|

市場調査レポート

商品コード

1784309

4680電池技術の開発動向と見通し(2025年)<2025> 4680 Battery Technology Development Trend and Outlook |

||||||

|

|||||||

| 4680電池技術の開発動向と見通し(2025年) |

|

出版日: 2025年07月29日

発行: SNE Research

ページ情報: 英文 494 Pages

納期: お問合せ

|

概要

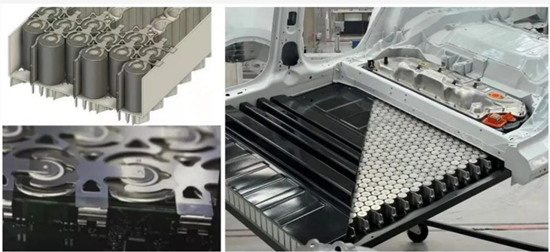

4680電池は、直径46mm、長さ80mmの大型円筒型リチウムイオンセルです。Teslaが同社の2020 Battery Dayで初めて発表して以来、世界の電池産業と電気自動車産業の技術革新をリードする象徴的なセルフォームファクターとして登場しました。既存の2170/1865フォーマットと比較して、4680はより高いエネルギー密度、セル組立数の削減、熱管理効率の向上、コストの低減といった多次元的な優位性を強調しています。

そのため、Teslaだけでなく、Panasonic、LG Energy Solution、サムスンSDI、CATL、EVE Energyなどの主要セルメーカーも4680の生産能力を確保しようと競っています。

4680電池は特に、CtC(Cell-to-Chassis)設計によるEVプラットフォームの構造効率の向上を可能にし、高い充放電性能を実現するタブレス電極構造などのイノベーションを取り入れています。これらの進化により、4680はEVの効率とコスト競争力を飛躍的に向上させる重要な技術として位置づけられています。

4680の最大の特徴であるタブレス電極構造は、集電タブをセルの端に配置するのではなく、電極全体に分散させています。これにより、電流の流れがより均一になり、抵抗分布が減少し、発熱が抑制され、熱拡散効率が向上するため、高出力条件下での局所的な過熱を防ぐことができます。さらに、製造工程が簡素化されるため、電極とタブの接続工程が不要となり、歩留まりが向上します。このアーキテクチャはパウチ型や角型のセルでは実装が困難ですが、円筒型セル(特に大型セル)ではその利点が最大限に発揮されます。Teslaの自社製セルは、ドライ電極コーティングとともにこの構造を積極的に活用しています。

一方、TeslaはMaxwell Technologiesの買収を通じて導入したドライ電極コーティング技術を4680に適用しようとしました。溶媒を使わず高速プレスで固体電極材料を集電体に付着させるこの方法は、環境にやさしい(NMPフリーの)プロセスです。乾燥が不要なため生産時間が短縮され、電極の厚みと密度を高めることができるため、エネルギー密度が向上します。しかし、塗膜厚の均一性や界面接着の安定性など、量産化には課題が残っています。そのため、ウェットプロセスをベースとした代替高速コーティングソリューションを開発している企業もあります。

エネルギー密度を最大化するために、高エネルギー活物質が適用されています。正極は、密度と寿命の両方を向上させるために高ニッケル(ニッケル88%超)NCM/NCAを採用し、負極は急速充電能力を高めるためにシリコン複合グラファイト(Si-C)または完全シリコンベースの設計を使用し、電解質は耐久性と安定性を向上させるために高電圧安定化添加剤またはゲル電解質を組み込んでいます。特に、シリコン負極は膨張制御と導電性の課題に直面しており、ナノコンポジット技術、カーボンマトリクス構造、界面安定化添加剤によって対処しています。

容量が増加するにつれて、熱暴走や安全性の対策も必要となります。4680はセルが大きいため、単一セルの故障がモジュール全体に素早く連鎖する可能性があります。そのため、サーマルバリア、内蔵PTC/温度ヒューズ、難燃性セルケーシング、分散冷却経路などの安全技術が開発されています。構造解析はパウチ型セルや角型セルよりも複雑になるため、シミュレーションに基づく構造・熱・電気統合設計が拡大しています。

Teslaはこのコンセプトの先駆者ですが、46-Phi大型セルの開発は現在、韓国、日本、中国で活発に進められています。Teslaは同社のTexas Gigafactoryとベルリンプラントで4680セルを量産しており、2024年に1億ユニットを突破します。同社は第2世代のCybercellをCybertruckに適用して充電速度と性能を向上させ、2026年までにドライコーティングをベースとしたNC05を含む少なくとも4つの新バリエーションを開発する計画です。Panasonicは和歌山(日本)とネバダ(米国)の施設で試験生産と供給を行っており、カンザス州では4680の大規模プラントの改修を完了しました。また、Tesla以外のOEMとのサンプリングや承認プロセスも進めています。

当レポートでは、世界の4680市場について調査分析し、開発動向、セルとパックの分解レポートの詳細な分析、市場規模と生産高の見通し、材料と技術のレビューなどを提供しています。

目次

第1章 4680円筒型電池の概要

- Tesla Battery Day(2020年9月22日)のサマリーと主な調査結果

- 電池セル設計

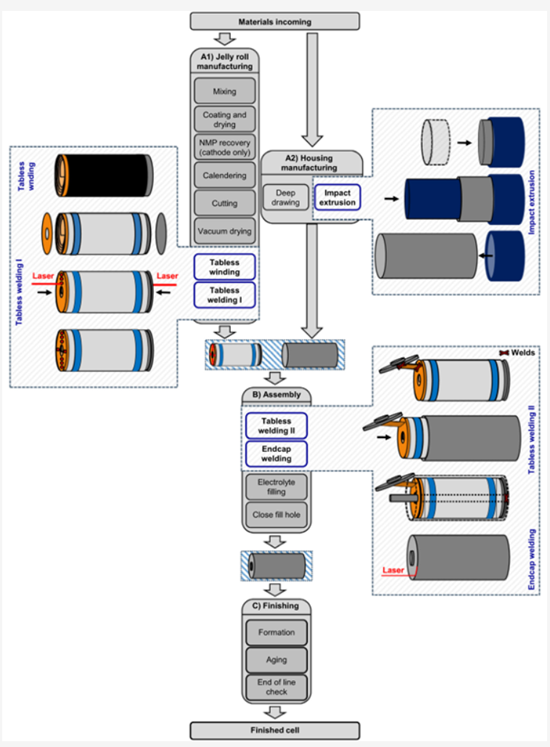

- 電池セルの製造プロセス

- シリコン負極材料

- 高ニッケル正極材料

- Cell-to-Vehicle統合

- 電池コストの削減

- 4680電池開発

- 世界の46xx電池生産能力

第2章 4680電池セルの開発

- コスト削減と効率向上戦略

- 安全要件の強化(熱管理のアップグレード)

- 将来の動向としての急速充電:4680の高速充電の優位性

- 主要企業の市場参入競合

- 46xx電池の詳細な仕様:企業別

第3章 4680電池の技術の詳細

- 正極材料

- 負極材料

- その他の電池材料

- 4680製造プロセスの改良

第4章 4680電池の分解と分析

- 概要

- 分解と分析プロセス

- Teslaの4680セルとパックの詳細なエンジニアリングの分析

第5章 Teslaの4680セルの分解と電気化学的研究

- サマリー

- 研究の概要

- 以前の調査

- 詳細な分析

- 実験

- 結果と考察

- 結論

第6章 4680電池の成功に求められる技術

- マルチタブ技術

- タブ溶接技術

- 正極・負極材料

- 冷却技術

第7章 4680と18650・2170の比較:エネルギー密度とコスト削減

- 概要

- 4680:エネルギー密度、急速充電、コスト削減

- 高濃度電解質の使用

- 4680の主な電解質の企業

第8章 Teslaの4680モジュール向け電池熱管理システム(BTMS)の設計

- イントロダクション

- EV電池におけるBTMSの必要性

- 冷却方法

- 文献のレビュー

- 4680モジュール向け液体冷却+ヒートパイプ:方法、結果、結論

- 提案された冷却システムの熱解析

- 結果と考察

- 結論

第9章 4680セルの熱管理:設計と冷却

- 概要

- イントロダクション

- 実験

- シミュレーションモデル

- シミュレーション結果

- 結論

第10章 円筒型LIBセルの設計、特性、製造

- 概要

- 実験材料と方法

- 実験結果と考察

- 結論

第11章 タブレス円筒型LIBセルにおけるセルのサイズとハウジング材料の影響

- 概要

- 実験

- 結果と考察

- 結論

第12章 大型円筒型LIBセルにおける熱暴走とその伝播

- TRとTPの特性に関する研究

- イントロダクション:新設計の必要性

- 実験

第13章 比較分析:Teslaの4680 vs. BYDのBlade Cell

- イントロダクション

- 結果と考察

第14章 モデリング研究:タブレス円筒型LIBにおけるセルのサイズとハウジングの影響

- イントロダクション

- プロセス分析

- モデリング

- 結果と考察

- 結論

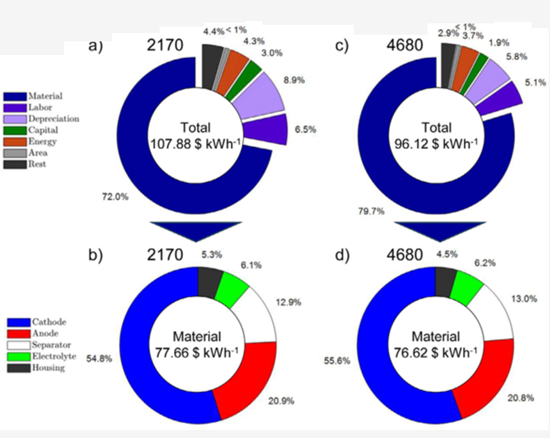

第15章 コストの比較:タブレス vs. 標準電極円筒型LIB

- サマリー:Teslaのタブレス設計

- イントロダクション

- 手法

- 結果

- 結論

第16章 4680セルメーカーの状況

- Tesla

- Panasonic

- LGES

- Samsung SDI

- SK On

- EVE

- BAK

- CATL

- Gotion Hi-TECH

- SVOLT

- CALB

- Envision AESC

- LISHEN

- Easpring (Dangsheng Technology)

- Kumyang

- BMW

- Dongwon Systems

- Sungwoo

- TCC Steel

- Dongkuk Industries

- Shinheung SEC

- Sangsin EDP

- LT Precision

- NIO

第17章 4680電池の特許分析

- タブレス電極付き電池

- Tesla:タブレスエネルギーストレージデバイスと製造方式

- Teslaのドライ電極プロセスの特許(1):微粒子非繊維状バインダー

- Teslaのドライ電極プロセスの特許(2):ドライ電極向け接着性パッシベーションフィルム組成

- LG Energy Solution:タブレス関連特許(電極組立、電池、電池パック、車両)

- Murata:タブレス電池

- Jiangsu Zenergy Battery

- EVE Energy(タブ平坦化デバイス)

- Microvast Inc.(タブプレート・巻線電池)

第18章 4680電池の市場見通し

- 全体的な市場見通し

- 4680の材料とプロセス技術の予測

- 化学産業:シリコンカーボン負極、PTFE、LiFSI、その他の材料

- 4680を取り巻く政策、需要、CAPAの予測

第19章 Teslaの4680セル生産の予測

- GIGA TEXASの推定生産高

- Teslaの4680電池生産のタイムラインと主なマイルストーン

- 最新のTeslaの4680電池プログラムのサマリー

- Teslaの4680電池セルのコスト構造

- 効率改良とコスト削減の要因

- Teslaの4680セル開発の現状

- Teslaの4680とスーパーチャージャーネットワークの近年の発展

- Teslaの電池生産とリチウム精製事業のサマリー

- 4680セルの生産能力 vs. Cybertruckの生産高

- 年間の4680のCAPA vs. 1日当たりの生産高

- 4680のCAPA vs. 生産時間の動向

- Tesla Giga FactoryのP/Pラインにおける主要な組立工程