|

|

市場調査レポート

商品コード

1787263

鉄鋼の世界市場:タイプ別、生産技術別、最終用途産業別、地域別 - 2030年までの予測Iron & Steel Market by Type (Iron and Steel), Iron Production Technology, Steel Production Technology, End-use Industry (Construction & Building, Automotive & Transportation, Mechanical Equipment, Metal Products), and Region - Global Forecast to 2030 |

||||||

カスタマイズ可能

|

|||||||

| 鉄鋼の世界市場:タイプ別、生産技術別、最終用途産業別、地域別 - 2030年までの予測 |

|

出版日: 2025年08月05日

発行: MarketsandMarkets

ページ情報: 英文 395 Pages

納期: 即納可能

|

全表示

- 概要

- 図表

- 目次

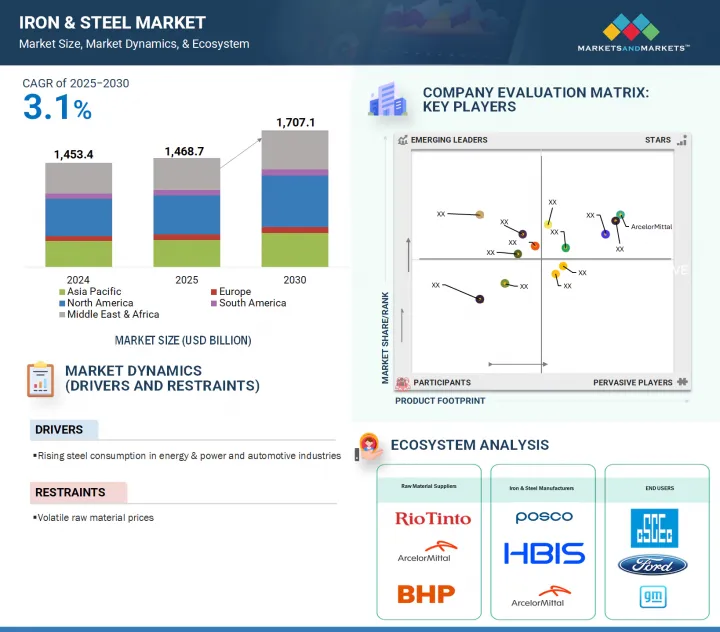

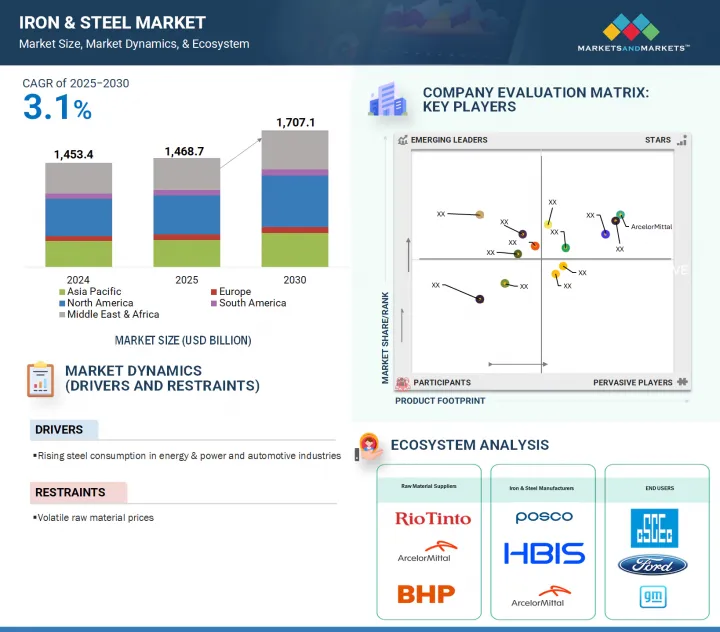

鉄鋼の市場規模は2024年に1兆4,534億米ドルとなりました。

同市場は、CAGR 3.1%で拡大し、2030年には1兆7,071億米ドルに達すると予測されています。鉄鋼セクターは、先進国市場と新興国市場の都市化、工業化、インフラ開拓など、いくつかの要因によって需要が大きく伸びています。建設、自動車、エネルギー、機械などの主要な最終用途部門からの大きな需要が、鉄鋼製品の需要を引き続き牽引しています。

| 調査範囲 | |

|---|---|

| 調査対象年 | 2021年~2030年 |

| 基準年 | 2024年 |

| 予測期間 | 2025年~2030年 |

| 検討単位 | 金額(10億米ドル)数量(100万トン) |

| セグメント | タイプ別、生産技術別、最終用途産業別、地域別 |

| 対象地域 | 北米、欧州、アジア太平洋、中東・アフリカ、南米 |

鉄鋼製品の用途は多岐にわたりますが、国や地方自治体による大規模な公共インフラ・プロジェクトの展開、新しい住宅、商業施設、政府機関の継続的な構造開発、輸送・物流ネットワークへの投資が、引き続き全体的な成長を牽引しています。さらに、中国、インド、ブラジルのような新興国において、国内製造を促進し、産業成長を刺激する政府のインセンティブが、鉄鋼イニシアティブの新たな産業ドライバーとして台頭しています。市場の勢いは、生産方法と生産プロセスにおける技術の進歩によって補完され、リサイクルや持続可能性に関する変化する規制の期待に応え続けながら、効率性の向上をもたらしています。

高炉プロセス・セグメントは、予測期間中、鉄鋼市場で最大のシェアを占めると予想されます。これは、数十年にわたり大規模な鉄生産の大部分を歴史的に占めてきたことに起因します。高炉プロセスは、鉄鉱石を(高温で)コークスと石灰石で還元して溶けた鉄(銑鉄)を生産するもので、基礎酸素プロセスで鉄鋼を製造するために直接使用されるか、ブロックに鋳造されて鋳造所で使用されます。鉄鋼業における微粉鉱石の高炉ルートは、一定の品質で大量生産が可能なため、大規模な鉄鋼生産国で使用されている主要プロセスでもあります。

さらに、高炉プロセスは原料の分級が比較的効率的であり、コスト構造は伝統的に研究され、共有されてきたため、特に中国、インド、ロシアなど、鉄鋼の消費が国内および輸出要件に拍車をかけている国々では、はるかに大きな容量の一貫製鉄所と鉄鋼生産を可能にし、支えています。脱炭素化と低炭素コスト(電気炉の使用など)に基づく代替技術へのシフトが進んでいますが、高炉プロセスは、鉄筋、鉄骨、フェンス、鉄骨屋根などを提供します。例えば、高炉はすべての原料を処理し、スケールメリットとコスト低減をもたらし、より高品位な鉄の生産を可能にし、この傾向は当分の間続くでしょう。

電気アーク炉(EAF)セグメントは、持続可能で比較的エネルギー効率の高い製鉄への移行が世界的に大きく進展していることから、予測期間中、鉄鋼市場において最も高い複合年間成長率(CAGR)で成長すると予測されます。鉄鉱石とコークスに大きく依存する従来の高炉とは異なり、EAFはリサイクルされた金属スクラップを主原料として使用するため、炭素排出量とエネルギー消費量が大幅に削減されます。

EAFの生産には多くの利点があります。技術は柔軟で、資本集約的でなく、高炉よりも起動時間が短いです。環境規制が強化され、リサイクルと循環型経済が重視される中、EAF生産は、リサイクルと金属取引インフラを維持する地域で操業する生産者にとって、ますます魅力的になっています。多くの国々が脱炭素化目標に関心を示すようになったため、各国は実践の動向を追い、最終的には製鉄所に対して、この移行と鉄鋼生産による環境への影響の削減を促しています。

北米や欧州のような先進地域では、鉄鋼メーカーはEAFベースの生産へとシフトしています。一方、新興地域では、新たな投資が鉄鋼セクターの更新に役立っているため、EAF設備への投資が徐々に進んでいます。特に、EAFでDRI(直接還元鉄)を使用できるようになった技術的進歩は、鉄鋼生産効率を改善し、エネルギー消費を削減し、製品品質を向上させました。その結果、EAFベースの鉄鋼生産は急速に成長し、持続可能な鉄鋼製造の将来的な開発において重要な役割を果たすと予想されます。

中東・アフリカ地域は、インフラ開発、産業成長、人口増加のための鉄鋼使用の増加により、予測期間中、鉄鋼市場において最も高い複合年間成長率(CAGR)で成長すると予想されます。中東・アフリカの多くの国(サウジアラビア、アラブ首長国連邦、エジプト、南アフリカ)は、大規模な建設プロジェクト、交通網、エネルギー関連プロジェクトに投資しており、これが鉄鋼需要を生み出しています。サウジアラビアでは「ビジョン2030」、UAEでは経済の多角化と工業化プログラムの拡大に取り組んでおり、鉄鋼の国内生産を促進するなど、政府のイニシアチブがこの成長を支えています。同時に、石油・ガス、鉱業、再生可能エネルギー産業からの投資の増加も、MEA地域での鉄鋼使用を増加させています。MEA地域は、入手可能な原材料と金属部門への外国直接投資を活用し、世界の大手鉄鋼メーカーに対する地域の競争力を戦略的に開発しています。進行中の都市化、住宅需要、経済の多様化の必要性により、MEAは成長する立場にあります。これらの原動力のそれぞれが相まって、MEAは今後数年間、鉄鋼業界にとって最もダイナミックで高成長を遂げる地域のひとつとなると思われます。

当レポートでは、世界の鉄鋼市場について調査し、タイプ別、生産技術別、最終用途産業別、地域別動向、および市場に参入する企業のプロファイルなどをまとめています。

目次

第1章 イントロダクション

第2章 調査手法

第3章 エグゼクティブサマリー

第4章 重要考察

第5章 市場概要

- イントロダクション

- 市場力学

第6章 業界動向

- 顧客のビジネスに影響を与える動向と混乱

- エコシステム分析

- バリューチェーン分析

- 関税と規制状況

- 価格分析

- 貿易分析

- 技術分析

- ケーススタディ分析

- 特許分析

- 2025年~2026年の主な会議とイベント

- 投資と資金調達のシナリオ

- 鉄鋼業界におけるAI世代の影響

- ポーターのファイブフォース分析

- 主要な利害関係者と購入基準

- マクロ経済分析

- 2025年の米国関税が鉄鋼市場に与える影響

第7章 鉄鋼市場(タイプ別)

- イントロダクション

- 鉄

- 鋼鉄

第8章 鉄市場(生産技術別)

- イントロダクション

- 高炉プロセス

- DRIプロセス

第9章 鋼鉄市場(生産技術別)

- イントロダクション

- 基本酸素炉

- 電気アーク炉

- その他

第10章 鉄鋼市場(最終用途産業別)

- イントロダクション

- 建築・建設

- 自動車・輸送

- 機械設備

- 金属製品

- その他

第11章 鉄鋼市場(地域別)

- イントロダクション

- アジア太平洋

- 中国

- インド

- 日本

- 韓国

- その他

- 欧州

- ドイツ

- イタリア

- フランス

- スペイン

- 英国

- ロシア

- その他

- 北米

- 米国

- カナダ

- メキシコ

- その他

- 中東・アフリカ

- GCC諸国

- 南アフリカ

- その他中東とアフリカ

- 南米

- ブラジル

- アルゼンチン

- その他

第12章 競合情勢

- 概要

- 主要参入企業の戦略

- 市場シェア分析

- 収益分析

- 企業評価と財務指標

- 製品/ブランド比較分析

- 企業評価マトリックス:主要参入企業、2024年

- 企業評価マトリックス:スタートアップ/中小企業、2024年

- 競合シナリオと動向

第13章 企業プロファイル

- 主要参入企業

- ARCELORMITTAL

- CHINA BAOWU STEEL GROUP CORPORATION LIMITED

- ANSTEEL GROUP

- HBIS GROUP

- NIPPON STEEL CORPORATION

- TATA STEEL

- JSW

- NUCOR CORPORATION

- POSCO

- SAIL

- CSN(NATIONAL STEEL COMPANY)

- SSAB AB

- その他の企業

- JIANGSU SHAGANG GROUP

- 7 STEEL UK

- SONGSHUN STEEL

- C.D. WALZHOLZ GMBH & CO. KG

- HUAXIAO METAL CORPORATION LIMITED

- HEBEI DONGHAI SPECIAL STEEL GROUP CO., LTD.

- FENG HSIN STEEL CO., LTD.

- WORTHINGTON STEEL

- LIBERTY STEEL GROUP

- GERDAU

- D.S. METAL

- ARJAS STEEL

- SHREE JI STEEL

- RAHUL STEEL INDIA

- CORROS METALS PVT. LTD.

第14章 隣接市場と関連市場

第15章 付録

List of Tables

- TABLE 1 WORLD MINE PRODUCTION OF IRON ORE, BY COUNTRY, 2023

- TABLE 2 WORLD RESERVES FOR CRUDE IRON ORE, BY COUNTRY, 2023

- TABLE 3 IRON & STEEL MARKET: ROLE OF PLAYERS IN ECOSYSTEM

- TABLE 4 TARIFF SCENARIO FOR HS CODE 72 COMPLIANT PRODUCTS, BY COUNTRY, 2024

- TABLE 5 NORTH AMERICA: REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 6 EUROPE: REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 7 ASIA PACIFIC: REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 8 MIDDLE EAST & AFRICA: REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 9 SOUTH AMERICA: REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 10 AVERAGE SELLING PRICE TREND OF TYPE, BY KEY PLAYERS, 2024 (USD/KG)

- TABLE 11 IRON & STEEL: AVERAGE SELLING PRICE OF KEY PLAYERS, BY REGION, 2021-2030 (USD/KG)

- TABLE 12 EXPORT DATA RELATED TO HS CODE 72-COMPLIANT PRODUCTS, BY COUNTRY, 2020-2024 (USD BILLION)

- TABLE 13 IMPORT DATA RELATED TO HS CODE 72-COMPLIANT PRODUCTS, BY COUNTRY, 2020-2024 (USD BILLION)

- TABLE 14 JFE STEEL - ADVANCING AUTOMOTIVE SAFETY AND SUSTAINABILITY WITH 1.5GPA COLD-ROLLED STEEL AND COLD PRESSING TECHNOLOGY

- TABLE 15 ARCELORMITTAL - ENHANCING STEEL-MAKING EFFICIENCY THROUGH AI AUTOMATION

- TABLE 16 NUCOR CORPORATION - OPTIMIZING SUPPLY CHAIN WITH AI

- TABLE 17 IRON & STEEL MARKET: KEY PATENTS, 2022-2024

- TABLE 18 IRON & STEEL MARKET: CONFERENCES AND EVENTS, 2025-2026

- TABLE 19 IRON & STEEL MARKET: PORTER'S FIVE FORCES ANALYSIS

- TABLE 20 INFLUENCE OF STAKEHOLDERS ON BUYING PROCESS FOR TOP THREE STEEL END-USE INDUSTRIES

- TABLE 21 KEY BUYING CRITERIA FOR TOP THREE END-USE INDUSTRIES

- TABLE 22 GLOBAL GDP GROWTH PROJECTION, BY REGION, 2021-2028 (USD TRILLION)

- TABLE 23 IRON & STEEL MARKET, BY TYPE, 2021-2023 (USD BILLION)

- TABLE 24 IRON & STEEL MARKET, BY TYPE, 2024-2030 (USD BILLION)

- TABLE 25 IRON & STEEL MARKET, BY TYPE, 2021-2023 (MILLION TONS)

- TABLE 26 IRON & STEEL MARKET, BY TYPE, 2024-2030 (MILLION TONS)

- TABLE 27 IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 28 IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 29 IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 30 IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 31 STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 32 STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 33 STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 34 STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 35 STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (USD BILLION)

- TABLE 36 STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (USD BILLION)

- TABLE 37 STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (MILLION TONS)

- TABLE 38 STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (MILLION TONS)

- TABLE 39 IRON & STEEL MARKET, BY REGION, 2021-2023 (USD BILLION)

- TABLE 40 IRON & STEEL MARKET, BY REGION, 2024-2030 (USD BILLION)

- TABLE 41 IRON & STEEL MARKET, BY REGION, 2021-2023 (MILLION TONS)

- TABLE 42 IRON & STEEL MARKET, BY REGION, 2024-2030 (MILLION TONS)

- TABLE 43 ASIA PACIFIC: IRON & STEEL MARKET, BY COUNTRY, 2021-2023 (USD BILLION)

- TABLE 44 ASIA PACIFIC: IRON & STEEL MARKET, BY COUNTRY, 2024-2030 (USD BILLION)

- TABLE 45 ASIA PACIFIC: IRON & STEEL MARKET, BY COUNTRY, 2021-2023 (MILLION TONS)

- TABLE 46 ASIA PACIFIC: IRON & STEEL MARKET, BY COUNTRY, 2024-2030 (MILLION TONS)

- TABLE 47 ASIA PACIFIC: IRON & STEEL MARKET, BY TYPE, 2021-2023 (USD BILLION)

- TABLE 48 ASIA PACIFIC: IRON & STEEL MARKET, BY TYPE, 2024-2030 (USD BILLION)

- TABLE 49 ASIA PACIFIC: IRON & STEEL MARKET, BY TYPE, 2021-2023 (MILLION TONS)

- TABLE 50 ASIA PACIFIC: IRON & STEEL MARKET, BY TYPE, 2024-2030 (MILLION TONS)

- TABLE 51 ASIA PACIFIC: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 52 ASIA PACIFIC: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 53 ASIA PACIFIC: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 54 ASIA PACIFIC: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 55 ASIA PACIFIC: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 56 ASIA PACIFIC: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 57 ASIA PACIFIC: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 58 ASIA PACIFIC: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 59 ASIA PACIFIC: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (USD BILLION)

- TABLE 60 ASIA PACIFIC: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (USD BILLION)

- TABLE 61 ASIA PACIFIC: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (MILLION TONS)

- TABLE 62 ASIA PACIFIC: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (MILLION TONS)

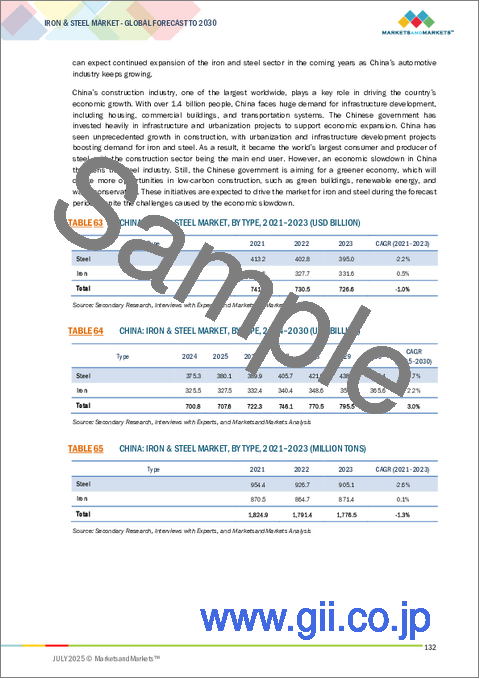

- TABLE 63 CHINA: IRON & STEEL MARKET, BY TYPE, 2021-2023 (USD BILLION)

- TABLE 64 CHINA: IRON & STEEL MARKET, BY TYPE, 2024-2030 (USD BILLION)

- TABLE 65 CHINA: IRON & STEEL MARKET, BY TYPE, 2021-2023 (MILLION TONS)

- TABLE 66 CHINA: IRON & STEEL MARKET, BY TYPE, 2024-2030 (MILLION TONS)

- TABLE 67 CHINA: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 68 CHINA: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 69 CHINA: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 70 CHINA: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 71 CHINA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 72 CHINA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 73 CHINA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 74 CHINA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 75 CHINA: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (USD BILLION)

- TABLE 76 CHINA: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (USD BILLION)

- TABLE 77 CHINA: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (MILLION TONS)

- TABLE 78 CHINA: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (MILLION TONS)

- TABLE 79 INDIA: IRON & STEEL MARKET, BY TYPE, 2021-2023 (USD BILLION)

- TABLE 80 INDIA: IRON & STEEL MARKET, BY TYPE, 2024-2030 (USD BILLION)

- TABLE 81 INDIA: IRON & STEEL MARKET, BY TYPE, 2021-2023 (MILLION TONS)

- TABLE 82 INDIA: IRON & STEEL MARKET, BY TYPE, 2024-2030 (MILLION TONS)

- TABLE 83 INDIA: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 84 INDIA: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 85 INDIA: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 86 INDIA: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 87 INDIA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 88 INDIA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 89 INDIA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 90 INDIA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 91 INDIA: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (USD BILLION)

- TABLE 92 INDIA: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (USD BILLION)

- TABLE 93 INDIA: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (MILLION TONS)

- TABLE 94 INDIA: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (MILLION TONS)

- TABLE 95 JAPAN: IRON & STEEL MARKET, BY TYPE, 2021-2023 (USD BILLION)

- TABLE 96 JAPAN: IRON & STEEL MARKET, BY TYPE, 2024-2030 (USD BILLION)

- TABLE 97 JAPAN: IRON & STEEL MARKET, BY TYPE, 2021-2023 (MILLION TONS)

- TABLE 98 JAPAN: IRON & STEEL MARKET, BY TYPE, 2024-2030 (MILLION TONS)

- TABLE 99 JAPAN: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 100 JAPAN: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 101 JAPAN: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 102 JAPAN: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 103 JAPAN: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 104 JAPAN: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 105 JAPAN: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 106 JAPAN: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 107 JAPAN: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (USD BILLION)

- TABLE 108 JAPAN: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (USD BILLION)

- TABLE 109 JAPAN: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (MILLION TONS)

- TABLE 110 JAPAN: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (MILLION TONS)

- TABLE 111 SOUTH KOREA: IRON & STEEL MARKET, BY TYPE, 2021-2023 (USD BILLION)

- TABLE 112 SOUTH KOREA: IRON & STEEL MARKET, BY TYPE, 2024-2030 (USD BILLION)

- TABLE 113 SOUTH KOREA: IRON & STEEL MARKET, BY TYPE, 2021-2023 (MILLION TONS)

- TABLE 114 SOUTH KOREA: IRON & STEEL MARKET, BY TYPE, 2024-2030 (MILLION TONS)

- TABLE 115 SOUTH KOREA: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 116 SOUTH KOREA: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 117 SOUTH KOREA: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 118 SOUTH KOREA: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 119 SOUTH KOREA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 120 SOUTH KOREA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 121 SOUTH KOREA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 122 SOUTH KOREA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 123 SOUTH KOREA: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (USD BILLION)

- TABLE 124 SOUTH KOREA: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (USD BILLION)

- TABLE 125 SOUTH KOREA: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (MILLION TONS)

- TABLE 126 SOUTH KOREA: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (MILLION TONS)

- TABLE 127 REST OF ASIA PACIFIC: IRON & STEEL MARKET, BY TYPE, 2021-2023 (USD BILLION)

- TABLE 128 REST OF ASIA PACIFIC: IRON & STEEL MARKET, BY TYPE, 2024-2030 (USD BILLION)

- TABLE 129 REST OF ASIA PACIFIC: IRON & STEEL MARKET, BY TYPE, 2021-2023 (MILLION TONS)

- TABLE 130 REST OF ASIA PACIFIC: IRON & STEEL MARKET, BY TYPE, 2024-2030 (MILLION TONS)

- TABLE 131 REST OF ASIA PACIFIC: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 132 REST OF ASIA PACIFIC: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 133 REST OF ASIA PACIFIC: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 134 REST OF ASIA PACIFIC: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 135 REST OF ASIA PACIFIC: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 136 REST OF ASIA PACIFIC: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 137 REST OF ASIA PACIFIC: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 138 REST OF ASIA PACIFIC: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 139 REST OF ASIA PACIFIC: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (USD BILLION)

- TABLE 140 REST OF ASIA PACIFIC: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (USD BILLION)

- TABLE 141 REST OF ASIA PACIFIC: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (MILLION TONS)

- TABLE 142 REST OF ASIA PACIFIC: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (MILLION TONS)

- TABLE 143 EUROPE: IRON & STEEL MARKET, BY COUNTRY, 2021-2023 (USD BILLION)

- TABLE 144 EUROPE: IRON & STEEL MARKET, BY COUNTRY, 2024-2030 (USD BILLION)

- TABLE 145 EUROPE: IRON & STEEL MARKET, BY COUNTRY, 2021-2023 (MILLION TONS)

- TABLE 146 EUROPE: IRON & STEEL MARKET, BY COUNTRY, 2024-2030 (MILLION TONS)

- TABLE 147 EUROPE: IRON & STEEL MARKET, BY TYPE, 2021-2023 (USD BILLION)

- TABLE 148 EUROPE: IRON & STEEL MARKET, BY TYPE, 2024-2030 (USD BILLION)

- TABLE 149 EUROPE: IRON & STEEL MARKET, BY TYPE, 2021-2023 (MILLION TONS)

- TABLE 150 EUROPE: IRON & STEEL MARKET, BY TYPE, 2024-2030 (MILLION TONS)

- TABLE 151 EUROPE: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 152 EUROPE: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 153 EUROPE: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 154 EUROPE: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 155 EUROPE: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 156 EUROPE: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 157 EUROPE: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 158 EUROPE: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 159 EUROPE: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (USD BILLION)

- TABLE 160 EUROPE: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (USD BILLION)

- TABLE 161 EUROPE: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (MILLION TONS)

- TABLE 162 EUROPE: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (MILLION TONS)

- TABLE 163 GERMANY: IRON & STEEL MARKET, BY TYPE, 2021-2023 (USD BILLION)

- TABLE 164 GERMANY: IRON & STEEL MARKET, BY TYPE, 2024-2030 (USD BILLION)

- TABLE 165 GERMANY: IRON & STEEL MARKET, BY TYPE, 2021-2023 (MILLION TONS)

- TABLE 166 GERMANY: IRON & STEEL MARKET, BY TYPE, 2024-2030 (MILLION TONS)

- TABLE 167 GERMANY: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 168 GERMANY: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 169 GERMANY: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 170 GERMANY: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 171 GERMANY: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 172 GERMANY: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 173 GERMANY: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 174 GERMANY: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 175 GERMANY: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (USD BILLION)

- TABLE 176 GERMANY: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (USD BILLION)

- TABLE 177 GERMANY: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (MILLION TONS)

- TABLE 178 GERMANY: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (MILLION TONS)

- TABLE 179 ITALY: IRON & STEEL MARKET, BY TYPE, 2021-2023 (USD BILLION)

- TABLE 180 ITALY: IRON & STEEL MARKET, BY TYPE, 2024-2030 (USD BILLION)

- TABLE 181 ITALY: IRON & STEEL MARKET, BY TYPE, 2021-2023 (MILLION TONS)

- TABLE 182 ITALY: IRON & STEEL MARKET, BY TYPE, 2024-2030 (MILLION TONS)

- TABLE 183 ITALY: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 184 ITALY: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 185 ITALY: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 186 ITALY: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 187 ITALY: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 188 ITALY: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 189 ITALY: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 190 ITALY: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 191 ITALY: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (USD BILLION)

- TABLE 192 ITALY: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (USD BILLION)

- TABLE 193 ITALY: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (MILLION TONS)

- TABLE 194 ITALY: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (MILLION TONS)

- TABLE 195 FRANCE: IRON & STEEL MARKET, BY TYPE, 2021-2023 (USD BILLION)

- TABLE 196 FRANCE: IRON & STEEL MARKET, BY TYPE, 2024-2030 (USD BILLION)

- TABLE 197 FRANCE: IRON & STEEL MARKET, BY TYPE, 2021-2023 (MILLION TONS)

- TABLE 198 FRANCE: IRON & STEEL MARKET, BY TYPE, 2024-2030 (MILLION TONS)

- TABLE 199 FRANCE: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 200 FRANCE: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 201 FRANCE: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 202 FRANCE: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 203 FRANCE: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 204 FRANCE: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 205 FRANCE: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 206 FRANCE: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 207 FRANCE: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (USD BILLION)

- TABLE 208 FRANCE: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (USD BILLION)

- TABLE 209 FRANCE: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (MILLION TONS)

- TABLE 210 FRANCE: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (MILLION TONS)

- TABLE 211 SPAIN: IRON & STEEL MARKET, BY TYPE, 2021-2023 (USD BILLION)

- TABLE 212 SPAIN: IRON & STEEL MARKET, BY TYPE, 2024-2030 (USD BILLION)

- TABLE 213 SPAIN: IRON & STEEL MARKET, BY TYPE, 2021-2023 (MILLION TONS)

- TABLE 214 SPAIN: IRON & STEEL MARKET, BY TYPE, 2024-2030 (MILLION TONS)

- TABLE 215 SPAIN: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 216 SPAIN: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 217 SPAIN: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 218 SPAIN: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 219 SPAIN: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 220 SPAIN: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 221 SPAIN: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 222 SPAIN: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 223 SPAIN: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (USD BILLION)

- TABLE 224 SPAIN: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (USD BILLION)

- TABLE 225 SPAIN: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (MILLION TONS)

- TABLE 226 SPAIN: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (MILLION TONS)

- TABLE 227 UK: IRON & STEEL MARKET, BY TYPE, 2021-2023 (USD BILLION)

- TABLE 228 UK: IRON & STEEL MARKET, BY TYPE, 2024-2030 (USD BILLION)

- TABLE 229 UK: IRON & STEEL MARKET, BY TYPE, 2021-2023 (MILLION TONS)

- TABLE 230 UK: IRON & STEEL MARKET, BY TYPE, 2024-2030 (MILLION TONS)

- TABLE 231 UK: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 232 UK: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 233 UK: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 234 UK: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 235 UK: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 236 UK: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 237 UK: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 238 UK: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 239 UK: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (USD BILLION)

- TABLE 240 UK: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (USD BILLION)

- TABLE 241 UK: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (MILLION TONS)

- TABLE 242 UK: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (MILLION TONS)

- TABLE 243 RUSSIA: IRON & STEEL MARKET, BY TYPE, 2021-2023 (USD BILLION)

- TABLE 244 RUSSIA: IRON & STEEL MARKET, BY TYPE, 2024-2030 (USD BILLION)

- TABLE 245 RUSSIA: IRON & STEEL MARKET, BY TYPE, 2021-2023 (MILLION TONS)

- TABLE 246 RUSSIA: IRON & STEEL MARKET, BY TYPE, 2024-2030 (MILLION TONS)

- TABLE 247 RUSSIA: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 248 RUSSIA: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 249 RUSSIA: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 250 RUSSIA: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 251 RUSSIA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 252 RUSSIA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 253 RUSSIA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 254 RUSSIA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 255 RUSSIA: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (USD BILLION)

- TABLE 256 RUSSIA: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (USD BILLION)

- TABLE 257 RUSSIA: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (MILLION TONS)

- TABLE 258 RUSSIA: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (MILLION TONS)

- TABLE 259 REST OF EUROPE: IRON & STEEL MARKET, BY TYPE, 2021-2023 (USD BILLION)

- TABLE 260 REST OF EUROPE: IRON & STEEL MARKET, BY TYPE, 2024-2030 (USD BILLION)

- TABLE 261 REST OF EUROPE: IRON & STEEL MARKET, BY TYPE, 2021-2023 (MILLION TONS)

- TABLE 262 REST OF EUROPE: IRON & STEEL MARKET, BY TYPE, 2024-2030 (MILLION TONS)

- TABLE 263 REST OF EUROPE: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 264 REST OF EUROPE: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 265 REST OF EUROPE: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 266 REST OF EUROPE: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 267 REST OF EUROPE: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 268 REST OF EUROPE: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 269 REST OF EUROPE: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 270 REST OF EUROPE: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 271 REST OF EUROPE: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (USD BILLION)

- TABLE 272 REST OF EUROPE: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (USD BILLION)

- TABLE 273 REST OF EUROPE: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (MILLION TONS)

- TABLE 274 REST OF EUROPE: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (MILLION TONS)

- TABLE 275 NORTH AMERICA: IRON & STEEL MARKET, BY COUNTRY, 2021-2023 (USD BILLION)

- TABLE 276 NORTH AMERICA: IRON & STEEL MARKET, BY COUNTRY, 2024-2030 (USD BILLION)

- TABLE 277 NORTH AMERICA: IRON & STEEL MARKET, BY COUNTRY, 2021-2023 (MILLION TONS)

- TABLE 278 NORTH AMERICA: IRON & STEEL MARKET, BY COUNTRY, 2024-2030 (MILLION TONS)

- TABLE 279 NORTH AMERICA: IRON & STEEL MARKET, BY TYPE, 2021-2023 (USD BILLION)

- TABLE 280 NORTH AMERICA: IRON & STEEL MARKET, BY TYPE, 2024-2030 (USD BILLION)

- TABLE 281 NORTH AMERICA: IRON & STEEL MARKET, BY TYPE, 2021-2023 (MILLION TONS)

- TABLE 282 NORTH AMERICA: IRON & STEEL MARKET, BY TYPE, 2024-2030 (MILLION TONS)

- TABLE 283 NORTH AMERICA: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 284 NORTH AMERICA: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 285 NORTH AMERICA: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 286 NORTH AMERICA: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 287 NORTH AMERICA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 288 NORTH AMERICA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 289 NORTH AMERICA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 290 NORTH AMERICA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 291 NORTH AMERICA: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (USD BILLION)

- TABLE 292 NORTH AMERICA: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (USD BILLION)

- TABLE 293 NORTH AMERICA: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (MILLION TONS)

- TABLE 294 NORTH AMERICA: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (MILLION TONS)

- TABLE 295 US: IRON & STEEL MARKET, BY TYPE, 2021-2023 (USD BILLION)

- TABLE 296 US: IRON & STEEL MARKET, BY TYPE, 2024-2030 (USD BILLION)

- TABLE 297 US: IRON & STEEL MARKET, BY TYPE, 2021-2023 (MILLION TONS)

- TABLE 298 US: IRON & STEEL MARKET, BY TYPE, 2024-2030 (MILLION TONS)

- TABLE 299 US: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 300 US: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 301 US: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 302 US: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 303 US: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 304 US: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 305 US: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 306 US: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 307 US: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (USD BILLION)

- TABLE 308 US: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (USD BILLION)

- TABLE 309 US: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (MILLION TONS)

- TABLE 310 US: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (MILLION TONS)

- TABLE 311 CANADA: IRON & STEEL MARKET, BY TYPE, 2021-2023 (USD BILLION)

- TABLE 312 CANADA: IRON & STEEL MARKET, BY TYPE, 2024-2030 (USD BILLION)

- TABLE 313 CANADA: IRON & STEEL MARKET, BY TYPE, 2021-2023 (MILLION TONS)

- TABLE 314 CANADA: IRON & STEEL MARKET, BY TYPE, 2024-2030 (MILLION TONS)

- TABLE 315 CANADA: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 316 CANADA: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 317 CANADA: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 318 CANADA: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 319 CANADA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 320 CANADA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 321 CANADA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 322 CANADA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 323 CANADA: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (USD BILLION)

- TABLE 324 CANADA: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (USD BILLION)

- TABLE 325 CANADA: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (MILLION TONS)

- TABLE 326 CANADA: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (MILLION TONS)

- TABLE 327 MEXICO: IRON & STEEL MARKET, BY TYPE, 2021-2023 (USD BILLION)

- TABLE 328 MEXICO: IRON & STEEL MARKET, BY TYPE, 2024-2030 (USD BILLION)

- TABLE 329 MEXICO: IRON & STEEL MARKET, BY TYPE, 2021-2023 (MILLION TONS)

- TABLE 330 MEXICO: IRON & STEEL MARKET, BY TYPE, 2024-2030 (MILLION TONS)

- TABLE 331 MEXICO: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 332 MEXICO: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 333 MEXICO: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 334 MEXICO: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 335 MEXICO: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 336 MEXICO: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 337 MEXICO: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 338 MEXICO: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 339 MEXICO: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (USD BILLION)

- TABLE 340 MEXICO: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (USD BILLION)

- TABLE 341 MEXICO: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (MILLION TONS)

- TABLE 342 MEXICO: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (MILLION TONS)

- TABLE 343 REST OF NORTH AMERICA: IRON & STEEL MARKET, BY TYPE, 2021-2023 (USD BILLION)

- TABLE 344 REST OF NORTH AMERICA: IRON & STEEL MARKET, BY TYPE, 2024-2030 (USD BILLION)

- TABLE 345 REST OF NORTH AMERICA: IRON & STEEL MARKET, BY TYPE, 2021-2023 (MILLION TONS)

- TABLE 346 REST OF NORTH AMERICA: IRON & STEEL MARKET, BY TYPE, 2024-2030 (MILLION TONS)

- TABLE 347 REST OF NORTH AMERICA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 348 REST OF NORTH AMERICA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 349 REST OF NORTH AMERICA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 350 REST OF NORTH AMERICA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 351 REST OF NORTH AMERICA: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (USD BILLION)

- TABLE 352 REST OF NORTH AMERICA: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (USD BILLION)

- TABLE 353 REST OF NORTH AMERICA: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (MILLION TONS)

- TABLE 354 REST OF NORTH AMERICA: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (MILLION TONS)

- TABLE 355 MIDDLE EAST & AFRICA: IRON & STEEL MARKET, BY COUNTRY, 2021-2023 (USD BILLION)

- TABLE 356 MIDDLE EAST & AFRICA: IRON & STEEL MARKET, BY COUNTRY, 2024-2030 (USD BILLION)

- TABLE 357 MIDDLE EAST & AFRICA: IRON & STEEL MARKET, BY COUNTRY, 2021-2023 (MILLION TONS)

- TABLE 358 MIDDLE EAST & AFRICA: IRON & STEEL MARKET, BY COUNTRY, 2024-2030 (MILLION TONS)

- TABLE 359 MIDDLE EAST & AFRICA: IRON & STEEL MARKET, BY TYPE, 2021-2023 (USD BILLION)

- TABLE 360 MIDDLE EAST & AFRICA: IRON & STEEL MARKET, BY TYPE, 2024-2030 (USD BILLION)

- TABLE 361 MIDDLE EAST & AFRICA: IRON & STEEL MARKET, BY TYPE, 2021-2023 (MILLION TONS)

- TABLE 362 MIDDLE EAST & AFRICA: IRON & STEEL MARKET, BY TYPE, 2024-2030 (MILLION TONS)

- TABLE 363 MIDDLE EAST & AFRICA: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 364 MIDDLE EAST & AFRICA: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 365 MIDDLE EAST & AFRICA: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 366 MIDDLE EAST & AFRICA: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 367 MIDDLE EAST & AFRICA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 368 MIDDLE EAST & AFRICA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 369 MIDDLE EAST & AFRICA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 370 MIDDLE EAST & AFRICA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 371 MIDDLE EAST & AFRICA: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (USD BILLION)

- TABLE 372 MIDDLE EAST & AFRICA: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (USD BILLION)

- TABLE 373 MIDDLE EAST & AFRICA: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (MILLION TONS)

- TABLE 374 MIDDLE EAST & AFRICA: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (MILLION TONS)

- TABLE 375 GCC COUNTRIES: IRON & STEEL MARKET, BY TYPE, 2021-2023 (USD BILLION)

- TABLE 376 GCC COUNTRIES: IRON & STEEL MARKET, BY TYPE, 2024-2030 (USD BILLION)

- TABLE 377 GCC COUNTRIES: IRON & STEEL MARKET, BY TYPE, 2021-2023 (MILLION TONS)

- TABLE 378 GCC COUNTRIES: IRON & STEEL MARKET, BY TYPE, 2024-2030 (MILLION TONS)

- TABLE 379 GCC COUNTRIES: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 380 GCC COUNTRIES: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 381 GCC COUNTRIES: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 382 GCC COUNTRIES: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 383 GCC COUNTRIES: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 384 GCC COUNTRIES: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 385 GCC COUNTRIES: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 386 GCC COUNTRIES: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 387 GCC COUNTRIES: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (USD BILLION)

- TABLE 388 GCC COUNTRIES: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (USD BILLION)

- TABLE 389 GCC COUNTRIES: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (MILLION TONS)

- TABLE 390 GCC COUNTRIES: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (MILLION TONS)

- TABLE 391 SAUDI ARABIA: IRON & STEEL MARKET, BY TYPE, 2021-2023 (USD BILLION)

- TABLE 392 SAUDI ARABIA: IRON & STEEL MARKET, BY TYPE, 2024-2030 (USD BILLION)

- TABLE 393 SAUDI ARABIA: IRON & STEEL MARKET, BY TYPE, 2021-2023 (MILLION TONS)

- TABLE 394 SAUDI ARABIA: IRON & STEEL MARKET, BY TYPE, 2024-2030 (MILLION TONS)

- TABLE 395 SAUDI ARABIA: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 396 SAUDI ARABIA: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 397 SAUDI ARABIA: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 398 SAUDI ARABIA: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 399 SAUDI ARABIA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 400 SAUDI ARABIA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 401 SAUDI ARABIA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 402 SAUDI ARABIA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 403 SAUDI ARABIA: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (USD BILLION)

- TABLE 404 SAUDI ARABIA: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (USD BILLION)

- TABLE 405 SAUDI ARABIA: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (MILLION TONS)

- TABLE 406 SAUDI ARABIA: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (MILLION TONS)

- TABLE 407 UAE: IRON & STEEL MARKET, BY TYPE, 2021-2023 (USD BILLION)

- TABLE 408 UAE: IRON & STEEL MARKET, BY TYPE, 2024-2030 (USD BILLION)

- TABLE 409 UAE: IRON & STEEL MARKET, BY TYPE, 2021-2023 (MILLION TONS)

- TABLE 410 UAE: IRON & STEEL MARKET, BY TYPE, 2024-2030 (MILLION TONS)

- TABLE 411 UAE: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 412 UAE: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 413 UAE: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 414 UAE: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 415 UAE: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 416 UAE: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 417 UAE: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 418 UAE: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 419 UAE: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (USD BILLION)

- TABLE 420 UAE: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (USD BILLION)

- TABLE 421 UAE: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (MILLION TONS)

- TABLE 422 UAE: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (MILLION TONS)

- TABLE 423 OTHER GCC COUNTRIES: IRON & STEEL MARKET, BY TYPE, 2021-2023 (USD BILLION)

- TABLE 424 OTHER GCC COUNTRIES: IRON & STEEL MARKET, BY TYPE, 2024-2030 (USD BILLION)

- TABLE 425 OTHER GCC COUNTRIES: IRON & STEEL MARKET, BY TYPE, 2021-2023 (MILLION TONS)

- TABLE 426 OTHER GCC COUNTRIES: IRON & STEEL MARKET, BY TYPE, 2024-2030 (MILLION TONS)

- TABLE 427 OTHER GCC COUNTRIES: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 428 OTHER GCC COUNTRIES: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 429 OTHER GCC COUNTRIES: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 430 OTHER GCC COUNTRIES: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 431 OTHER GCC COUNTRIES: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 432 OTHER GCC COUNTRIES: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 433 OTHER GCC COUNTRIES: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 434 OTHER GCC COUNTRIES: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 435 OTHER GCC COUNTRIES: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (USD BILLION)

- TABLE 436 OTHER GCC COUNTRIES: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (USD BILLION)

- TABLE 437 OTHER GCC COUNTRIES: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (MILLION TONS)

- TABLE 438 OTHER GCC COUNTRIES: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (MILLION TONS)

- TABLE 439 SOUTH AFRICA: IRON & STEEL MARKET, BY TYPE, 2021-2023 (USD BILLION)

- TABLE 440 SOUTH AFRICA: IRON & STEEL MARKET, BY TYPE, 2024-2030 (USD BILLION)

- TABLE 441 SOUTH AFRICA: IRON & STEEL MARKET, BY TYPE, 2021-2023 (MILLION TONS)

- TABLE 442 SOUTH AFRICA: IRON & STEEL MARKET, BY TYPE, 2024-2030 (MILLION TONS)

- TABLE 443 SOUTH AFRICA: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 444 SOUTH AFRICA: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 445 SOUTH AFRICA: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 446 SOUTH AFRICA: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 447 SOUTH AFRICA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 448 SOUTH AFRICA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 449 SOUTH AFRICA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 450 SOUTH AFRICA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 451 SOUTH AFRICA: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (USD BILLION)

- TABLE 452 SOUTH AFRICA: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (USD BILLION)

- TABLE 453 SOUTH AFRICA: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (MILLION TONS)

- TABLE 454 SOUTH AFRICA: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (MILLION TONS)

- TABLE 455 REST OF MIDDLE EAST & AFRICA: IRON & STEEL MARKET, BY TYPE, 2021-2023 (USD BILLION)

- TABLE 456 REST OF MIDDLE EAST & AFRICA: IRON & STEEL MARKET, BY TYPE, 2024-2030 (USD BILLION)

- TABLE 457 REST OF MIDDLE EAST & AFRICA: IRON & STEEL MARKET, BY TYPE, 2021-2023 (MILLION TONS)

- TABLE 458 REST OF MIDDLE EAST & AFRICA: IRON & STEEL MARKET, BY TYPE, 2024-2030 (MILLION TONS)

- TABLE 459 REST OF MIDDLE EAST & AFRICA: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 460 REST OF MIDDLE EAST & AFRICA: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 461 REST OF MIDDLE EAST & AFRICA: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 462 REST OF MIDDLE EAST & AFRICA: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 463 REST OF MIDDLE EAST & AFRICA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 464 REST OF MIDDLE EAST & AFRICA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 465 REST OF MIDDLE EAST & AFRICA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 466 REST OF MIDDLE EAST & AFRICA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 467 REST OF MIDDLE EAST & AFRICA: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (USD BILLION)

- TABLE 468 REST OF MIDDLE EAST & AFRICA: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (USD BILLION)

- TABLE 469 REST OF MIDDLE EAST & AFRICA: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (MILLION TONS)

- TABLE 470 REST OF MIDDLE EAST & AFRICA: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (MILLION TONS)

- TABLE 471 SOUTH AMERICA: IRON & STEEL MARKET, BY COUNTRY, 2021-2023 (USD BILLION)

- TABLE 472 SOUTH AMERICA: IRON & STEEL MARKET, BY COUNTRY, 2024-2030 (USD BILLION)

- TABLE 473 SOUTH AMERICA: IRON & STEEL MARKET, BY COUNTRY, 2021-2023 (MILLION TONS)

- TABLE 474 SOUTH AMERICA: IRON & STEEL MARKET, BY COUNTRY, 2024-2030 (MILLION TONS)

- TABLE 475 SOUTH AMERICA: IRON & STEEL MARKET, BY TYPE, 2021-2023 (USD BILLION)

- TABLE 476 SOUTH AMERICA: IRON & STEEL MARKET, BY TYPE, 2024-2030 (USD BILLION)

- TABLE 477 SOUTH AMERICA: IRON & STEEL MARKET, BY TYPE, 2021-2023 (MILLION TONS)

- TABLE 478 SOUTH AMERICA: IRON & STEEL MARKET, BY TYPE, 2024-2030 (MILLION TONS)

- TABLE 479 SOUTH AMERICA: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 480 SOUTH AMERICA: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 481 SOUTH AMERICA: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 482 SOUTH AMERICA: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 483 SOUTH AMERICA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 484 SOUTH AMERICA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 485 SOUTH AMERICA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 486 SOUTH AMERICA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 487 SOUTH AMERICA: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (USD BILLION)

- TABLE 488 SOUTH AMERICA: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (USD BILLION)

- TABLE 489 SOUTH AMERICA: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (MILLION TONS)

- TABLE 490 SOUTH AMERICA: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (MILLION TONS)

- TABLE 491 BRAZIL: IRON & STEEL MARKET, BY TYPE, 2021-2023 (USD BILLION)

- TABLE 492 BRAZIL: IRON & STEEL MARKET, BY TYPE, 2024-2030 (USD BILLION)

- TABLE 493 BRAZIL: IRON & STEEL MARKET, BY TYPE, 2021-2023 (MILLION TONS)

- TABLE 494 BRAZIL: IRON & STEEL MARKET, BY TYPE, 2024-2030 (MILLION TONS)

- TABLE 495 BRAZIL: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 496 BRAZIL: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 497 BRAZIL: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 498 BRAZIL: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 499 BRAZIL: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 500 BRAZIL: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 501 BRAZIL: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 502 BRAZIL: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 503 BRAZIL: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (USD BILLION)

- TABLE 504 BRAZIL: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (USD BILLION)

- TABLE 505 BRAZIL: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (MILLION TONS)

- TABLE 506 BRAZIL: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (MILLION TONS)

- TABLE 507 ARGENTINA: IRON & STEEL MARKET, BY TYPE, 2021-2023 (USD BILLION)

- TABLE 508 ARGENTINA: IRON & STEEL MARKET, BY TYPE, 2024-2030 (USD BILLION)

- TABLE 509 ARGENTINA: IRON & STEEL MARKET, BY TYPE, 2021-2023 (MILLION TONS)

- TABLE 510 ARGENTINA: IRON & STEEL MARKET, BY TYPE, 2024-2030 (MILLION TONS)

- TABLE 511 ARGENTINA: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 512 ARGENTINA: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 513 ARGENTINA: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 514 ARGENTINA: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 515 ARGENTINA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 516 ARGENTINA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 517 ARGENTINA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 518 ARGENTINA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 519 ARGENTINA: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (USD BILLION)

- TABLE 520 ARGENTINA: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (USD BILLION)

- TABLE 521 ARGENTINA: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (MILLION TONS)

- TABLE 522 ARGENTINA: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (MILLION TONS)

- TABLE 523 REST OF SOUTH AMERICA: IRON & STEEL MARKET, BY TYPE, 2021-2023 (USD BILLION)

- TABLE 524 REST OF SOUTH AMERICA: IRON & STEEL MARKET, BY TYPE, 2024-2030 (USD BILLION)

- TABLE 525 REST OF SOUTH AMERICA: IRON & STEEL MARKET, BY TYPE, 2021-2023 (MILLION TONS)

- TABLE 526 REST OF SOUTH AMERICA: IRON & STEEL MARKET, BY TYPE, 2024-2030 (MILLION TONS)

- TABLE 527 REST OF SOUTH AMERICA: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 528 REST OF SOUTH AMERICA: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 529 REST OF SOUTH AMERICA: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 530 REST OF SOUTH AMERICA: IRON MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 531 REST OF SOUTH AMERICA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (USD BILLION)

- TABLE 532 REST OF SOUTH AMERICA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (USD BILLION)

- TABLE 533 REST OF SOUTH AMERICA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2021-2023 (MILLION TONS)

- TABLE 534 REST OF SOUTH AMERICA: STEEL MARKET, BY PRODUCTION TECHNOLOGY, 2024-2030 (MILLION TONS)

- TABLE 535 REST OF SOUTH AMERICA: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (USD BILLION)

- TABLE 536 REST OF SOUTH AMERICA: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (USD BILLION)

- TABLE 537 REST OF SOUTH AMERICA: STEEL MARKET, BY END-USE INDUSTRY, 2021-2023 (MILLION TONS)

- TABLE 538 REST OF SOUTH AMERICA: STEEL MARKET, BY END-USE INDUSTRY, 2024-2030 (MILLION TONS)

- TABLE 539 IRON & STEEL MARKET: OVERVIEW OF MAJOR STRATEGIES ADOPTED BY KEY PLAYERS, JANUARY 2020-JUNE 2025

- TABLE 540 IRON & STEEL MARKET: DEGREE OF COMPETITION, 2024

- TABLE 541 IRON & STEEL MARKET: REGION FOOTPRINT

- TABLE 542 IRON & STEEL MARKET: TYPE FOOTPRINT

- TABLE 543 IRON MARKET: IRON PRODUCTION TECHNOLOGY FOOTPRINT

- TABLE 544 STEEL MARKET: STEEL PRODUCTION TECHNOLOGY FOOTPRINT

- TABLE 545 STEEL MARKET: END-USE INDUSTRY FOOTPRINT

- TABLE 546 IRON & STEEL MARKET: KEY STARTUPS/SMES

- TABLE 547 IRON & STEEL MARKET: COMPETITIVE BENCHMARKING OF KEY STARTUPS/SMES

- TABLE 548 IRON & STEEL MARKET: PRODUCT LAUNCHES, JANUARY 2020-JUNE 2025

- TABLE 549 IRON & STEEL MARKET: DEALS, JANUARY 2020-JUNE 2025

- TABLE 550 IRON & STEEL MARKET: EXPANSIONS, JANUARY 2020- JUNE 2025

- TABLE 551 ARCELORMITTAL: COMPANY OVERVIEW

- TABLE 552 ARCELORMITTAL: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 553 ARCELORMITTAL: PRODUCT LAUNCHES, JANUARY 2020-JUNE 2025

- TABLE 554 ARCELORMITTAL: DEALS, JANUARY 2020-JUNE 2025

- TABLE 555 ARCELORMITTAL: EXPANSIONS, JANUARY 2020-JUNE 2025

- TABLE 556 CHINA BAOWU STEEL GROUP CORPORATION LIMITED: COMPANY OVERVIEW

- TABLE 557 CHINA BAOWU STEEL GROUP CORPORATION LIMITED: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 558 CHINA BAOWU STEEL GROUP CORPORATION LIMITED: PRODUCT LAUNCHES, JANUARY 2020-JUNE 2025

- TABLE 559 CHINA BAOWU STEEL GROUP CORPORATION LIMITED: DEALS, JANUARY 2020-JUNE 2025

- TABLE 560 ANSTEEL GROUP: COMPANY OVERVIEW

- TABLE 561 ANSTEEL GROUP: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 562 ANSTEEL GROUP: PRODUCT LAUNCHES, JANUARY 2020 - JUNE 2025

- TABLE 563 ANSTEEL GROUP: DEALS, JANUARY 2020 - JUNE 2025

- TABLE 564 ANSTEEL GROUP: OTHER DEVELOPMENTS, JANUARY 2020 - JUNE 2025

- TABLE 565 HBIS GROUP: COMPANY OVERVIEW

- TABLE 566 HBIS GROUP: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 567 HBIS GROUP: PRODUCT LAUNCHES, JANUARY 2020-JUNE 2025

- TABLE 568 HBIS GROUP: DEALS, JANUARY 2020 - JUNE 2025

- TABLE 569 HBIS GROUP: EXPANSIONS, JANUARY 2020 - JUNE 2025

- TABLE 570 NIPPON STEEL CORPORATION: COMPANY OVERVIEW

- TABLE 571 NIPPON STEEL CORPORATION: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 572 NIPPON STEEL CORPORATION: PRODUCT LAUNCHES, JANUARY 2020-JUNE 2025

- TABLE 573 NIPPON STEEL CORPORATION: DEALS, JANUARY 2020-JUNE 2025

- TABLE 574 NIPPON STEEL CORPORATION: EXPANSIONS, JANUARY 2020-JUNE 2025

- TABLE 575 TATA STEEL: COMPANY OVERVIEW

- TABLE 576 TATA STEEL: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 577 TATA STEEL: PRODUCT LAUNCHES, JANUARY 2020-JUNE 2025

- TABLE 578 TATA STEEL: DEALS, JANUARY 2020-JUNE 2025

- TABLE 579 ARCELORMITTAL: EXPANSIONS, JANUARY 2020-JUNE 2025

- TABLE 580 TATA STEEL: OTHER DEVELOPMENTS, JANUARY 2020-JUNE 2025

- TABLE 581 JSW: COMPANY OVERVIEW

- TABLE 582 JSW: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 583 JSW: DEALS, JANUARY 2020-JUNE 2025

- TABLE 584 JSW: EXPANSIONS, JANUARY 2019-SEPTEMBER 2024

- TABLE 585 NUCOR CORPORATION: COMPANY OVERVIEW

- TABLE 586 NUCOR CORPORATION: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 587 NUCOR CORPORATION: PRODUCT LAUNCHES, JANUARY 2020-JUNE 2025

- TABLE 588 NUCOR CORPORATION: DEALS, JANUARY 2019-SEPTEMBER 2024

- TABLE 589 NUCOR CORPORATION: EXPANSIONS, JANUARY 2020-JUNE 2025

- TABLE 590 POSCO: COMPANY OVERVIEW

- TABLE 591 POSCO: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 592 POSCO: DEALS, JANUARY 2020-JUNE 2025

- TABLE 593 SAIL: COMPANY OVERVIEW

- TABLE 594 SAIL: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 595 SAIL: PRODUCT LAUNCHES, JANUARY 2020 - JUNE 2025

- TABLE 596 SAIL: DEALS, JANUARY 2020 - JUNE 2025

- TABLE 597 SAIL: EXPANSIONS, JANUARY 2020-JUNE 2025

- TABLE 598 CSN (NATIONAL STEEL COMPANY): COMPANY OVERVIEW

- TABLE 599 CSN (NATIONAL STEEL COMPANY): PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 600 SSAB AB: COMPANY OVERVIEW

- TABLE 601 SSAB AB: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 602 SSAB AB: PRODUCT LAUNCHES, JANUARY 2020 - JUNE 2025

- TABLE 603 SSAB AB: DEALS, JANUARY 2020 - JUNE 2025

- TABLE 604 SSAB AB: EXPANSIONS, JANUARY 2020 - JUNE 2025

- TABLE 605 SSAB AB: OTHER DEVELOPMENTS, JANUARY 2020-JUNE 2025

- TABLE 606 JIANGSU SHAGANG GROUP: COMPANY OVERVIEW

- TABLE 607 7 STEEL UK: COMPANY OVERVIEW

- TABLE 608 HEBEI DONGHAI SPECIAL STEEL GROUP CO., LTD.: COMPANY OVERVIEW

- TABLE 609 FENG HSIN STEEL CO., LTD.: COMPANY OVERVIEW

- TABLE 610 WORTHINGTON STEEL: COMPANY OVERVIEW

- TABLE 611 LIBERTY STEEL GROUP: COMPANY OVERVIEW

- TABLE 612 GERDAU: COMPANY OVERVIEW

- TABLE 613 D.S. METAL: COMPANY OVERVIEW

- TABLE 614 ARJAS STEEL: COMPANY OVERVIEW

- TABLE 615 SHREE JI STEEL: COMPANY OVERVIEW

- TABLE 616 RAHUL STEEL INDIA: COMPANY OVERVIEW

- TABLE 617 CORROS METALS PVT. LTD.: COMPANY OVERVIEW

- TABLE 618 METAL RECYCLING MARKET, BY SCRAP TYPE, 2019-2021 (USD MILLION)

- TABLE 619 METAL RECYCLING MARKET, BY SCRAP TYPE, 2022-2029 (USD MILLION)

- TABLE 620 METAL RECYCLING MARKET, BY SCRAP TYPE, 2019-2021 (MILLION TON)

- TABLE 621 METAL RECYCLING MARKET, BY SCRAP TYPE, 2022-2029 (MILLION TON)

- TABLE 622 METAL RECYCLING MARKET, BY TYPE, 2019-2021 (USD MILLION)

- TABLE 623 METAL RECYCLING MARKET, BY TYPE, 2022-2029 (USD MILLION)

- TABLE 624 METAL RECYCLING MARKET, BY TYPE, 2019-2021 (MILLION TON)

- TABLE 625 METAL RECYCLING MARKET, BY TYPE, 2022-2029 (MILLION TON)

- TABLE 626 METAL RECYCLING MARKET, BY END-USE INDUSTRY, 2019-2021 (USD MILLION)

- TABLE 627 METAL RECYCLING MARKET, BY END-USE INDUSTRY, 2022-2029 (USD MILLION)

- TABLE 628 METAL RECYCLING MARKET, BY END-USE INDUSTRY, 2019-2021 (MILLION TON)

- TABLE 629 METAL RECYCLING MARKET, BY END-USE INDUSTRY, 2022-2029 (MILLION TON)

- TABLE 630 METAL RECYCLING MARKET, BY REGION, 2019-2021 (USD MILLION)

- TABLE 631 METAL RECYCLING MARKET, BY REGION, 2022-2029 (USD MILLION)

- TABLE 632 METAL RECYCLING MARKET, BY REGION, 2019-2021 (MILLION TON)

- TABLE 633 METAL RECYCLING MARKET, BY REGION, 2022-2029 (MILLION TON)

- TABLE 634 SINTERED STEEL MARKET, BY STEEL TYPE, 2018-2021 (KILOTON)

- TABLE 635 SINTERED STEEL MARKET, BY STEEL TYPE, 2022-2028 (KILOTON)

- TABLE 636 SINTERED STEEL MARKET, BY STEEL TYPE, 2018-2021 (USD MILLION)

- TABLE 637 SINTERED STEEL MARKET, BY STEEL TYPE, 2022-2028 (USD MILLION)

- TABLE 638 SINTERED STEEL MARKET, BY PROCESS, 2018-2021 (KILOTON)

- TABLE 639 SINTERED STEEL MARKET, BY PROCESS, 2022-2028 (KILOTON)

- TABLE 640 SINTERED STEEL MARKET, BY PROCESS, 2018-2021 (USD MILLION)

- TABLE 641 SINTERED STEEL MARKET, BY PROCESS, 2022-2028 (USD MILLION)

- TABLE 642 SINTERED STEEL MARKET, BY END-USE SECTOR, 2018-2021 (KILOTON)

- TABLE 643 SINTERED STEEL MARKET, BY END-USE SECTOR, 2022-2028 (KILOTON)

- TABLE 644 SINTERED STEEL MARKET, BY END-USE SECTOR, 2018-2021 (USD MILLION)

- TABLE 645 SINTERED STEEL MARKET, BY END-USE SECTOR, 2022-2028 (USD MILLION)

- TABLE 646 SINTERED STEEL MARKET, BY APPLICATION, 2018-2021 (KILOTON)

- TABLE 647 SINTERED STEEL MARKET, BY APPLICATION, 2022-2028 (KILOTON)

- TABLE 648 SINTERED STEEL MARKET, BY APPLICATION, 2018-2021 (USD MILLION)

- TABLE 649 SINTERED STEEL MARKET, BY APPLICATION, 2022-2028 (USD MILLION)

- TABLE 650 SINTERED STEEL MARKET, BY REGION, 2018-2021 (KILOTON)

- TABLE 651 SINTERED STEEL MARKET, BY REGION, 2022-2028 (KILOTON)

- TABLE 652 SINTERED STEEL MARKET, BY REGION, 2018-2021 (USD MILLION)

- TABLE 653 SINTERED STEEL MARKET, BY REGION, 2022-2028 (USD MILLION)

List of Figures

- FIGURE 1 IRON & STEEL MARKET SEGMENTATION AND REGIONAL SCOPE

- FIGURE 2 IRON & STEEL MARKET: RESEARCH DESIGN

- FIGURE 3 MARKET SIZE ESTIMATION: TOP-DOWN APPROACH

- FIGURE 4 MARKET SIZE ESTIMATION: BOTTOM-UP APPROACH

- FIGURE 5 IRON & STEEL MARKET: APPROACH

- FIGURE 6 IRON & STEEL MARKET: DATA TRIANGULATION

- FIGURE 7 STEEL SEGMENT TO DOMINATE MARKET

- FIGURE 8 BLAST FURNACE PROCESS - LARGEST IRON PRODUCTION TECHNOLOGY SEGMENT

- FIGURE 9 BASIC OXYGEN FURNACE - DOMINANT STEEL PRODUCTION TECHNOLOGY SEGMENT

- FIGURE 10 BUILDING & CONSTRUCTION TO BE LARGEST END-USE INDUSTRY IN 2030

- FIGURE 11 ASIA PACIFIC ACCOUNTED FOR LARGEST SHARE OF IRON & STEEL MARKET IN 2024

- FIGURE 12 HIGH-RISE CONSTRUCTION AND ACCELERATED URBAN INFRASTRUCTURE TO DRIVE MARKET

- FIGURE 13 STEEL SEGMENT TO REGISTER HIGHER GROWTH RATE DURING FORECAST PERIOD

- FIGURE 14 BLAST FURNACE PROCESS SEGMENT TO REGISTER HIGHEST CAGR DURING FORECAST PERIOD

- FIGURE 15 BASIC OXYGEN FURNACE SEGMENT TO GROW FASTEST DURING FORECAST PERIOD

- FIGURE 16 BUILDING & CONSTRUCTION SEGMENT TO REGISTER RAPID GROWTH BETWEEN 2025 & 2030

- FIGURE 17 STEEL SEGMENT ACCOUNTED FOR LARGEST SHARE OF ASIA PACIFIC MARKET IN 2025

- FIGURE 18 INDIA TO REGISTER HIGHEST CAGR DURING FORECAST PERIOD

- FIGURE 19 DRIVERS, RESTRAINTS, OPPORTUNITIES, AND CHALLENGES IN IRON & STEEL MARKET

- FIGURE 20 YEAR-WISE INCREASE IN WORLD POPULATION (BILLION)

- FIGURE 21 YEAR-WISE RURAL VS. URBAN POPULATION (BILLION)

- FIGURE 22 TRENDS AND DISRUPTIONS IMPACTING CUSTOMER BUSINESS

- FIGURE 23 IRON & STEEL MARKET: ECOSYSTEM ANALYSIS

- FIGURE 24 IRON & STEEL MARKET: VALUE CHAIN ANALYSIS

- FIGURE 25 AVERAGE SELLING PRICE TREND OF TYPE, BY KEY PLAYERS, 2024 (USD/KG)

- FIGURE 27 EXPORT DATA FOR HS CODE 72 COMPLAINT PRODUCTS, BY COUNTRY, 2020-2024 (USD BILLION)

- FIGURE 28 IMPORT DATA FOR HS CODE 72 COMPLIANT PRODUCTS, BY COUNTRY, 2020-2024 (USD BILLION)

- FIGURE 29 LIST OF MAJOR PATENTS FOR IRON & STEEL (2015-2024)

- FIGURE 30 MAJOR PATENTS APPLIED AND GRANTED RELATED TO IRON & STEEL, BY COUNTRY/REGION, 2015-2024

- FIGURE 31 INVESTOR AND FUNDING SCENARIO

- FIGURE 32 IRON & STEEL MARKET: PORTER'S FIVE FORCES ANALYSIS

- FIGURE 33 INFLUENCE OF STAKEHOLDERS ON BUYING PROCESS FOR TOP THREE STEEL END-USE INDUSTRIES

- FIGURE 34 KEY BUYING CRITERIA FOR TOP THREE STEEL END-USE INDUSTRIES

- FIGURE 35 STEEL TO DOMINATE MARKET IN 2025 AND 2030

- FIGURE 36 DRI PROCESS SEGMENT TO GROW AT HIGHER CAGR DURING FORECAST PERIOD

- FIGURE 37 ELECTRIC ARC FURNACE SEGMENT TO GROW AT HIGHER CAGR DURING FORECAST PERIOD

- FIGURE 38 BUILDING & CONSTRUCTION TO ACCOUNT FOR LARGEST MARKET SIZE IN 2025

- FIGURE 39 IRON & STEEL MARKET GROWTH RATE, BY COUNTRY, 2025-2030

- FIGURE 40 MIDDLE EAST & AFRICA TO BE FASTEST-GROWING MARKET DURING FORECAST PERIOD

- FIGURE 41 ASIA PACIFIC: IRON & STEEL MARKET SNAPSHOT

- FIGURE 42 EUROPE: IRON & STEEL MARKET SNAPSHOT

- FIGURE 44 IRON & STEEL MARKET: REVENUE ANALYSIS OF KEY COMPANIES IN LAST FIVE YEARS, 2020-2024 (USD BILLION)

- FIGURE 48 IRON & STEEL MARKET: PRODUCT/BRAND COMPARISON

- FIGURE 49 IRON & STEEL MARKET: COMPANY EVALUATION MATRIX (KEY PLAYERS), 2024

- FIGURE 50 IRON & STEEL MARKET: COMPANY FOOTPRINT

- FIGURE 51 IRON & STEEL MARKET: COMPANY EVALUATION MATRIX (STARTUPS/SMES), 2024

- FIGURE 52 ARCELORMITTAL: COMPANY SNAPSHOT

- FIGURE 53 NIPPON STEEL CORPORATION: COMPANY SNAPSHOT

- FIGURE 54 TATA STEEL: COMPANY SNAPSHOT

- FIGURE 55 JSW: COMPANY SNAPSHOT

- FIGURE 56 NUCOR CORPORATION: COMPANY SNAPSHOT

- FIGURE 57 POSCO: COMPANY SNAPSHOT

- FIGURE 58 SAIL: COMPANY SNAPSHOT

- FIGURE 59 CSN (NATIONAL STEEL COMPANY): COMPANY SNAPSHOT

- FIGURE 60 SSAB AB: COMPANY SNAPSHOT

The market for iron & steel was valued at USD 1,453.4 billion in 2024 and is projected to reach USD 1,707.1 billion by 2030, at a CAGR of 3.1%. The iron and steel sector is experiencing strong growth in demand due to several factors, including urbanization, industrialization, and infrastructure development across developed and emerging markets. Significant demand from major end-use sectors like construction, automotive, energy, and machinery, continues to drive demand for iron and steel products.

| Scope of the Report | |

|---|---|

| Years Considered for the Study | 2021-2030 |

| Base Year | 2024 |

| Forecast Period | 2025-2030 |

| Units Considered | Value (USD Billion) Volume (Million Ton) |

| Segments | Type, Iron Production Technology, Steel Production Technology, End-use Industry, and Region |

| Regions covered | North America, Europe, Asia Pacific, Middle East & Africa, South America |

While there are numerous applications of iron and steel products, the national and local deployment of significant public infrastructure projects, continued structural development of new residential, commercial, and government entities, and investments in transportation and logistics networks, continue to drive overall growth. Additionally, government incentives to promote domestic manufacturing and stimulate industrial growth in emerging countries, such as China, India, and Brazil is emerging as a new industry driver for iron and steel initiatives. Market momentum is supplemented by technology advances in production methods and processes, providing enhancements in efficiency, while continuing to meet changing regulatory expectations regarding recycling and sustainability, which should further enhance demand for iron and steel throughout the world over the long-term.

Based on iron production technology, the blast furnace process segment is projected to account for the largest market share during the forecast period

The blast furnace process segment is expected to account for the largest share of the iron and steel market during the forecast period. This is attributed to the fact that it has historically accounted for the majority of large-scale iron production for decades. The blast furnace process encompasses reducing iron ore either with coke and limestone (at high temperatures) to produce molten iron (pig iron) which is used directly to make steel in a basic oxygen process or cast into blocks and used in foundries. The blast furnace route for pulverized ore in the iron and steel industry also continues to be the main process used in larger steel-producing countries as it allows high volume production with a constant quality of output.

Additionally, the blast furnace process is comparatively efficient at classifying the raw materials, and the cost structure has traditionally been researched and shared that enables and supports much larger capacity integrated steel plants and steel production, especially in countries such as China, India, and Russia, where consumption of iron and steel is fueling domestic and export requirements. Although there is an upward shift in alternative technologies based on decarbonization and lower carbon costs (such as using electric arc furnaces), the blast furnace process provides the rebar, steel frame, fencing, steel roofing, etc. For example, the blast furnace processes all the raw materials and provides economies of scale and lowers costs, enabling the production of a higher-grade iron, and this trend will prevail for the foreseeable future.

Based on steel production technology, the Electric Arc Furnace (EAF) segment is expected to grow at the highest CAGR during the forecast period

The Electric Arc Furnace (EAF) segment is projected to grow at the highest compound annual growth rate (CAGR) in the iron and steel market over the forecast period, as major progress has been made worldwide in the transition to sustainable, relatively energy-efficient steelmaking. Unlike traditional blast furnaces, which are heavily reliant on iron ore and coke, EAFs use recycled scrap metal as their main raw material, resulting in a significant reduction in carbon emissions and energy consumption.

EAF production has a number of advantages: the technology is flexible, is less capital-intensive, and has shorter startup times than blast furnaces. With stricter environmental regulations, and a stronger emphasis on recycling and circular economies, EAF production is increasingly attractive for producers that operate in regions that maintain recycling and metal trading infrastructures. As many nations have increasingly expressed interest in decarbonization goals, they are following practice trends and ultimately encouraging mills to make this transition and reduce the environmental impact of steel production.

In developed regions like North America and Europe, steel producers are shifting toward EAF-based production. While in emerging regions, there is gradual investment in EAF facilities, as new investments are helping update the steel sector. In particular, technological advancements which allowed for DRI (direct reduced iron) to be used in EAFs, have improved steel production efficiency, reduced energy consumption, and improved product quality. As a result, EAF based steel production is expected to grow rapidly and play a crucial role in the future developments in sustainable steelmaking.

Middle East & Africa region is expected to grow at highest CAGR during forecast period

The Middle East & Africa (MEA) region is expected to grow at the highest compound annual growth rate (CAGR) in the iron and steel market during the forecast period due to the increased use of iron and steel for infrastructure development, industrial growth, and population growth. A number of countries in the MEA (Saudi Arabia, UAE, Egypt. and South Africa) have been investing in larger-scale construction projects, transportation networks, and projects associated with energy, which create demand for iron and steel. Governmental initiatives are supporting this growth, with programs such as Vision 2030 in Saudi Arabia and the UAE's commitment to diversify its economy and expand industrialization programs to facilitate domestic manufactured steel. At the same time, growing investments from the oil & gas, mining, and renewable energy industries are also increasing steel use in the MEA region. The MEA region is being strategic about developing the competitiveness of the region against large global producers of iron and steel, taking advantage of accessible raw materials and foreign direct investments in the metals sector. With ongoing urbanization, demand for housing, and a need to diversify their economies, MEA is in a position for growth. Each of these drivers, together, will see MEA as one of the most dynamic and high-growth regions for the iron and steel industry over the coming years.

- By Company Type: Tier 1: 40%, Tier 2: 25%, Tier 3: 35%

- By Designation: C Level: 35%, Director Level: 30%, Others: 35%

- By Region: North America: 25%, Europe: 20%, Asia Pacific: 45%, Middle East & Africa: 5%, and South America: 5%

Companies Covered:

ArcelorMittal (Luxembourg), China Baowu Steel group Corporation Limited (China ), TATA Steel (India), JSW (India), Nucor Corporation (US), NIPPON STEEL CORPORATION (Japan), Ansteel Group Corporation Limited (China), POSCO (UK), HBIS Group (China), and SAIL (India) are some key players in iron & steel market.

Research Coverage

The market study covers the iron & steel market across various segments. It aims to estimate the market size and the growth potential of this market across different segments based on type, iron production technology, steel production technology, end-use industry, and region. The study also includes an in-depth competitive analysis of key players in the market, their company profiles, key observations related to their products and business offerings, recent developments undertaken by them, and key growth strategies adopted by them to improve their positions in the iron & steel market.

Key Benefits of Buying the Report

The report is expected to help the market leaders/new entrants in this market share the closest approximations of the revenue numbers of the overall iron & steel market and its segments and subsegments. This report is projected to help stakeholders understand the competitive landscape of the market, gain insights to improve the positions of their businesses and plan suitable go-to-market strategies. The report also aims to help stakeholders understand the pulse of the market and provides them with information on the key market drivers, challenges, and opportunities.

The report provides insights on the following pointers:

- Analysis of key drivers (Rising steel consumption in energy & power and automotive industries), restraints (Volatile raw material prices), opportunities (Growing investments and government support in emerging economies), and challenges (Global climate change and environmental degradation due to fossil fuel combustion) influencing the growth of the iron & steel market.

- Product Development/Innovation: Detailed insights on upcoming technologies, research & development activities, and product & service launches in the iron & steel market

- Market Development: Comprehensive information about profitable markets - the report analyzes the iron & steel market across regions

Market Diversification: Exhaustive information about new products & services, untapped geographies, recent developments, and investments in the iron & steel market

- Competitive Assessment: In-depth assessment of market shares, growth strategies, and service offerings of leading players like as ArcelorMittal (Luxembourg), China Baowu Steel group Corporation Limited (China ), TATA Steel (India), JSW (India), Nucor Corporation (US) , NIPPON STEEL CORPORATION (Japan), Ansteel Group Corporation Limited (China), POSCO (UK), HBIS Group (China), and SAIL (India) and others in the iron & steel market. The report also helps stakeholders understand the pulse of the iron & steel market and provides them with information on the key market drivers, restraints, challenges, and opportunities.

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 STUDY OBJECTIVES

- 1.2 MARKET DEFINITION

- 1.3 STUDY SCOPE

- 1.3.1 MARKETS COVERED AND REGIONAL SCOPE

- 1.3.2 INCLUSIONS AND EXCLUSIONS

- 1.3.3 YEARS CONSIDERED

- 1.4 CURRENCY CONSIDERED

- 1.5 UNITS CONSIDERED

- 1.6 LIMITATIONS

- 1.7 STAKEHOLDERS

- 1.8 SUMMARY OF CHANGES

2 RESEARCH METHODOLOGY

- 2.1 RESEARCH DATA

- 2.1.1 SECONDARY DATA

- 2.1.1.1 Key data from secondary sources

- 2.1.1.2 List of secondary sources

- 2.1.2 PRIMARY DATA

- 2.1.2.1 Key primary participants

- 2.1.2.2 Key data from primary sources

- 2.1.2.3 Breakdown of interviews with experts

- 2.1.2.4 Key industry insights

- 2.1.1 SECONDARY DATA

- 2.2 MARKET SIZE ESTIMATION

- 2.2.1 TOP-DOWN APPROACH

- 2.2.2 BOTTOM-UP APPROACH

- 2.3 BASE NUMBER CALCULATION

- 2.3.1 SUPPLY-SIDE APPROACH

- 2.4 GROWTH FORECAST

- 2.5 DATA TRIANGULATION

- 2.6 RESEARCH ASSUMPTIONS

- 2.7 FACTOR ANALYSIS

- 2.8 RESEARCH LIMITATIONS

- 2.9 RISK ASSESSMENT

3 EXECUTIVE SUMMARY

4 PREMIUM INSIGHTS

- 4.1 ATTRACTIVE OPPORTUNITIES FOR PLAYERS IN IRON & STEEL MARKET

- 4.2 IRON & STEEL MARKET, BY TYPE

- 4.3 IRON MARKET, BY PRODUCTION TECHNOLOGY

- 4.4 STEEL MARKET, BY PRODUCTION TECHNOLOGY

- 4.5 IRON & STEEL MARKET, BY END-USE INDUSTRY

- 4.6 ASIA PACIFIC: IRON & STEEL MARKET, BY TYPE AND COUNTRY

- 4.7 IRON & STEEL MARKET, BY KEY COUNTRY

5 MARKET OVERVIEW

- 5.1 INTRODUCTION

- 5.2 MARKET DYNAMICS

- 5.2.1 DRIVERS

- 5.2.1.1 Abundance of iron ore & other minerals for steel production

- 5.2.1.2 Rapid urbanization

- 5.2.1.3 Rising steel consumption in energy & power and automotive industries

- 5.2.2 RESTRAINTS

- 5.2.2.1 Vulnerability of construction industry to crisis

- 5.2.2.2 Volatile raw material prices

- 5.2.3 OPPORTUNITIES

- 5.2.3.1 Transition toward net-zero steel

- 5.2.3.2 Growing investments and government support in emerging economies

- 5.2.4 CHALLENGES

- 5.2.4.1 Environmental challenge

- 5.2.4.2 Problem of excess capacity

- 5.2.1 DRIVERS

6 INDUSTRY TRENDS

- 6.1 TRENDS AND DISRUPTIONS IMPACTING CUSTOMER BUSINESS

- 6.2 ECOSYSTEM ANALYSIS

- 6.3 VALUE CHAIN ANALYSIS

- 6.3.1 RAW MATERIAL SUPPLIERS

- 6.3.2 MANUFACTURERS

- 6.3.3 DISTRIBUTORS

- 6.3.4 END USERS

- 6.4 TARIFF AND REGULATORY LANDSCAPE

- 6.4.1 TARIFF ANALYSIS (HS CODE: 72)

- 6.4.2 REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- 6.4.3 KEY REGULATIONS

- 6.4.3.1 Bureau of Indian Standards (BIS) - IS Standards for Steel Products

- 6.4.3.2 ASTM International - Steel Standards

- 6.4.3.3 European Norms (EN) - Steel Harmonized Standards

- 6.4.3.4 Import Monitoring and Analysis System (IMAS) - US Department of Commerce

- 6.5 PRICING ANALYSIS

- 6.5.1 PRICING ANALYSIS BASED ON REGION

- 6.6 TRADE ANALYSIS

- 6.6.1 EXPORT SCENARIO (HS CODE 72)

- 6.6.2 IMPORT SCENARIO (HS CODE 72)

- 6.7 TECHNOLOGY ANALYSIS

- 6.7.1 KEY TECHNOLOGIES

- 6.7.1.1 Hydrogen steel plant

- 6.7.1.2 Organic Rankine Cycle

- 6.7.2 COMPLEMENTARY TECHNOLOGIES

- 6.7.2.1 HYBRIT process

- 6.7.2.2 Potato-based biodegradable foam

- 6.7.1 KEY TECHNOLOGIES

- 6.8 CASE STUDY ANALYSIS

- 6.9 PATENT ANALYSIS

- 6.9.1 INTRODUCTION

- 6.9.2 METHODOLOGY

- 6.9.3 IRON & STEEL MARKET, PATENT ANALYSIS (2015-2024)

- 6.10 KEY CONFERENCES AND EVENTS, 2025-2026

- 6.11 INVESTMENT AND FUNDING SCENARIO

- 6.12 IMPACT OF GEN AI ON IRON & STEEL

- 6.12.1 INTEGRATING AI IN IRON & STEEL

- 6.12.2 BEST PRACTICES TO LEVERAGE AI FOR IRON & STEEL MARKET