|

|

年間契約型情報サービス

商品コード

1225782

エポキシ樹脂の世界市場:工場生産能力、生産量、稼働率、需要と供給、エンドユーザー産業、グレード、タイプ、販売チャネル、地域需要、企業シェア、海外貿易(2015年~2030年)Global Epoxy Resin Market Analysis: Plant Capacity, Production, Operating Efficiency, Demand & Supply, End-User Industries, Grade, Type, Sales Channel, Regional Demand, Foreign Trade, Company Share, 2015-2030 |

||||||

|

|||||||

| エポキシ樹脂の世界市場:工場生産能力、生産量、稼働率、需要と供給、エンドユーザー産業、グレード、タイプ、販売チャネル、地域需要、企業シェア、海外貿易(2015年~2030年) |

|

出版日: 年間契約型情報サービス

発行: ChemAnalyst

ページ情報: 英文

|

全表示

- 概要

- 目次

世界のエポキシ樹脂の市場規模は、2021年に約350万トンに達し、2030年までに4.05%のCAGRで成長すると予測されています。建設と工業化、風力発電や航空宇宙産業における高性能材料の需要増、生分解性ポリマーへのニーズの高まりは、市場の成長を促進しています。

当データベースでは、世界のエポキシ樹脂市場について調査分析し、生産能力、需要分析、国別輸出入など、体系的な情報を提供しています。

オンラインデータベースをPDFまたはExcelとしてダウンロード可能です。データ内のテキスト等のコピー&ペースト及び、データの印刷は可能です。データは四半期ごとに更新されます。

目次

第1章 生産能力:企業別

当社のオンラインプラットフォームでは、エポキシ樹脂の重要なメーカーとその現在および将来の生産能力をほぼリアルタイムで最新の情報に入手できます。

第2章 生産能力:場所別

メーカーの場所ベースの生産能力を分析することにより、エポキシ樹脂の地域供給を説明しています。

第3章 生産量:企業別

主要企業による過去のエポキシ樹脂の年間生産量を調査し、今後数年間でどのように成長するかを予測します。

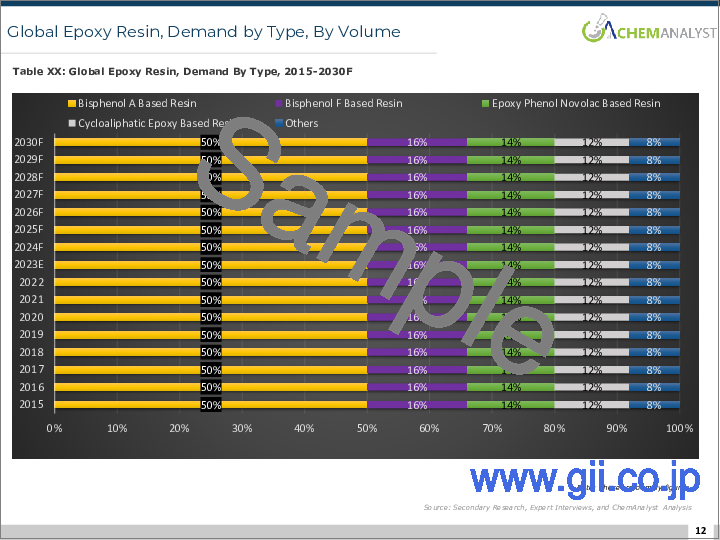

第4章 需要:タイプ別

ビスフェノールA系樹脂、ビスフェノールF系樹脂、エポキシフェノールノボラック系樹脂、脂環式エポキシ系樹脂、その他のタイプとその需要について学びます。戦略を設計する際に、どのタイプに集中するかを説明しています。

第5章 需要:グレード別

エポキシ樹脂のさまざまなグレード、液体、半固体、固体、およびそれらの需要について説明しています。戦略を設計する際に、どのグレードに集中するかを決定できます。

第6章 需要:最終用途別

どのエンドユーザー業界(塗料およびコーティング、電気および電子、建設、複合材料、接着剤、その他)が市場を生み出しているか、およびエポキシ樹脂市場の成長予測を説明しています。

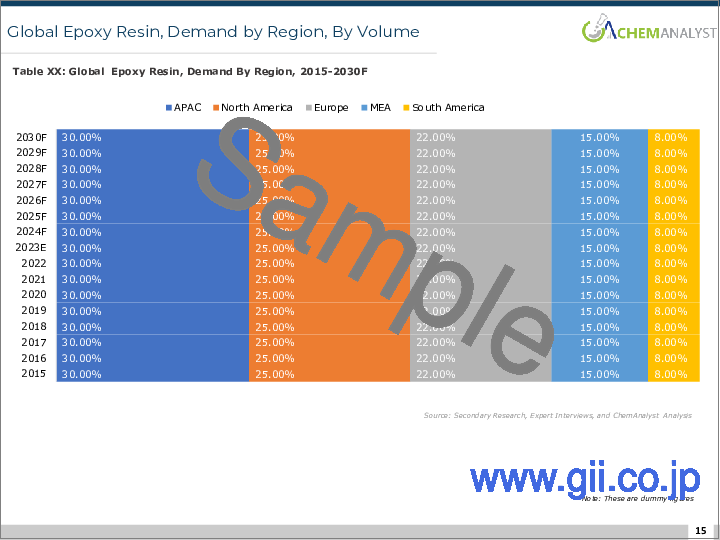

第7章 需要:地域別

北米、アジア太平洋、中東・アフリカ、南米のさまざまな地域でのエポキシ樹脂の需要の変化を分析し、地域の需要をマッピングする際に役立ちます。

第8章 需要:販売チャネル別(直接および間接)

複数のチャネルを使用してエポキシ樹脂を販売しています。当社の販売チャネルは、業界の販売の大部分を代理店やディーラー、または直接販売が占めているかどうかを分析するのに役立ちます。

第9章 需給ギャップ

需要と供給のギャップを決定して、エポキシ樹脂の貿易上での余剰や不足に関する情報を説明しています。

第10章 企業シェア

現在、エポキシ樹脂の市場シェアのうち、世界中の主要企業が占める割合を把握できます。

第11章 国別輸出

主要国のエポキシ樹脂の輸出量に関する詳細を説明しています。

第12章 国別輸入

主要国のエポキシ樹脂の輸入量に関する詳細を説明しています。

The global Epoxy Resin market stood around 3500 thousand tonnes in 2021 and is expected to grow at a CAGR of 4.05% during the forecast period until 2030. In the year 2021, the market showed a significant growth of 2.5% in comparison to 2020. Meghmani Finechem Ltd., on the leading producers of Chlor-Alkali and derivatives, has announced the construction of epichlorohydrin (ECH) plant worth INR 275 crore situated in Dahej, Gujarat, India. This plant is estimated to be operational in 2024 with an annual capacity of 50 thousand tonnes. The project is anticipated to reduce India's dependance on other nations for importing Epoxy Resin.

Epoxy resin is a thermosetting copolymer produced through polymerization of epoxide and other monomers containing hydroxyl group. Epoxy resins consists of a monomeric resin, an accelerator, a hardener, and a plasticizer. These resins have various properties such as corrosion resistance, high thermal stability, high mechanical strength, high chemical and environmental resistance, durability, adhesion etc. owing to these properties, epoxy resins find application in several areas including paints and coatings, adhesives, composites, electronic encapsulation, and others. Major applications for epoxy resins include building and construction, automotive, general industrial, consumer goods, wind power, aerospace, marine, and others.

The Epoxy Resin market is primary driven by the construction and industrialization. Increasing demand of light weight high performance materials from the construction and automotive sectors coupled with the increasing demand for high performance materials in the wind power and aerospace industry is expected to drive the demand for epoxy resins for the forecast period. Moreover, the increasing need for biodegradable polymers and stringent environmental regulations regarding bisphenol A are expected to hinder the demand growth during the forecast period. Throughout the projection period, the automotive and construction industries are anticipated to exhibit significant increase which will further swell the Epoxy Resin demand in the forecast period and total market to reach about 5000 thousand tonnes by 2030.

Based on region, Asia Pacific and Europe are the leading consumers across the globe. In 2021, the highest demand was accounted by Asia Pacific region with a market share of about 60%. Due to increasing demand of application areas including construction and automotive, it is anticipated that Epoxy Resin market is anticipated to swell in the forthcoming years. Moreover, increasing population and per capita income is another factor propelling demand growth in Asia Pacific. Furthermore, China is leading producer of Epoxy Resin on an international level.

Based on type, the global Epoxy Resin market is divided into Bisphenol A Based Resin, Bisphenol F Based Resin, Epoxy Phenol Novolac Based Resin, Cycloaliphatic Epoxy Based Resin, and Others. Bisphenol A Based Resin is dominating the market due to heavy usage to manufacture Polycarbonate plastic and epoxy- based inner lining of canned goods. Some of the other applications of polycarbonate plastic are high performance paints and coatings, DVDs, laptops, refrigerators, eyewear, protective goggles, and optical lenses, and food storage containers.

Based on grade, the Epoxy Resin market is segregated into Liquid, Semi-Solid, and Solid. Amongst these grades, Liquid grade is the most popular kind in the market. Liquid grade was holding a market share of about 50% in 2021. This grade of Epoxy Resin can withstand chemical and physical reactions, and is corrosion resistance. Liquid Epoxy Resins are employed in many different applications, including coating materials, sealants, marine parts, electrical and electronics, and composites.

Based on the end-user industry, the global Epoxy Resin market is segmented into Paints & Coatings, Electrical & Electronics, Construction, Composite Materials, Adhesives, and Others. Paints & Coatings industry is the dominating as a consumer, with a market share of approximately 40% of the total demand in 2021. Electrical & Electronics is also a prominent consumer of Epoxy Resin market.

Major players in the production of Global Epoxy Resin market are Olin Coporation, Nan Ya Plastics Co Ltd, Jiangsu Sanmu Group, Kukdo Chemical Co., Ltd., Hexion Inc., Kumho P&B Chemicals, Huntsman Corporation, Nantong Xincheng Synthetic Material Co Ltd, Zhuhai Hongchang Electronic Material Co Ltd, Jiangsu Yangnong Kumho Chemical Co., Ltd., Sinopec Baling Petrochemical Co., Ltd, and NAMA Chemicals.

Years considered for this report:

Historical Period: 2015- 2021

Base Year: 2021

Estimated Year: 2022

Forecast Period: 2023-2030

Objective of the Study:

- To assess the demand-supply scenario of Epoxy Resin which covers production, demand and supply of Epoxy Resin market in the globe.

- To analyse and forecast the market size of Epoxy Resin

- To classify and forecast Global Epoxy Resin market based on end-use and regional distribution.

- To examine competitive developments such as expansions, mergers & acquisitions, etc., of Epoxy Resin market in the globe.

To extract data for Global Epoxy Resin market, primary research surveys were conducted with Epoxy Resin manufacturers, suppliers, distributors, wholesalers and Traders. While interviewing, the respondents were also inquired about their competitors. Through this technique, ChemAnalyst was able to include manufacturers that could not be identified due to the limitations of secondary research. Moreover, ChemAnalyst analyzed various segments and projected a positive outlook for Global Epoxy Resin market over the coming years.

ChemAnalyst calculated Epoxy Resin demand in the globe by analyzing the historical data and demand forecast which was carried out considering the historical extraction and supply and demand of Epoxy Resin across the globe. ChemAnalyst sourced these values from industry experts, and company representatives and externally validated through analyzing historical sales data of respective manufacturers to arrive at the overall market size. Various secondary sources such as company websites, association reports, annual reports, etc., were also studied by ChemAnalyst.

Key Target Audience:

- Epoxy Resin manufacturers and other stakeholders

- Organizations, forums and alliances related to Epoxy Resin distribution

- Government bodies such as regulating authorities and policy makers

- Market research organizations and consulting companies

The study is useful in providing answers to several critical questions that are important for industry stakeholders such as Epoxy Resin manufacturers, customers and policy makers. The study would also help them to target the growing segments over the coming years (next two to five years), thereby aiding the stakeholders in taking investment decisions and facilitating their expansion.

Report Scope:

In this report, Global Epoxy Resin s market has been segmented into following categories, in addition to the industry trends which have also been detailed below:

- Market, by Type: Bisphenol A Based Resin, Bisphenol F Based Resin, Epoxy Phenol Novolac Based Resin, Cycloaliphatic Epoxy Based Resin, and Others

- Market, by Grade: Liquid, Semi-Solid, and Solid

- Market, by End Use: Paints & Coatings, Electrical & Electronics, Construction, Composite Materials, Adhesives, and Others

- Market, by Sales Channel: Direct Sale and Indirect Sale

- Market, by Region: North America, Europe, Asia Pacific, Middle East and Africa, and South America.

Available Customizations:

With the given market data, ChemAnalyst offers customizations according to a company's specific needs.

Table of Contents

Table of Content

1. Capacity By Company

On our online platform, you can stay up to date with essential manufacturers and their current and future operation capacity on a practically real-time basis for Epoxy Resin.

2. Capacity By Location

To better understand the regional supply of Epoxy Resin by analyzing its manufacturers' location-based capacity.

3. Production By Company

Study the historical annual production of Epoxy Resin by the leading players and forecast how it will grow in the coming years.

4. Demand by Type

Learn about the various types: Bisphenol A Based Resin, Bisphenol F Based Resin, Epoxy Phenol Novolac Based Resin, Cycloaliphatic Epoxy Based Resin, and Others and their demands. It will allow you to choose which type to concentrate on when designing your strategy.

5. Demand by Grade

Learn about the various grades of Epoxy Resin- Liquid, Semi-Solid, and Solid, and their demands. It will allow you to choose which grade to concentrate on when designing your strategy.

6. Demand by End- Use

Discover which end-user industry (Paints & Coatings, Electrical & Electronics, Construction, Composite Materials, Adhesives, and Others) are creating a market and the forecast for the growth of the Epoxy Resin market.

7. Demand by Region

Analyzing the change in demand of Epoxy Resin in different regions, i.e., North America, Europe, Asia Pacific, Middle East and Africa, and South America, that can direct you in mapping the regional demand.

8. Demand by Sales Channel (Direct and Indirect)

Multiple channels are used to sell Epoxy Resin. Our sales channel will help in analyzing whether distributors and dealers or direct sales make up most of the industry's sales.

9. Demand-Supply Gap

Determine the supply-demand gap to gain information about the trade surplus or deficiency of Epoxy Resin.

10. Company Share

Figure out what proportion of the market share of Epoxy Resin is currently held by leading players across the globe.

11. Country-wise Export

Get details about quantity of Epoxy Resin exported by major countries.

12. Country-wise Import

Get details about quantity of Epoxy Resin imported by major countries.