|

|

市場調査レポート

商品コード

1807574

建設・建築資材市場:素材タイプ、カテゴリー、販売チャネル、用途、建設タイプ別-2025-2030年世界予測Construction & Building Materials Market by Material Type, Category, Sales Channel, Application, Construction Type - Global Forecast 2025-2030 |

||||||

カスタマイズ可能

適宜更新あり

|

|||||||

| 建設・建築資材市場:素材タイプ、カテゴリー、販売チャネル、用途、建設タイプ別-2025-2030年世界予測 |

|

出版日: 2025年08月28日

発行: 360iResearch

ページ情報: 英文 194 Pages

納期: 即日から翌営業日

|

全表示

- 概要

- 図表

- 目次

建設・建築資材市場は、2024年には2兆400億米ドルと評価され、2025年には2兆1,600億米ドル、CAGR 5.93%で成長し、2030年には2兆8,900億米ドルに達すると予測されています。

| 主な市場の統計 | |

|---|---|

| 基準年2024 | 2兆400億米ドル |

| 推定年2025 | 2兆1,600億米ドル |

| 予測年2030 | 2兆8,900億米ドル |

| CAGR(%) | 5.93% |

新たな市場動向と規制改革に対応し、建設・建材業界を形成する現代の力学を理解する

建設・建材セクターは、急速な都市化と持続可能性への要求の高まりの影響を同時に受け、極めて重要な岐路に立っています。世界の人口が大都市圏の密集地にシフトするにつれ、インフラプロジェクトや住宅開発が激化し、複雑なサプライチェーンダイナミクスが生み出され、革新的な材料ソリューションの必要性が高まっています。同時に、環境規制の強化やグリーンビルディング認証の取得により、メーカーや請負業者は従来のプロセスを再評価し、低炭素の代替案を採用せざるを得なくなっています。

持続可能性の要求とデジタル技術の進歩が牽引する、建設資材市場を再定義する重要な変革の検証

近年、持続可能性は建設資材分野における戦略的意思決定の要として浮上しています。メーカー各社は、厳しい環境規制に対応するため、再生骨材、バイオベースの断熱材、低排出セメントへの投資を増やしています。同時に、循環型経済の原則に向けた動きが製品設計に影響を及ぼし、企業は廃棄物の流れを最小限に抑えるための引き取りプログラムや材料の再利用戦略を模索しています。

2025年米国関税が建築材料のサプライチェーン、コスト構造、競合力学に及ぼす包括的影響の評価

2025年の米国関税改正の実施は、世界の建材サプライチェーンに多面的な影響を及ぼしています。一部の金属輸入品に対する関税の引き上げは、メーカーがコスト圧力を緩和し、マージンの健全性を守ろうとしたため、国内生産への取り組みが最初に活発化するきっかけとなりました。同時に、調達チームはリスクを分散し、大きな影響を受けるトレードレーンへの依存を減らすため、近隣市場の代替ソースを模索し始めました。

戦略的意思決定のために、素材タイプ、カテゴリー、販売チャネル、用途、建設タイプにまたがる重要な市場セグメンテーションの洞察を明らかにします

材料タイプというレンズを通して市場を観察すると、レンガやブロックなどの伝統的な石積み製品、どこにでもあるコンクリートやセメントのセグメント、特殊な断熱材、アルミニウム、銅、鉄、スチールなどの多様な金属、自然石や骨材、再生可能な木材ソリューションなどが分析対象となります。各カテゴリーは、それぞれ異なる性能特性とコストプロファイルを示し、建築家やエンジニアを特定の用途に最適な選択へと導きます。

南北アメリカ、欧州・中東・アフリカ、アジア太平洋の成長地域における建築・建材市場を形成する重要な地域力学を解明

南北アメリカでは、インフラ近代化計画や都市再開発の取り組みにより、弾力性があり持続可能な建築ソリューションに対する需要が高まっています。政府も民間投資家も同様に、交通機関の拡張、環境に配慮した改修、洪水軽減プロジェクトに資金を投入しています。こうした取り組みにより、高性能コンクリート配合、高度な複合強化材、ネット・ゼロ目標に沿ったエネルギー効率の高い外壁システムの採用が促進されています。

世界の建設・建築資材情勢を変える主要企業の戦略的動きと競合情勢を浮き彫りにする

建築・建材分野の主要企業は、競争力を強化するために様々な戦略的取り組みを行っています。一部のグローバルプレーヤーは、地理的範囲を拡大し、ポートフォリオを多様化するためにM&Aを推進し、地域の専門知識と革新的な製品ラインを融合させています。また、合弁事業や戦略的提携を結び、新技術へのアクセス、生産能力の強化、高成長分野への市場参入を加速させている企業もあります。

市場の複雑さを乗り越え、イノベーションを受け入れ、競合優位性を確保するために、業界リーダーに実行可能な戦略的提言を提供します

業界リーダーは、イノベーションとコラボレーションの二重焦点を優先すべきです。技術プロバイダー、研究機関、新興企業とセクターを超えたパートナーシップを確立することで、組織は持続可能な材料の開発を加速し、高度な製造技術の採用を合理化することができます。この協力的な精神は、知的財産の共有を促進し、世界市場においてソリューションをより迅速に拡大します。

データの分析、調査結果の検証、建設材料市場の包括的な調査対象の確保に採用した厳格な調査手法の概略

本レポートは、一次情報と二次情報を組み合わせた厳密な多段階調査手法に裏打ちされています。最初に、市場力学と過去の動向の基礎的理解を確立するために、業界出版物、規制の枠組み、業界団体、専門誌を活用した広範な2次調査を実施しました。

利害関係者の意思決定を促し、建設資材セクターの将来の成長を促進するための、核となる調査結果と戦略的考察の統合

この分析により、持続可能性への要請、デジタル変革、モジュラー構造、進化する貿易政策といった集約的な力が、建設・建材業界を総体的に再構築しつつあることが明らかになりました。サーキュラー・エコノミーの原則を技術革新と効果的に統合する利害関係者は、明確な競争優位性を獲得する一方、従来の慣行に依存する利害関係者は、マージンの圧縮や規制上の課題に直面する可能性があります。

目次

第1章 序文

第2章 調査手法

第3章 エグゼクティブサマリー

第4章 市場の概要

第5章 市場力学

- 建設プロジェクトにおける環境への影響を大幅に削減するために、持続可能で環境に優しい建築材料の採用が増加しています。

- 建築資材へのスマートテクノロジーの統合を促進し、建物全体の効率と運用パフォーマンスを向上

- 厳しい世界的炭素削減と気候目標を満たすために、エネルギー効率の高い建設資材への注目が高まっている

- 都市開発における軽量・高性能な建設複合材の需要増加

- プロジェクトの早期完了に向けたプレハブ工法およびモジュール工法の拡大

- ナノテクノロジーの進歩により、建設資材の耐久性と機能性が向上しました。

- 建設における循環型経済を促進するため、リサイクル材料や廃棄物由来材料の使用が急増

- 耐火材料の革新を促進する厳格な建築基準の実施

- 高度な防水・断熱材を組み込んだ緑の屋根や壁の人気が高まっている

- インフラの長寿命化を図る自己治癒コンクリートなどの革新的材料の開発

第6章 市場洞察

- ポーターのファイブフォース分析

- PESTEL分析

第7章 米国の関税の累積的な影響2025

第8章 建設・建築資材市場:素材タイプ別

- レンガとブロック

- コンクリート・セメント

- 断熱材

- 金属

- アルミニウム

- 銅

- 鉄

- 鋼鉄

- 石材および骨材

- 木材

第9章 建設・建築資材市場:カテゴリー別

- 建築材料

- 補助材料

- 構造材料

第10章 建設・建築資材市場:販売チャネル別

- オフライン販売

- オンライン販売

第11章 建設・建築資材市場:用途別

- 外観

- クラッディング

- 屋根葺き

- 窓とドア

- インテリア

- フローリング

- 壁と天井

- 構造

- ファンデーション

- フレームワーク

第12章 建設・建築資材市場建設タイプ別

- 商業用

- 産業

- インフラストラクチャー

- 住宅用

第13章 南北アメリカの建設・建築資材市場

- 米国

- カナダ

- メキシコ

- ブラジル

- アルゼンチン

第14章 欧州・中東・アフリカの建設・建築資材市場

- 英国

- ドイツ

- フランス

- ロシア

- イタリア

- スペイン

- アラブ首長国連邦

- サウジアラビア

- 南アフリカ

- デンマーク

- オランダ

- カタール

- フィンランド

- スウェーデン

- ナイジェリア

- エジプト

- トルコ

- イスラエル

- ノルウェー

- ポーランド

- スイス

第15章 アジア太平洋地域の建設・建築資材市場

- 中国

- インド

- 日本

- オーストラリア

- 韓国

- インドネシア

- タイ

- フィリピン

- マレーシア

- シンガポール

- ベトナム

- 台湾

第16章 競合情勢

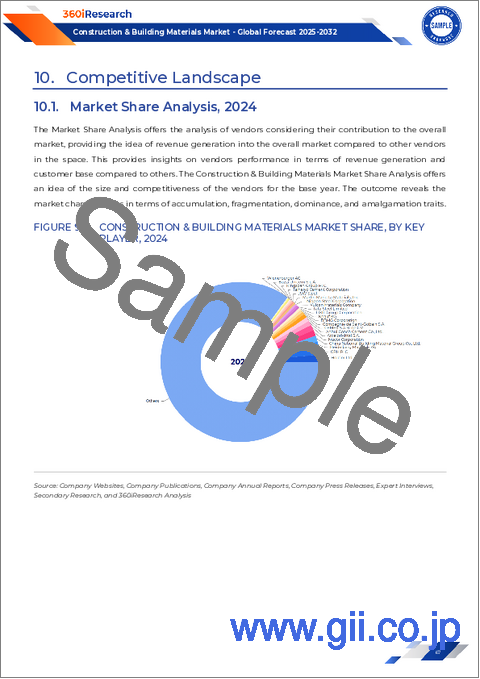

- 市場シェア分析, 2024

- FPNVポジショニングマトリックス, 2024

- 競合分析

- Alghanim Industries

- Ambuja Cements Ltd. by Adani Group

- Anhui Conch Cement Co., Ltd.

- ArcelorMittal S.A.

- Armstrong World Industries, Inc.

- ASIA CEMENT CORPORATION

- Asia Cement Public Company Ltd.

- Atad Steel Structure Corporation

- Athabasca Minerals Inc.

- BASF SE

- BBMG Corporation

- Binderholz Group

- Boral Limited

- Buzzi Unicem S.p.A.

- CEMEX S.A.B. de C.V.

- China National Building Material Group Co., Ltd.

- Compagnie de Saint-Gobain S.A.

- CRH PLC

- Heidelberg Materials

- Holcim Ltd

- James Hardie Industries PLC

- JFE Holdings, Inc.

- JSW Steel

- Kingspan Group PLC

- Knauf KG

- Lindab Group

- LIXIL Group Corporation

- Martin Marietta Materials, Inc

- Memaar Building Systems

- Mitsubishi Chemical Group Corporation

- Nippon Steel Corporation

- Nucor Corporation

- Owens Corning

- Stora Enso Oyj

- Sumitomo Corporation

- Taiheiyo Cement Corporation

- Taiwan Cement Corporation

- Tata Steel Limited

- Vulcan Materials Company

- Wienerberger AG

第17章 リサーチAI

第18章 リサーチ統計

第19章 リサーチコンタクト

第20章 リサーチ記事

第21章 付録

LIST OF FIGURES

- FIGURE 1. CONSTRUCTION & BUILDING MATERIALS MARKET RESEARCH PROCESS

- FIGURE 2. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, 2018-2030 (USD MILLION)

- FIGURE 3. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY REGION, 2024 VS 2025 VS 2030 (USD MILLION)

- FIGURE 4. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY COUNTRY, 2024 VS 2025 VS 2030 (USD MILLION)

- FIGURE 5. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY MATERIAL TYPE, 2024 VS 2030 (%)

- FIGURE 6. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY MATERIAL TYPE, 2024 VS 2025 VS 2030 (USD MILLION)

- FIGURE 7. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CATEGORY, 2024 VS 2030 (%)

- FIGURE 8. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CATEGORY, 2024 VS 2025 VS 2030 (USD MILLION)

- FIGURE 9. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY SALES CHANNEL, 2024 VS 2030 (%)

- FIGURE 10. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY SALES CHANNEL, 2024 VS 2025 VS 2030 (USD MILLION)

- FIGURE 11. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY APPLICATION, 2024 VS 2030 (%)

- FIGURE 12. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY APPLICATION, 2024 VS 2025 VS 2030 (USD MILLION)

- FIGURE 13. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CONSTRUCTION TYPE, 2024 VS 2030 (%)

- FIGURE 14. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CONSTRUCTION TYPE, 2024 VS 2025 VS 2030 (USD MILLION)

- FIGURE 15. AMERICAS CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY COUNTRY, 2024 VS 2030 (%)

- FIGURE 16. AMERICAS CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY COUNTRY, 2024 VS 2025 VS 2030 (USD MILLION)

- FIGURE 17. UNITED STATES CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY STATE, 2024 VS 2030 (%)

- FIGURE 18. UNITED STATES CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY STATE, 2024 VS 2025 VS 2030 (USD MILLION)

- FIGURE 19. EUROPE, MIDDLE EAST & AFRICA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY COUNTRY, 2024 VS 2030 (%)

- FIGURE 20. EUROPE, MIDDLE EAST & AFRICA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY COUNTRY, 2024 VS 2025 VS 2030 (USD MILLION)

- FIGURE 21. ASIA-PACIFIC CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY COUNTRY, 2024 VS 2030 (%)

- FIGURE 22. ASIA-PACIFIC CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY COUNTRY, 2024 VS 2025 VS 2030 (USD MILLION)

- FIGURE 23. CONSTRUCTION & BUILDING MATERIALS MARKET SHARE, BY KEY PLAYER, 2024

- FIGURE 24. CONSTRUCTION & BUILDING MATERIALS MARKET, FPNV POSITIONING MATRIX, 2024

- FIGURE 25. CONSTRUCTION & BUILDING MATERIALS MARKET: RESEARCHAI

- FIGURE 26. CONSTRUCTION & BUILDING MATERIALS MARKET: RESEARCHSTATISTICS

- FIGURE 27. CONSTRUCTION & BUILDING MATERIALS MARKET: RESEARCHCONTACTS

- FIGURE 28. CONSTRUCTION & BUILDING MATERIALS MARKET: RESEARCHARTICLES

LIST OF TABLES

- TABLE 1. CONSTRUCTION & BUILDING MATERIALS MARKET SEGMENTATION & COVERAGE

- TABLE 2. UNITED STATES DOLLAR EXCHANGE RATE, 2018-2024

- TABLE 3. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, 2018-2024 (USD MILLION)

- TABLE 4. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, 2025-2030 (USD MILLION)

- TABLE 5. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY REGION, 2018-2024 (USD MILLION)

- TABLE 6. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY REGION, 2025-2030 (USD MILLION)

- TABLE 7. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY COUNTRY, 2018-2024 (USD MILLION)

- TABLE 8. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 9. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY MATERIAL TYPE, 2018-2024 (USD MILLION)

- TABLE 10. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY MATERIAL TYPE, 2025-2030 (USD MILLION)

- TABLE 11. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY BRICKS & BLOCKS, BY REGION, 2018-2024 (USD MILLION)

- TABLE 12. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY BRICKS & BLOCKS, BY REGION, 2025-2030 (USD MILLION)

- TABLE 13. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CONCRETE & CEMENT, BY REGION, 2018-2024 (USD MILLION)

- TABLE 14. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CONCRETE & CEMENT, BY REGION, 2025-2030 (USD MILLION)

- TABLE 15. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY INSULATION MATERIALS, BY REGION, 2018-2024 (USD MILLION)

- TABLE 16. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY INSULATION MATERIALS, BY REGION, 2025-2030 (USD MILLION)

- TABLE 17. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY METAL, BY REGION, 2018-2024 (USD MILLION)

- TABLE 18. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY METAL, BY REGION, 2025-2030 (USD MILLION)

- TABLE 19. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY ALUMINIUM, BY REGION, 2018-2024 (USD MILLION)

- TABLE 20. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY ALUMINIUM, BY REGION, 2025-2030 (USD MILLION)

- TABLE 21. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY COPPER, BY REGION, 2018-2024 (USD MILLION)

- TABLE 22. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY COPPER, BY REGION, 2025-2030 (USD MILLION)

- TABLE 23. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY IRON, BY REGION, 2018-2024 (USD MILLION)

- TABLE 24. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY IRON, BY REGION, 2025-2030 (USD MILLION)

- TABLE 25. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY STEEL, BY REGION, 2018-2024 (USD MILLION)

- TABLE 26. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY STEEL, BY REGION, 2025-2030 (USD MILLION)

- TABLE 27. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY METAL, 2018-2024 (USD MILLION)

- TABLE 28. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY METAL, 2025-2030 (USD MILLION)

- TABLE 29. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY STONE & AGGREGATES, BY REGION, 2018-2024 (USD MILLION)

- TABLE 30. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY STONE & AGGREGATES, BY REGION, 2025-2030 (USD MILLION)

- TABLE 31. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY WOOD, BY REGION, 2018-2024 (USD MILLION)

- TABLE 32. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY WOOD, BY REGION, 2025-2030 (USD MILLION)

- TABLE 33. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CATEGORY, 2018-2024 (USD MILLION)

- TABLE 34. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CATEGORY, 2025-2030 (USD MILLION)

- TABLE 35. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY ARCHITECTURAL MATERIALS, BY REGION, 2018-2024 (USD MILLION)

- TABLE 36. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY ARCHITECTURAL MATERIALS, BY REGION, 2025-2030 (USD MILLION)

- TABLE 37. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY AUXILIARY MATERIALS, BY REGION, 2018-2024 (USD MILLION)

- TABLE 38. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY AUXILIARY MATERIALS, BY REGION, 2025-2030 (USD MILLION)

- TABLE 39. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY STRUCTURAL MATERIALS, BY REGION, 2018-2024 (USD MILLION)

- TABLE 40. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY STRUCTURAL MATERIALS, BY REGION, 2025-2030 (USD MILLION)

- TABLE 41. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY SALES CHANNEL, 2018-2024 (USD MILLION)

- TABLE 42. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY SALES CHANNEL, 2025-2030 (USD MILLION)

- TABLE 43. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY OFFLINE SALES, BY REGION, 2018-2024 (USD MILLION)

- TABLE 44. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY OFFLINE SALES, BY REGION, 2025-2030 (USD MILLION)

- TABLE 45. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY ONLINE SALES, BY REGION, 2018-2024 (USD MILLION)

- TABLE 46. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY ONLINE SALES, BY REGION, 2025-2030 (USD MILLION)

- TABLE 47. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY APPLICATION, 2018-2024 (USD MILLION)

- TABLE 48. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY APPLICATION, 2025-2030 (USD MILLION)

- TABLE 49. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY EXTERIOR, BY REGION, 2018-2024 (USD MILLION)

- TABLE 50. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY EXTERIOR, BY REGION, 2025-2030 (USD MILLION)

- TABLE 51. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CLADDING, BY REGION, 2018-2024 (USD MILLION)

- TABLE 52. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CLADDING, BY REGION, 2025-2030 (USD MILLION)

- TABLE 53. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY ROOFING, BY REGION, 2018-2024 (USD MILLION)

- TABLE 54. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY ROOFING, BY REGION, 2025-2030 (USD MILLION)

- TABLE 55. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY WINDOWS & DOORS, BY REGION, 2018-2024 (USD MILLION)

- TABLE 56. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY WINDOWS & DOORS, BY REGION, 2025-2030 (USD MILLION)

- TABLE 57. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY EXTERIOR, 2018-2024 (USD MILLION)

- TABLE 58. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY EXTERIOR, 2025-2030 (USD MILLION)

- TABLE 59. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY INTERIOR, BY REGION, 2018-2024 (USD MILLION)

- TABLE 60. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY INTERIOR, BY REGION, 2025-2030 (USD MILLION)

- TABLE 61. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY FLOORING, BY REGION, 2018-2024 (USD MILLION)

- TABLE 62. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY FLOORING, BY REGION, 2025-2030 (USD MILLION)

- TABLE 63. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY WALLS & CEILINGS, BY REGION, 2018-2024 (USD MILLION)

- TABLE 64. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY WALLS & CEILINGS, BY REGION, 2025-2030 (USD MILLION)

- TABLE 65. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY INTERIOR, 2018-2024 (USD MILLION)

- TABLE 66. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY INTERIOR, 2025-2030 (USD MILLION)

- TABLE 67. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY STRUCTURES, BY REGION, 2018-2024 (USD MILLION)

- TABLE 68. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY STRUCTURES, BY REGION, 2025-2030 (USD MILLION)

- TABLE 69. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY FOUNDATIONS, BY REGION, 2018-2024 (USD MILLION)

- TABLE 70. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY FOUNDATIONS, BY REGION, 2025-2030 (USD MILLION)

- TABLE 71. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY FRAMEWORKS, BY REGION, 2018-2024 (USD MILLION)

- TABLE 72. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY FRAMEWORKS, BY REGION, 2025-2030 (USD MILLION)

- TABLE 73. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY STRUCTURES, 2018-2024 (USD MILLION)

- TABLE 74. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY STRUCTURES, 2025-2030 (USD MILLION)

- TABLE 75. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CONSTRUCTION TYPE, 2018-2024 (USD MILLION)

- TABLE 76. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CONSTRUCTION TYPE, 2025-2030 (USD MILLION)

- TABLE 77. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY COMMERCIAL, BY REGION, 2018-2024 (USD MILLION)

- TABLE 78. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY COMMERCIAL, BY REGION, 2025-2030 (USD MILLION)

- TABLE 79. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY INDUSTRIAL, BY REGION, 2018-2024 (USD MILLION)

- TABLE 80. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY INDUSTRIAL, BY REGION, 2025-2030 (USD MILLION)

- TABLE 81. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY INFRASTRUCTURE, BY REGION, 2018-2024 (USD MILLION)

- TABLE 82. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY INFRASTRUCTURE, BY REGION, 2025-2030 (USD MILLION)

- TABLE 83. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY RESIDENTIAL, BY REGION, 2018-2024 (USD MILLION)

- TABLE 84. GLOBAL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY RESIDENTIAL, BY REGION, 2025-2030 (USD MILLION)

- TABLE 85. AMERICAS CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY MATERIAL TYPE, 2018-2024 (USD MILLION)

- TABLE 86. AMERICAS CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY MATERIAL TYPE, 2025-2030 (USD MILLION)

- TABLE 87. AMERICAS CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY METAL, 2018-2024 (USD MILLION)

- TABLE 88. AMERICAS CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY METAL, 2025-2030 (USD MILLION)

- TABLE 89. AMERICAS CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CATEGORY, 2018-2024 (USD MILLION)

- TABLE 90. AMERICAS CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CATEGORY, 2025-2030 (USD MILLION)

- TABLE 91. AMERICAS CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY SALES CHANNEL, 2018-2024 (USD MILLION)

- TABLE 92. AMERICAS CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY SALES CHANNEL, 2025-2030 (USD MILLION)

- TABLE 93. AMERICAS CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY APPLICATION, 2018-2024 (USD MILLION)

- TABLE 94. AMERICAS CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY APPLICATION, 2025-2030 (USD MILLION)

- TABLE 95. AMERICAS CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY EXTERIOR, 2018-2024 (USD MILLION)

- TABLE 96. AMERICAS CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY EXTERIOR, 2025-2030 (USD MILLION)

- TABLE 97. AMERICAS CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY INTERIOR, 2018-2024 (USD MILLION)

- TABLE 98. AMERICAS CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY INTERIOR, 2025-2030 (USD MILLION)

- TABLE 99. AMERICAS CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY STRUCTURES, 2018-2024 (USD MILLION)

- TABLE 100. AMERICAS CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY STRUCTURES, 2025-2030 (USD MILLION)

- TABLE 101. AMERICAS CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CONSTRUCTION TYPE, 2018-2024 (USD MILLION)

- TABLE 102. AMERICAS CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CONSTRUCTION TYPE, 2025-2030 (USD MILLION)

- TABLE 103. AMERICAS CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY COUNTRY, 2018-2024 (USD MILLION)

- TABLE 104. AMERICAS CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 105. UNITED STATES CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY MATERIAL TYPE, 2018-2024 (USD MILLION)

- TABLE 106. UNITED STATES CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY MATERIAL TYPE, 2025-2030 (USD MILLION)

- TABLE 107. UNITED STATES CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY METAL, 2018-2024 (USD MILLION)

- TABLE 108. UNITED STATES CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY METAL, 2025-2030 (USD MILLION)

- TABLE 109. UNITED STATES CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CATEGORY, 2018-2024 (USD MILLION)

- TABLE 110. UNITED STATES CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CATEGORY, 2025-2030 (USD MILLION)

- TABLE 111. UNITED STATES CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY SALES CHANNEL, 2018-2024 (USD MILLION)

- TABLE 112. UNITED STATES CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY SALES CHANNEL, 2025-2030 (USD MILLION)

- TABLE 113. UNITED STATES CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY APPLICATION, 2018-2024 (USD MILLION)

- TABLE 114. UNITED STATES CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY APPLICATION, 2025-2030 (USD MILLION)

- TABLE 115. UNITED STATES CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY EXTERIOR, 2018-2024 (USD MILLION)

- TABLE 116. UNITED STATES CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY EXTERIOR, 2025-2030 (USD MILLION)

- TABLE 117. UNITED STATES CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY INTERIOR, 2018-2024 (USD MILLION)

- TABLE 118. UNITED STATES CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY INTERIOR, 2025-2030 (USD MILLION)

- TABLE 119. UNITED STATES CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY STRUCTURES, 2018-2024 (USD MILLION)

- TABLE 120. UNITED STATES CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY STRUCTURES, 2025-2030 (USD MILLION)

- TABLE 121. UNITED STATES CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CONSTRUCTION TYPE, 2018-2024 (USD MILLION)

- TABLE 122. UNITED STATES CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CONSTRUCTION TYPE, 2025-2030 (USD MILLION)

- TABLE 123. UNITED STATES CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY STATE, 2018-2024 (USD MILLION)

- TABLE 124. UNITED STATES CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY STATE, 2025-2030 (USD MILLION)

- TABLE 125. CANADA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY MATERIAL TYPE, 2018-2024 (USD MILLION)

- TABLE 126. CANADA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY MATERIAL TYPE, 2025-2030 (USD MILLION)

- TABLE 127. CANADA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY METAL, 2018-2024 (USD MILLION)

- TABLE 128. CANADA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY METAL, 2025-2030 (USD MILLION)

- TABLE 129. CANADA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CATEGORY, 2018-2024 (USD MILLION)

- TABLE 130. CANADA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CATEGORY, 2025-2030 (USD MILLION)

- TABLE 131. CANADA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY SALES CHANNEL, 2018-2024 (USD MILLION)

- TABLE 132. CANADA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY SALES CHANNEL, 2025-2030 (USD MILLION)

- TABLE 133. CANADA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY APPLICATION, 2018-2024 (USD MILLION)

- TABLE 134. CANADA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY APPLICATION, 2025-2030 (USD MILLION)

- TABLE 135. CANADA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY EXTERIOR, 2018-2024 (USD MILLION)

- TABLE 136. CANADA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY EXTERIOR, 2025-2030 (USD MILLION)

- TABLE 137. CANADA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY INTERIOR, 2018-2024 (USD MILLION)

- TABLE 138. CANADA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY INTERIOR, 2025-2030 (USD MILLION)

- TABLE 139. CANADA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY STRUCTURES, 2018-2024 (USD MILLION)

- TABLE 140. CANADA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY STRUCTURES, 2025-2030 (USD MILLION)

- TABLE 141. CANADA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CONSTRUCTION TYPE, 2018-2024 (USD MILLION)

- TABLE 142. CANADA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CONSTRUCTION TYPE, 2025-2030 (USD MILLION)

- TABLE 143. MEXICO CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY MATERIAL TYPE, 2018-2024 (USD MILLION)

- TABLE 144. MEXICO CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY MATERIAL TYPE, 2025-2030 (USD MILLION)

- TABLE 145. MEXICO CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY METAL, 2018-2024 (USD MILLION)

- TABLE 146. MEXICO CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY METAL, 2025-2030 (USD MILLION)

- TABLE 147. MEXICO CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CATEGORY, 2018-2024 (USD MILLION)

- TABLE 148. MEXICO CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CATEGORY, 2025-2030 (USD MILLION)

- TABLE 149. MEXICO CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY SALES CHANNEL, 2018-2024 (USD MILLION)

- TABLE 150. MEXICO CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY SALES CHANNEL, 2025-2030 (USD MILLION)

- TABLE 151. MEXICO CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY APPLICATION, 2018-2024 (USD MILLION)

- TABLE 152. MEXICO CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY APPLICATION, 2025-2030 (USD MILLION)

- TABLE 153. MEXICO CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY EXTERIOR, 2018-2024 (USD MILLION)

- TABLE 154. MEXICO CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY EXTERIOR, 2025-2030 (USD MILLION)

- TABLE 155. MEXICO CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY INTERIOR, 2018-2024 (USD MILLION)

- TABLE 156. MEXICO CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY INTERIOR, 2025-2030 (USD MILLION)

- TABLE 157. MEXICO CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY STRUCTURES, 2018-2024 (USD MILLION)

- TABLE 158. MEXICO CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY STRUCTURES, 2025-2030 (USD MILLION)

- TABLE 159. MEXICO CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CONSTRUCTION TYPE, 2018-2024 (USD MILLION)

- TABLE 160. MEXICO CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CONSTRUCTION TYPE, 2025-2030 (USD MILLION)

- TABLE 161. BRAZIL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY MATERIAL TYPE, 2018-2024 (USD MILLION)

- TABLE 162. BRAZIL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY MATERIAL TYPE, 2025-2030 (USD MILLION)

- TABLE 163. BRAZIL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY METAL, 2018-2024 (USD MILLION)

- TABLE 164. BRAZIL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY METAL, 2025-2030 (USD MILLION)

- TABLE 165. BRAZIL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CATEGORY, 2018-2024 (USD MILLION)

- TABLE 166. BRAZIL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CATEGORY, 2025-2030 (USD MILLION)

- TABLE 167. BRAZIL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY SALES CHANNEL, 2018-2024 (USD MILLION)

- TABLE 168. BRAZIL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY SALES CHANNEL, 2025-2030 (USD MILLION)

- TABLE 169. BRAZIL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY APPLICATION, 2018-2024 (USD MILLION)

- TABLE 170. BRAZIL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY APPLICATION, 2025-2030 (USD MILLION)

- TABLE 171. BRAZIL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY EXTERIOR, 2018-2024 (USD MILLION)

- TABLE 172. BRAZIL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY EXTERIOR, 2025-2030 (USD MILLION)

- TABLE 173. BRAZIL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY INTERIOR, 2018-2024 (USD MILLION)

- TABLE 174. BRAZIL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY INTERIOR, 2025-2030 (USD MILLION)

- TABLE 175. BRAZIL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY STRUCTURES, 2018-2024 (USD MILLION)

- TABLE 176. BRAZIL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY STRUCTURES, 2025-2030 (USD MILLION)

- TABLE 177. BRAZIL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CONSTRUCTION TYPE, 2018-2024 (USD MILLION)

- TABLE 178. BRAZIL CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CONSTRUCTION TYPE, 2025-2030 (USD MILLION)

- TABLE 179. ARGENTINA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY MATERIAL TYPE, 2018-2024 (USD MILLION)

- TABLE 180. ARGENTINA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY MATERIAL TYPE, 2025-2030 (USD MILLION)

- TABLE 181. ARGENTINA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY METAL, 2018-2024 (USD MILLION)

- TABLE 182. ARGENTINA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY METAL, 2025-2030 (USD MILLION)

- TABLE 183. ARGENTINA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CATEGORY, 2018-2024 (USD MILLION)

- TABLE 184. ARGENTINA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CATEGORY, 2025-2030 (USD MILLION)

- TABLE 185. ARGENTINA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY SALES CHANNEL, 2018-2024 (USD MILLION)

- TABLE 186. ARGENTINA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY SALES CHANNEL, 2025-2030 (USD MILLION)

- TABLE 187. ARGENTINA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY APPLICATION, 2018-2024 (USD MILLION)

- TABLE 188. ARGENTINA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY APPLICATION, 2025-2030 (USD MILLION)

- TABLE 189. ARGENTINA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY EXTERIOR, 2018-2024 (USD MILLION)

- TABLE 190. ARGENTINA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY EXTERIOR, 2025-2030 (USD MILLION)

- TABLE 191. ARGENTINA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY INTERIOR, 2018-2024 (USD MILLION)

- TABLE 192. ARGENTINA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY INTERIOR, 2025-2030 (USD MILLION)

- TABLE 193. ARGENTINA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY STRUCTURES, 2018-2024 (USD MILLION)

- TABLE 194. ARGENTINA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY STRUCTURES, 2025-2030 (USD MILLION)

- TABLE 195. ARGENTINA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CONSTRUCTION TYPE, 2018-2024 (USD MILLION)

- TABLE 196. ARGENTINA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CONSTRUCTION TYPE, 2025-2030 (USD MILLION)

- TABLE 197. EUROPE, MIDDLE EAST & AFRICA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY MATERIAL TYPE, 2018-2024 (USD MILLION)

- TABLE 198. EUROPE, MIDDLE EAST & AFRICA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY MATERIAL TYPE, 2025-2030 (USD MILLION)

- TABLE 199. EUROPE, MIDDLE EAST & AFRICA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY METAL, 2018-2024 (USD MILLION)

- TABLE 200. EUROPE, MIDDLE EAST & AFRICA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY METAL, 2025-2030 (USD MILLION)

- TABLE 201. EUROPE, MIDDLE EAST & AFRICA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CATEGORY, 2018-2024 (USD MILLION)

- TABLE 202. EUROPE, MIDDLE EAST & AFRICA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CATEGORY, 2025-2030 (USD MILLION)

- TABLE 203. EUROPE, MIDDLE EAST & AFRICA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY SALES CHANNEL, 2018-2024 (USD MILLION)

- TABLE 204. EUROPE, MIDDLE EAST & AFRICA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY SALES CHANNEL, 2025-2030 (USD MILLION)

- TABLE 205. EUROPE, MIDDLE EAST & AFRICA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY APPLICATION, 2018-2024 (USD MILLION)

- TABLE 206. EUROPE, MIDDLE EAST & AFRICA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY APPLICATION, 2025-2030 (USD MILLION)

- TABLE 207. EUROPE, MIDDLE EAST & AFRICA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY EXTERIOR, 2018-2024 (USD MILLION)

- TABLE 208. EUROPE, MIDDLE EAST & AFRICA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY EXTERIOR, 2025-2030 (USD MILLION)

- TABLE 209. EUROPE, MIDDLE EAST & AFRICA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY INTERIOR, 2018-2024 (USD MILLION)

- TABLE 210. EUROPE, MIDDLE EAST & AFRICA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY INTERIOR, 2025-2030 (USD MILLION)

- TABLE 211. EUROPE, MIDDLE EAST & AFRICA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY STRUCTURES, 2018-2024 (USD MILLION)

- TABLE 212. EUROPE, MIDDLE EAST & AFRICA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY STRUCTURES, 2025-2030 (USD MILLION)

- TABLE 213. EUROPE, MIDDLE EAST & AFRICA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CONSTRUCTION TYPE, 2018-2024 (USD MILLION)

- TABLE 214. EUROPE, MIDDLE EAST & AFRICA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CONSTRUCTION TYPE, 2025-2030 (USD MILLION)

- TABLE 215. EUROPE, MIDDLE EAST & AFRICA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY COUNTRY, 2018-2024 (USD MILLION)

- TABLE 216. EUROPE, MIDDLE EAST & AFRICA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 217. UNITED KINGDOM CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY MATERIAL TYPE, 2018-2024 (USD MILLION)

- TABLE 218. UNITED KINGDOM CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY MATERIAL TYPE, 2025-2030 (USD MILLION)

- TABLE 219. UNITED KINGDOM CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY METAL, 2018-2024 (USD MILLION)

- TABLE 220. UNITED KINGDOM CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY METAL, 2025-2030 (USD MILLION)

- TABLE 221. UNITED KINGDOM CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CATEGORY, 2018-2024 (USD MILLION)

- TABLE 222. UNITED KINGDOM CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CATEGORY, 2025-2030 (USD MILLION)

- TABLE 223. UNITED KINGDOM CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY SALES CHANNEL, 2018-2024 (USD MILLION)

- TABLE 224. UNITED KINGDOM CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY SALES CHANNEL, 2025-2030 (USD MILLION)

- TABLE 225. UNITED KINGDOM CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY APPLICATION, 2018-2024 (USD MILLION)

- TABLE 226. UNITED KINGDOM CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY APPLICATION, 2025-2030 (USD MILLION)

- TABLE 227. UNITED KINGDOM CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY EXTERIOR, 2018-2024 (USD MILLION)

- TABLE 228. UNITED KINGDOM CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY EXTERIOR, 2025-2030 (USD MILLION)

- TABLE 229. UNITED KINGDOM CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY INTERIOR, 2018-2024 (USD MILLION)

- TABLE 230. UNITED KINGDOM CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY INTERIOR, 2025-2030 (USD MILLION)

- TABLE 231. UNITED KINGDOM CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY STRUCTURES, 2018-2024 (USD MILLION)

- TABLE 232. UNITED KINGDOM CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY STRUCTURES, 2025-2030 (USD MILLION)

- TABLE 233. UNITED KINGDOM CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CONSTRUCTION TYPE, 2018-2024 (USD MILLION)

- TABLE 234. UNITED KINGDOM CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CONSTRUCTION TYPE, 2025-2030 (USD MILLION)

- TABLE 235. GERMANY CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY MATERIAL TYPE, 2018-2024 (USD MILLION)

- TABLE 236. GERMANY CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY MATERIAL TYPE, 2025-2030 (USD MILLION)

- TABLE 237. GERMANY CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY METAL, 2018-2024 (USD MILLION)

- TABLE 238. GERMANY CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY METAL, 2025-2030 (USD MILLION)

- TABLE 239. GERMANY CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CATEGORY, 2018-2024 (USD MILLION)

- TABLE 240. GERMANY CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CATEGORY, 2025-2030 (USD MILLION)

- TABLE 241. GERMANY CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY SALES CHANNEL, 2018-2024 (USD MILLION)

- TABLE 242. GERMANY CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY SALES CHANNEL, 2025-2030 (USD MILLION)

- TABLE 243. GERMANY CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY APPLICATION, 2018-2024 (USD MILLION)

- TABLE 244. GERMANY CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY APPLICATION, 2025-2030 (USD MILLION)

- TABLE 245. GERMANY CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY EXTERIOR, 2018-2024 (USD MILLION)

- TABLE 246. GERMANY CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY EXTERIOR, 2025-2030 (USD MILLION)

- TABLE 247. GERMANY CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY INTERIOR, 2018-2024 (USD MILLION)

- TABLE 248. GERMANY CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY INTERIOR, 2025-2030 (USD MILLION)

- TABLE 249. GERMANY CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY STRUCTURES, 2018-2024 (USD MILLION)

- TABLE 250. GERMANY CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY STRUCTURES, 2025-2030 (USD MILLION)

- TABLE 251. GERMANY CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CONSTRUCTION TYPE, 2018-2024 (USD MILLION)

- TABLE 252. GERMANY CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CONSTRUCTION TYPE, 2025-2030 (USD MILLION)

- TABLE 253. FRANCE CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY MATERIAL TYPE, 2018-2024 (USD MILLION)

- TABLE 254. FRANCE CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY MATERIAL TYPE, 2025-2030 (USD MILLION)

- TABLE 255. FRANCE CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY METAL, 2018-2024 (USD MILLION)

- TABLE 256. FRANCE CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY METAL, 2025-2030 (USD MILLION)

- TABLE 257. FRANCE CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CATEGORY, 2018-2024 (USD MILLION)

- TABLE 258. FRANCE CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CATEGORY, 2025-2030 (USD MILLION)

- TABLE 259. FRANCE CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY SALES CHANNEL, 2018-2024 (USD MILLION)

- TABLE 260. FRANCE CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY SALES CHANNEL, 2025-2030 (USD MILLION)

- TABLE 261. FRANCE CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY APPLICATION, 2018-2024 (USD MILLION)

- TABLE 262. FRANCE CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY APPLICATION, 2025-2030 (USD MILLION)

- TABLE 263. FRANCE CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY EXTERIOR, 2018-2024 (USD MILLION)

- TABLE 264. FRANCE CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY EXTERIOR, 2025-2030 (USD MILLION)

- TABLE 265. FRANCE CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY INTERIOR, 2018-2024 (USD MILLION)

- TABLE 266. FRANCE CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY INTERIOR, 2025-2030 (USD MILLION)

- TABLE 267. FRANCE CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY STRUCTURES, 2018-2024 (USD MILLION)

- TABLE 268. FRANCE CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY STRUCTURES, 2025-2030 (USD MILLION)

- TABLE 269. FRANCE CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CONSTRUCTION TYPE, 2018-2024 (USD MILLION)

- TABLE 270. FRANCE CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CONSTRUCTION TYPE, 2025-2030 (USD MILLION)

- TABLE 271. RUSSIA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY MATERIAL TYPE, 2018-2024 (USD MILLION)

- TABLE 272. RUSSIA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY MATERIAL TYPE, 2025-2030 (USD MILLION)

- TABLE 273. RUSSIA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY METAL, 2018-2024 (USD MILLION)

- TABLE 274. RUSSIA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY METAL, 2025-2030 (USD MILLION)

- TABLE 275. RUSSIA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CATEGORY, 2018-2024 (USD MILLION)

- TABLE 276. RUSSIA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CATEGORY, 2025-2030 (USD MILLION)

- TABLE 277. RUSSIA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY SALES CHANNEL, 2018-2024 (USD MILLION)

- TABLE 278. RUSSIA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY SALES CHANNEL, 2025-2030 (USD MILLION)

- TABLE 279. RUSSIA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY APPLICATION, 2018-2024 (USD MILLION)

- TABLE 280. RUSSIA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY APPLICATION, 2025-2030 (USD MILLION)

- TABLE 281. RUSSIA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY EXTERIOR, 2018-2024 (USD MILLION)

- TABLE 282. RUSSIA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY EXTERIOR, 2025-2030 (USD MILLION)

- TABLE 283. RUSSIA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY INTERIOR, 2018-2024 (USD MILLION)

- TABLE 284. RUSSIA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY INTERIOR, 2025-2030 (USD MILLION)

- TABLE 285. RUSSIA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY STRUCTURES, 2018-2024 (USD MILLION)

- TABLE 286. RUSSIA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY STRUCTURES, 2025-2030 (USD MILLION)

- TABLE 287. RUSSIA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CONSTRUCTION TYPE, 2018-2024 (USD MILLION)

- TABLE 288. RUSSIA CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CONSTRUCTION TYPE, 2025-2030 (USD MILLION)

- TABLE 289. ITALY CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY MATERIAL TYPE, 2018-2024 (USD MILLION)

- TABLE 290. ITALY CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY MATERIAL TYPE, 2025-2030 (USD MILLION)

- TABLE 291. ITALY CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY METAL, 2018-2024 (USD MILLION)

- TABLE 292. ITALY CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY METAL, 2025-2030 (USD MILLION)

- TABLE 293. ITALY CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CATEGORY, 2018-2024 (USD MILLION)

- TABLE 294. ITALY CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY CATEGORY, 2025-2030 (USD MILLION)

- TABLE 295. ITALY CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY SALES CHANNEL, 2018-2024 (USD MILLION)

- TABLE 296. ITALY CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY SALES CHANNEL, 2025-2030 (USD MILLION)

- TABLE 297. ITALY CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY APPLICATION, 2018-2024 (USD MILLION)

- TABLE 298. ITALY CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY APPLICATION, 2025-2030 (USD MILLION)

- TABLE 299. ITALY CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY EXTERIOR, 2018-2024 (USD MILLION)

- TABLE 300. ITALY CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY EXTERIOR, 2025-2030 (USD MILLION)

- TABLE 301. ITALY CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY INTERIOR, 2018-2024 (USD MILLION)

- TABLE 302. ITALY CONSTRUCTION & BUILDING MATERIALS MARKET SIZE, BY INTERIOR, 2025-2030 (USD

The Construction & Building Materials Market was valued at USD 2.04 trillion in 2024 and is projected to grow to USD 2.16 trillion in 2025, with a CAGR of 5.93%, reaching USD 2.89 trillion by 2030.

| KEY MARKET STATISTICS | |

|---|---|

| Base Year [2024] | USD 2.04 trillion |

| Estimated Year [2025] | USD 2.16 trillion |

| Forecast Year [2030] | USD 2.89 trillion |

| CAGR (%) | 5.93% |

Understanding the Modern Dynamics Shaping the Construction and Building Materials Industry in Response to Emerging Market Trends and Regulatory Innovations

The construction and building materials sector stands at a pivotal crossroads, influenced simultaneously by rapid urbanization and escalating sustainability demands. As global populations shift toward dense metropolitan hubs, infrastructure projects and residential developments are intensifying, creating complex supply chain dynamics and driving the need for innovative material solutions. Simultaneously, heightened environmental regulations and green building certifications are compelling manufacturers and contractors to reevaluate traditional processes in favor of low-carbon alternatives.

In parallel, technological innovations such as digital project management, Building Information Modeling (BIM), and advanced manufacturing techniques like 3D printing are revolutionizing how materials are specified, produced, and delivered. These developments not only streamline construction timelines but also foster data-driven decision-making, resulting in improved quality control and reduced waste. Moreover, integrating automation across manufacturing plants and job sites is beginning to redefine cost structures and labor requirements, creating both opportunities and challenges for stakeholders.

Against this backdrop of urban growth, regulatory evolution, and technological acceleration, it becomes essential to understand the forces shaping the industry's trajectory. This introduction lays the groundwork for analyzing transformative shifts, tariff impacts, market segmentation, regional trends, leading company strategies, and actionable recommendations that follow. By establishing this contextual framework, decision-makers can better navigate the complexities of a market in flux and position themselves for sustainable success.

Examining the Pivotal Transformations Redefining Construction Materials Markets Driven by Sustainability Demands and Digital Technology Advancements

In recent years, sustainability has emerged as a cornerstone of strategic decision-making within the construction materials sphere. Manufacturers are increasingly investing in recycled aggregates, bio-based insulation, and low-emission cement alternatives to comply with stringent environmental mandates. Concurrently, the drive toward circular economy principles is influencing product design, with companies exploring take-back programs and material reuse strategies to minimize waste streams.

Digital transformation is also rewriting the industry playbook. The expansion of cloud-based collaboration platforms and artificial intelligence-powered analytics has enhanced project forecasting and risk mitigation. As a result, material suppliers are able to synchronize production schedules with on-site requirements, reducing delays and cost overruns. Moreover, blockchain pilots for supply chain traceability are gaining traction, promising to enhance transparency and ensure compliance with ethical sourcing standards.

The shift toward modular and off-site construction methods represents another paradigm change. Prefabricated components, assembled under controlled conditions, are delivering faster build times, improved quality, and enhanced safety. This evolution is prompting material manufacturers to adapt their offerings, providing customized panel systems, connection hardware, and integrated services that align with modular project specifications. Taken together, these transformative shifts underscore a redefined landscape in which sustainability imperatives, digital innovation, and process optimization converge to establish new benchmarks.

Assessing the Comprehensive Implications of 2025 United States Tariffs on Building Material Supply Chains, Cost Structures, and Competitive Dynamics

The implementation of revised United States tariffs in 2025 has exerted a multifaceted influence on global building material supply chains. Elevated duties on select metal imports triggered an initial uptick in domestic production initiatives, as manufacturers sought to mitigate cost pressures and safeguard margin integrity. At the same time, procurement teams began exploring alternate sources in neighboring markets to spread risk and reduce reliance on heavily impacted trade lanes.

Furthermore, these tariff adjustments have accelerated strategic realignments across supplier networks. Stakeholders have increasingly prioritized vertical integration and local partnerships to enhance supply chain visibility and control. In response, certain regional producers have expanded capacity investments, aiming to capture market share amid shifting import dynamics. This repositioning has prompted global contractors to reevaluate vendor portfolios and adopt more agile sourcing frameworks.

Beyond cost considerations, the 2025 tariff landscape has also influenced material innovation. Companies have intensified research into composite formulations and hybrid assemblies that reduce reliance on high-duty inputs. Concurrently, emerging green procurement policies among public agencies are reinforcing the move toward domestically produced, low-embodied-carbon alternatives. As a result, the industry finds itself navigating a new equilibrium where trade policy, cost management, and sustainability objectives intersect.

Revealing Critical Market Segmentation Insights Across Material Types, Categories, Sales Channels, Applications, and Construction Types for Strategic Decision Making

When observing the market through the lens of material type, the analysis encompasses traditional masonry products such as bricks and blocks, the ubiquitous concrete and cement segment, specialized insulation materials, a diverse set of metals including aluminum, copper, iron, and steel, natural stone and aggregates, and renewable wood solutions. Each category demonstrates distinct performance attributes and cost profiles, guiding architects and engineers toward optimal selections for specific applications.

Transitioning to product classification, the study differentiates architectural materials that shape aesthetic and functional facade elements, auxiliary materials that provide essential bonding, sealing, and finishing capabilities, and structural materials that bear primary loads in buildings and infrastructure. This categorization reveals divergent growth drivers, as architectural trends may be propelled by design movements while structural innovations hinge on engineering advancements.

Analyzing distribution channels uncovers a duality between traditional offline outlets, such as building supply centers and direct contractor networks, and online sales platforms that offer streamlined ordering, broader product visibility, and digital inventory management. This evolution in channel preference highlights an ongoing migration toward e-commerce integration, even as established relationships continue to influence procurement decisions.

Exploring end-use applications, the examination spans exterior systems-cladding, roofing, windows, and doors-interior solutions including flooring and wall and ceiling finishes, and core structural components encompassing foundations and frameworks. Each application segment showcases unique performance requirements and regulatory considerations, influencing material selection and installation processes.

Finally, construction type segmentation considers the environments in which materials are deployed, from commercial office and retail projects to heavy industrial facilities, critical infrastructure undertakings, and residential developments. This perspective illuminates how sector-specific demands-from durability and scale to customization and cost constraints-shape innovation trajectories and investment priorities.

Uncovering Essential Regional Dynamics Shaping the Construction and Building Materials Market Across the Americas, EMEA, and Asia-Pacific Growth Destinations

In the Americas, infrastructure modernization programs and urban redevelopment initiatives are generating robust demand for resilient and sustainable building solutions. Governments and private investors alike are channeling funds into transit expansions, green retrofits, and flood-mitigation projects. These undertakings are encouraging the adoption of high-performance concrete formulations, advanced composite reinforcements, and energy-efficient envelope systems that align with net-zero objectives.

Across Europe, the Middle East, and Africa, regulatory frameworks are increasingly harmonized around carbon reduction targets and circular economy principles. In response, manufacturers are collaborating with certification bodies to develop environmental product declarations and life-cycle assessments that validate performance claims. Concurrently, the rise of public-private partnerships in major Middle Eastern urban developments is creating opportunities for modular construction and integrated smart building deployments.

Meanwhile, the Asia-Pacific region continues to experience unparalleled urbanization, with mega-cities driving a surge in both residential and commercial construction. Local material producers are scaling operations to meet this growth, often leveraging cost advantages and proximity to emerging markets. At the same time, governments are incentivizing green building certifications and fostering domestic innovation clusters focused on advanced insulation, sustainable timber products, and next-generation cement technologies. Together, these regional dynamics underscore how divergent policy environments and investment priorities are shaping the global market's trajectory.

Highlighting Strategic Movements and Competitive Positioning of Leading Companies Transforming the Construction and Building Materials Landscape Globally

Leading companies in the construction and building materials arena are engaging in a spectrum of strategic initiatives to bolster their competitive positioning. Some global players are pursuing mergers and acquisitions to expand geographic reach and diversify portfolios, merging regional expertise with innovative product lines. Others are forging joint ventures and strategic alliances to access new technologies, enhance production capabilities, and accelerate market entry in high-growth areas.

Investment in research and development remains a cornerstone of competitive differentiation. Top firms are allocating capital toward next-generation materials such as carbon-capture cement, bio-composites, and smart-infused surfaces that can monitor structural health. In addition, digital transformation initiatives are central to corporate roadmaps-pilot programs integrating IoT sensors into supply chains are enabling real-time tracking of shipments, and advanced analytics platforms are unlocking predictive maintenance insights for manufacturing facilities.

Sustainability leadership is also taking center stage, with corporations publishing comprehensive environmental, social, and governance (ESG) reports that outline decarbonization pathways, circularity targets, and community engagement efforts. As procurement teams and regulatory bodies intensify scrutiny, these declarations serve as both a compliance mechanism and a brand differentiator, reinforcing the link between corporate responsibility and market credibility.

Delivering Actionable Strategic Recommendations for Industry Leaders to Navigate Market Complexities, Embrace Innovation, and Secure a Competitive Edge

Industry leaders should prioritize a dual focus on innovation and collaboration. By establishing cross-sector partnerships with technology providers, research institutions, and startups, organizations can accelerate the development of sustainable materials and streamline adoption of advanced manufacturing techniques. This collaborative ethos will foster shared intellectual property and scale solutions more rapidly across global markets.

Simultaneously, investing in digital supply chain platforms that integrate real-time data, predictive analytics, and blockchain traceability will enhance resilience against geopolitical disruptions and tariff fluctuations. Companies that implement end-to-end visibility tools will be better equipped to anticipate risks, optimize inventory levels, and respond swiftly to changing project timelines.

Another critical recommendation is to adopt modular and off-site construction methodologies where feasible. Not only do these approaches reduce on-site labor demands and safety risks, but they also enable pre-validated quality standards and faster project delivery. By collaborating with design-build firms and modular fabricators early in the project lifecycle, material suppliers can tailor products to exact specifications and unlock new revenue streams.

Finally, embedding sustainability metrics into every decision-from R&D roadmaps to capital expenditure reviews-will ensure that environmental, social, and governance objectives are integrated into core business strategies. Leaders who transparently measure and communicate progress against these goals will enhance stakeholder trust and position themselves as market frontrunners.

Outlining the Rigorous Research Methodology Employed to Analyze Data, Validate Findings, and Ensure Comprehensive Coverage of the Construction Materials Market

This report is underpinned by a rigorous, multi-stage research methodology that combines primary and secondary data sources. Initially, extensive secondary research was conducted, leveraging industry publications, regulatory frameworks, trade associations, and technical journals to establish a foundational understanding of market dynamics and historical trends.

Building on these insights, primary research efforts included in-depth interviews with key stakeholders such as material manufacturers, construction contractors, architects, and regulatory authorities. These qualitative discussions provided perspective on emerging challenges, innovation roadmaps, and regional policy implications. Simultaneously, quantitative surveys were deployed across diverse end-user segments to validate product adoption rates, procurement preferences, and investment priorities.

To ensure data integrity, responses were triangulated with company financial reports, publicly available project databases, and proprietary shipment records. Advanced analytics techniques, including regression analysis and scenario modeling, were utilized to interpret relationships between macroeconomic indicators, tariff developments, and material demand patterns. Finally, all findings were subjected to a multi-layered validation process involving expert panel reviews and stakeholder feedback loops to guarantee accuracy and comprehensive coverage.

Synthesizing Core Findings and Strategic Considerations to Inform Stakeholder Decisions and Propel Future Growth in the Construction Materials Sector

The analysis reveals that converging forces-sustainability imperatives, digital transformation, modular construction, and evolving trade policies-are collectively reshaping the construction and building materials industry. Stakeholders who effectively integrate circular economy principles with technological innovation will gain distinct competitive advantages, while those relying on legacy practices may face margin compression and regulatory challenges.

Moreover, segmentation analysis underscores that performance requirements vary significantly across material types, categories, sales channels, application areas, and construction sectors. Tailored strategies that align product development and distribution models with these nuanced demands will drive differentiation and customer loyalty. Regional insights further emphasize the importance of localized approaches, as policy environments and growth trajectories differ markedly between the Americas, EMEA, and Asia-Pacific markets.

Finally, the strategic moves by leading companies-embracing M&A, prioritizing R&D, and embedding sustainability within corporate governance-highlight a landscape in which agility and innovation are paramount. Organizations that adopt a proactive posture, invest in collaborative ecosystems, and leverage advanced analytics will be well positioned to navigate uncertainty and capture new opportunities.

Table of Contents

1. Preface

- 1.1. Objectives of the Study

- 1.2. Market Segmentation & Coverage

- 1.3. Years Considered for the Study

- 1.4. Currency & Pricing

- 1.5. Language

- 1.6. Stakeholders

2. Research Methodology

- 2.1. Define: Research Objective

- 2.2. Determine: Research Design

- 2.3. Prepare: Research Instrument

- 2.4. Collect: Data Source

- 2.5. Analyze: Data Interpretation

- 2.6. Formulate: Data Verification

- 2.7. Publish: Research Report

- 2.8. Repeat: Report Update

3. Executive Summary

4. Market Overview

- 4.1. Introduction

- 4.2. Market Sizing & Forecasting

5. Market Dynamics

- 5.1. Rising adoption of sustainable and eco-friendly building materials to significantly reduce environmental impact in construction projects

- 5.2. Increasing integration of smart technology in construction materials to enhance overall building efficiency and operational performance

- 5.3. Growing focus on energy-efficient construction materials to meet stringent global carbon reduction and climate goals

- 5.4. Growing demand for lightweight and high-performance construction composites in urban development

- 5.5. Expansion of prefabricated and modular construction methods for faster project completion

- 5.6. Advancements in nanotechnology improving durability and functionality of construction materials

- 5.7. Surge in use of recycled and waste-derived materials to promote circular economy in construction

- 5.8. Implementation of stringent building codes driving innovation in fire-resistant materials

- 5.9. Rising popularity of green roofs and walls incorporating advanced waterproofing and insulation

- 5.10. Development of self-healing concrete and other innovative materials enhancing infrastructure longevity

6. Market Insights

- 6.1. Porter's Five Forces Analysis

- 6.2. PESTLE Analysis

7. Cumulative Impact of United States Tariffs 2025

8. Construction & Building Materials Market, by Material Type

- 8.1. Introduction

- 8.2. Bricks & Blocks

- 8.3. Concrete & Cement

- 8.4. Insulation Materials

- 8.5. Metal

- 8.5.1. Aluminium

- 8.5.2. Copper

- 8.5.3. Iron

- 8.5.4. Steel

- 8.6. Stone & Aggregates

- 8.7. Wood

9. Construction & Building Materials Market, by Category

- 9.1. Introduction

- 9.2. Architectural Materials

- 9.3. Auxiliary Materials

- 9.4. Structural Materials

10. Construction & Building Materials Market, by Sales Channel

- 10.1. Introduction

- 10.2. Offline Sales

- 10.3. Online Sales

11. Construction & Building Materials Market, by Application

- 11.1. Introduction

- 11.2. Exterior

- 11.2.1. Cladding

- 11.2.2. Roofing

- 11.2.3. Windows & Doors

- 11.3. Interior

- 11.3.1. Flooring

- 11.3.2. Walls & Ceilings

- 11.4. Structures

- 11.4.1. Foundations

- 11.4.2. Frameworks

12. Construction & Building Materials Market, by Construction Type

- 12.1. Introduction

- 12.2. Commercial

- 12.3. Industrial

- 12.4. Infrastructure

- 12.5. Residential

13. Americas Construction & Building Materials Market

- 13.1. Introduction

- 13.2. United States

- 13.3. Canada

- 13.4. Mexico

- 13.5. Brazil

- 13.6. Argentina

14. Europe, Middle East & Africa Construction & Building Materials Market

- 14.1. Introduction

- 14.2. United Kingdom

- 14.3. Germany

- 14.4. France

- 14.5. Russia

- 14.6. Italy

- 14.7. Spain

- 14.8. United Arab Emirates

- 14.9. Saudi Arabia

- 14.10. South Africa

- 14.11. Denmark

- 14.12. Netherlands

- 14.13. Qatar

- 14.14. Finland

- 14.15. Sweden

- 14.16. Nigeria

- 14.17. Egypt

- 14.18. Turkey

- 14.19. Israel

- 14.20. Norway

- 14.21. Poland

- 14.22. Switzerland

15. Asia-Pacific Construction & Building Materials Market

- 15.1. Introduction

- 15.2. China

- 15.3. India

- 15.4. Japan

- 15.5. Australia

- 15.6. South Korea

- 15.7. Indonesia

- 15.8. Thailand

- 15.9. Philippines

- 15.10. Malaysia

- 15.11. Singapore

- 15.12. Vietnam

- 15.13. Taiwan

16. Competitive Landscape

- 16.1. Market Share Analysis, 2024

- 16.2. FPNV Positioning Matrix, 2024

- 16.3. Competitive Analysis

- 16.3.1. Alghanim Industries

- 16.3.2. Ambuja Cements Ltd. by Adani Group

- 16.3.3. Anhui Conch Cement Co., Ltd.

- 16.3.4. ArcelorMittal S.A.

- 16.3.5. Armstrong World Industries, Inc.

- 16.3.6. ASIA CEMENT CORPORATION

- 16.3.7. Asia Cement Public Company Ltd.

- 16.3.8. Atad Steel Structure Corporation

- 16.3.9. Athabasca Minerals Inc.

- 16.3.10. BASF SE

- 16.3.11. BBMG Corporation

- 16.3.12. Binderholz Group

- 16.3.13. Boral Limited

- 16.3.14. Buzzi Unicem S.p.A.

- 16.3.15. CEMEX S.A.B. de C.V.

- 16.3.16. China National Building Material Group Co., Ltd.

- 16.3.17. Compagnie de Saint-Gobain S.A.

- 16.3.18. CRH PLC

- 16.3.19. Heidelberg Materials

- 16.3.20. Holcim Ltd

- 16.3.21. James Hardie Industries PLC

- 16.3.22. JFE Holdings, Inc.

- 16.3.23. JSW Steel

- 16.3.24. Kingspan Group PLC

- 16.3.25. Knauf KG

- 16.3.26. Lindab Group

- 16.3.27. LIXIL Group Corporation

- 16.3.28. Martin Marietta Materials, Inc

- 16.3.29. Memaar Building Systems

- 16.3.30. Mitsubishi Chemical Group Corporation

- 16.3.31. Nippon Steel Corporation

- 16.3.32. Nucor Corporation

- 16.3.33. Owens Corning

- 16.3.34. Stora Enso Oyj

- 16.3.35. Sumitomo Corporation

- 16.3.36. Taiheiyo Cement Corporation

- 16.3.37. Taiwan Cement Corporation

- 16.3.38. Tata Steel Limited

- 16.3.39. Vulcan Materials Company

- 16.3.40. Wienerberger AG