|

市場調査レポート

商品コード

1640583

AGV(無人搬送車):市場シェア分析、産業動向・統計、成長予測(2025~2030年)AGV - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

カスタマイズ可能

適宜更新あり

|

|||||||

| AGV(無人搬送車):市場シェア分析、産業動向・統計、成長予測(2025~2030年) |

|

出版日: 2025年01月05日

発行: Mordor Intelligence

ページ情報: 英文 120 Pages

納期: 2~3営業日

|

全表示

- 概要

- 目次

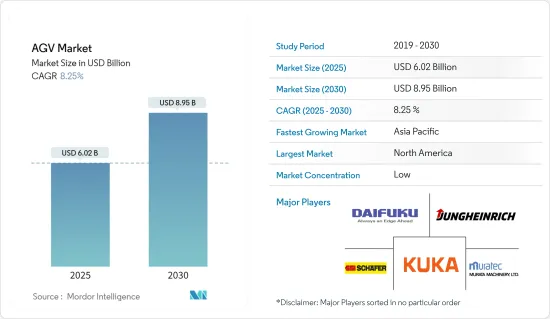

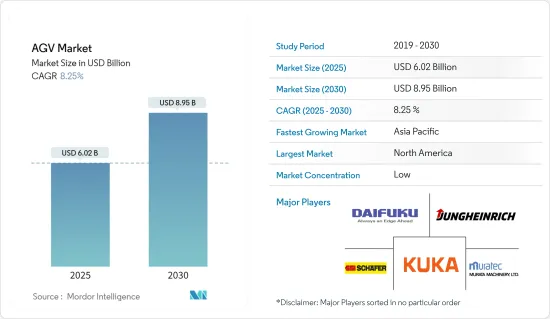

AGV(無人搬送車)市場規模は2025年に60億2,000万米ドルと推計され、予測期間(2025-2030年)のCAGRは8.25%で、2030年には89億5,000万米ドルに達すると予測されます。

主なハイライト

- 技術進歩の高まり、産業における自動化需要の増加、製造・倉庫施設におけるロボット需要の増加、新興市場の成長が、自動搬送車市場の成長を促進する主な要因です。

- 近年、自動化は製造業に革命をもたらし、生産性、効率性、安全性を向上させています。自動化技術における最新のブレークスルーは、無人搬送車(AGV)です。AGVは、人間の安全を確保し、最適な効率性の要求を満たす能力により、製造施設でかなりの認知度を得ています。技術の進歩により、製造業者は自社の運用要件に合わせたAGVを作成し、さまざまな用途に効果的に導入できるようになった。

- 自動車業界では、オートメーションとAGVの製造現場への導入が進んでいます。例えば、スペインのマルトレルにあるSEATの工場は、デジタル化されたスマートな工場へと変貌を遂げています。同社は、SLAMナビゲーション、4G接続、誘導バッテリー充電を備えたAGVを導入しました。この施設には、屋外作業用のAGVが8台と、マルトレル工場とバルセロナ工場の組み立て作業場内で部品を運搬するAGVが200台以上あります。

- 世界の労働市場は非常に逼迫しており、これが自動フォークリフトの成長の主な理由となっています。失業率が過去50年間で最低水準にあるにもかかわらず、物流センターや倉庫では、信頼できる労働者を見つけ、確保することが難しいです。自動化は、24時間体制で継続的かつ信頼性の高いパフォーマンスを提供し、労働力格差の解消に役立つ可能性があります。

- さらに、同市場では複数のベンダーがビル内駐車場向けAGVの発売に注力しており、市場の成長をさらに後押ししています。例えば、オーテック・オーティス・パーキング・システムズは2024年4月、人工知能(AI)技術を活用した無人搬送車(AGV)駐車ロボットを発売しました。これはAIとモノのインターネット(IoT)技術を組み合わせた自律走行システムです。その目的は、自動運転駐車場の最適ルートを自動的に見つけ、無人駐車を容易にすることです。

- 継続的に増加する研究開発費と世界の生産事業所数の増加が、中堅産業、特に食品加工と製薬分野での世界の自動化需要を牽引しています。

- さらに、サプライチェーンや製造工程をAGVで自動化する企業は、多額の投資をしなければならないです。これは、AGVを購入し、設置し、作業スペースをAGVに適したものに調整するための価格を引き受けるものです。さらに、製造業者は、AGVのコストが高いため、AGVの使用を思いとどまるかもしれないです。中小企業は、自動化システムを購入する余裕がなく、代わりに従来の手動フォークリフトトラックを使用しなければならないため、AGVを採用するのは難しいと感じるかもしれないです。

- さらに、景気後退、インフレ、戦争、気候変動、貿易紛争、エネルギーアクセス、産業スパイなどの他の脅威は、エンドユーザー部門におけるAGVの役割を直接形作る原因となっている要因の一部です。

AGV(無人搬送車)市場の動向

より高い効率を求めるeコマースの急成長

- 製造業の成長にもかかわらず、倉庫・ロジスティクス部門からのかなりの需要はeコマース活動に捧げられています。例えば、カナダの倉庫ポートフォリオは主にeコマースで構成されており、同国の倉庫事業の50%以上を占めると推定されています。

- AGVの導入は、eコマースにおけるさまざまな分野に機会を提供します。具体的には、AGVは、広い倉庫エリアに広がる大きなSKU範囲の大量の小口注文を含むフルフィルメント業務に適しています。水平走行を行うために自律型ロボットを使用することで、注文処理効率を高めることができます。

- 常時接続のeコマースのイントロダクション、より迅速な対応への要求、より少ないエラーでより多くの在庫管理ユニットを管理する必要性により、倉庫は規模を拡大し、インテリジェントで効率的な自動倉庫の基準を満たす必要があります。このような世界化の進展、オンライン小売や大量小売の台頭は、小売業界におけるAGVの需要を増大させています。

- 先進国でも新興国でも、増加する1日配達の注文に対応するeコマース企業の需要が高まっているため、こうしたスキームの商業的な実行可能性により、効率が大幅に向上しています。eコマースの倉庫は、AGVの助けを借りて1日配送を実施しています。

- eコマース産業の成長は、世界中の効率的な倉庫管理および在庫管理の必要性と共に、調査された市場を牽引しています。例えば、米国商務省国勢調査局によると、2023年第4四半期、米国の小売売上高全体に占めるeコマースの割合は15.6%となり、前四半期から上昇しました。2023年10月から12月にかけて、米国の小売eコマース売上高は2,850億米ドルを超え、四半期ベースで史上最高を記録しました。

- 急速に変化する小売市場により、物流センターはeコマース注文処理に対する革新的かつ柔軟で自動化されたアプローチを模索し、導入する必要に迫られています。このようなeコマース購入の増加は、スムーズなワークフローを強化するために、企業が自動マテリアルハンドリング機器を操作プロセスに導入することを後押しすると予想されます。

- さらに、サプライチェーンはeコマース需要の増加に対応して物流センターでAGVを使用し始め、産業が高い生産性で機能することを可能にしています。医薬品などの分野では、需要への対応や衛生維持のためにAGVの利用が拡大しています。病院やその他のヘルスケア施設では、食品、ゴミ箱、リネン、無菌消耗品の非接触搬送にAGVが活用されています。

大幅な成長が期待されるアジア太平洋地域

- 中国のAGV市場は、主に同国の製造業の成長によって牽引されています。中国は世界最大の製造業を擁し、国の経済成長にも大きく貢献しています。

- 小売業が拡大し、投資が増加していることから、中国は自動搬送車にとって重要な市場になると予想されます。消費率の上昇と倉庫の大型化需要の高まりも、無人搬送車の必要性を高めています。

- さらに、中国はインダストリー4.0の主要な導入国であり、欧州連合、米国、日本などの地域を抑えて、この地域には世界で最も先進的な製造施設があります。

- 世界経済フォーラムによると、現在インダストリー4.0技術を使用している世界の69の工場のうち、中国は20の工場があり、EUの19、米国の7、日本の5がそれに続いています。工場全体の自動化の基盤であるだけでなく、自動保管・検索システムもインダストリー4.0の基盤となっています。

- さらに、インド、中国、近隣諸国などの新興国におけるeコマース需要の増加に伴い、eコマース企業は倉庫にAGVを大幅に導入しています。IBEFによると、インドのeコマースはCAGR 27%を記録し、2026年までに1,630億米ドルに達すると予測されています。同様に23年度には、インドのeコマースの商品総額(GMV)は600億米ドルに達し、前年比22%増となった。

- さらに、複数の企業が業務の自動化をサポートするためにAGVを採用しており、市場をさらに牽引しています。例えば、2024年4月には、釜山ニューポートの東原世界ターミナル(DGT)が正式な落成式を行った。これは韓国の港湾自動化の旅における重要なマイルストーンであり、このターミナルは水平輸送にAGVを使用する国内初のターミナルです。釜山新港では、DGTが7番目のコンテナ・ターミナルとなります。別名「トランスファークレーン」とも呼ばれる自動ヤードクレーンは、釜山新港の他の6つのターミナルすべてに設置されています。しかし、AGVを使用するのはDGTが初めてです。

- 同様に、2023年8月、ウェストポート・マレーシアは、将来のターミナル開発計画で電動無人搬送車を使用する可能性を調査する計画を発表しました。

AGV(無人搬送車)産業の概要

世界のAGV(無人搬送車)市場は細分化されており、多数のプレーヤーが市場シェアを争っています。この業界は、デジタルトランスフォーメーションやインダストリー4.0とIoTの統合といった要因によって、大きな成長機会を目の当たりにしています。業界をリードするのは、Kuka AG、ダイフク、SSI Schaefer AG、村田機械、ユングハインリッヒAGなどの有力企業です。

- 2024年3月FFTは、誘導充電技術を提供するWiferionと提携し、新たな無人搬送車システムでポートフォリオを拡大することを発表。FFTigvとWiferionの充電システムは、ライプチヒにあるBMWグループの工場に導入されました。FFTは新たな製造施設を建設し、ワイヤレス充電とAGVを活用して生産量と効率を向上させました。

- 2024年3月Cypher Roboticsは、効率的で正確なサイクルカウントと工業用スキャニングを実現するCaptis AGV(自律型地上走行車)の発売を発表。Captis AGVは倉庫内を自走することができます。インフラに変更を加える必要はなく、人や物に衝突することもないです。

その他の特典:

- エクセル形式の市場予測(ME)シート

- 3ヶ月のアナリスト・サポート

目次

第1章 イントロダクション

- 調査の前提条件と市場定義

- 調査範囲

第2章 調査手法

第3章 エグゼクティブサマリー

第4章 市場洞察

- 市場概要

- 産業バリューチェーン分析

- 業界の魅力度-ポーターのファイブフォース分析

- 供給企業の交渉力

- 買い手/消費者の交渉力

- 新規参入業者の脅威

- 代替品の脅威

- 競争企業間の敵対関係の強さ

- COVID-19の影響とその他のマクロ経済要因が市場に与える影響

第5章 市場力学

- 市場促進要因

- より高い効率性を求めるeコマースの急成長

- 技術とロボットへの投資の増加

- 市場抑制要因

- 通信遅延によるリアルタイム無線制御の限界

第6章 市場セグメンテーション

- 製品タイプ別

- 自動フォークリフト

- 自動牽引/トラクター/タグ

- ユニットロード

- 組立ライン

- 特殊用途

- エンドユーザー産業別

- 飲食品

- 自動車

- 小売

- 電子・電気

- 一般製造業

- 製薬

- その他エンドユーザー産業

- 地域別

- 北米

- 欧州

- アジア

- オーストラリア・ニュージーランド

- ラテンアメリカ

- 中東・アフリカ

第7章 競合情勢

- 企業プロファイル

- KUKA AG

- Jungheinrich AG

- Murata Machinery Ltd

- Daifuku Co. Ltd

- SSI Schaefer Systems International DWC LLC

- Swisslog Holding

- Dematic Corp.

- Toyota Material Handling

- Scott Technology Limited

- John Bean Technologies(JBT)Corporation

- Systems Logistics SPA

- Seegrid Corporation

第8章 投資分析

第9章 市場の将来

The AGV Market size is estimated at USD 6.02 billion in 2025, and is expected to reach USD 8.95 billion by 2030, at a CAGR of 8.25% during the forecast period (2025-2030).

Key Highlights

- Rising technological advancements, increased demand for automation in industries, increased demand for robots in manufacturing and warehousing facilities, and growing emerging markets are the key factors driving the growth of the automated guided vehicles market.

- In recent years, automation has revolutionized the manufacturing sector, resulting in enhanced productivity, efficiency, and safety. Among the latest breakthroughs in automation technology are automated guided vehicles (AGVs). AGVs have gained considerable recognition in manufacturing facilities due to their ability to ensure human safety and meet the demand for optimal efficiency. Technological advancements have empowered manufacturers to create AGVs tailored to their operational requirements and effectively implement them for various applications.

- The automotive industry is increasingly incorporating automation and AGVs into its manufacturing floors. For instance, the SEAT plant in Martorell, Spain, is transforming into a digitalized and smart factory. The company implemented AGVs with SLAM navigation, 4G connectivity, and induction battery charging. The facility has eight AGVs for outdoor operation and over 200 AGVs that deliver parts inside the assembly workshops at the Martorell and Barcelona factories.

- The global labor market is extremely tight, which is the primary reason for the growth of automated forklifts. Despite the fact that unemployment is at its lowest level in fifty years, distribution centers and warehouses find it difficult to find and keep trustworthy workers. Automation could provide continuous, reliable performance around the clock, helping to close the labor gap.

- Furthermore, several vendors in the market are focusing on launching AGVs for parking in the buildings, further supporting the market's growth. For instance, in April 2024, Autech-Otis Parking Systems launched an automatic guided vehicle (AGV) parking robot utilizing artificial intelligence (AI) technology. It is an autonomous driving system that combines AI and Internet of Things (IoT) technologies. Its goal is to automatically find the best routes for self-driving parking lots so that unmanned parking can be made easier.

- The continuously increasing R&D expenditure and the rising number of production establishments worldwide are driving the demand for automation worldwide in mid-range industries, especially in the food processing and pharmaceutical sectors.

- Moreover, companies that automate their supply chains or manufacturing processes with AGVs have to invest a lot of money. This takes care of the price of buying, setting up, and adjusting the workspace to make it more AGV-friendly. Moreover, manufacturers might be dissuaded from using AGVs due to their high cost. Smaller businesses may find it difficult to adopt AGVs since they cannot afford automated systems and must instead use traditional, manual forklift trucks.

- Furthermore, other threats such as recession, inflation, war, climate change, trade disputes, energy access, and industrial espionage are some of the factors that are responsible for directly shaping the role of AGVs in end-user sectors.

Automated Guided Vehicles Market Trends

Rapid Growth of E-commerce Demanding Higher Efficency

- Despite growth in the manufacturing industry, considerable demand from the warehousing and logistics sector is dedicated to e-commerce activity. For instance, the Canadian warehouse portfolio is mainly comprised of e-commerce, which is estimated to make up more than 50% of the country's warehouse business.

- The deployment of AGVs provides an opportunity for different areas in e-commerce. Specifically, the AGVs are suited for fulfillment operations involving large quantities of small orders for large SKU ranges spread across large warehouse areas. Using autonomous robots to perform horizontal traveling can increase order fulfillment efficiency.

- With the introduction of always-on e-commerce, the demand for faster responses, and the need to manage a more significant number of stock-keeping units with fewer errors, warehouses need to scale up and meet the standards of an intelligent, efficient, and automated warehouse. Such increasing globalization and the rise of online retail and bulk retail have increased demand for AGVs in the retail industry.

- The rising demand for e-commerce companies to cater to the increasing number of single-day delivery orders, both in advanced and emerging economies, has resulted in a significant increase in efficiency owing to the commercial viability of these schemes. E-commerce warehouses carry out the single-day delivery method with the aid of AGVs.

- The growth in the e-commerce industry, along with the need for efficient warehousing and inventory management across the world, are driving the market studied. For instance, according to the Census Bureau of the Department of Commerce, in the fourth quarter of 2023, the share of e-commerce in total US retail sales stood at 15.6%, up from the previous quarter. From October to December 2023, retail e-commerce sales in the United States hit over USD 285 billion, the highest quarterly revenue in history.

- The rapidly changing retail market compels distribution centers to seek out and implement innovative, flexible, and automated approaches to e-commerce order fulfillment. Such a rise in e-commerce purchases is expected to push companies to deploy automated material handling equipment in their operation process to enhance smooth workflow.

- Moreover, supply chains began using AGVs in distribution centers in response to increased e-commerce demand, allowing industries to function at high productivity. AGVs' use has expanded in sectors like pharmaceuticals to keep up with demand and maintain sanitation. Hospitals and other healthcare facilities utilize AGVs to undertake the contactless transfer of food, trash bins, linens, and sterile supplies.

Asia-Pacific Expected to Witness Significant Growth

- The AGV market in China is primarily driven by the country's proliferating manufacturing industry. China has the largest manufacturing industry in the world, and it is also a key contributor to the country's economic growth.

- China is anticipated to be a crucial market for automated guided vehicles, given the expanding retail sector and increased investments. Rising consumption rates and the growing demand for larger warehouses are also driving the need for AGVs.

- Moreover, China is a major adopter of Industry 4.0, and the region is home to some of the most advanced manufacturing facilities in the world, ahead of regions like the European Union, the United States, and Japan.

- According to the World Economic Forum, of the 69 factories around the world now considered leaders using Industry 4.0 technologies, China is now home to 20, followed by 19 in the European Union, 7 in the United States, and 5 in Japan. Besides being the foundation for plant-wide automation, the automated storage and retrieval system also serves as a foundation for Industry 4.0.

- Moreover, with the increasing demand for e-commerce in emerging countries, such as India, China, and neighboring countries, e-commerce companies have been deploying AGVs at warehouses significantly. According to the IBEF, Indian e-commerce is projected to witness a CAGR of 27% to reach USD 163 billion by 2026. Similarly, in FY23, the gross merchandise value (GMV) of e-commerce in India reached USD 60 billion, increasing 22% over the previous year.

- In addition, several companies are adopting AGVs to support automation in the business, further driving the market. For instance, in April 2024, Busan Newport's Dongwon Global Terminal (DGT) held its formal inauguration ceremony. This was a significant milestone in Korea's port automation journey, as the terminal is the first in the country to use AGVs for horizontal transportation. At Busan Newport, DGT is the seventh container terminal. Automated yard cranes, also known as "transfer cranes," are present in all six of the other terminals at Busan New Port. However, DGT is the first to use AGVs.

- Similarly, in August 2023, Westports Malaysia announced plans to investigate the potential of using electric automated guided vehicles in future terminal development plans.

Automated Guided Vehicle Industry Overview

The global automated guided vehicle market is fragmented, with numerous players vying for market share. The industry is witnessing significant growth opportunities, driven by factors like digital transformation and the integration of Industry 4.0 with IoT. Leading the pack are prominent players, including Kuka AG, Daifuku Co. Ltd, SSI Schaefer AG, Murata Machinery Ltd, and Jungheinrich AG.

- March 2024: FFT announced the expansion of its portfolio with a new automated guided vehicle system by partnering with inductive charging tech provider Wiferion, which automaker BMW is now using. The charging systems from FFTigv and Wiferion have been implemented at the BMW Group plant in Leipzig. FFT created a new manufacturing facility, thereby utilizing wireless charging and AGVs to increase output and efficiency.

- March 2024: Cypher Robotics announced the release of the Captis Autonomous Ground Vehicle (AGV) for efficient and accurate cycle counting and industrial scanning. The Captis AGV is capable of navigating warehouses by itself. It does not require any changes to the infrastructure and will not collide with people or objects.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Value Chain Analysis

- 4.3 Industry Attractiveness - Porter's Five Forces Analysis

- 4.3.1 Bargaining Power of Suppliers

- 4.3.2 Bargaining Power of Buyers/Consumers

- 4.3.3 Threat of New Entrants

- 4.3.4 Threat of Substitute Products

- 4.3.5 Intensity of Competitive Rivalry

- 4.4 Impact of COVID-19 Aftereffects and Other Macroeconomic Factors on the Market

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Rapid Growth of E-commerce Demanding Higher Efficiency

- 5.1.2 Increasing Investments in Technology and Robotics

- 5.2 Market Restraints

- 5.2.1 Limitation of Real-Time Wireless Control Due to Communication Delays

6 MARKET SEGMENTATION

- 6.1 By Product Type

- 6.1.1 Automated Fork Lift

- 6.1.2 Automated Tow/Tractor/Tugs

- 6.1.3 Unit Load

- 6.1.4 Assembly Line

- 6.1.5 Special Purpose

- 6.2 By End-User Industry

- 6.2.1 Food & Beverage

- 6.2.2 Automotive

- 6.2.3 Retail

- 6.2.4 Electronics & Electrical

- 6.2.5 General Manufacturing

- 6.2.6 Pharmaceuticals

- 6.2.7 Other End User Industries

- 6.3 By Geography

- 6.3.1 North America

- 6.3.2 Europe

- 6.3.3 Asia

- 6.3.4 Australia and New Zealand

- 6.3.5 Latin America

- 6.3.6 Middle East and Africa

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 KUKA AG

- 7.1.2 Jungheinrich AG

- 7.1.3 Murata Machinery Ltd

- 7.1.4 Daifuku Co. Ltd

- 7.1.5 SSI Schaefer Systems International DWC LLC

- 7.1.6 Swisslog Holding

- 7.1.7 Dematic Corp.

- 7.1.8 Toyota Material Handling

- 7.1.9 Scott Technology Limited

- 7.1.10 John Bean Technologies (JBT) Corporation

- 7.1.11 Systems Logistics SPA

- 7.1.12 Seegrid Corporation