|

|

市場調査レポート

商品コード

1676879

ハイブリッドボンディング技術市場:技術、基板材料、エンドユーザー産業、用途別-2025-2030年の世界予測Hybrid Bonding Technology Market by Technology, Substrate Material, End-User Industries, Application - Global Forecast 2025-2030 |

||||||

カスタマイズ可能

適宜更新あり

|

|||||||

| ハイブリッドボンディング技術市場:技術、基板材料、エンドユーザー産業、用途別-2025-2030年の世界予測 |

|

出版日: 2025年03月09日

発行: 360iResearch

ページ情報: 英文 191 Pages

納期: 即日から翌営業日

|

全表示

- 概要

- 図表

- 目次

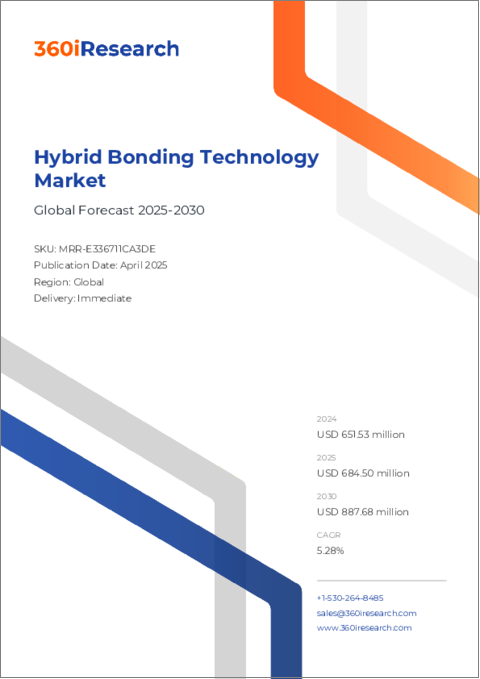

ハイブリッドボンディング技術市場は、2024年には6億5,153万米ドルとなり、2025年には6億8,463万米ドル、CAGR 5.29%で成長し、2030年には8億8,785万米ドルに達すると予測されています。

| 主な市場の統計 | |

|---|---|

| 基準年 2024 | 6億5,153万米ドル |

| 推定年 2025 | 6億8,463万米ドル |

| 予測年 2030 | 8億8,785万米ドル |

| CAGR(%) | 5.29% |

ハイブリッド・ボンディング技術は、エレクトロニクスおよび半導体産業で革命的な力を発揮しています。マイクロスケールやナノスケールでより効率的な接続を可能にするこの技術は、デバイスの性能と集積度を向上させる舞台となっています。この技術は、複数の接合技術を組み合わせることで相互接続に新たなアプローチを提供し、需要の高いいくつかのアプリケーションに技術革新の新たな道を開きます。メーカー各社は、デジタル・エレクトロニクスと高性能コンピューティングの急速な進歩が顕著な時代に不可欠な、サイズ、速度、消費電力に関連する従来の制限を克服するために、ハイブリッド接合に注目しています。

この革新的なアプローチは、継続的な研究開発と、民生用電子機器、医療機器、自動車システム、および防衛アプリケーションにおけるより高い機能性と統合に対する差し迫ったニーズによって推進されています。ハイブリッドボンディングの進化は、現在の技術的要求を満たすだけでなく、将来の飛躍的進歩への道を開くものでもあります。市場が成熟し続ける中、主要な利害関係者は、進化する顧客ニーズや規制状況に適応し、研究への投資が持続的な競争優位性をもたらすようにしなければならないです。本レポートでは、市場を詳細に分析し、技術動向、地域的影響、業界リーダーによる戦略的動きを明らかにします。

ハイブリッドボンディング技術市場の変革

ハイブリッドボンディング分野は、急速な技術進歩と進化する市場力学によって大きな変化を経験しています。近年、多様な接合技術の融合により、従来のパッケージング手法から、デバイスの高密度化と高性能化を可能にする高集積ソリューションへとパラダイムがシフトしています。材料科学と精密工学の進歩により、従来のハードウェアの制約から、よりコンパクトで効率的な設計への移行が可能になりました。

現在では、通信、コンピューティング、車載システムで使用される高周波アプリケーションに不可欠な、信号経路の短縮と電気的性能の向上により、メーカーはメリットを享受しています。また、さまざまな接合方法を戦略的に統合することで、革新的なデバイス・アーキテクチャへの道が開かれ、信頼性を犠牲にすることなく小型化の要求に応えることができるようになりました。この変化は、強固なサプライチェーン、世界なパートナーシップ、競合環境下での持続的成長を目指した研究開発イニシアティブによって支えられています。

こうした変革は、より安全で、よりスマートで、よりエネルギー効率の高いデバイスを求める最終市場の要求と規制基準の両方によって後押しされています。利害関係者は、拡張性と相互運用性の向上を約束する技術に焦点を当てて投資ポートフォリオを再評価し始めており、ハイブリッドボンディングは業界進化の焦点となっています。

ハイブリッドボンディングの市場セグメンテーションに関する主要な洞察

市場セグメンテーションを詳細に検証することで、ハイブリッドボンディング技術領域の研究に採用されている多面的なアプローチが明らかになります。市場セグメンテーションでは、ダイ・ツー・ダイボンディング、ダイ・ツー・ウェーハボンディング、TSV(Through-Silicon Vias)、ウェーハ・ツー・ウェーハボンディングなど、技術ベースのセグメントを分析しています。同様に重要なのは、セラミック、ガラス、ポリマー、シリコンを含む基板材料に基づくセグメンテーションであり、ボンディングの品質と耐久性に影響する多様な物理的パラメータを反映しています。

自動車メーカーは、革新的なパッケージング・ソリューションに対する意欲の高まりを示す一方、エレクトロニクス製造分野では、洗練された統合技術を求めるエレクトロニクス組立サービス・プロバイダーと相手先ブランド製造業者に二分されます。さらに、診断機器メーカーや外科器具メーカーを含むヘルスケア機器メーカーは、デバイスの精度を高めるために接合技術を急速に採用しています。同様に、軍事通信システム開発やレーダーシステム開発に代表される軍事・防衛分野も、堅牢で安全な接合プロセスに投資しています。半導体業界では、鋳造と集積デバイスメーカーが、大量生産におけるボンディング技術の重要性を強調しています。

最後に、アプリケーションベースのセグメンテーションでは、ファンアウト型ウエハーレベルパッケージング、ハイパワーエレクトロニクス、オプトエレクトロニクス、半導体パッケージング、センサーとMEMSデバイス、高度な熱管理用に設計されたソリューションなどの主要分野がハイライトされており、それぞれがこの分野における個別の課題と機会を支えています。

目次

第1章 序文

第2章 調査手法

第3章 エグゼクティブサマリー

第4章 市場の概要

第5章 市場洞察

- 市場力学

- 促進要因

- インダストリー4.0とIoTの導入の台頭により、ハイブリッドボンディングによる相互接続性の強化が求められています。

- 電子機器の小型化に対する需要の高まりがハイブリッドボンディング技術の成長を牽引

- 3D ICや先進パッケージングにおけるハイブリッドボンディングの採用拡大が市場拡大を促進

- 抑制要因

- 初期投資要件が高いため、ハイブリッドボンディング技術の市場拡大が制限される

- 機会

- AIとMLの進歩により、強力な高性能コンピューティングにおけるハイブリッド結合の必要性が高まっています。

- ハイブリッド接合技術の開発と改良に向けたテクノロジー企業間の提携が増加

- 課題

- ハイブリッド接合技術と材料に関連する環境と持続可能性に関する懸念の高まり

- 促進要因

- 市場セグメンテーション分析

- 技術:信号遅延を低減した高密度相互接続を実現するダイツーダイボンディング技術の採用

- エンドユーザー産業:さまざまな動作条件下で高い信頼性を維持するために自動車分野でハイブリッドボンディング技術を採用

- ポーターのファイブフォース分析

- PESTEL分析

- 政治的

- 経済

- 社会

- 技術的

- 法律上

- 環境

第6章 ハイブリッドボンディング技術市場:技術別

- ダイ・ツー・ダイ接合

- ダイ・ウェーハ接合

- シリコン貫通ビア(TSV)

- ウェーハ間接合

第7章 ハイブリッドボンディング技術市場基材別

- セラミック

- ガラス

- ポリマー

- シリコン

第8章 ハイブリッドボンディング技術市場エンドユーザー業界別

- 自動車メーカー

- 電子機器製造

- 電子機器組立サービスプロバイダー

- オリジナル機器メーカー

- ヘルスケア機器メーカー

- 診断機器メーカー

- 外科用器具メーカー

- 軍事および防衛関連請負業者

- 軍事通信システム開発

- レーダーシステムの開発

- 半導体産業

- 鋳造

- 統合デバイスメーカー

第9章 ハイブリッドボンディング技術市場:用途別

- ファンアウトウェーハレベルパッケージング(FOWLP)

- 高出力エレクトロニクス

- オプトエレクトロニクス

- 半導体パッケージング

- センサーとMEMSデバイス

- 熱管理ソリューション

第10章 南北アメリカのハイブリッドボンディング技術市場

- アルゼンチン

- ブラジル

- カナダ

- メキシコ

- 米国

第11章 アジア太平洋地域のハイブリッドボンディング技術市場

- オーストラリア

- 中国

- インド

- インドネシア

- 日本

- マレーシア

- フィリピン

- シンガポール

- 韓国

- 台湾

- タイ

- ベトナム

第12章 欧州・中東・アフリカのハイブリッドボンディング技術市場

- デンマーク

- エジプト

- フィンランド

- フランス

- ドイツ

- イスラエル

- イタリア

- オランダ

- ナイジェリア

- ノルウェー

- ポーランド

- カタール

- ロシア

- サウジアラビア

- 南アフリカ

- スペイン

- スウェーデン

- スイス

- トルコ

- アラブ首長国連邦

- 英国

第13章 競合情勢

- 市場シェア分析, 2024

- FPNVポジショニングマトリックス, 2024

- 競合シナリオ分析

- 戦略分析と提言

企業一覧

- Adeia Inc by Xperi Holding Corp

- Advanced Micro Devices, Inc.

- Amkor Technology, Inc.

- Applied Materials, Inc.

- GLOBALFOUNDRIES Inc.

- Infineon Technologies AG

- KLA Corporation

- Lam Research Corporation

- Rohm Semiconductor

- Samsung Electronics Co., Ltd.

- SK Hynix Inc.

- STMicroelectronics N.V.

- Taiwan Semiconductor Manufacturing Company Limited

- Tokyo Electron Limited

- United Microelectronics Corporation

LIST OF FIGURES

- FIGURE 1. HYBRID BONDING TECHNOLOGY MARKET MULTI-CURRENCY

- FIGURE 2. HYBRID BONDING TECHNOLOGY MARKET MULTI-LANGUAGE

- FIGURE 3. HYBRID BONDING TECHNOLOGY MARKET RESEARCH PROCESS

- FIGURE 4. HYBRID BONDING TECHNOLOGY MARKET SIZE, 2024 VS 2030

- FIGURE 5. GLOBAL HYBRID BONDING TECHNOLOGY MARKET SIZE, 2018-2030 (USD MILLION)

- FIGURE 6. GLOBAL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY REGION, 2024 VS 2025 VS 2030 (USD MILLION)

- FIGURE 7. GLOBAL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY COUNTRY, 2024 VS 2025 VS 2030 (USD MILLION)

- FIGURE 8. GLOBAL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY TECHNOLOGY, 2024 VS 2030 (%)

- FIGURE 9. GLOBAL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY TECHNOLOGY, 2024 VS 2025 VS 2030 (USD MILLION)

- FIGURE 10. GLOBAL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SUBSTRATE MATERIAL, 2024 VS 2030 (%)

- FIGURE 11. GLOBAL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SUBSTRATE MATERIAL, 2024 VS 2025 VS 2030 (USD MILLION)

- FIGURE 12. GLOBAL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY END-USER INDUSTRIES, 2024 VS 2030 (%)

- FIGURE 13. GLOBAL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY END-USER INDUSTRIES, 2024 VS 2025 VS 2030 (USD MILLION)

- FIGURE 14. GLOBAL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY APPLICATION, 2024 VS 2030 (%)

- FIGURE 15. GLOBAL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY APPLICATION, 2024 VS 2025 VS 2030 (USD MILLION)

- FIGURE 16. AMERICAS HYBRID BONDING TECHNOLOGY MARKET SIZE, BY COUNTRY, 2024 VS 2030 (%)

- FIGURE 17. AMERICAS HYBRID BONDING TECHNOLOGY MARKET SIZE, BY COUNTRY, 2024 VS 2025 VS 2030 (USD MILLION)

- FIGURE 18. UNITED STATES HYBRID BONDING TECHNOLOGY MARKET SIZE, BY STATE, 2024 VS 2030 (%)

- FIGURE 19. UNITED STATES HYBRID BONDING TECHNOLOGY MARKET SIZE, BY STATE, 2024 VS 2025 VS 2030 (USD MILLION)

- FIGURE 20. ASIA-PACIFIC HYBRID BONDING TECHNOLOGY MARKET SIZE, BY COUNTRY, 2024 VS 2030 (%)

- FIGURE 21. ASIA-PACIFIC HYBRID BONDING TECHNOLOGY MARKET SIZE, BY COUNTRY, 2024 VS 2025 VS 2030 (USD MILLION)

- FIGURE 22. EUROPE, MIDDLE EAST & AFRICA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY COUNTRY, 2024 VS 2030 (%)

- FIGURE 23. EUROPE, MIDDLE EAST & AFRICA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY COUNTRY, 2024 VS 2025 VS 2030 (USD MILLION)

- FIGURE 24. HYBRID BONDING TECHNOLOGY MARKET SHARE, BY KEY PLAYER, 2024

- FIGURE 25. HYBRID BONDING TECHNOLOGY MARKET, FPNV POSITIONING MATRIX, 2024

LIST OF TABLES

- TABLE 1. HYBRID BONDING TECHNOLOGY MARKET SEGMENTATION & COVERAGE

- TABLE 2. UNITED STATES DOLLAR EXCHANGE RATE, 2018-2024

- TABLE 3. GLOBAL HYBRID BONDING TECHNOLOGY MARKET SIZE, 2018-2030 (USD MILLION)

- TABLE 4. GLOBAL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY REGION, 2018-2030 (USD MILLION)

- TABLE 5. GLOBAL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY COUNTRY, 2018-2030 (USD MILLION)

- TABLE 6. HYBRID BONDING TECHNOLOGY MARKET DYNAMICS

- TABLE 7. GLOBAL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY TECHNOLOGY, 2018-2030 (USD MILLION)

- TABLE 8. GLOBAL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY DIE-TO-DIE BONDING, BY REGION, 2018-2030 (USD MILLION)

- TABLE 9. GLOBAL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY DIE-TO-WAFER BONDING, BY REGION, 2018-2030 (USD MILLION)

- TABLE 10. GLOBAL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY THROUGH-SILICON VIAS (TSVS), BY REGION, 2018-2030 (USD MILLION)

- TABLE 11. GLOBAL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY WAFER-TO-WAFER BONDING, BY REGION, 2018-2030 (USD MILLION)

- TABLE 12. GLOBAL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SUBSTRATE MATERIAL, 2018-2030 (USD MILLION)

- TABLE 13. GLOBAL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY CERAMIC, BY REGION, 2018-2030 (USD MILLION)

- TABLE 14. GLOBAL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY GLASS, BY REGION, 2018-2030 (USD MILLION)

- TABLE 15. GLOBAL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY POLYMER, BY REGION, 2018-2030 (USD MILLION)

- TABLE 16. GLOBAL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SILICON, BY REGION, 2018-2030 (USD MILLION)

- TABLE 17. GLOBAL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY END-USER INDUSTRIES, 2018-2030 (USD MILLION)

- TABLE 18. GLOBAL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY AUTOMOTIVE MANUFACTURERS, BY REGION, 2018-2030 (USD MILLION)

- TABLE 19. GLOBAL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY ELECTRONICS MANUFACTURING, BY REGION, 2018-2030 (USD MILLION)

- TABLE 20. GLOBAL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY ELECTRONICS ASSEMBLY SERVICE PROVIDERS, BY REGION, 2018-2030 (USD MILLION)

- TABLE 21. GLOBAL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY ORIGINAL EQUIPMENT MANUFACTURERS, BY REGION, 2018-2030 (USD MILLION)

- TABLE 22. GLOBAL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY ELECTRONICS MANUFACTURING, 2018-2030 (USD MILLION)

- TABLE 23. GLOBAL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY HEALTHCARE EQUIPMENT MAKERS, BY REGION, 2018-2030 (USD MILLION)

- TABLE 24. GLOBAL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY DIAGNOSTIC EQUIPMENT MANUFACTURERS, BY REGION, 2018-2030 (USD MILLION)

- TABLE 25. GLOBAL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SURGICAL INSTRUMENT PRODUCERS, BY REGION, 2018-2030 (USD MILLION)

- TABLE 26. GLOBAL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY HEALTHCARE EQUIPMENT MAKERS, 2018-2030 (USD MILLION)

- TABLE 27. GLOBAL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY MILITARY & DEFENSE CONTRACTORS, BY REGION, 2018-2030 (USD MILLION)

- TABLE 28. GLOBAL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY MILITARY COMMUNICATION SYSTEM DEVELOPMENT, BY REGION, 2018-2030 (USD MILLION)

- TABLE 29. GLOBAL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY RADAR SYSTEM DEVELOPMENTS, BY REGION, 2018-2030 (USD MILLION)

- TABLE 30. GLOBAL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY MILITARY & DEFENSE CONTRACTORS, 2018-2030 (USD MILLION)

- TABLE 31. GLOBAL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SEMICONDUCTOR INDUSTRY, BY REGION, 2018-2030 (USD MILLION)

- TABLE 32. GLOBAL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY FOUNDRIES, BY REGION, 2018-2030 (USD MILLION)

- TABLE 33. GLOBAL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY INTEGRATED DEVICE MANUFACTURERS, BY REGION, 2018-2030 (USD MILLION)

- TABLE 34. GLOBAL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SEMICONDUCTOR INDUSTRY, 2018-2030 (USD MILLION)

- TABLE 35. GLOBAL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY APPLICATION, 2018-2030 (USD MILLION)

- TABLE 36. GLOBAL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY FAN-OUT WAFER-LEVEL PACKAGING (FOWLP), BY REGION, 2018-2030 (USD MILLION)

- TABLE 37. GLOBAL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY HIGH-POWER ELECTRONICS, BY REGION, 2018-2030 (USD MILLION)

- TABLE 38. GLOBAL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY OPTOELECTRONICS, BY REGION, 2018-2030 (USD MILLION)

- TABLE 39. GLOBAL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SEMICONDUCTOR PACKAGING, BY REGION, 2018-2030 (USD MILLION)

- TABLE 40. GLOBAL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SENSOR & MEMS DEVICES, BY REGION, 2018-2030 (USD MILLION)

- TABLE 41. GLOBAL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY THERMAL MANAGEMENT SOLUTIONS, BY REGION, 2018-2030 (USD MILLION)

- TABLE 42. AMERICAS HYBRID BONDING TECHNOLOGY MARKET SIZE, BY TECHNOLOGY, 2018-2030 (USD MILLION)

- TABLE 43. AMERICAS HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SUBSTRATE MATERIAL, 2018-2030 (USD MILLION)

- TABLE 44. AMERICAS HYBRID BONDING TECHNOLOGY MARKET SIZE, BY END-USER INDUSTRIES, 2018-2030 (USD MILLION)

- TABLE 45. AMERICAS HYBRID BONDING TECHNOLOGY MARKET SIZE, BY ELECTRONICS MANUFACTURING, 2018-2030 (USD MILLION)

- TABLE 46. AMERICAS HYBRID BONDING TECHNOLOGY MARKET SIZE, BY HEALTHCARE EQUIPMENT MAKERS, 2018-2030 (USD MILLION)

- TABLE 47. AMERICAS HYBRID BONDING TECHNOLOGY MARKET SIZE, BY MILITARY & DEFENSE CONTRACTORS, 2018-2030 (USD MILLION)

- TABLE 48. AMERICAS HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SEMICONDUCTOR INDUSTRY, 2018-2030 (USD MILLION)

- TABLE 49. AMERICAS HYBRID BONDING TECHNOLOGY MARKET SIZE, BY APPLICATION, 2018-2030 (USD MILLION)

- TABLE 50. AMERICAS HYBRID BONDING TECHNOLOGY MARKET SIZE, BY COUNTRY, 2018-2030 (USD MILLION)

- TABLE 51. ARGENTINA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY TECHNOLOGY, 2018-2030 (USD MILLION)

- TABLE 52. ARGENTINA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SUBSTRATE MATERIAL, 2018-2030 (USD MILLION)

- TABLE 53. ARGENTINA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY END-USER INDUSTRIES, 2018-2030 (USD MILLION)

- TABLE 54. ARGENTINA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY ELECTRONICS MANUFACTURING, 2018-2030 (USD MILLION)

- TABLE 55. ARGENTINA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY HEALTHCARE EQUIPMENT MAKERS, 2018-2030 (USD MILLION)

- TABLE 56. ARGENTINA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY MILITARY & DEFENSE CONTRACTORS, 2018-2030 (USD MILLION)

- TABLE 57. ARGENTINA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SEMICONDUCTOR INDUSTRY, 2018-2030 (USD MILLION)

- TABLE 58. ARGENTINA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY APPLICATION, 2018-2030 (USD MILLION)

- TABLE 59. BRAZIL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY TECHNOLOGY, 2018-2030 (USD MILLION)

- TABLE 60. BRAZIL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SUBSTRATE MATERIAL, 2018-2030 (USD MILLION)

- TABLE 61. BRAZIL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY END-USER INDUSTRIES, 2018-2030 (USD MILLION)

- TABLE 62. BRAZIL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY ELECTRONICS MANUFACTURING, 2018-2030 (USD MILLION)

- TABLE 63. BRAZIL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY HEALTHCARE EQUIPMENT MAKERS, 2018-2030 (USD MILLION)

- TABLE 64. BRAZIL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY MILITARY & DEFENSE CONTRACTORS, 2018-2030 (USD MILLION)

- TABLE 65. BRAZIL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SEMICONDUCTOR INDUSTRY, 2018-2030 (USD MILLION)

- TABLE 66. BRAZIL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY APPLICATION, 2018-2030 (USD MILLION)

- TABLE 67. CANADA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY TECHNOLOGY, 2018-2030 (USD MILLION)

- TABLE 68. CANADA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SUBSTRATE MATERIAL, 2018-2030 (USD MILLION)

- TABLE 69. CANADA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY END-USER INDUSTRIES, 2018-2030 (USD MILLION)

- TABLE 70. CANADA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY ELECTRONICS MANUFACTURING, 2018-2030 (USD MILLION)

- TABLE 71. CANADA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY HEALTHCARE EQUIPMENT MAKERS, 2018-2030 (USD MILLION)

- TABLE 72. CANADA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY MILITARY & DEFENSE CONTRACTORS, 2018-2030 (USD MILLION)

- TABLE 73. CANADA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SEMICONDUCTOR INDUSTRY, 2018-2030 (USD MILLION)

- TABLE 74. CANADA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY APPLICATION, 2018-2030 (USD MILLION)

- TABLE 75. MEXICO HYBRID BONDING TECHNOLOGY MARKET SIZE, BY TECHNOLOGY, 2018-2030 (USD MILLION)

- TABLE 76. MEXICO HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SUBSTRATE MATERIAL, 2018-2030 (USD MILLION)

- TABLE 77. MEXICO HYBRID BONDING TECHNOLOGY MARKET SIZE, BY END-USER INDUSTRIES, 2018-2030 (USD MILLION)

- TABLE 78. MEXICO HYBRID BONDING TECHNOLOGY MARKET SIZE, BY ELECTRONICS MANUFACTURING, 2018-2030 (USD MILLION)

- TABLE 79. MEXICO HYBRID BONDING TECHNOLOGY MARKET SIZE, BY HEALTHCARE EQUIPMENT MAKERS, 2018-2030 (USD MILLION)

- TABLE 80. MEXICO HYBRID BONDING TECHNOLOGY MARKET SIZE, BY MILITARY & DEFENSE CONTRACTORS, 2018-2030 (USD MILLION)

- TABLE 81. MEXICO HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SEMICONDUCTOR INDUSTRY, 2018-2030 (USD MILLION)

- TABLE 82. MEXICO HYBRID BONDING TECHNOLOGY MARKET SIZE, BY APPLICATION, 2018-2030 (USD MILLION)

- TABLE 83. UNITED STATES HYBRID BONDING TECHNOLOGY MARKET SIZE, BY TECHNOLOGY, 2018-2030 (USD MILLION)

- TABLE 84. UNITED STATES HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SUBSTRATE MATERIAL, 2018-2030 (USD MILLION)

- TABLE 85. UNITED STATES HYBRID BONDING TECHNOLOGY MARKET SIZE, BY END-USER INDUSTRIES, 2018-2030 (USD MILLION)

- TABLE 86. UNITED STATES HYBRID BONDING TECHNOLOGY MARKET SIZE, BY ELECTRONICS MANUFACTURING, 2018-2030 (USD MILLION)

- TABLE 87. UNITED STATES HYBRID BONDING TECHNOLOGY MARKET SIZE, BY HEALTHCARE EQUIPMENT MAKERS, 2018-2030 (USD MILLION)

- TABLE 88. UNITED STATES HYBRID BONDING TECHNOLOGY MARKET SIZE, BY MILITARY & DEFENSE CONTRACTORS, 2018-2030 (USD MILLION)

- TABLE 89. UNITED STATES HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SEMICONDUCTOR INDUSTRY, 2018-2030 (USD MILLION)

- TABLE 90. UNITED STATES HYBRID BONDING TECHNOLOGY MARKET SIZE, BY APPLICATION, 2018-2030 (USD MILLION)

- TABLE 91. UNITED STATES HYBRID BONDING TECHNOLOGY MARKET SIZE, BY STATE, 2018-2030 (USD MILLION)

- TABLE 92. ASIA-PACIFIC HYBRID BONDING TECHNOLOGY MARKET SIZE, BY TECHNOLOGY, 2018-2030 (USD MILLION)

- TABLE 93. ASIA-PACIFIC HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SUBSTRATE MATERIAL, 2018-2030 (USD MILLION)

- TABLE 94. ASIA-PACIFIC HYBRID BONDING TECHNOLOGY MARKET SIZE, BY END-USER INDUSTRIES, 2018-2030 (USD MILLION)

- TABLE 95. ASIA-PACIFIC HYBRID BONDING TECHNOLOGY MARKET SIZE, BY ELECTRONICS MANUFACTURING, 2018-2030 (USD MILLION)

- TABLE 96. ASIA-PACIFIC HYBRID BONDING TECHNOLOGY MARKET SIZE, BY HEALTHCARE EQUIPMENT MAKERS, 2018-2030 (USD MILLION)

- TABLE 97. ASIA-PACIFIC HYBRID BONDING TECHNOLOGY MARKET SIZE, BY MILITARY & DEFENSE CONTRACTORS, 2018-2030 (USD MILLION)

- TABLE 98. ASIA-PACIFIC HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SEMICONDUCTOR INDUSTRY, 2018-2030 (USD MILLION)

- TABLE 99. ASIA-PACIFIC HYBRID BONDING TECHNOLOGY MARKET SIZE, BY APPLICATION, 2018-2030 (USD MILLION)

- TABLE 100. ASIA-PACIFIC HYBRID BONDING TECHNOLOGY MARKET SIZE, BY COUNTRY, 2018-2030 (USD MILLION)

- TABLE 101. AUSTRALIA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY TECHNOLOGY, 2018-2030 (USD MILLION)

- TABLE 102. AUSTRALIA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SUBSTRATE MATERIAL, 2018-2030 (USD MILLION)

- TABLE 103. AUSTRALIA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY END-USER INDUSTRIES, 2018-2030 (USD MILLION)

- TABLE 104. AUSTRALIA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY ELECTRONICS MANUFACTURING, 2018-2030 (USD MILLION)

- TABLE 105. AUSTRALIA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY HEALTHCARE EQUIPMENT MAKERS, 2018-2030 (USD MILLION)

- TABLE 106. AUSTRALIA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY MILITARY & DEFENSE CONTRACTORS, 2018-2030 (USD MILLION)

- TABLE 107. AUSTRALIA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SEMICONDUCTOR INDUSTRY, 2018-2030 (USD MILLION)

- TABLE 108. AUSTRALIA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY APPLICATION, 2018-2030 (USD MILLION)

- TABLE 109. CHINA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY TECHNOLOGY, 2018-2030 (USD MILLION)

- TABLE 110. CHINA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SUBSTRATE MATERIAL, 2018-2030 (USD MILLION)

- TABLE 111. CHINA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY END-USER INDUSTRIES, 2018-2030 (USD MILLION)

- TABLE 112. CHINA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY ELECTRONICS MANUFACTURING, 2018-2030 (USD MILLION)

- TABLE 113. CHINA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY HEALTHCARE EQUIPMENT MAKERS, 2018-2030 (USD MILLION)

- TABLE 114. CHINA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY MILITARY & DEFENSE CONTRACTORS, 2018-2030 (USD MILLION)

- TABLE 115. CHINA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SEMICONDUCTOR INDUSTRY, 2018-2030 (USD MILLION)

- TABLE 116. CHINA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY APPLICATION, 2018-2030 (USD MILLION)

- TABLE 117. INDIA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY TECHNOLOGY, 2018-2030 (USD MILLION)

- TABLE 118. INDIA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SUBSTRATE MATERIAL, 2018-2030 (USD MILLION)

- TABLE 119. INDIA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY END-USER INDUSTRIES, 2018-2030 (USD MILLION)

- TABLE 120. INDIA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY ELECTRONICS MANUFACTURING, 2018-2030 (USD MILLION)

- TABLE 121. INDIA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY HEALTHCARE EQUIPMENT MAKERS, 2018-2030 (USD MILLION)

- TABLE 122. INDIA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY MILITARY & DEFENSE CONTRACTORS, 2018-2030 (USD MILLION)

- TABLE 123. INDIA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SEMICONDUCTOR INDUSTRY, 2018-2030 (USD MILLION)

- TABLE 124. INDIA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY APPLICATION, 2018-2030 (USD MILLION)

- TABLE 125. INDONESIA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY TECHNOLOGY, 2018-2030 (USD MILLION)

- TABLE 126. INDONESIA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SUBSTRATE MATERIAL, 2018-2030 (USD MILLION)

- TABLE 127. INDONESIA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY END-USER INDUSTRIES, 2018-2030 (USD MILLION)

- TABLE 128. INDONESIA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY ELECTRONICS MANUFACTURING, 2018-2030 (USD MILLION)

- TABLE 129. INDONESIA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY HEALTHCARE EQUIPMENT MAKERS, 2018-2030 (USD MILLION)

- TABLE 130. INDONESIA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY MILITARY & DEFENSE CONTRACTORS, 2018-2030 (USD MILLION)

- TABLE 131. INDONESIA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SEMICONDUCTOR INDUSTRY, 2018-2030 (USD MILLION)

- TABLE 132. INDONESIA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY APPLICATION, 2018-2030 (USD MILLION)

- TABLE 133. JAPAN HYBRID BONDING TECHNOLOGY MARKET SIZE, BY TECHNOLOGY, 2018-2030 (USD MILLION)

- TABLE 134. JAPAN HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SUBSTRATE MATERIAL, 2018-2030 (USD MILLION)

- TABLE 135. JAPAN HYBRID BONDING TECHNOLOGY MARKET SIZE, BY END-USER INDUSTRIES, 2018-2030 (USD MILLION)

- TABLE 136. JAPAN HYBRID BONDING TECHNOLOGY MARKET SIZE, BY ELECTRONICS MANUFACTURING, 2018-2030 (USD MILLION)

- TABLE 137. JAPAN HYBRID BONDING TECHNOLOGY MARKET SIZE, BY HEALTHCARE EQUIPMENT MAKERS, 2018-2030 (USD MILLION)

- TABLE 138. JAPAN HYBRID BONDING TECHNOLOGY MARKET SIZE, BY MILITARY & DEFENSE CONTRACTORS, 2018-2030 (USD MILLION)

- TABLE 139. JAPAN HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SEMICONDUCTOR INDUSTRY, 2018-2030 (USD MILLION)

- TABLE 140. JAPAN HYBRID BONDING TECHNOLOGY MARKET SIZE, BY APPLICATION, 2018-2030 (USD MILLION)

- TABLE 141. MALAYSIA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY TECHNOLOGY, 2018-2030 (USD MILLION)

- TABLE 142. MALAYSIA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SUBSTRATE MATERIAL, 2018-2030 (USD MILLION)

- TABLE 143. MALAYSIA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY END-USER INDUSTRIES, 2018-2030 (USD MILLION)

- TABLE 144. MALAYSIA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY ELECTRONICS MANUFACTURING, 2018-2030 (USD MILLION)

- TABLE 145. MALAYSIA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY HEALTHCARE EQUIPMENT MAKERS, 2018-2030 (USD MILLION)

- TABLE 146. MALAYSIA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY MILITARY & DEFENSE CONTRACTORS, 2018-2030 (USD MILLION)

- TABLE 147. MALAYSIA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SEMICONDUCTOR INDUSTRY, 2018-2030 (USD MILLION)

- TABLE 148. MALAYSIA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY APPLICATION, 2018-2030 (USD MILLION)

- TABLE 149. PHILIPPINES HYBRID BONDING TECHNOLOGY MARKET SIZE, BY TECHNOLOGY, 2018-2030 (USD MILLION)

- TABLE 150. PHILIPPINES HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SUBSTRATE MATERIAL, 2018-2030 (USD MILLION)

- TABLE 151. PHILIPPINES HYBRID BONDING TECHNOLOGY MARKET SIZE, BY END-USER INDUSTRIES, 2018-2030 (USD MILLION)

- TABLE 152. PHILIPPINES HYBRID BONDING TECHNOLOGY MARKET SIZE, BY ELECTRONICS MANUFACTURING, 2018-2030 (USD MILLION)

- TABLE 153. PHILIPPINES HYBRID BONDING TECHNOLOGY MARKET SIZE, BY HEALTHCARE EQUIPMENT MAKERS, 2018-2030 (USD MILLION)

- TABLE 154. PHILIPPINES HYBRID BONDING TECHNOLOGY MARKET SIZE, BY MILITARY & DEFENSE CONTRACTORS, 2018-2030 (USD MILLION)

- TABLE 155. PHILIPPINES HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SEMICONDUCTOR INDUSTRY, 2018-2030 (USD MILLION)

- TABLE 156. PHILIPPINES HYBRID BONDING TECHNOLOGY MARKET SIZE, BY APPLICATION, 2018-2030 (USD MILLION)

- TABLE 157. SINGAPORE HYBRID BONDING TECHNOLOGY MARKET SIZE, BY TECHNOLOGY, 2018-2030 (USD MILLION)

- TABLE 158. SINGAPORE HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SUBSTRATE MATERIAL, 2018-2030 (USD MILLION)

- TABLE 159. SINGAPORE HYBRID BONDING TECHNOLOGY MARKET SIZE, BY END-USER INDUSTRIES, 2018-2030 (USD MILLION)

- TABLE 160. SINGAPORE HYBRID BONDING TECHNOLOGY MARKET SIZE, BY ELECTRONICS MANUFACTURING, 2018-2030 (USD MILLION)

- TABLE 161. SINGAPORE HYBRID BONDING TECHNOLOGY MARKET SIZE, BY HEALTHCARE EQUIPMENT MAKERS, 2018-2030 (USD MILLION)

- TABLE 162. SINGAPORE HYBRID BONDING TECHNOLOGY MARKET SIZE, BY MILITARY & DEFENSE CONTRACTORS, 2018-2030 (USD MILLION)

- TABLE 163. SINGAPORE HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SEMICONDUCTOR INDUSTRY, 2018-2030 (USD MILLION)

- TABLE 164. SINGAPORE HYBRID BONDING TECHNOLOGY MARKET SIZE, BY APPLICATION, 2018-2030 (USD MILLION)

- TABLE 165. SOUTH KOREA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY TECHNOLOGY, 2018-2030 (USD MILLION)

- TABLE 166. SOUTH KOREA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SUBSTRATE MATERIAL, 2018-2030 (USD MILLION)

- TABLE 167. SOUTH KOREA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY END-USER INDUSTRIES, 2018-2030 (USD MILLION)

- TABLE 168. SOUTH KOREA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY ELECTRONICS MANUFACTURING, 2018-2030 (USD MILLION)

- TABLE 169. SOUTH KOREA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY HEALTHCARE EQUIPMENT MAKERS, 2018-2030 (USD MILLION)

- TABLE 170. SOUTH KOREA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY MILITARY & DEFENSE CONTRACTORS, 2018-2030 (USD MILLION)

- TABLE 171. SOUTH KOREA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SEMICONDUCTOR INDUSTRY, 2018-2030 (USD MILLION)

- TABLE 172. SOUTH KOREA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY APPLICATION, 2018-2030 (USD MILLION)

- TABLE 173. TAIWAN HYBRID BONDING TECHNOLOGY MARKET SIZE, BY TECHNOLOGY, 2018-2030 (USD MILLION)

- TABLE 174. TAIWAN HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SUBSTRATE MATERIAL, 2018-2030 (USD MILLION)

- TABLE 175. TAIWAN HYBRID BONDING TECHNOLOGY MARKET SIZE, BY END-USER INDUSTRIES, 2018-2030 (USD MILLION)

- TABLE 176. TAIWAN HYBRID BONDING TECHNOLOGY MARKET SIZE, BY ELECTRONICS MANUFACTURING, 2018-2030 (USD MILLION)

- TABLE 177. TAIWAN HYBRID BONDING TECHNOLOGY MARKET SIZE, BY HEALTHCARE EQUIPMENT MAKERS, 2018-2030 (USD MILLION)

- TABLE 178. TAIWAN HYBRID BONDING TECHNOLOGY MARKET SIZE, BY MILITARY & DEFENSE CONTRACTORS, 2018-2030 (USD MILLION)

- TABLE 179. TAIWAN HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SEMICONDUCTOR INDUSTRY, 2018-2030 (USD MILLION)

- TABLE 180. TAIWAN HYBRID BONDING TECHNOLOGY MARKET SIZE, BY APPLICATION, 2018-2030 (USD MILLION)

- TABLE 181. THAILAND HYBRID BONDING TECHNOLOGY MARKET SIZE, BY TECHNOLOGY, 2018-2030 (USD MILLION)

- TABLE 182. THAILAND HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SUBSTRATE MATERIAL, 2018-2030 (USD MILLION)

- TABLE 183. THAILAND HYBRID BONDING TECHNOLOGY MARKET SIZE, BY END-USER INDUSTRIES, 2018-2030 (USD MILLION)

- TABLE 184. THAILAND HYBRID BONDING TECHNOLOGY MARKET SIZE, BY ELECTRONICS MANUFACTURING, 2018-2030 (USD MILLION)

- TABLE 185. THAILAND HYBRID BONDING TECHNOLOGY MARKET SIZE, BY HEALTHCARE EQUIPMENT MAKERS, 2018-2030 (USD MILLION)

- TABLE 186. THAILAND HYBRID BONDING TECHNOLOGY MARKET SIZE, BY MILITARY & DEFENSE CONTRACTORS, 2018-2030 (USD MILLION)

- TABLE 187. THAILAND HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SEMICONDUCTOR INDUSTRY, 2018-2030 (USD MILLION)

- TABLE 188. THAILAND HYBRID BONDING TECHNOLOGY MARKET SIZE, BY APPLICATION, 2018-2030 (USD MILLION)

- TABLE 189. VIETNAM HYBRID BONDING TECHNOLOGY MARKET SIZE, BY TECHNOLOGY, 2018-2030 (USD MILLION)

- TABLE 190. VIETNAM HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SUBSTRATE MATERIAL, 2018-2030 (USD MILLION)

- TABLE 191. VIETNAM HYBRID BONDING TECHNOLOGY MARKET SIZE, BY END-USER INDUSTRIES, 2018-2030 (USD MILLION)

- TABLE 192. VIETNAM HYBRID BONDING TECHNOLOGY MARKET SIZE, BY ELECTRONICS MANUFACTURING, 2018-2030 (USD MILLION)

- TABLE 193. VIETNAM HYBRID BONDING TECHNOLOGY MARKET SIZE, BY HEALTHCARE EQUIPMENT MAKERS, 2018-2030 (USD MILLION)

- TABLE 194. VIETNAM HYBRID BONDING TECHNOLOGY MARKET SIZE, BY MILITARY & DEFENSE CONTRACTORS, 2018-2030 (USD MILLION)

- TABLE 195. VIETNAM HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SEMICONDUCTOR INDUSTRY, 2018-2030 (USD MILLION)

- TABLE 196. VIETNAM HYBRID BONDING TECHNOLOGY MARKET SIZE, BY APPLICATION, 2018-2030 (USD MILLION)

- TABLE 197. EUROPE, MIDDLE EAST & AFRICA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY TECHNOLOGY, 2018-2030 (USD MILLION)

- TABLE 198. EUROPE, MIDDLE EAST & AFRICA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SUBSTRATE MATERIAL, 2018-2030 (USD MILLION)

- TABLE 199. EUROPE, MIDDLE EAST & AFRICA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY END-USER INDUSTRIES, 2018-2030 (USD MILLION)

- TABLE 200. EUROPE, MIDDLE EAST & AFRICA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY ELECTRONICS MANUFACTURING, 2018-2030 (USD MILLION)

- TABLE 201. EUROPE, MIDDLE EAST & AFRICA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY HEALTHCARE EQUIPMENT MAKERS, 2018-2030 (USD MILLION)

- TABLE 202. EUROPE, MIDDLE EAST & AFRICA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY MILITARY & DEFENSE CONTRACTORS, 2018-2030 (USD MILLION)

- TABLE 203. EUROPE, MIDDLE EAST & AFRICA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SEMICONDUCTOR INDUSTRY, 2018-2030 (USD MILLION)

- TABLE 204. EUROPE, MIDDLE EAST & AFRICA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY APPLICATION, 2018-2030 (USD MILLION)

- TABLE 205. EUROPE, MIDDLE EAST & AFRICA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY COUNTRY, 2018-2030 (USD MILLION)

- TABLE 206. DENMARK HYBRID BONDING TECHNOLOGY MARKET SIZE, BY TECHNOLOGY, 2018-2030 (USD MILLION)

- TABLE 207. DENMARK HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SUBSTRATE MATERIAL, 2018-2030 (USD MILLION)

- TABLE 208. DENMARK HYBRID BONDING TECHNOLOGY MARKET SIZE, BY END-USER INDUSTRIES, 2018-2030 (USD MILLION)

- TABLE 209. DENMARK HYBRID BONDING TECHNOLOGY MARKET SIZE, BY ELECTRONICS MANUFACTURING, 2018-2030 (USD MILLION)

- TABLE 210. DENMARK HYBRID BONDING TECHNOLOGY MARKET SIZE, BY HEALTHCARE EQUIPMENT MAKERS, 2018-2030 (USD MILLION)

- TABLE 211. DENMARK HYBRID BONDING TECHNOLOGY MARKET SIZE, BY MILITARY & DEFENSE CONTRACTORS, 2018-2030 (USD MILLION)

- TABLE 212. DENMARK HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SEMICONDUCTOR INDUSTRY, 2018-2030 (USD MILLION)

- TABLE 213. DENMARK HYBRID BONDING TECHNOLOGY MARKET SIZE, BY APPLICATION, 2018-2030 (USD MILLION)

- TABLE 214. EGYPT HYBRID BONDING TECHNOLOGY MARKET SIZE, BY TECHNOLOGY, 2018-2030 (USD MILLION)

- TABLE 215. EGYPT HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SUBSTRATE MATERIAL, 2018-2030 (USD MILLION)

- TABLE 216. EGYPT HYBRID BONDING TECHNOLOGY MARKET SIZE, BY END-USER INDUSTRIES, 2018-2030 (USD MILLION)

- TABLE 217. EGYPT HYBRID BONDING TECHNOLOGY MARKET SIZE, BY ELECTRONICS MANUFACTURING, 2018-2030 (USD MILLION)

- TABLE 218. EGYPT HYBRID BONDING TECHNOLOGY MARKET SIZE, BY HEALTHCARE EQUIPMENT MAKERS, 2018-2030 (USD MILLION)

- TABLE 219. EGYPT HYBRID BONDING TECHNOLOGY MARKET SIZE, BY MILITARY & DEFENSE CONTRACTORS, 2018-2030 (USD MILLION)

- TABLE 220. EGYPT HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SEMICONDUCTOR INDUSTRY, 2018-2030 (USD MILLION)

- TABLE 221. EGYPT HYBRID BONDING TECHNOLOGY MARKET SIZE, BY APPLICATION, 2018-2030 (USD MILLION)

- TABLE 222. FINLAND HYBRID BONDING TECHNOLOGY MARKET SIZE, BY TECHNOLOGY, 2018-2030 (USD MILLION)

- TABLE 223. FINLAND HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SUBSTRATE MATERIAL, 2018-2030 (USD MILLION)

- TABLE 224. FINLAND HYBRID BONDING TECHNOLOGY MARKET SIZE, BY END-USER INDUSTRIES, 2018-2030 (USD MILLION)

- TABLE 225. FINLAND HYBRID BONDING TECHNOLOGY MARKET SIZE, BY ELECTRONICS MANUFACTURING, 2018-2030 (USD MILLION)

- TABLE 226. FINLAND HYBRID BONDING TECHNOLOGY MARKET SIZE, BY HEALTHCARE EQUIPMENT MAKERS, 2018-2030 (USD MILLION)

- TABLE 227. FINLAND HYBRID BONDING TECHNOLOGY MARKET SIZE, BY MILITARY & DEFENSE CONTRACTORS, 2018-2030 (USD MILLION)

- TABLE 228. FINLAND HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SEMICONDUCTOR INDUSTRY, 2018-2030 (USD MILLION)

- TABLE 229. FINLAND HYBRID BONDING TECHNOLOGY MARKET SIZE, BY APPLICATION, 2018-2030 (USD MILLION)

- TABLE 230. FRANCE HYBRID BONDING TECHNOLOGY MARKET SIZE, BY TECHNOLOGY, 2018-2030 (USD MILLION)

- TABLE 231. FRANCE HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SUBSTRATE MATERIAL, 2018-2030 (USD MILLION)

- TABLE 232. FRANCE HYBRID BONDING TECHNOLOGY MARKET SIZE, BY END-USER INDUSTRIES, 2018-2030 (USD MILLION)

- TABLE 233. FRANCE HYBRID BONDING TECHNOLOGY MARKET SIZE, BY ELECTRONICS MANUFACTURING, 2018-2030 (USD MILLION)

- TABLE 234. FRANCE HYBRID BONDING TECHNOLOGY MARKET SIZE, BY HEALTHCARE EQUIPMENT MAKERS, 2018-2030 (USD MILLION)

- TABLE 235. FRANCE HYBRID BONDING TECHNOLOGY MARKET SIZE, BY MILITARY & DEFENSE CONTRACTORS, 2018-2030 (USD MILLION)

- TABLE 236. FRANCE HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SEMICONDUCTOR INDUSTRY, 2018-2030 (USD MILLION)

- TABLE 237. FRANCE HYBRID BONDING TECHNOLOGY MARKET SIZE, BY APPLICATION, 2018-2030 (USD MILLION)

- TABLE 238. GERMANY HYBRID BONDING TECHNOLOGY MARKET SIZE, BY TECHNOLOGY, 2018-2030 (USD MILLION)

- TABLE 239. GERMANY HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SUBSTRATE MATERIAL, 2018-2030 (USD MILLION)

- TABLE 240. GERMANY HYBRID BONDING TECHNOLOGY MARKET SIZE, BY END-USER INDUSTRIES, 2018-2030 (USD MILLION)

- TABLE 241. GERMANY HYBRID BONDING TECHNOLOGY MARKET SIZE, BY ELECTRONICS MANUFACTURING, 2018-2030 (USD MILLION)

- TABLE 242. GERMANY HYBRID BONDING TECHNOLOGY MARKET SIZE, BY HEALTHCARE EQUIPMENT MAKERS, 2018-2030 (USD MILLION)

- TABLE 243. GERMANY HYBRID BONDING TECHNOLOGY MARKET SIZE, BY MILITARY & DEFENSE CONTRACTORS, 2018-2030 (USD MILLION)

- TABLE 244. GERMANY HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SEMICONDUCTOR INDUSTRY, 2018-2030 (USD MILLION)

- TABLE 245. GERMANY HYBRID BONDING TECHNOLOGY MARKET SIZE, BY APPLICATION, 2018-2030 (USD MILLION)

- TABLE 246. ISRAEL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY TECHNOLOGY, 2018-2030 (USD MILLION)

- TABLE 247. ISRAEL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SUBSTRATE MATERIAL, 2018-2030 (USD MILLION)

- TABLE 248. ISRAEL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY END-USER INDUSTRIES, 2018-2030 (USD MILLION)

- TABLE 249. ISRAEL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY ELECTRONICS MANUFACTURING, 2018-2030 (USD MILLION)

- TABLE 250. ISRAEL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY HEALTHCARE EQUIPMENT MAKERS, 2018-2030 (USD MILLION)

- TABLE 251. ISRAEL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY MILITARY & DEFENSE CONTRACTORS, 2018-2030 (USD MILLION)

- TABLE 252. ISRAEL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SEMICONDUCTOR INDUSTRY, 2018-2030 (USD MILLION)

- TABLE 253. ISRAEL HYBRID BONDING TECHNOLOGY MARKET SIZE, BY APPLICATION, 2018-2030 (USD MILLION)

- TABLE 254. ITALY HYBRID BONDING TECHNOLOGY MARKET SIZE, BY TECHNOLOGY, 2018-2030 (USD MILLION)

- TABLE 255. ITALY HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SUBSTRATE MATERIAL, 2018-2030 (USD MILLION)

- TABLE 256. ITALY HYBRID BONDING TECHNOLOGY MARKET SIZE, BY END-USER INDUSTRIES, 2018-2030 (USD MILLION)

- TABLE 257. ITALY HYBRID BONDING TECHNOLOGY MARKET SIZE, BY ELECTRONICS MANUFACTURING, 2018-2030 (USD MILLION)

- TABLE 258. ITALY HYBRID BONDING TECHNOLOGY MARKET SIZE, BY HEALTHCARE EQUIPMENT MAKERS, 2018-2030 (USD MILLION)

- TABLE 259. ITALY HYBRID BONDING TECHNOLOGY MARKET SIZE, BY MILITARY & DEFENSE CONTRACTORS, 2018-2030 (USD MILLION)

- TABLE 260. ITALY HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SEMICONDUCTOR INDUSTRY, 2018-2030 (USD MILLION)

- TABLE 261. ITALY HYBRID BONDING TECHNOLOGY MARKET SIZE, BY APPLICATION, 2018-2030 (USD MILLION)

- TABLE 262. NETHERLANDS HYBRID BONDING TECHNOLOGY MARKET SIZE, BY TECHNOLOGY, 2018-2030 (USD MILLION)

- TABLE 263. NETHERLANDS HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SUBSTRATE MATERIAL, 2018-2030 (USD MILLION)

- TABLE 264. NETHERLANDS HYBRID BONDING TECHNOLOGY MARKET SIZE, BY END-USER INDUSTRIES, 2018-2030 (USD MILLION)

- TABLE 265. NETHERLANDS HYBRID BONDING TECHNOLOGY MARKET SIZE, BY ELECTRONICS MANUFACTURING, 2018-2030 (USD MILLION)

- TABLE 266. NETHERLANDS HYBRID BONDING TECHNOLOGY MARKET SIZE, BY HEALTHCARE EQUIPMENT MAKERS, 2018-2030 (USD MILLION)

- TABLE 267. NETHERLANDS HYBRID BONDING TECHNOLOGY MARKET SIZE, BY MILITARY & DEFENSE CONTRACTORS, 2018-2030 (USD MILLION)

- TABLE 268. NETHERLANDS HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SEMICONDUCTOR INDUSTRY, 2018-2030 (USD MILLION)

- TABLE 269. NETHERLANDS HYBRID BONDING TECHNOLOGY MARKET SIZE, BY APPLICATION, 2018-2030 (USD MILLION)

- TABLE 270. NIGERIA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY TECHNOLOGY, 2018-2030 (USD MILLION)

- TABLE 271. NIGERIA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SUBSTRATE MATERIAL, 2018-2030 (USD MILLION)

- TABLE 272. NIGERIA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY END-USER INDUSTRIES, 2018-2030 (USD MILLION)

- TABLE 273. NIGERIA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY ELECTRONICS MANUFACTURING, 2018-2030 (USD MILLION)

- TABLE 274. NIGERIA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY HEALTHCARE EQUIPMENT MAKERS, 2018-2030 (USD MILLION)

- TABLE 275. NIGERIA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY MILITARY & DEFENSE CONTRACTORS, 2018-2030 (USD MILLION)

- TABLE 276. NIGERIA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SEMICONDUCTOR INDUSTRY, 2018-2030 (USD MILLION)

- TABLE 277. NIGERIA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY APPLICATION, 2018-2030 (USD MILLION)

- TABLE 278. NORWAY HYBRID BONDING TECHNOLOGY MARKET SIZE, BY TECHNOLOGY, 2018-2030 (USD MILLION)

- TABLE 279. NORWAY HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SUBSTRATE MATERIAL, 2018-2030 (USD MILLION)

- TABLE 280. NORWAY HYBRID BONDING TECHNOLOGY MARKET SIZE, BY END-USER INDUSTRIES, 2018-2030 (USD MILLION)

- TABLE 281. NORWAY HYBRID BONDING TECHNOLOGY MARKET SIZE, BY ELECTRONICS MANUFACTURING, 2018-2030 (USD MILLION)

- TABLE 282. NORWAY HYBRID BONDING TECHNOLOGY MARKET SIZE, BY HEALTHCARE EQUIPMENT MAKERS, 2018-2030 (USD MILLION)

- TABLE 283. NORWAY HYBRID BONDING TECHNOLOGY MARKET SIZE, BY MILITARY & DEFENSE CONTRACTORS, 2018-2030 (USD MILLION)

- TABLE 284. NORWAY HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SEMICONDUCTOR INDUSTRY, 2018-2030 (USD MILLION)

- TABLE 285. NORWAY HYBRID BONDING TECHNOLOGY MARKET SIZE, BY APPLICATION, 2018-2030 (USD MILLION)

- TABLE 286. POLAND HYBRID BONDING TECHNOLOGY MARKET SIZE, BY TECHNOLOGY, 2018-2030 (USD MILLION)

- TABLE 287. POLAND HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SUBSTRATE MATERIAL, 2018-2030 (USD MILLION)

- TABLE 288. POLAND HYBRID BONDING TECHNOLOGY MARKET SIZE, BY END-USER INDUSTRIES, 2018-2030 (USD MILLION)

- TABLE 289. POLAND HYBRID BONDING TECHNOLOGY MARKET SIZE, BY ELECTRONICS MANUFACTURING, 2018-2030 (USD MILLION)

- TABLE 290. POLAND HYBRID BONDING TECHNOLOGY MARKET SIZE, BY HEALTHCARE EQUIPMENT MAKERS, 2018-2030 (USD MILLION)

- TABLE 291. POLAND HYBRID BONDING TECHNOLOGY MARKET SIZE, BY MILITARY & DEFENSE CONTRACTORS, 2018-2030 (USD MILLION)

- TABLE 292. POLAND HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SEMICONDUCTOR INDUSTRY, 2018-2030 (USD MILLION)

- TABLE 293. POLAND HYBRID BONDING TECHNOLOGY MARKET SIZE, BY APPLICATION, 2018-2030 (USD MILLION)

- TABLE 294. QATAR HYBRID BONDING TECHNOLOGY MARKET SIZE, BY TECHNOLOGY, 2018-2030 (USD MILLION)

- TABLE 295. QATAR HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SUBSTRATE MATERIAL, 2018-2030 (USD MILLION)

- TABLE 296. QATAR HYBRID BONDING TECHNOLOGY MARKET SIZE, BY END-USER INDUSTRIES, 2018-2030 (USD MILLION)

- TABLE 297. QATAR HYBRID BONDING TECHNOLOGY MARKET SIZE, BY ELECTRONICS MANUFACTURING, 2018-2030 (USD MILLION)

- TABLE 298. QATAR HYBRID BONDING TECHNOLOGY MARKET SIZE, BY HEALTHCARE EQUIPMENT MAKERS, 2018-2030 (USD MILLION)

- TABLE 299. QATAR HYBRID BONDING TECHNOLOGY MARKET SIZE, BY MILITARY & DEFENSE CONTRACTORS, 2018-2030 (USD MILLION)

- TABLE 300. QATAR HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SEMICONDUCTOR INDUSTRY, 2018-2030 (USD MILLION)

- TABLE 301. QATAR HYBRID BONDING TECHNOLOGY MARKET SIZE, BY APPLICATION, 2018-2030 (USD MILLION)

- TABLE 302. RUSSIA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY TECHNOLOGY, 2018-2030 (USD MILLION)

- TABLE 303. RUSSIA HYBRID BONDING TECHNOLOGY MARKET SIZE, BY SUBSTRATE MATERIAL, 2018-2030 (USD

The Hybrid Bonding Technology Market was valued at USD 651.53 million in 2024 and is projected to grow to USD 684.63 million in 2025, with a CAGR of 5.29%, reaching USD 887.85 million by 2030.

| KEY MARKET STATISTICS | |

|---|---|

| Base Year [2024] | USD 651.53 million |

| Estimated Year [2025] | USD 684.63 million |

| Forecast Year [2030] | USD 887.85 million |

| CAGR (%) | 5.29% |

Hybrid bonding technology is emerging as a revolutionary force in the electronics and semiconductor industries. Its ability to enable more efficient connections at the micro and nano scale is setting the stage for enhanced device performance and integration. The technology offers novel approaches to interconnects by combining multiple bonding techniques, thereby opening up new avenues for innovation in several high-demand applications. Manufacturers are turning to hybrid bonding to overcome traditional limitations related to size, speed, and power consumption, which are critical in an era marked by rapid advancements in digital electronics and high-performance computing.

This transformative approach is driven by continuous research and development, coupled with the pressing need for higher functionality and integration in consumer electronics, medical instrumentation, automotive systems, and defense applications. The evolution of hybrid bonding is not only about meeting current technological demands but also paving the way for future breakthroughs. As the market continues to mature, key stakeholders must adapt to evolving customer needs and regulatory landscapes, ensuring that investments in research deliver sustained competitive advantages. This report provides an in-depth analysis of the market, offering clarity on technological trends, regional influences, and strategic moves by industry leaders.

Transformative Shifts in the Hybrid Bonding Landscape

The hybrid bonding arena has experienced significant shifts catalyzed by rapid technological advancements and evolving market dynamics. In recent years, the convergence of diverse bonding techniques has shifted the paradigm from conventional packaging methods to highly integrated solutions that allow for increased device density and performance. Advancements in materials science and precision engineering have enabled a transition from traditional hardware constraints to more compact and efficient designs.

Manufacturers now benefit from shorter signal paths and improved electrical performance, which are critical in high-frequency applications encountered in telecommunications, computing, and automotive systems. The strategic integration of various bonding methods has also paved the way for innovative device architectures, allowing systems to meet the demand for miniaturization without sacrificing reliability. This shift is supported by robust supply chains, global partnerships, and concerted R&D initiatives aimed at sustaining growth in a competitive environment.

These transformative changes are fueled by both end-market requirements and regulatory standards that push for safer, smarter, and more energy-efficient devices. Stakeholders have begun to re-assess their investment portfolios with a focus on technologies that promise scalability and enhanced interoperability, making hybrid bonding a focal point of industry evolution.

Key Insights on Market Segmentation in Hybrid Bonding

A detailed examination of market segmentation reveals the multifaceted approaches employed in studying the hybrid bonding technology domain. The market analysis dissects technology-based segments, including Die-to-Die Bonding, Die-to-Wafer Bonding, Through-Silicon Vias (TSVs), and Wafer-to-Wafer Bonding; each contributing unique attributes in terms of performance and integration. Equally important is the segmentation based on substrate materials, which encompasses Ceramic, Glass, Polymer, and Silicon, reflecting the diverse physical parameters that influence bonding quality and durability.

Further granularity is offered by evaluating the end-user industries, where Automotive Manufacturers demonstrate a growing appetite for innovative packaging solutions, while the Electronics Manufacturing sector sees a bifurcation into Electronics Assembly Service Providers and Original Equipment Manufacturers who demand refined integration techniques. In addition, Healthcare Equipment Makers, including Diagnostic Equipment Manufacturers and Surgical Instrument Producers, are rapidly adopting bonding technologies to enhance device precision. Likewise, the Military & Defense sector, represented by Military Communication System Development and Radar System Developments, invests in robust and secure bonding processes. The Semiconductor Industry, examined through the lenses of Foundries and Integrated Device Manufacturers, underscores the technology's critical relevance in high volume production.

Finally, application-based segmentation highlights key areas like Fan-out wafer-level packaging, High-Power Electronics, Optoelectronics, Semiconductor Packaging, Sensor and MEMS Devices, and solutions designed for advanced Thermal Management, each underpinning a distinct set of challenges and opportunities in the field.

Based on Technology, market is studied across Die-to-Die Bonding, Die-to-Wafer Bonding, Through-Silicon Vias (TSVs), and Wafer-to-Wafer Bonding.

Based on Substrate Material, market is studied across Ceramic, Glass, Polymer, and Silicon.

Based on End-User Industries, market is studied across Automotive Manufacturers, Electronics Manufacturing, Healthcare Equipment Makers, Military & Defense Contractors, and Semiconductor Industry. The Electronics Manufacturing is further studied across Electronics Assembly Service Providers and Original Equipment Manufacturers. The Healthcare Equipment Makers is further studied across Diagnostic Equipment Manufacturers and Surgical Instrument Producers. The Military & Defense Contractors is further studied across Military Communication System Development and Radar System Developments. The Semiconductor Industry is further studied across Foundries and Integrated Device Manufacturers.

Based on Application, market is studied across Fan-out wafer-level packaging (FOWLP), High-Power Electronics, Optoelectronics, Semiconductor Packaging, Sensor & MEMS Devices, and Thermal Management Solutions.

Regional Insights Highlighting the Global Footprint

A comprehensive regional analysis unveils distinct trends and market dynamics across key geographies. In the Americas, rapid advancements in semiconductor manufacturing, driven by innovation hubs and extensive industrial collaborations, are fostering an environment ripe for hybrid bonding integration. In Europe, the Middle East, and Africa, an amalgamation of regulatory reform and heightened R&D investments is resulting in progressive alignment with global standards and an accelerated pace of technology adoption. Meanwhile, the Asia-Pacific region remains a powerhouse of manufacturing excellence, with substantial investments in infrastructure and a focus on precision engineering that propels the adoption of hybrid bonding solutions.

These regions are not only geographically diverse but also encapsulate varying consumer demands, regulatory frameworks, and economic landscapes. The Americas offer a blend of technological innovation and established market presence, while Europe, the Middle East, and Africa provide a diverse spectrum of opportunities driven by governmental incentives and robust industrial policies. Meanwhile, Asia-Pacific stands out for its sheer production capacities and rapid prototyping initiatives, making it a bellwether for global trends in semiconductor and electronics manufacturing.

This global perspective reinforces the idea that strategic geographic positioning, along with localized market insights, plays a crucial role in guiding industry stakeholders towards sustainable growth.

Based on Region, market is studied across Americas, Asia-Pacific, and Europe, Middle East & Africa. The Americas is further studied across Argentina, Brazil, Canada, Mexico, and United States. The United States is further studied across California, Florida, Illinois, New York, Ohio, Pennsylvania, and Texas. The Asia-Pacific is further studied across Australia, China, India, Indonesia, Japan, Malaysia, Philippines, Singapore, South Korea, Taiwan, Thailand, and Vietnam. The Europe, Middle East & Africa is further studied across Denmark, Egypt, Finland, France, Germany, Israel, Italy, Netherlands, Nigeria, Norway, Poland, Qatar, Russia, Saudi Arabia, South Africa, Spain, Sweden, Switzerland, Turkey, United Arab Emirates, and United Kingdom.

Key Companies Driving Innovation in Hybrid Bonding

The competitive landscape is rich with illustrious companies that are at the forefront of developing and implementing hybrid bonding technology. Leading players in the market, including Adeia Inc by Xperi Holding Corp, Advanced Micro Devices, Inc., and Amkor Technology, Inc., are continuously investing in state-of-the-art research to drive technological enhancements. Equally pivotal are companies like Applied Materials, Inc. and GLOBALFOUNDRIES Inc., which are contributing significantly to the development of manufacturing processes that ensure optimal performance and cost-effectiveness.

Industry giants such as Infineon Technologies AG, KLA Corporation, and Lam Research Corporation have further augmented the market with innovative solutions that address the growing demand for high-precision bonding techniques. Additionally, Rohm Semiconductor and Samsung Electronics Co., Ltd. are actively advancing the technology, backed by thorough market understanding and technical proficiency. The role of SK Hynix Inc., STMicroelectronics N.V., Taiwan Semiconductor Manufacturing Company Limited, Tokyo Electron Limited, and United Microelectronics Corporation cannot be understated, as they drive efficiency and speed in production.

Collectively, these key players herald a new era in semiconductor packaging and electronic component integration, demonstrating the strategic importance of continued innovation and agile adaptation in an increasingly competitive global marketplace.

The report delves into recent significant developments in the Hybrid Bonding Technology Market, highlighting leading vendors and their innovative profiles. These include Adeia Inc by Xperi Holding Corp, Advanced Micro Devices, Inc., Amkor Technology, Inc., Applied Materials, Inc., GLOBALFOUNDRIES Inc., Infineon Technologies AG, KLA Corporation, Lam Research Corporation, Rohm Semiconductor, Samsung Electronics Co., Ltd., SK Hynix Inc., STMicroelectronics N.V., Taiwan Semiconductor Manufacturing Company Limited, Tokyo Electron Limited, and United Microelectronics Corporation. Actionable Recommendations for Industry Leaders

Industry leaders are encouraged to adopt a multidimensional strategy to harness the full potential of hybrid bonding technology. First, it is imperative to continually invest in research and development initiatives that focus on refining bonding precision and ensuring compatibility with advanced packaging solutions. This strategic focus will help in addressing both current market requirements and future technological breakthroughs.

Secondly, ensuring close collaboration with suppliers and technology partners is essential. Coordinated efforts in streamlining the supply chain, establishing strategic partnerships, and leveraging shared expertise can significantly reduce transitional hurdles and enhance overall process efficiency. Leaders should also look into incorporating digital transformation strategies to optimize manufacturing processes and enable real-time monitoring and quality control systems.

Additionally, it is vital to stay abreast of regional market trends and regulatory changes that may affect production dynamics and market entry strategies. Having a robust framework for risk management and regulatory compliance can serve as a competitive advantage. Finally, companies should focus on aligning their product portfolios to emerging application areas such as High-Power Electronics and Sensor and MEMS Devices, ensuring they are well positioned to capture growth from evolving market demands.

By adopting these strategic recommendations, industry leaders will not only solidify their market presence but also catalyze innovation, driving long-term sustainable growth.

Conclusion: Embracing a New Era in Bonding Technology

The evolving landscape of hybrid bonding technology underscores an era of transformative change in the electronics and semiconductor sectors. As seen across various technological, material, and application-related segments, the shift towards integrated, high-performance solutions is both inevitable and beneficial. The industry's move from conventional bonding techniques to more sophisticated methods reflects the broader trend of innovation and precision that defines modern electronic manufacturing.

Key regional insights reveal that while each market possesses its unique set of drivers, the global push towards miniaturization, energy efficiency, and enhanced device performance is a unifying factor across the board. Leading companies continue to set benchmarks in technological advancements, ensuring that hybrid bonding remains a pivotal element in materializing next-generation devices.

In conclusion, successful navigation of this complex landscape will require a blend of strategic investments, agile operational frameworks, and an unwavering commitment to innovation. The future of hybrid bonding technology is bright, promising a level of performance and integration that could redefine entire industries and set new standards in electronic manufacturing.

Table of Contents

1. Preface

- 1.1. Objectives of the Study

- 1.2. Market Segmentation & Coverage

- 1.3. Years Considered for the Study

- 1.4. Currency & Pricing

- 1.5. Language

- 1.6. Stakeholders

2. Research Methodology

- 2.1. Define: Research Objective

- 2.2. Determine: Research Design

- 2.3. Prepare: Research Instrument

- 2.4. Collect: Data Source

- 2.5. Analyze: Data Interpretation

- 2.6. Formulate: Data Verification

- 2.7. Publish: Research Report

- 2.8. Repeat: Report Update

3. Executive Summary

4. Market Overview

5. Market Insights

- 5.1. Market Dynamics

- 5.1.1. Drivers

- 5.1.1.1. The rise of Industry 4.0 and IoT deployment requires enhanced interconnectivity provided by hybrid bonding

- 5.1.1.2. Increasing demand for miniaturization in electronics propels the growth of hybrid bonding technology

- 5.1.1.3. Expanding use of hybrid bonding in 3D ICs and advanced packaging fostering market expansion

- 5.1.2. Restraints

- 5.1.2.1. High initial investment requirements restricting market progression for hybrid bonding technology

- 5.1.3. Opportunities

- 5.1.3.1. Advancements in AI and ML fueling the need for hybrid bonding in powerful, high-performance computing

- 5.1.3.2. Rising partnerships between tech companies to develop and refine hybrid bonding technologies

- 5.1.4. Challenges

- 5.1.4.1. Rising environmental and sustainability concerns associated with hybrid bonding techniques and materials

- 5.1.1. Drivers

- 5.2. Market Segmentation Analysis

- 5.2.1. Technology: Preference for die to die bonding technology for high-density interconnections with reduced signal latency

- 5.2.2. End-User Industries: Adoption of hybrid bonding technology in automotive sectors to maintain high reliability under various operating conditions

- 5.3. Porter's Five Forces Analysis

- 5.3.1. Threat of New Entrants

- 5.3.2. Threat of Substitutes

- 5.3.3. Bargaining Power of Customers

- 5.3.4. Bargaining Power of Suppliers

- 5.3.5. Industry Rivalry

- 5.4. PESTLE Analysis

- 5.4.1. Political

- 5.4.2. Economic

- 5.4.3. Social

- 5.4.4. Technological

- 5.4.5. Legal

- 5.4.6. Environmental

6. Hybrid Bonding Technology Market, by Technology

- 6.1. Introduction

- 6.2. Die-to-Die Bonding

- 6.3. Die-to-Wafer Bonding

- 6.4. Through-Silicon Vias (TSVs)

- 6.5. Wafer-to-Wafer Bonding

7. Hybrid Bonding Technology Market, by Substrate Material

- 7.1. Introduction

- 7.2. Ceramic

- 7.3. Glass

- 7.4. Polymer

- 7.5. Silicon

8. Hybrid Bonding Technology Market, by End-User Industries

- 8.1. Introduction

- 8.2. Automotive Manufacturers

- 8.3. Electronics Manufacturing

- 8.3.1. Electronics Assembly Service Providers

- 8.3.2. Original Equipment Manufacturers

- 8.4. Healthcare Equipment Makers

- 8.4.1. Diagnostic Equipment Manufacturers

- 8.4.2. Surgical Instrument Producers

- 8.5. Military & Defense Contractors

- 8.5.1. Military Communication System Development

- 8.5.2. Radar System Developments

- 8.6. Semiconductor Industry

- 8.6.1. Foundries

- 8.6.2. Integrated Device Manufacturers

9. Hybrid Bonding Technology Market, by Application

- 9.1. Introduction

- 9.2. Fan-out wafer-level packaging (FOWLP)

- 9.3. High-Power Electronics

- 9.4. Optoelectronics

- 9.5. Semiconductor Packaging

- 9.6. Sensor & MEMS Devices

- 9.7. Thermal Management Solutions

10. Americas Hybrid Bonding Technology Market

- 10.1. Introduction

- 10.2. Argentina

- 10.3. Brazil

- 10.4. Canada

- 10.5. Mexico

- 10.6. United States

11. Asia-Pacific Hybrid Bonding Technology Market

- 11.1. Introduction

- 11.2. Australia

- 11.3. China

- 11.4. India

- 11.5. Indonesia

- 11.6. Japan

- 11.7. Malaysia

- 11.8. Philippines

- 11.9. Singapore

- 11.10. South Korea

- 11.11. Taiwan

- 11.12. Thailand

- 11.13. Vietnam

12. Europe, Middle East & Africa Hybrid Bonding Technology Market

- 12.1. Introduction

- 12.2. Denmark

- 12.3. Egypt

- 12.4. Finland

- 12.5. France

- 12.6. Germany

- 12.7. Israel

- 12.8. Italy

- 12.9. Netherlands

- 12.10. Nigeria

- 12.11. Norway

- 12.12. Poland

- 12.13. Qatar

- 12.14. Russia

- 12.15. Saudi Arabia

- 12.16. South Africa

- 12.17. Spain

- 12.18. Sweden

- 12.19. Switzerland

- 12.20. Turkey

- 12.21. United Arab Emirates

- 12.22. United Kingdom

13. Competitive Landscape

- 13.1. Market Share Analysis, 2024

- 13.2. FPNV Positioning Matrix, 2024

- 13.3. Competitive Scenario Analysis

- 13.3.1. Kulicke & Soffa and ROHM introduce CuFirst for enhanced hybrid bonding efficiency

- 13.3.2. ASMPT and IBM collaborate to revolutionize chiplet packaging with advanced hybrid bonding methods

- 13.3.3. Adeia expands hybrid bonding reach with Hamamatsu Photonics agreement

- 13.4. Strategy Analysis & Recommendation

Companies Mentioned

- 1. Adeia Inc by Xperi Holding Corp

- 2. Advanced Micro Devices, Inc.

- 3. Amkor Technology, Inc.

- 4. Applied Materials, Inc.

- 5. GLOBALFOUNDRIES Inc.

- 6. Infineon Technologies AG

- 7. KLA Corporation

- 8. Lam Research Corporation

- 9. Rohm Semiconductor

- 10. Samsung Electronics Co., Ltd.

- 11. SK Hynix Inc.

- 12. STMicroelectronics N.V.

- 13. Taiwan Semiconductor Manufacturing Company Limited

- 14. Tokyo Electron Limited

- 15. United Microelectronics Corporation