmosphere Packaging (Convenience Food) Market: Sales Value (in Million USD), 2019 & 2024

- Figure 48: Global: Modified Atmosphere Packaging (Convenience Food) Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 49: Global: Modified Atmosphere Packaging (Fruits and Vegetables) Market: Sales Value (in Million USD), 2019 & 2024

- Figure 50: Global: Modified Atmosphere Packaging (Fruits and Vegetables) Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 51: Global: Modified Atmosphere Packaging (Other Applications) Market: Sales Value (in Million USD), 2019 & 2024

- Figure 52: Global: Modified Atmosphere Packaging (Other Applications) Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 53: North America: Modified Atmosphere Packaging Market: Sales Value (in Million USD), 2019 & 2024

- Figure 54: North America: Modified Atmosphere Packaging Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 55: United States: Modified Atmosphere Packaging Market: Sales Value (in Million USD), 2019 & 2024

- Figure 56: United States: Modified Atmosphere Packaging Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 57: Canada: Modified Atmosphere Packaging Market: Sales Value (in Million USD), 2019 & 2024

- Figure 58: Canada: Modified Atmosphere Packaging Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 59: Asia-Pacific: Modified Atmosphere Packaging Market: Sales Value (in Million USD), 2019 & 2024

- Figure 60: Asia-Pacific: Modified Atmosphere Packaging Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 61: China: Modified Atmosphere Packaging Market: Sales Value (in Million USD), 2019 & 2024

- Figure 62: China: Modified Atmosphere Packaging Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 63: Japan: Modified Atmosphere Packaging Market: Sales Value (in Million USD), 2019 & 2024

- Figure 64: Japan: Modified Atmosphere Packaging Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 65: India: Modified Atmosphere Packaging Market: Sales Value (in Million USD), 2019 & 2024

- Figure 66: India: Modified Atmosphere Packaging Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 67: South Korea: Modified Atmosphere Packaging Market: Sales Value (in Million USD), 2019 & 2024

- Figure 68: South Korea: Modified Atmosphere Packaging Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 69: Australia: Modified Atmosphere Packaging Market: Sales Value (in Million USD), 2019 & 2024

- Figure 70: Australia: Modified Atmosphere Packaging Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 71: Indonesia: Modified Atmosphere Packaging Market: Sales Value (in Million USD), 2019 & 2024

- Figure 72: Indonesia: Modified Atmosphere Packaging Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 73: Others: Modified Atmosphere Packaging Market: Sales Value (in Million USD), 2019 & 2024

- Figure 74: Others: Modified Atmosphere Packaging Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 75: Europe: Modified Atmosphere Packaging Market: Sales Value (in Million USD), 2019 & 2024

- Figure 76: Europe: Modified Atmosphere Packaging Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 77: Germany: Modified Atmosphere Packaging Market: Sales Value (in Million USD), 2019 & 2024

- Figure 78: Germany: Modified Atmosphere Packaging Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 79: France: Modified Atmosphere Packaging Market: Sales Value (in Million USD), 2019 & 2024

- Figure 80: France: Modified Atmosphere Packaging Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 81: United Kingdom: Modified Atmosphere Packaging Market: Sales Value (in Million USD), 2019 & 2024

- Figure 82: United Kingdom: Modified Atmosphere Packaging Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 83: Italy: Modified Atmosphere Packaging Market: Sales Value (in Million USD), 2019 & 2024

- Figure 84: Italy: Modified Atmosphere Packaging Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 85: Spain: Modified Atmosphere Packaging Market: Sales Value (in Million USD), 2019 & 2024

- Figure 86: Spain: Modified Atmosphere Packaging Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 87: Russia: Modified Atmosphere Packaging Market: Sales Value (in Million USD), 2019 & 2024

- Figure 88: Russia: Modified Atmosphere Packaging Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 89: Others: Modified Atmosphere Packaging Market: Sales Value (in Million USD), 2019 & 2024

- Figure 90: Others: Modified Atmosphere Packaging Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 91: Latin America: Modified Atmosphere Packaging Market: Sales Value (in Million USD), 2019 & 2024

- Figure 92: Latin America: Modified Atmosphere Packaging Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 93: Brazil: Modified Atmosphere Packaging Market: Sales Value (in Million USD), 2019 & 2024

- Figure 94: Brazil: Modified Atmosphere Packaging Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 95: Mexico: Modified Atmosphere Packaging Market: Sales Value (in Million USD), 2019 & 2024

- Figure 96: Mexico: Modified Atmosphere Packaging Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 97: Others: Modified Atmosphere Packaging Market: Sales Value (in Million USD), 2019 & 2024

- Figure 98: Others: Modified Atmosphere Packaging Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 99: Middle East and Africa: Modified Atmosphere Packaging Market: Sales Value (in Million USD), 2019 & 2024

- Figure 100: Middle East and Africa: Modified Atmosphere Packaging Market: Breakup by Country (in %), 2024

- Figure 101: Middle East and Africa: Modified Atmosphere Packaging Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 102: Global: Modified Atmosphere Packaging Industry: SWOT Analysis

- Figure 103: Global: Modified Atmosphere Packaging Industry: Value Chain Analysis

- Figure 104: Global: Modified Atmosphere Packaging Industry: Porter's Five Forces Analysis

List of Tables

- Table 1: Global: Modified Atmosphere Packaging Market: Key Industry Highlights, 2024 and 2033

- Table 2: Global: Modified Atmosphere Packaging Market Forecast: Breakup by Material (in Million USD), 2025-2033

- Table 3: Global: Modified Atmosphere Packaging Market Forecast: Breakup by Technology (in Million USD), 2025-2033

- Table 4: Global: Modified Atmosphere Packaging Market Forecast: Breakup by Packaging Gases (in Million USD), 2025-2033

- Table 5: Global: Modified Atmosphere Packaging Market Forecast: Breakup by Application (in Million USD), 2025-2033

- Table 6: Global: Modified Atmosphere Packaging Market Forecast: Breakup by Region (in Million USD), 2025-2033

- Table 7: Global: Modified Atmosphere Packaging Market: Competitive Structure

- Table 8: Global: Modified Atmosphere Packaging Market: Key Players

The global modified atmosphere packaging market size reached USD 16.7 Billion in 2024. Looking forward, IMARC Group expects the market to reach USD 25.4 Billion by 2033, exhibiting a growth rate (CAGR) of 4.56% during 2025-2033. The extended shelf life offered by the product, improved food safety, increasing consumer demand for freshly packaged foods, rising concerns for sustainability, rapid globalization of food supply chain, and advancements in food packaging technology are some of the major factors propelling the market.

Modified Atmosphere Packaging (MAP) is a food packaging technique that involves altering the composition of gases inside a sealed package to extend the shelf life of perishable products. This method is widely used in the food industry to preserve the freshness and quality of various food items, including fruits, vegetables, meats, and seafood. By adjusting the levels of oxygen, carbon dioxide, and nitrogen within the packaging, MAP slows down the deterioration processes that occur naturally, such as microbial growth and oxidation. As a result, products packaged using MAP can remain fresh for a longer period, reducing food waste and ensuring that consumers receive high-quality goods. This technology has proven to be an effective and reliable solution for food manufacturers and retailers seeking to enhance product safety, extend distribution distances, and ultimately provide consumers with a more convenient and sustainable food experience.

MAP significantly extends the shelf life of perishable food products by creating an optimal gas environment. This reduces food waste and allows for longer distribution periods, especially important in today's globalized supply chains. Additionally, MAP helps maintain the freshness and quality of food items while inhibiting the growth of pathogens and spoilage microorganisms. This contributes to improved food safety standards, reducing the risk of foodborne illnesses. Other than this, consumers are increasingly seeking fresh, minimally processed foods with longer shelf lives. MAP meets this demand by preserving the natural taste, color, and texture of products. Besides this, MAP reduces food waste, which aligns with the growing global emphasis on sustainability. It minimizes the environmental impact associated with food disposal and transportation. Besides this, as food distribution networks expand across borders, MAP enables products to withstand longer journeys while remaining fresh. This supports the global trade of perishable goods. In line with this, businesses benefit from reduced losses due to extended shelf life, making MAP a cost-effective solution in the long run.

Modified Atmosphere Packaging Market Trends/Drivers:

Extended Shelf Life

Modified atmosphere packaging extends the shelf life of perishable food products by controlling the levels of oxygen, carbon dioxide, and nitrogen within the packaging. This precise control inhibits the growth of spoilage microorganisms and slows down oxidative reactions. As a result, products like fresh produce, meats, and dairy items can stay fresh for a significantly longer time compared to traditional packaging methods.

Enhanced Food Safety

MAP contributes to enhanced food safety by creating an environment inside the package that inhibits the proliferation of harmful pathogens. By reducing the oxygen level and modifying the gas composition, MAP minimizes the risk of bacterial growth, thereby lowering the chances of foodborne illnesses. This technology ensures that consumers can trust the safety of the products they purchase, reinforcing the reputation of brands and fostering consumer confidence.

Increasing Consumer Demand for Freshness

In the food industry, consumers place a high premium on freshness. They seek products that retain their natural taste, color, and texture. MAP meets this demand by preserving the sensory qualities of food items. Whether it's crisp vegetables, succulent fruits, or tender meats, MAP ensures that these products maintain their appeal for an extended period. This aligns with consumer preferences for minimally processed and natural foods, ultimately driving purchasing decisions and brand loyalty.

Modified Atmosphere Packaging Industry Segmentation:

Breakup by Material:

Ethylene Vinyl Alcohol

- Polyethylene

- Oriented Polyethylene Terephthalate

- Polyamide

- Others

Polyethylene (PE) dominates the market

Its widespread use in packaging can be attributed to its versatility and cost-effectiveness. Polyethylene is available in various forms, including low-density polyethylene (LDPE) and high-density polyethylene (HDPE), allowing manufacturers to choose the most suitable type for specific packaging applications. Additionally, the excellent barrier properties of polyethylene make it highly effective in preserving the freshness of food products and protecting them from external contaminants. It is particularly adept at preventing moisture and oxygen from permeating the packaging, which is vital for extending the shelf life of perishable goods. Furthermore, polyethylene is known for its durability and strength, which ensures that packaged products remain intact during transportation and handling. Its flexibility also makes it an ideal choice for creating various packaging formats, from bags and pouches to bottles and containers.

Breakup by Technology:

- Tray-Sealer Machine

- Horizontal and Vertical Flow Packaging Machine

- Deep-Drawing Machine

- Vacuum Chamber Machine

- Bag-Sealing Machine

- Others

Tray-sealer machines are designed for sealing products in trays or containers, offering excellent product protection and presentation. They are widely used for packaging fresh and processed foods, pharmaceuticals, and various consumer goods. The market for tray-sealer machines is driven by the demand for extended shelf life, tamper-evident packaging, and attractive product display. These machines provide airtight seals, preventing contamination and preserving product freshness. Additionally, the flexibility to accommodate different tray sizes and sealing options makes tray-sealer machines a preferred choice for manufacturers aiming to meet diverse packaging requirements.

Horizontal machines are ideal for wrapping products like bars, bakery items, and hardware, while vertical machines excel at packaging items like candies, grains, and liquids. The market for these machines has expanded due to their speed, flexibility, and ability to create airtight packages. Horizontal and vertical flow packaging machines enhance product visibility and ensure consistent, high-quality packaging. The demand is driven by industries such as food and beverages, pharmaceuticals, and cosmetics, where efficient and attractive packaging is essential for product differentiation and consumer appeal.

Deep-drawing machines create customized trays or containers by forming plastic sheets into the desired shape and then sealing them. The market for deep-drawing machines is growing as manufacturers seek precise and secure packaging solutions to protect and present their products effectively. Deep-drawn packaging offers excellent product protection and extends shelf life, making it essential for industries focused on perishable goods. The ability to create tailored packaging solutions with deep-drawing machines addresses the diverse needs of manufacturers and enhances the overall efficiency of their packaging processes.

Breakup by Packaging Gases:

- Nitrogen

- Oxygen

- Carbon Dioxide

- Others

Carbon dioxide accounts for the majority of the overall market share

CO2 is a natural component of the atmosphere of the Earth, making it readily available and cost-effective. This accessibility ensures that CO2 is a practical choice for many packaging applications. Additionally, CO2 offers outstanding preservation properties. It functions as a natural preservative by displacing oxygen inside packaging, which helps inhibit the growth of aerobic microorganisms and prevents oxidative reactions in food products. This preservation capability significantly extends the shelf life of a wide range of perishable goods, including meat, seafood, and bakery items. Moreover, carbon dioxide is eco-friendly and poses no harm to the environment when properly handled and disposed of. This aligns with the global shift toward sustainable and environmentally responsible packaging practices.

Breakup by Application:

- Dairy Products

- Poultry

- Bakery and Confectionary

- Seafood and Meat Products

- Convenience Food

- Fruits and Vegetables

- Others

Fruits and vegetables represent the largest application area

Fruits and vegetables are staples in the human diet and are consumed globally. Their prominence in diets makes them a substantial segment within the food industry. Moreover, with the increasing awareness about the health benefits associated with a diet rich in fresh produce, there is a growing demand for these items. Additionally, the perishable nature of fruits and vegetables necessitates effective preservation and packaging methods. Modified Atmosphere Packaging (MAP), for instance, plays a critical role in extending the shelf life of these products, reducing food waste, and ensuring they reach consumers in optimal condition. Furthermore, the visual appeal and freshness of fruits and vegetables are crucial factors influencing consumer purchasing decisions. Proper packaging, such as clear films or trays, allows consumers to inspect the quality of the produce, which is essential in the competitive market. Moreover, the global trade of fruits and vegetables has surged in recent years, with products often traveling long distances. Effective packaging not only maintains product freshness but also reduces damage during transit, enhancing the viability of international trade.

Breakup by Region:

- North America

- United States

- Canada

- Asia-Pacific

- China

- Japan

- India

- South Korea

- Australia

- Indonesia

- Others

- Europe

- Germany

- France

- United Kingdom

- Italy

- Spain

- Russia

- Others

- Latin America

- Brazil

- Mexico

- Others

- Middle East and Africa

Asia Pacific leads the market, accounting for the largest modified atmosphere packaging market share

The market research report has also provided a comprehensive analysis of all the major regional markets, which include North America (the United States and Canada); Europe (Germany, France, the United Kingdom, Italy, Spain, Russia, and others); Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, and others); Latin America (Brazil, Mexico, and others); and the Middle East and Africa. According to the report, Asia Pacific accounted for the largest market share.

The region possesses a massive and diverse food industry with a high demand for MAP technology. The growing middle-class population and urbanization have led to increased consumption of packaged, convenience, and ready-to-eat foods, all of which benefit significantly from MAP in terms of shelf-life extension and preservation of freshness. Additionally, Asia Pacific countries are major producers and exporters of fresh produce, seafood, and processed foods. MAP enables these nations to expand their export capabilities by extending the shelf life of perishable goods, maintaining product quality during transportation, and complying with stringent international food safety standards. Furthermore, the region's focus on sustainability and reducing food waste aligns with the eco-friendly aspects of MAP technology. Reducing food loss is a priority, and MAP helps achieve this goal by minimizing spoilage and increasing product longevity.

Competitive Landscape:

Research and development have been a focal point for these companies. They invest heavily in developing innovative MAP solutions that cater to a wide range of products and packaging needs. This includes the development of advanced gas-mixing technologies, more sustainable packaging materials, and improved sealing techniques to enhance the effectiveness of MAP. Additionally, these players actively engage in collaborations and partnerships with food manufacturers and retailers. By providing comprehensive MAP solutions and offering technical support, they create mutually beneficial relationships that encourage the adoption of MAP technology among their clients. Other than this, key players prioritize educating the market about the benefits of MAP. They conduct awareness campaigns, seminars, and workshops to highlight how MAP can reduce food waste, extend shelf life, and improve food safety. These efforts not only enhance the understanding of MAP but also foster trust in the technology. Besides this, sustainability is a growing concern, and key players are taking steps to develop eco-friendly MAP solutions. This includes using recyclable materials for packaging and exploring alternative, more environmentally friendly gases for modified atmospheres.

The market research report has provided a comprehensive analysis of the competitive landscape. Detailed profiles of all major companies have also been provided. Some of the key players in the market include:

- Air Products & Chemicals Inc.

- Amcor plc

- Barry-Wehmiller Companies

- Berry Global Inc

- Ilapak International S.A.

- Linde plc

- Multisorb Technologies Inc. (Filtration Group Corporation)

- Orics Industries Inc.

- Robert Reiser & Co. Inc.

- Sealed Air Corporation

- The Middleby Corporation

Key Questions Answered in This Report

- 1.What was the size of the global modified atmosphere packaging market in 2024?

- 2.What is the expected growth rate of the global modified atmosphere packaging market during 2025-2033?

- 3.What are the key factors driving the global modified atmosphere packaging market?

- 4.What has been the impact of COVID-19 on the global modified atmosphere packaging market?

- 5.What is the breakup of the global modified atmosphere packaging market based on the material?

- 6.What is the breakup of the global modified atmosphere packaging market based on the packaging gases?

- 7.What is the breakup of the global modified atmosphere packaging market based on the application?

- 8.What are the key regions in the global modified atmosphere packaging market?

- 9.Who are the key players/companies in the global modified atmosphere packaging market?

Table of Contents

1 Preface

2 Scope and Methodology

- 2.1 Objectives of the Study

- 2.2 Stakeholders

- 2.3 Data Sources

- 2.3.1 Primary Sources

- 2.3.2 Secondary Sources

- 2.4 Market Estimation

- 2.4.1 Bottom-Up Approach

- 2.4.2 Top-Down Approach

- 2.5 Forecasting Methodology

3 Executive Summary

4 Introduction

- 4.1 Overview

- 4.2 Key Industry Trends

5 Global Modified Atmosphere Packaging Market

- 5.1 Market Overview

- 5.2 Market Performance

- 5.3 Impact of COVID-19

- 5.4 Market Forecast

6 Market Breakup by Material

- 6.1 Ethylene Vinyl Alcohol

- 6.1.1 Market Trends

- 6.1.2 Market Forecast

- 6.2 Polyethylene

- 6.2.1 Market Trends

- 6.2.2 Market Forecast

- 6.3 Oriented Polyethylene Terephthalate

- 6.3.1 Market Trends

- 6.3.2 Market Forecast

- 6.4 Polyamide

- 6.4.1 Market Trends

- 6.4.2 Market Forecast

- 6.5 Others

- 6.5.1 Market Trends

- 6.5.2 Market Forecast

7 Market Breakup by Technology

- 7.1 Tray-Sealer Machine

- 7.1.1 Market Trends

- 7.1.2 Market Forecast

- 7.2 Horizontal and Vertical Flow Packaging Machine

- 7.2.1 Market Trends

- 7.2.2 Market Forecast

- 7.3 Deep-Drawing Machine

- 7.3.1 Market Trends

- 7.3.2 Market Forecast

- 7.4 Vacuum Chamber Machine

- 7.4.1 Market Trends

- 7.4.2 Market Forecast

- 7.5 Bag-Sealing Machine

- 7.5.1 Market Trends

- 7.5.2 Market Forecast

- 7.6 Others

- 7.6.1 Market Trends

- 7.6.2 Market Forecast

8 Market Breakup by Packaging Gases

- 8.1 Nitrogen

- 8.1.1 Market Trends

- 8.1.2 Market Forecast

- 8.2 Oxygen

- 8.2.1 Market Trends

- 8.2.2 Market Forecast

- 8.3 Carbon Dioxide

- 8.3.1 Market Trends

- 8.3.2 Market Forecast

- 8.4 Others

- 8.4.1 Market Trends

- 8.4.2 Market Forecast

9 Market Breakup by Application

- 9.1 Dairy Products

- 9.1.1 Market Trends

- 9.1.2 Market Forecast

- 9.2 Poultry

- 9.2.1 Market Trends

- 9.2.2 Market Forecast

- 9.3 Bakery and Confectionary

- 9.3.1 Market Trends

- 9.3.2 Market Forecast

- 9.4 Seafood and Meat Products

- 9.4.1 Market Trends

- 9.4.2 Market Forecast

- 9.5 Convenience Food

- 9.5.1 Market Trends

- 9.5.2 Market Forecast

- 9.6 Fruits and Vegetables

- 9.6.1 Market Trends

- 9.6.2 Market Forecast

- 9.7 Others

- 9.7.1 Market Trends

- 9.7.2 Market Forecast

10 Market Breakup by Region

- 10.1 North America

- 10.1.1 United States

- 10.1.1.1 Market Trends

- 10.1.1.2 Market Forecast

- 10.1.2 Canada

- 10.1.2.1 Market Trends

- 10.1.2.2 Market Forecast

- 10.1.1 United States

- 10.2 Asia-Pacific

- 10.2.1 China

- 10.2.1.1 Market Trends

- 10.2.1.2 Market Forecast

- 10.2.2 Japan

- 10.2.2.1 Market Trends

- 10.2.2.2 Market Forecast

- 10.2.3 India

- 10.2.3.1 Market Trends

- 10.2.3.2 Market Forecast

- 10.2.4 South Korea

- 10.2.4.1 Market Trends

- 10.2.4.2 Market Forecast

- 10.2.5 Australia

- 10.2.5.1 Market Trends

- 10.2.5.2 Market Forecast

- 10.2.6 Indonesia

- 10.2.6.1 Market Trends

- 10.2.6.2 Market Forecast

- 10.2.7 Others

- 10.2.7.1 Market Trends

- 10.2.7.2 Market Forecast

- 10.2.1 China

- 10.3 Europe

- 10.3.1 Germany

- 10.3.1.1 Market Trends

- 10.3.1.2 Market Forecast

- 10.3.2 France

- 10.3.2.1 Market Trends

- 10.3.2.2 Market Forecast

- 10.3.3 United Kingdom

- 10.3.3.1 Market Trends

- 10.3.3.2 Market Forecast

- 10.3.4 Italy

- 10.3.4.1 Market Trends

- 10.3.4.2 Market Forecast

- 10.3.5 Spain

- 10.3.5.1 Market Trends

- 10.3.5.2 Market Forecast

- 10.3.6 Russia

- 10.3.6.1 Market Trends

- 10.3.6.2 Market Forecast

- 10.3.7 Others

- 10.3.7.1 Market Trends

- 10.3.7.2 Market Forecast

- 10.3.1 Germany

- 10.4 Latin America

- 10.4.1 Brazil

- 10.4.1.1 Market Trends

- 10.4.1.2 Market Forecast

- 10.4.2 Mexico

- 10.4.2.1 Market Trends

- 10.4.2.2 Market Forecast

- 10.4.3 Others

- 10.4.3.1 Market Trends

- 10.4.3.2 Market Forecast

- 10.4.1 Brazil

- 10.5 Middle East and Africa

- 10.5.1 Market Trends

- 10.5.2 Market Breakup by Country

- 10.5.3 Market Forecast

11 SWOT Analysis

- 11.1 Overview

- 11.2 Strengths

- 11.3 Weaknesses

- 11.4 Opportunities

- 11.5 Threats

12 Value Chain Analysis

13 Porters Five Forces Analysis

- 13.1 Overview

- 13.2 Bargaining Power of Buyers

- 13.3 Bargaining Power of Suppliers

- 13.4 Degree of Competition

- 13.5 Threat of New Entrants

- 13.6 Threat of Substitutes

14 Price Analysis

15 Competitive Landscape

- 15.1 Market Structure

- 15.2 Key Players

- 15.3 Profiles of Key Players

- 15.3.1 Air Products & Chemicals Inc.

- 15.3.1.1 Company Overview

- 15.3.1.2 Product Portfolio

- 15.3.1.3 Financials

- 15.3.1.4 SWOT Analysis

- 15.3.2 Amcor plc

- 15.3.2.1 Company Overview

- 15.3.2.2 Product Portfolio

- 15.3.3 Barry-Wehmiller Companies

- 15.3.3.1 Company Overview

- 15.3.3.2 Product Portfolio

- 15.3.4 Berry Global Inc

- 15.3.4.1 Company Overview

- 15.3.4.2 Product Portfolio

- 15.3.4.3 Financials

- 15.3.4.4 SWOT Analysis

- 15.3.5 Ilapak International S.A.

- 15.3.5.1 Company Overview

- 15.3.5.2 Product Portfolio

- 15.3.6 Linde plc

- 15.3.6.1 Company Overview

- 15.3.6.2 Product Portfolio

- 15.3.6.3 Financials

- 15.3.7 Multisorb Technologies Inc. (Filtration Group Corporation)

- 15.3.7.1 Company Overview

- 15.3.7.2 Product Portfolio

- 15.3.8 Orics Industries Inc.

- 15.3.8.1 Company Overview

- 15.3.8.2 Product Portfolio

- 15.3.9 Robert Reiser & Co. Inc.

- 15.3.9.1 Company Overview

- 15.3.9.2 Product Portfolio

- 15.3.10 Sealed Air Corporation

- 15.3.10.1 Company Overview

- 15.3.10.2 Product Portfolio

- 15.3.10.3 Financials

- 15.3.10.4 SWOT Analysis

- 15.3.11 The Middleby Corporation

- 15.3.11.1 Company Overview

- 15.3.11.2 Product Portfolio

- 15.3.11.3 Financials

- 15.3.11.4 SWOT Analysis

- 15.3.1 Air Products & Chemicals Inc.