|

|

市場調査レポート

商品コード

1680526

COFグレードフレキシブル銅箔基板市場レポート:動向、予測、競合分析 (2031年まで)COF Grade Flexible Copper Foil Substrate Market Report: Trends, Forecast and Competitive Analysis to 2031 |

||||||

カスタマイズ可能

適宜更新あり

|

|||||||

| COFグレードフレキシブル銅箔基板市場レポート:動向、予測、競合分析 (2031年まで) |

|

出版日: 2025年03月13日

発行: Lucintel

ページ情報: 英文 150 Pages

納期: 3営業日

|

全表示

- 概要

- 目次

世界のCOFグレードフレキシブル銅箔基板市場の将来は、LCDテレビ、車載電子機器、スマートフォン、IoTデバイス市場での機会で有望視されています。世界のCOFグレードフレキシブル銅箔基板市場は、2025年から2031年にかけてCAGR 3.5%で成長すると予想されています。この市場の主な促進要因は、フレキシブルエレクトロニクスの需要増加と自動車分野での用途拡大です。

- Lucintelの予測では、種類別では片面ソフト基板が予測期間中に最も高い成長が見込まれます。

- 用途別では、液晶テレビが最も高い成長が見込まれます。

- 地域別では、北米が予測期間中に最も高い成長が見込まれます。

COFグレードフレキシブル銅箔基板市場の戦略的成長機会

COFグレードフレキシブル銅箔基板市場は、技術の進歩やさまざまな用途での需要増に後押しされ、大きく成長するものと思われます。産業が進化し、軽量で効率的、高性能な電子ソリューションへのニーズが高まるにつれ、いくつかの戦略的成長機会が生まれつつあります。民生用電子機器、自動車、通信、ウェアラブル、医療機器などの主要用途は、技術革新と拡大のための新たな道を開いています。これらの機会を活用することで、メーカーは市場での地位を高め、進化するフレキシブルエレクトロニクスの展望において持続可能な成長を推進することができます。

- 民生用電子機器:民生用電子機器分野は、薄型・軽量デバイスの需要に牽引され、チップオンフレックス基板にとって主要な成長機会となっています。スマートフォン、タブレット、ノートパソコンが進化を続ける中、高度な相互接続ソリューションの必要性が高まっています。チップオンフレックス基板は、必要な柔軟性と性能を提供するため、メーカーは機能を損なうことなく、よりスマートなデバイスを設計することができます。この分野に合わせた革新的なチップオンフレックス・ソリューションの研究開発に投資することで、企業は大きな市場シェアを獲得し、コンパクトで高性能な電子機器に対する消費者の嗜好の変化に対応することができます。

- 自動車向け用途:自動車産業は、特に電気自動車(EV)や先進運転支援システム(ADAS)の台頭により、チップオンフレックス基板の成長機会をもたらしています。これらの用途には、チップオンフレックス技術が提供できる軽量で高性能な相互接続ソリューションが必要です。自動車メーカーが自動車の効率と安全性の向上に注力する中、高温や機械的ストレスに対応できるフレキシブル基板への需要が高まっています。車載用途専用に設計されたチップオンフレックス・ソリューションを開発することで、メーカーはこの拡大する市場に参入し、業界の電動化と自動化への移行をサポートすることができます。

- 通信:通信もチップオンフレックス市場の成長を牽引する重要な用途の一つであり、特に5G技術の展開が注目されています。データ伝送の高速化とネットワーク性能の向上が求められているため、高度な相互接続ソリューションが必要とされています。チップオンフレックス基板は、高密度用途に必要な柔軟性と性能を提供し、5Gインフラとデバイスの効率的な接続を可能にします。通信企業がネットワークの拡大に投資する中、通信向けにカスタマイズされたチップオンフレックス・ソリューションの開発に注力するメーカーは、競争優位性を獲得し、大幅な収益成長を促進することができます。

- ウェアラブル技術:ウェアラブル技術の台頭は、チップオンフレックス基板に大きな機会をもたらしています。スマートウォッチやフィットネストラッカーのようなデバイスには、性能を維持しながらコンパクトな設計に収まる軽量で柔軟なソリューションが必要です。チップオンフレックス技術は、こうした用途に適しており、必要な耐久性と効率を提供します。健康とフィットネスに対する消費者の関心が高まり続ける中、ウェアラブル向けのチップオンフレックス・ソリューションを革新するメーカーは、市場シェアを獲得し、この急成長分野の発展に貢献することができます。

- 医療機器:医療機器市場は、特に診断機器やウェアラブルヘルスモニターなどの用途において、チップオンフレックス基板にとって有望な成長機会となります。これらの機器には、チップオンフレックス技術が提供できる信頼性、柔軟性、高性能の相互接続が必要です。ヘルスケアのデジタル化が進み、患者モニタリング機器が普及するにつれて、接続性と機能性をサポートする高度な基板への需要は高まるでしょう。医療分野に特化したチップオンフレックス・ソリューションの開発に注力することで、メーカーはこの重要な市場でリーダーとしての地位を確立することができます。

このような戦略的成長機会は主要な用途にまたがり、COFグレードフレキシブル銅箔基板市場に大きな影響を与えています。民生用電子機器、自動車、通信、ウェアラブル、医療機器に注目することで、メーカーはイノベーションを推進し、市場でのプレゼンスを拡大することができます。こうした動向を利用することは競争力を高めるだけでなく、フレキシブル・エレクトロニクスの全体的な進化にも貢献し、チップ・オン・フレックス市場を持続的な成長へと導くことになります。

COFグレードフレキシブル銅箔基板市場の促進要因・課題

COFグレードフレキシブル銅箔基板市場は、技術的、経済的、規制的な要因を含むさまざまな促進要因・課題によって影響を受けています。これらの要素を理解することは、複雑な市場を乗り切ろうとする利害関係者にとって不可欠です。主な促進要因としては、技術の進歩、小型化需要の高まり、持続可能性への注目の高まりなどが挙げられます。逆に、製造コストの高騰、サプライチェーンの混乱、厳しい規制要件といった課題も重要な役割を果たしています。これらの要因が相まって、チップオンフレックス基板市場力学が形成されています。

COFグレードフレキシブル銅箔基板市場を牽引している要因は以下の通りです:

- 技術の進歩:継続的な技術進歩はCOF (Chip-on-Flex) 市場の主要な促進要因です。材料科学や製造プロセスの革新は、より効率的で信頼性の高い基板の製造を可能にしています。熱管理の改善、導電性の向上、柔軟性の強化などの開発により、チップオンフレックス基板はさまざまな用途でより魅力的なものとなっています。産業界でこうした先端技術の採用が進むにつれて、チップオンフレックス・ソリューションの需要が高まり、市場の成長が促進されると予想されます。

- 小型化需要の高まり:電子機器の小型化・軽量化に対する需要の高まりが、チップオンフレックス市場を大きく押し上げています。消費者がよりコンパクトな製品を求める中、メーカーは性能を犠牲にすることなく小型化を実現するチップオンフレックス技術に注目しています。この動向は、洗練されたデザインが重要な民生用電子機器や自動車分野で特に顕著です。チップ・オン・フレックス基板は、高機能を維持しながら小型化をサポートできるため、市場の要求に応える上で不可欠なコンポーネントとなっています。

- 持続可能性の重視:企業や消費者が環境に配慮した取り組みを優先する中、持続可能性はチップオンフレックス市場の重要な促進要因になりつつあります。環境に優しい素材や生産プロセスを採用し、環境への影響を最小限に抑えるメーカーが増えています。このシフトは、ブランドの評判を高めるだけでなく、持続可能な製品に対する規制要件や消費者の期待にも応えるものです。持続可能性への注目は、チップ・オン・フレックス技術の革新を促し、リサイクル可能でエネルギー効率の高い基板の開発につながっています。

- IoTとウェアラブルの成長:モノのインターネット(IoT)とウェアラブル技術の急速な拡大により、チップオンフレックス基板に対する旺盛な需要が生まれています。これらの用途には、さまざまな接続ニーズに対応できる柔軟で高性能な相互接続ソリューションが必要です。スマートデバイスの市場が成長を続ける中、信頼性が高く効率的な通信をサポートする高度な基板へのニーズは、チップオンフレックス技術の採用を促進するでしょう。この動向は、チップオンフレックス市場のメーカーに大きな成長機会をもたらします。

- 研究開発投資の増加:エレクトロニクス分野における研究開発投資の増加が、チップオンフレックス基板の技術革新を促進しています。企業は、基板の性能を高める新しい材料や製造技術の探求にリソースを割いています。このような研究開発への注力は、耐久性、効率性、機能性を向上させるブレークスルーをもたらし、市場成長をさらに促進しています。メーカーが製品の差別化に努める中、R&D投資はチップ・オン・フレックス市場の将来を形作る上で重要な役割を果たし続けると思われます。

COFグレードフレキシブル銅箔基板市場の課題は以下のとおりです:

- 高い製造コスト:チップ・オン・フレックス市場が直面する主な課題のひとつは、先端基板の製造コストの高さです。製造工程には高価な材料や特殊な設備が使われることが多く、これが中小企業の市場参入を阻む要因となっています。このような高コストはメーカーの利益率も制限するため、生産効率を最適化し、経費を削減する方法を見つけることが不可欠となります。この課題に対処することは、チップ・オン・フレックス市場の成長と競争力を維持する上で極めて重要です。

- サプライチェーンの混乱:サプライチェーンの混乱は、特にCOVID-19パンデミックのような世界の出来事の影響を受け、チップオンフレックス基板市場にとって大きな課題となります。原材料の入手可能性の変動や輸送の問題は、生産の遅れやコスト増につながる可能性があります。メーカーは、部品の安定供給を確保するために、こうした不確定要素を乗り越えていかなければならないです。チップ・オン・フレックス生産における中断の影響を軽減するためには、強固なサプライチェーン戦略の開発と調達オプションの多様化が不可欠です。

- 厳しい規制要件:チップオンフレックス市場は、材料や製造プロセスに関連するさまざまな規制要件の対象となります。環境基準や安全規制を遵守することは、生産コストと複雑さを増大させる可能性があります。また、規制状況の把握はメーカーにとって時間のかかる作業です。競争力のある価格を維持しながらコンプライアンスを確保することは、企業がチップオンフレックス基板市場で成功するために取り組まなければならない課題です。市場参入企業にとって、これらの規制を理解し、適応することは極めて重要です。

COFグレードフレキシブル銅箔基板市場が直面する市場促進要因・課題は、その軌道に大きく影響します。技術の進歩、小型化の要求、持続可能性への注目は大きな成長機会をもたらしますが、一方で高い製造コスト、サプライチェーンの混乱、厳しい規制要件は、乗り越えなければならない課題をもたらします。長期的な持続可能性と競争力を確保しつつ、チップオンフレックス市場の可能性を活かそうとする利害関係者にとって、これらの要因のバランスを取ることが極めて重要になります。

目次

第1章 エグゼクティブサマリー

第2章 世界のCOFグレードフレキシブル銅箔基板市場:市場力学

- イントロダクション、背景、分類

- サプライチェーン

- 業界の促進要因と課題

第3章 市場動向と予測分析 (2019年~2031年)

- マクロ経済動向 (2019~2024年) と予測 (2025~2031年)

- 世界のCOFグレードフレキシブル銅箔基板市場の動向 (2019~2024年) と予測 (2025~2031年)

- 世界のCOFグレードフレキシブル銅箔基板市場:種類別

- 片面ソフトボード

- 両面ソフトボード

- 多層ソフトボード

- 世界のCOFグレードフレキシブル銅箔基板市場:用途別

- 液晶テレビ

- 車両エレクトロニクス

- スマートフォン

- IoTデバイス

- その他

第4章 地域別の市場動向と予測分析 (2019年~2031年)

- 世界のCOFグレードフレキシブル銅箔基板市場:地域別

- 北米のCOFグレードフレキシブル銅箔基板市場

- 欧州のCOFグレードフレキシブル銅箔基板市場

- アジア太平洋のCOFグレードフレキシブル銅箔基板市場

- その他地域のCOFグレードフレキシブル銅箔基板市場

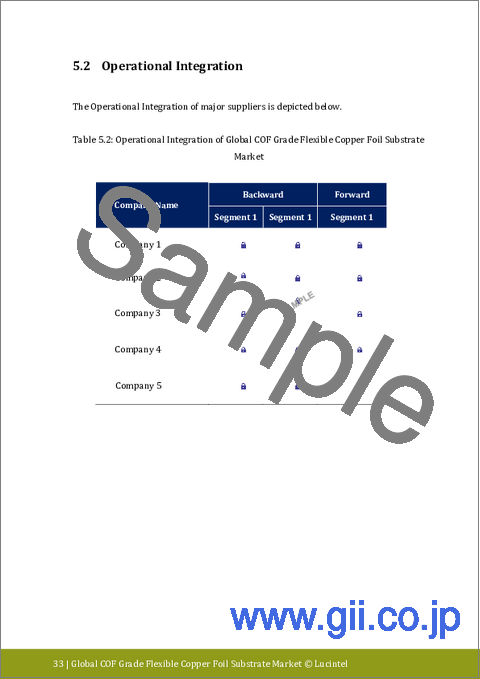

第5章 競合分析

- 製品ポートフォリオ分析

- 運用統合

- ポーターのファイブフォース分析

第6章 成長機会と戦略分析

- 成長機会分析

- 世界のCOFグレードフレキシブル銅箔基板市場の成長機会:種類別

- 世界のCOFグレードフレキシブル銅箔基板市場の成長機会:用途別

- 世界のCOFグレードフレキシブル銅箔基板市場の成長機会:地域別

- 世界のCOFグレードフレキシブル銅箔基板市場の新たな動向

- 戦略的分析

- 新製品の開発

- 世界のCOFグレードフレキシブル銅箔基板市場の生産能力拡大

- 世界のCOFグレードフレキシブル銅箔基板市場における企業合併・買収 (M&A)、合弁事業

- 認証とライセンシング

第7章 主要企業のプロファイル

- Honflex

- Danbang Technology

- TOP Nanometal Corporation

- Chang Chun Group

- DSBJ

- DuPont

- Nippon Steel Corporation

The future of the global COF grade flexible copper foil substrate market looks promising with opportunities in the LCD TV, vehicle electronic, smart phone, and IoT device markets. The global COF grade flexible copper foil substrate market is expected to grow with a CAGR of 3.5% from 2025 to 2031. The major drivers for this market are rise in demand for flexible electronics and growing application in automotive sector.

- Lucintel forecasts that, within the type category, single-sided soft board is expected to witness the highest growth over the forecast period.

- Within the application category, LCD TV is expected to witness the highest growth.

- In terms of regions, North America is expected to witness the highest growth over the forecast period.

Gain Valuable insights for your business decisions with our comprehensive 150+ page report.

Emerging Trends in the COF Grade Flexible Copper Foil Substrate Market

The COF grade flexible copper foil substrate market is evolving rapidly, driven by advancements in technology and increasing demand for high-performance electronic devices. As industries seek lighter, more efficient solutions, several key trends are emerging. These trends reflect a broader shift towards innovation, sustainability, and enhanced functionality in electronics. Key players are adapting to these changes, positioning themselves to meet the evolving needs of consumers and industries alike. Understanding these trends is crucial for stakeholders aiming to navigate the competitive landscape effectively.

- Increased Demand for Lightweight Solutions: The push for lighter devices, particularly in the consumer electronics and automotive sectors, is driving the demand for chip-on-flex flexible copper foil substrates. As manufacturers focus on reducing the overall weight of products, chip-on-flex flexible copper foil technology offers an excellent solution due to its thin profile and flexibility. This trend is especially significant in smartphones, tablets, and electric vehicles, where weight reduction can lead to improved energy efficiency and user experience. The ongoing trend towards miniaturization in electronic devices further fuels the need for lightweight, flexible interconnect solutions.

- Advancements in Manufacturing Technologies: Innovations in manufacturing processes are reshaping the chip-on-flex flexible copper foil market, with automation and precision engineering becoming increasingly prevalent. Advanced techniques such as laser processing and automated assembly lines improve production efficiency and reduce costs. These technological advancements enable manufacturers to produce high-quality substrates at scale, meeting the rising demand from various industries. Furthermore, enhanced manufacturing capabilities allow for more complex designs and functionalities, supporting the development of next-generation electronic devices.

- Sustainability and Eco-friendly Practices: Sustainability is becoming a key focus in the chip-on-flex flexible copper foil market as companies aim to reduce their environmental impact. Manufacturers are investing in eco-friendly materials and processes, such as recyclable substrates and waste-reduction techniques. This trend is driven by increasing regulatory pressure and consumer demand for sustainable products. By prioritizing sustainability, companies can not only enhance their brand reputation but also comply with environmental standards, making them more competitive in a market that increasingly values green technology.

- Integration of Advanced Materials: The integration of advanced materials into chip-on-flex flexible copper foil substrates is another emerging trend. Manufacturers are exploring options like nano-coatings and hybrid materials that enhance thermal and electrical performance. These advancements allow for better signal integrity and heat dissipation, crucial for high-performance applications in telecommunications and computing. As electronic devices become more sophisticated, the demand for substrates that can withstand higher operational demands continues to grow, driving innovation in material science within the chip-on-flex flexible copper foil sector.

- Growing Applications in Emerging Technologies The applications of chip-on-flex flexible copper foil technology are expanding beyond traditional uses. With the rise of the Internet of Things (IoT), wearable technology, and augmented reality, there is an increasing need for flexible and efficient interconnect solutions. Chi flexible copper foil substrates are well-suited for these emerging technologies due to their flexibility and adaptability. As industries increasingly adopt these technologies, the demand for chip-on-flex flexible copper foil substrates tailored for specific applications will grow, leading to further innovation and market diversification.

These trends are significantly reshaping the COF grade flexible copper foil substrate market by driving innovation, enhancing sustainability, and broadening applications. As manufacturers adapt to these developments, they are better positioned to meet the evolving demands of the electronics landscape. The convergence of lightweight design, advanced materials, and sustainable practices will not only enhance product performance but also create new growth opportunities, ensuring that the chip-on-flex flexible copper foil market remains a vital component of the future of flexible electronics.

Recent Developments in the COF Grade Flexible Copper Foil Substrate Market

The COF grade flexible copper foil substrate market is undergoing rapid transformation, driven by advancements in technology and the growing demand for high-performance electronic devices. As industries such as consumer electronics, automotive, and telecommunications expand, manufacturers are innovating to meet these needs. Recent developments in materials, manufacturing processes, and applications are reshaping the landscape, positioning chip-on-flex substrates as critical components for next-generation devices. Understanding these developments is essential for stakeholders aiming to stay competitive in this dynamic market.

- Advanced Material Innovations: Recent innovations in materials, such as the use of high-conductivity copper and hybrid substrates, have enhanced the performance characteristics of chip-on-flex products. These advancements improve electrical conductivity and thermal management, making them suitable for demanding applications in high-speed electronics. The introduction of flexible and lightweight materials allows manufacturers to create thinner and more compact designs, which is increasingly important in consumer electronics and automotive applications. This trend is facilitating the development of devices that are not only lighter but also more efficient and durable.

- Automation in Manufacturing: The adoption of automation technologies in the manufacturing of chip-on-flex substrates has significantly improved production efficiency and quality. Automated assembly lines and precision manufacturing techniques reduce the risk of human error and enhance output consistency. This shift allows companies to scale operations more effectively, meeting rising demand without compromising quality. The efficiency gains achieved through automation also translate to lower production costs, making chip-on-flex substrates more competitive in the market and enabling manufacturers to invest in further innovations.

- Eco-friendly Manufacturing Practices: Sustainability is becoming increasingly important in the chip-on-flex market, with manufacturers adopting eco-friendly practices and materials. This includes the development of recyclable substrates and the implementation of waste-reduction strategies in production. The emphasis on sustainability is not only driven by regulatory requirements but also by consumer preferences for environmentally responsible products. As companies prioritize sustainable practices, they enhance their brand image and meet the growing demand for green technology, ultimately contributing to a more responsible electronics industry.

- Enhanced Flexibility and Performance: Recent advancements have led to chip-on-flex substrates that offer improved flexibility and performance under various conditions. Innovations in polymer materials and bonding techniques have resulted in substrates that can withstand higher temperatures and mechanical stress. This enhanced durability is crucial for applications in automotive and wearable technology, where reliability is paramount. As chip-on-flex substrates become more resilient, they are increasingly adopted in diverse applications, broadening their market reach and potential.

- Expansion into New Applications: The COF grade flexible copper foil substrate market is witnessing an expansion into new applications, driven by the rise of the Internet of Things (IoT), wearables, and augmented reality. These emerging technologies require advanced interconnect solutions that chip-on-flex substrates can provide due to their flexibility and high performance. As industries continue to innovate and seek efficient solutions, the versatility of chip-on-flex substrates positions them as essential components for next-generation devices, driving further growth and diversification in the market.

These developments are significantly impacting the COF grade flexible copper foil substrate market by driving innovation, enhancing sustainability, and expanding application possibilities. As manufacturers adapt to these changes, they are positioned to meet the evolving demands of various industries, ensuring that chip-on-flex substrates remain integral to the future of flexible electronics. This dynamic landscape not only fosters competitive advantage but also promotes the growth of new technologies, ultimately shaping the direction of the electronics industry as a whole.

Strategic Growth Opportunities for COF Grade Flexible Copper Foil Substrate Market

The COF grade flexible copper foil substrate market is poised for significant growth, driven by advancements in technology and increasing demand across various applications. As industries evolve and the need for lightweight, efficient, and high-performance electronic solutions intensifies, several strategic growth opportunities are emerging. Key applications such as consumer electronics, automotive, telecommunications, wearables, and medical devices are opening new avenues for innovation and expansion. By capitalizing on these opportunities, manufacturers can enhance their market position and drive sustainable growth in the evolving landscape of flexible electronics.

- Consumer Electronics: The consumer electronics sector is a primary growth opportunity for chip-on-flex substrates, driven by the demand for thinner and lighter devices. As smartphones, tablets, and laptops continue to evolve, the need for advanced interconnect solutions is rising. Chip-on-flex substrates provide the necessary flexibility and performance, allowing manufacturers to design sleeker devices without compromising functionality. By investing in research and development for innovative chip-on-flex solutions tailored for this sector, companies can capture significant market share and meet the ever-changing consumer preferences for compact and high-performance electronics.

- Automotive Applications: The automotive industry presents a growing opportunity for chip-on-flex substrates, especially with the rise of electric vehicles (EVs) and advanced driver-assistance systems (ADAS). These applications require lightweight, high-performance interconnect solutions that chip-on-flex technology can provide. As automotive manufacturers focus on enhancing vehicle efficiency and safety, the demand for flexible substrates that can handle high temperatures and mechanical stress is increasing. By developing chip-on-flex solutions specifically designed for automotive applications, manufacturers can tap into this expanding market and support the industry's transition toward electrification and automation.

- Telecommunications: Telecommunications is another key application driving growth in the chip-on-flex market, particularly with the rollout of 5G technology. The demand for faster data transmission and improved network performance necessitates advanced interconnect solutions. Chip-on-flex substrates offer the flexibility and performance required for high-density applications, enabling efficient connections in 5G infrastructure and devices. As telecom companies invest in expanding their networks, manufacturers that focus on developing chip-on-flex solutions tailored for telecommunications can gain a competitive edge and drive significant revenue growth.

- Wearable Technology: The rise of wearable technology is creating substantial opportunities for chip-on-flex substrates. Devices like smartwatches and fitness trackers require lightweight, flexible solutions that can fit into compact designs while maintaining performance. Chip-on-flex technology is well-suited for these applications, offering the necessary durability and efficiency. As consumer interest in health and fitness continues to grow, manufacturers who innovate chip-on-flex solutions for wearables can capture market share and contribute to the advancement of this burgeoning sector.

- Medical Devices: The medical device market represents a promising growth opportunity for chip-on-flex substrates, particularly in applications such as diagnostic equipment and wearable health monitors. These devices require reliable, flexible, and high-performance interconnects that chip-on-flex technology can provide. As healthcare becomes increasingly digitized and patient monitoring devices proliferate, the demand for advanced substrates that support connectivity and functionality will grow. By focusing on developing chip-on-flex solutions tailored to the medical sector, manufacturers can establish themselves as leaders in this critical market.

These strategic growth opportunities across key applications are significantly impacting the COF grade flexible copper foil substrate market. By focusing on consumer electronics, automotive, telecommunications, wearables, and medical devices, manufacturers can drive innovation and expand their market presence. Capitalizing on these trends not only enhances competitiveness but also contributes to the overall evolution of flexible electronics, positioning the chip-on-flex market for sustained growth.

COF Grade Flexible Copper Foil Substrate Market Driver and Challenges

The COF grade flexible copper foil substrate market is influenced by a range of drivers and challenges, encompassing technological, economic, and regulatory factors. Understanding these elements is essential for stakeholders aiming to navigate the complexities of the market. The major drivers include advancements in technology, rising demand for miniaturization, and increased focus on sustainability. Conversely, challenges such as high manufacturing costs, supply chain disruptions, and stringent regulatory requirements also play a crucial role. Together, these factors shape the dynamics of the chip-on-flex substrate market.

The factors responsible for driving the COF grade flexible copper foil substrate market include:

- Technological Advancements: Continuous technological advancements are a major driver for the chip-on-flex market. Innovations in materials science and manufacturing processes are enabling the production of more efficient and reliable substrates. Developments such as improved thermal management, higher electrical conductivity, and enhanced flexibility are making chip-on-flex substrates more appealing for various applications. As industries increasingly adopt these advanced technologies, the demand for chip-on-flex solutions is expected to rise, driving growth in the market.

- Rising Demand for Miniaturization: The increasing demand for smaller, lighter electronic devices is significantly boosting the chip-on-flex market. As consumers seek more compact products, manufacturers are turning to chip-on-flex technology to achieve miniaturization without compromising performance. This trend is particularly evident in the consumer electronics and automotive sectors, where sleek designs are crucial. The ability of chip-on-flex substrates to support smaller form factors while maintaining high functionality positions them as an essential component in meeting market demands.

- Focus on Sustainability: Sustainability is becoming a key driver in the chip-on-flex market as companies and consumers prioritize environmentally friendly practices. Manufacturers are increasingly adopting eco-friendly materials and production processes to minimize their environmental impact. This shift not only enhances brand reputation but also meets regulatory requirements and consumer expectations for sustainable products. The focus on sustainability is driving innovation in chip-on-flex technology, leading to the development of recyclable and energy-efficient substrates.

- Growth of IoT and Wearables: The rapid expansion of the Internet of Things (IoT) and wearable technology is creating a robust demand for chip-on-flex substrates. These applications require flexible, high-performance interconnect solutions that can accommodate various connectivity needs. As the market for smart devices continues to grow, the need for advanced substrates that support reliable and efficient communication will drive the adoption of chip-on-flex technology. This trend presents significant growth opportunities for manufacturers in the chip-on-flex market.

- Increasing Investment in R&D: Growing investment in research and development within the electronics sector is fostering innovation in chip-on-flex substrates. Companies are allocating resources to explore new materials and manufacturing techniques that enhance substrate performance. This focus on R&D is leading to breakthroughs that improve durability, efficiency, and functionality, further driving market growth. As manufacturers strive to differentiate their products, R&D investments will continue to play a critical role in shaping the future of the chip-on-flex market.

Challenges in the COF grade flexible copper foil substrate market are:

- High Manufacturing Costs: One of the key challenges facing the chip-on-flex market is the high cost of manufacturing advanced substrates. The production processes often involve expensive materials and specialized equipment, which can deter smaller players from entering the market. These high costs can also limit profit margins for manufacturers, making it essential to find ways to optimize production efficiency and reduce expenses. Addressing this challenge is crucial for sustaining growth and competitiveness in the chip-on-flex market.

- Supply Chain Disruptions: Supply chain disruptions pose a significant challenge for the chip-on-flex substrate market, particularly in the wake of global events such as the COVID-19 pandemic. Fluctuations in raw material availability and transportation issues can lead to delays in production and increased costs. Manufacturers must navigate these uncertainties to ensure a steady supply of components. Developing robust supply chain strategies and diversifying sourcing options are essential to mitigate the impact of disruptions on chip-on-flex production.

- Stringent Regulatory Requirements: The chip-on-flex market is subject to various regulatory requirements related to materials and manufacturing processes. Compliance with environmental standards and safety regulations can increase production costs and complexity. Additionally, navigating the regulatory landscape can be time-consuming for manufacturers. Ensuring compliance while maintaining competitive pricing is a challenge that companies must address to succeed in the chip-on-flex substrate market. Understanding and adapting to these regulations will be crucial for market participants.

The drivers and challenges facing the COF grade flexible copper foil substrate market significantly influence its trajectory. While technological advancements, demand for miniaturization, and a focus on sustainability present substantial growth opportunities, high manufacturing costs, supply chain disruptions, and stringent regulatory requirements pose challenges that must be navigated. Balancing these factors will be critical for stakeholders seeking to capitalize on the potential of the chip-on-flex market while ensuring long-term sustainability and competitiveness.

List of COF Grade Flexible Copper Foil Substrate Companies

Companies in the market compete on the basis of product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. Through these strategies COF grade flexible copper foil substrate companies cater increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Some of the COF grade flexible copper foil substrate companies profiled in this report include-

- Honflex

- Danbang Technology

- TOP Nanometal Corporation

- Chang Chun Group

- DSBJ

- DuPont

- Nippon Steel Corporation

COF Grade Flexible Copper Foil Substrate by Segment

The study includes a forecast for the global COF grade flexible copper foil substrate market by type, application, and region.

COF Grade Flexible Copper Foil Substrate Market by Type [Analysis by Value from 2019 to 2031]:

- Single-Sided Soft Board

- Double-Sided Soft Board

- Multilayer Soft Board

COF Grade Flexible Copper Foil Substrate Market by Application [Analysis by Value from 2019 to 2031]:

- LCD TV

- Vehicle Electronics

- Smart Phone

- IoT Devices

- Others

COF Grade Flexible Copper Foil Substrate Market by Region [Analysis by Value from 2019 to 2031]:

- North America

- Europe

- Asia Pacific

- The Rest of the World

Country Wise Outlook for the COF Grade Flexible Copper Foil Substrate Market

The COF grade flexible copper foil substrate market has seen significant developments recently, driven by increasing demand for advanced electronics, particularly in the mobile and automotive sectors. This technology enables lightweight, high-performance interconnections, crucial for modern devices. As the global market expands, key players in the United States, China, Germany, India, and Japan are innovating to enhance product capabilities and sustainability. These countries are witnessing advancements in manufacturing processes, material properties, and applications, which are shaping the competitive landscape of the industry.

- United States: In the U.S., the COF grade flexible copper foil substrate market has advanced with the integration of new materials that enhance thermal conductivity and flexibility. Major companies are investing in R&D to produce more reliable and efficient substrates for high-performance applications, especially in consumer electronics. Additionally, the push for sustainable practices has led to the development of eco-friendly manufacturing processes, reducing waste and energy consumption.

- China: China remains a dominant player in the COF grade flexible copper foil substrate market, focusing on scaling production capabilities. Recent developments include advancements in automated manufacturing technologies, which improve efficiency and reduce costs. The Chinese government is also supporting innovation through funding and policies aimed at enhancing the semiconductor supply chain, fostering a robust ecosystem for COF grade flexible copper foil substrate applications, particularly in mobile devices and electric vehicles.

- Germany: Germany is emphasizing precision engineering and quality in the COF grade flexible copper foil substrate market. Recent developments include collaborations between manufacturers and research institutions to innovate substrate materials with improved electrical performance. The industry is also shifting towards smart manufacturing technologies, enabling greater customization and efficiency. This focus on quality aligns with Germany's reputation for engineering excellence, particularly in the automotive sector.

- India: In India, the COF grade flexible copper foil substrate market is emerging, supported by a growing electronics manufacturing sector. Recent developments include investments from both domestic and international players in production facilities, driven by the "Make in India" initiative. Indian companies are also exploring partnerships to enhance technological capabilities and meet the rising demand for flexible substrates in consumer electronics and telecommunications.

- Japan: Japan continues to be at the forefront of COF grade flexible copper foil substrate innovation, particularly in high-density applications. Recent advancements include the development of ultra-thin copper foils that offer enhanced performance while reducing weight. Japanese firms are also focusing on advanced bonding techniques to improve substrate reliability. Additionally, the market is seeing increased collaboration between industry leaders and academia to push the boundaries of flexible electronics technology.

Features of the Global COF Grade Flexible Copper Foil Substrate Market

Market Size Estimates: COF grade flexible copper foil substrate market size estimation in terms of value ($B).

Trend and Forecast Analysis: Market trends (2019 to 2024) and forecast (2025 to 2031) by various segments and regions.

Segmentation Analysis: COF grade flexible copper foil substrate market size by type, application, and region in terms of value ($B).

Regional Analysis: COF grade flexible copper foil substrate market breakdown by North America, Europe, Asia Pacific, and Rest of the World.

Growth Opportunities: Analysis of growth opportunities in different type, application, and regions for the COF grade flexible copper foil substrate market.

Strategic Analysis: This includes M&A, new product development, and competitive landscape of the COF grade flexible copper foil substrate market.

Analysis of competitive intensity of the industry based on Porter's Five Forces model.

If you are looking to expand your business in this market or adjacent markets, then contact us. We have done hundreds of strategic consulting projects in market entry, opportunity screening, due diligence, supply chain analysis, M & A, and more.

This report answers following 11 key questions:

- Q.1. What are some of the most promising, high-growth opportunities for the COF grade flexible copper foil substrate market by type (single-sided soft board, double-sided soft board, and multilayer soft board), application (LCD TV, vehicle electronics, smart phone, IoT devices, and others), and region (North America, Europe, Asia Pacific, and the Rest of the World)?

- Q.2. Which segments will grow at a faster pace and why?

- Q.3. Which region will grow at a faster pace and why?

- Q.4. What are the key factors affecting market dynamics? What are the key challenges and business risks in this market?

- Q.5. What are the business risks and competitive threats in this market?

- Q.6. What are the emerging trends in this market and the reasons behind them?

- Q.7. What are some of the changing demands of customers in the market?

- Q.8. What are the new developments in the market? Which companies are leading these developments?

- Q.9. Who are the major players in this market? What strategic initiatives are key players pursuing for business growth?

- Q.10. What are some of the competing products in this market and how big of a threat do they pose for loss of market share by material or product substitution?

- Q.11. What M&A activity has occurred in the last 5 years and what has its impact been on the industry?

Table of Contents

1. Executive Summary

2. Global COF Grade Flexible Copper Foil Substrate Market : Market Dynamics

- 2.1: Introduction, Background, and Classifications

- 2.2: Supply Chain

- 2.3: Industry Drivers and Challenges

3. Market Trends and Forecast Analysis from 2019 to 2031

- 3.1. Macroeconomic Trends (2019-2024) and Forecast (2025-2031)

- 3.2. Global COF Grade Flexible Copper Foil Substrate Market Trends (2019-2024) and Forecast (2025-2031)

- 3.3: Global COF Grade Flexible Copper Foil Substrate Market by Type

- 3.3.1: Single-Sided Soft Board

- 3.3.2: Double-Sided Soft Board

- 3.3.3: Multilayer Soft Board

- 3.4: Global COF Grade Flexible Copper Foil Substrate Market by Application

- 3.4.1: LCD TV

- 3.4.2: Vehicle Electronics

- 3.4.3: Smart Phone

- 3.4.4: IoT Devices

- 3.4.5: Others

4. Market Trends and Forecast Analysis by Region from 2019 to 2031

- 4.1: Global COF Grade Flexible Copper Foil Substrate Market by Region

- 4.2: North American COF Grade Flexible Copper Foil Substrate Market

- 4.2.1: North American Market by Type: Single-Sided Soft Board, Double-Sided Soft Board, and Multilayer Soft Board

- 4.2.2: North American Market by Application: LCD TV, Vehicle Electronics, Smart Phone, IoT Devices, and Others

- 4.3: European COF Grade Flexible Copper Foil Substrate Market

- 4.3.1: European Market by Type: Single-Sided Soft Board, Double-Sided Soft Board, and Multilayer Soft Board

- 4.3.2: European Market by Application: LCD TV, Vehicle Electronics, Smart Phone, IoT Devices, and Others

- 4.4: APAC COF Grade Flexible Copper Foil Substrate Market

- 4.4.1: APAC Market by Type: Single-Sided Soft Board, Double-Sided Soft Board, and Multilayer Soft Board

- 4.4.2: APAC Market by Application: LCD TV, Vehicle Electronics, Smart Phone, IoT Devices, and Others

- 4.5: ROW COF Grade Flexible Copper Foil Substrate Market

- 4.5.1: ROW Market by Type: Single-Sided Soft Board, Double-Sided Soft Board, and Multilayer Soft Board

- 4.5.2: ROW Market by Application: LCD TV, Vehicle Electronics, Smart Phone, IoT Devices, and Others

5. Competitor Analysis

- 5.1: Product Portfolio Analysis

- 5.2: Operational Integration

- 5.3: Porter's Five Forces Analysis

6. Growth Opportunities and Strategic Analysis

- 6.1: Growth Opportunity Analysis

- 6.1.1: Growth Opportunities for the Global COF Grade Flexible Copper Foil Substrate Market by Type

- 6.1.2: Growth Opportunities for the Global COF Grade Flexible Copper Foil Substrate Market by Application

- 6.1.3: Growth Opportunities for the Global COF Grade Flexible Copper Foil Substrate Market by Region

- 6.2: Emerging Trends in the Global COF Grade Flexible Copper Foil Substrate Market

- 6.3: Strategic Analysis

- 6.3.1: New Product Development

- 6.3.2: Capacity Expansion of the Global COF Grade Flexible Copper Foil Substrate Market

- 6.3.3: Mergers, Acquisitions, and Joint Ventures in the Global COF Grade Flexible Copper Foil Substrate Market

- 6.3.4: Certification and Licensing

7. Company Profiles of Leading Players

- 7.1: Honflex

- 7.2: Danbang Technology

- 7.3: TOP Nanometal Corporation

- 7.4: Chang Chun Group

- 7.5: DSBJ

- 7.6: DuPont

- 7.7: Nippon Steel Corporation