|

|

市場調査レポート

商品コード

1503374

フローケミストリーの2030年までの市場予測:製品タイプ、化学反応タイプ、動作モード、運用規模、技術、用途、地域別の世界分析Flow Chemistry Market Forecasts to 2030 - Global Analysis By Product, Chemical Reactions Type, Mode of Operation, Scale of Operation, Technology, Application and By Geography |

||||||

カスタマイズ可能

|

|||||||

| フローケミストリーの2030年までの市場予測:製品タイプ、化学反応タイプ、動作モード、運用規模、技術、用途、地域別の世界分析 |

|

出版日: 2024年06月06日

発行: Stratistics Market Research Consulting

ページ情報: 英文 200+ Pages

納期: 2~3営業日

|

全表示

- 概要

- 図表

- 目次

Stratistics MRCによると、フローケミストリーの世界市場は2024年に19億5,000万米ドルを占め、2030年には35億4,000万米ドルに達すると予測され、予測期間中のCAGRは12.4%です。

フローケミストリーは化学合成の一手法であり、反応器を通して反応物質を連続的に送り込むことで、温度、圧力、混合比などの反応条件を正確に制御することができます。フローケミストリーは反応の迅速な最適化を可能にし、複雑な分子の合成を容易にします。このアプローチは、安全性、スケーラビリティ、効率性の向上など、従来のバッチ処理に比べいくつかの利点があります。

欧州委員会によると、ドイツの研究開発費総額は1,308億8,000万米ドルに達し、2021年の1,217億5,000万米ドルから増加しました。同委員会はまた、「化学産業の移行経路」を通じて、化学産業を支援するための資金調達に関するガイダンスを導入しました。

化学者教育への注目の高まり

教育を受けた化学者は、化学合成における安全性、拡張性、効率性の向上など、連続フロープロセスの利点を活用するのに適しています。このような理解の深まりは、医薬品、ファインケミカル、その他の産業における技術革新を促進し、市場の拡大を促進します。さらに、フローケミストリーの研究開発において学界と産業界がより密接に協力することで、この分野は加速度的に進歩し、世界的に広く採用されるようになります。

複雑な統合

フローケミストリーにおける統合の複雑さは、連続プロセスにおける反応条件、溶媒適合性、試薬供給など、複数の変数を最適化する課題から生じる。産業界は、こうした統合の課題によってフローケミストリーの適応にハードルを感じ、この有望な技術への広範な採用や投資の妨げとなります。この複雑さは、開発コストの増加、専門知識の必要性、潜在的な拡張性の制限によって、市場の成長を妨げます。

ファインケミカル分野からの関心の高まり

フローケミストリーは、反応の正確な制御、安全性の向上、効率の向上を実現し、ファインケミカルの複雑な合成要件に合致しています。この技術は、反応の連続処理を可能にし、収率を最適化すると同時に、ダウンタイムや廃棄物に関連するコストを削減します。ファインケミカル業界では、その拡張性と持続可能性の利点からフローケミストリーの採用が進んでおり、医薬品、農薬、特殊化学品などの多様な用途に対応することで、市場の拡大を促進すると期待されています。

認識と採用の遅れ

フローケミストリーに対する認識と採用の遅れは、バッチ処理における慣習の定着と、大規模な再教育とインフラ投資の必要性によって生じる。この遅れは、効率改善、拡張性、廃棄物削減といった技術の利点の受容を遅らせ、市場成長の妨げとなります。産業界は、不慣れなことや認識されているリスクのために移行に慎重であり、フローケミストリー市場の拡大は、潜在的な利点にもかかわらず制限されています。

COVID-19の影響

COVID-19の大流行は当初、サプライチェーンの混乱、労働力の減少、研究開発活動の遅れにより、フローケミストリー市場を混乱させました。しかし、遠隔操作や最小限の人的介入といった利点を提供するフローケミストリーのような連続製造技術の回復力も浮き彫りになった。このため、世界の健康課題が続く中、医薬品やファインケミカル製造用のフローケミストリーシステムに対する関心と投資が高まっています。

予測期間中、ラボスケールセグメントが最大になる見込み

ラボスケールセグメントは有利な成長が見込まれます。ラボスケール・フローケミストリーでは、小規模なシステムを通して、試薬の制御された連続的な流れの中で化学反応を行う。温度、圧力、滞留時間などの反応パラメーターを正確に制御できるため、従来のバッチ法に比べて安全性と効率が向上します。このアプローチは、材料消費と廃棄物の発生を抑えながら迅速な実験を可能にし、研究および小規模生産環境における有機分子のプロセス開発、最適化、合成に理想的です。

予測期間中、医薬品分野のCAGRが最も高くなると予想される

医薬品分野は予測期間中に最も速いCAGRの成長が見込まれます。医薬品アプリケーションにおけるフローケミストリーは、連続プロセスにおける反応条件の精密な制御を可能にすることで、医薬品合成に革命をもたらします。効率性、安全性、拡張性を高め、複雑な分子の迅速な合成を促進し、生産コストを削減します。この技術は創薬、原薬の合成、新規製剤の開発を加速し、医薬品の革新と効率化に大きく貢献します。

最大のシェアを占める地域

アジア太平洋地域のフローケミストリー市場は、工業化の進展、製薬・化学分野の急速な拡大、持続可能な製造方法を支援する政府の取り組みなどを背景に、力強い成長を遂げています。中国、インド、日本、韓国のような国々は、強力な製造能力と研究開発への投資の増加により、有力なプレーヤーとなっています。同地域は、労働コストの低下、インフラの改善、先端技術の採用増加などの恩恵を受けています。

CAGRが最も高い地域:

北米では、フローケミストリー市場は製薬、化学、学術分野での採用が多いのが特徴です。この地域は、先進的なインフラ、強固な研究エコシステム、主要な市場プレーヤーやイノベーターが集中しているなどの利点があります。北米市場はダイナミックであり、フローリアクター技術の継続的な進歩と研究開発への投資の増加により、世界のフローケミストリー市場における地位を高めています。

無料カスタマイズサービス:

本レポートをご購読のお客様には、以下の無料カスタマイズオプションのいずれかをご利用いただけます:

- 企業プロファイル

- 追加市場プレイヤーの包括的プロファイリング(3社まで)

- 主要企業のSWOT分析(3社まで)

- 地域セグメンテーション

- 顧客の関心に応じた主要国の市場推計・予測・CAGR(注:フィージビリティチェックによる)

- 競合ベンチマーキング

- 製品ポートフォリオ、地理的プレゼンス、戦略的提携に基づく主要企業のベンチマーキング

目次

第1章 エグゼクティブサマリー

第2章 序文

- 概要

- ステークホルダー

- 調査範囲

- 調査手法

- データマイニング

- データ分析

- データ検証

- 調査アプローチ

- 調査情報源

- 1次調査情報源

- 2次調査情報源

- 前提条件

第3章 市場動向分析

- 促進要因

- 抑制要因

- 機会

- 脅威

- 製品分析

- 技術分析

- 用途分析

- 新興市場

- COVID-19の影響

第4章 ポーターのファイブフォース分析

- 供給企業の交渉力

- 買い手の交渉力

- 代替品の脅威

- 新規参入業者の脅威

- 競争企業間の敵対関係

第5章 世界のフローケミストリー市場:製品別

- 連続フローリアクター

- マイクロリアクター

- 連続撹拌タンク反応器(CSTR)

- プラグフローリアクター(PFR)

- マイクロ波フローリアクター

- その他の製品

第6章 世界のフローケミストリー市場:化学反応タイプ別

- 均一反応

- 不均一反応

- 気液反応

- 液液反応

- 固液反応

第7章 世界のフローケミストリー市場:動作モード別

- 連続フローケミストリー

- 半連続フローケミストリー

第8章 世界のフローケミストリー市場:運用規模別

- ラボ規模

- パイロットプラント規模

- 産業規模

第9章 世界のフローケミストリー市場:技術別

- 光化学フローリアクター

- 電気化学フローリアクター

- 熱フローリアクター

第10章 世界のフローケミストリー市場:用途別

- 製薬

- 化学薬品

- 石油化学

- 飲食品

- 水処理

- その他の用途

第11章 世界のフローケミストリー市場:地域別

- 北米

- 米国

- カナダ

- メキシコ

- 欧州

- ドイツ

- 英国

- イタリア

- フランス

- スペイン

- その他欧州

- アジア太平洋地域

- 日本

- 中国

- インド

- オーストラリア

- ニュージーランド

- 韓国

- その他アジア太平洋地域

- 南米

- アルゼンチン

- ブラジル

- チリ

- その他南米

- 中東・アフリカ

- サウジアラビア

- アラブ首長国連邦

- カタール

- 南アフリカ

- その他中東とアフリカ

第12章 主な発展

- 契約、パートナーシップ、コラボレーション、合弁事業

- 買収と合併

- 新製品発売

- 事業拡大

- その他の主要戦略

第13章 企業プロファイリング

- Corning Incorporated

- ThalesNano

- AGI Group

- Vapourtec Limited

- FutureChemistry Holding BV

- Uniqsis Limited

- Little Things Factory GmbH

- H.E.L Group

- Milestone Srl

- Chemtrix BV

- Biotage AB

- Cambridge Reactor Design Ltd.

- Parr Instrument Company

- Lonza Group AG

- Advion Interchim Scientific

- Syrris Limited

List of Tables

- Table 1 Global Flow Chemistry Market Outlook, By Region (2022-2030) ($MN)

- Table 2 Global Flow Chemistry Market Outlook, By Product (2022-2030) ($MN)

- Table 3 Global Flow Chemistry Market Outlook, By Continuous Flow Reactors (2022-2030) ($MN)

- Table 4 Global Flow Chemistry Market Outlook, By Microreactors (2022-2030) ($MN)

- Table 5 Global Flow Chemistry Market Outlook, By Continuous Stirred Tank Reactors (CSTR) (2022-2030) ($MN)

- Table 6 Global Flow Chemistry Market Outlook, By Plug Flow Reactors (PFR) (2022-2030) ($MN)

- Table 7 Global Flow Chemistry Market Outlook, By Microwave Flow Reactors (2022-2030) ($MN)

- Table 8 Global Flow Chemistry Market Outlook, By Other Products (2022-2030) ($MN)

- Table 9 Global Flow Chemistry Market Outlook, By Chemical Reactions Type (2022-2030) ($MN)

- Table 10 Global Flow Chemistry Market Outlook, By Homogeneous Reactions (2022-2030) ($MN)

- Table 11 Global Flow Chemistry Market Outlook, By Heterogeneous Reactions (2022-2030) ($MN)

- Table 12 Global Flow Chemistry Market Outlook, By Gas-Liquid Reactions (2022-2030) ($MN)

- Table 13 Global Flow Chemistry Market Outlook, By Liquid-Liquid Reactions (2022-2030) ($MN)

- Table 14 Global Flow Chemistry Market Outlook, By Solid-Liquid Reactions (2022-2030) ($MN)

- Table 15 Global Flow Chemistry Market Outlook, By Mode of Operation (2022-2030) ($MN)

- Table 16 Global Flow Chemistry Market Outlook, By Continuous Flow Chemistry (2022-2030) ($MN)

- Table 17 Global Flow Chemistry Market Outlook, By Semi-continuous Flow Chemistry (2022-2030) ($MN)

- Table 18 Global Flow Chemistry Market Outlook, By Scale of Operation (2022-2030) ($MN)

- Table 19 Global Flow Chemistry Market Outlook, By Laboratory Scale (2022-2030) ($MN)

- Table 20 Global Flow Chemistry Market Outlook, By Pilot Plant Scale (2022-2030) ($MN)

- Table 21 Global Flow Chemistry Market Outlook, By Industrial Scale (2022-2030) ($MN)

- Table 22 Global Flow Chemistry Market Outlook, By Technology (2022-2030) ($MN)

- Table 23 Global Flow Chemistry Market Outlook, By Photochemical Flow Reactors (2022-2030) ($MN)

- Table 24 Global Flow Chemistry Market Outlook, By Electrochemical Flow Reactors (2022-2030) ($MN)

- Table 25 Global Flow Chemistry Market Outlook, By Thermal Flow Reactors (2022-2030) ($MN)

- Table 26 Global Flow Chemistry Market Outlook, By Application (2022-2030) ($MN)

- Table 27 Global Flow Chemistry Market Outlook, By Pharmaceutical (2022-2030) ($MN)

- Table 28 Global Flow Chemistry Market Outlook, By Chemical (2022-2030) ($MN)

- Table 29 Global Flow Chemistry Market Outlook, By Petrochemical (2022-2030) ($MN)

- Table 30 Global Flow Chemistry Market Outlook, By Food & Beverage (2022-2030) ($MN)

- Table 31 Global Flow Chemistry Market Outlook, By Water Treatment (2022-2030) ($MN)

- Table 32 Global Flow Chemistry Market Outlook, By Other Applications (2022-2030) ($MN)

Note: Tables for North America, Europe, APAC, South America, and Middle East & Africa Regions are also represented in the same manner as above.

According to Stratistics MRC, the Global Flow Chemistry Market is accounted for $1.95 billion in 2024 and is expected to reach $3.54 billion by 2030 growing at a CAGR of 12.4% during the forecast period. Flow chemistry is a method of chemical synthesis that involves continuously pumping reactants together through a reactor, allowing for precise control over reaction conditions such as temperature, pressure, and mixing ratios. Flow chemistry enables rapid optimization of reactions and facilitates the synthesis of complex molecules. This approach offers several advantages over traditional batch processing, including enhanced safety, scalability, and efficiency.

According to the European Commission, total R&D expenditure by Germany reached USD 130.88 billion, increasing from USD 121.75 billion in 2021. It also introduced guidance on funding for supporting the chemical industry through the Transition Pathway of the Chemical Industry.

Market Dynamics:

Driver:

Growing focus on educating chemists

Educated chemists are better equipped to harness the advantages of continuous flow processes, such as improved safety, scalability, and efficiency in chemical synthesis. This increased understanding fosters innovation in pharmaceuticals, fine chemicals, and other industries, driving market expansion. Moreover, as academia and industry collaborate more closely on flow chemistry research and development, the field stands to benefit from accelerated advancements and broader adoption globally.

Restraint:

Complexity of integration

The complexity of integration in flow chemistry arises from challenges in optimizing multiple variables like reaction conditions, solvent compatibility, and reagent delivery in continuous processes. Industries face hurdles in adapting flow chemistry due to these integration challenges, which can deter widespread adoption and investment in this promising technology. This complexity hampers market growth by increasing development costs, requiring specialized expertise, and potentially limiting scalability.

Opportunity:

Rising interest from fine chemicals sector

Flow chemistry offers precise control over reactions, enhanced safety, and increased efficiency, aligning well with the complex synthesis requirements of fine chemicals. This technology enables continuous processing of reactions, reducing costs associated with downtime and waste while optimizing yields. As the fine chemicals industry increasingly adopts flow chemistry for its scalability and sustainability benefits, it is expected to propel market expansion, catering to diverse applications in pharmaceuticals, agrochemicals, and specialty chemicals.

Threat:

Perception and adoption lag

Perception and adoption lag in flow chemistry arise due to entrenched practices in batch processing and the need for extensive retraining and infrastructure investment. This delay hampers market growth by slowing acceptance of the technology's benefits, such as improved efficiency, scalability, and reduced waste. Industries are cautious about transitioning due to unfamiliarity and perceived risks, which restricts the flow chemistry market's expansion despite its potential advantages.

Covid-19 Impact

The covid-19 pandemic initially disrupted the flow chemistry market due to supply chain disruptions, reduced workforce availability, and delays in research and development activities. However, it also highlighted the resilience of continuous manufacturing technologies like flow chemistry, which offer advantages such as remote operation and minimal human intervention. This has spurred interest and investment in flow chemistry systems for pharmaceutical and fine chemical production amid ongoing global health challenges.

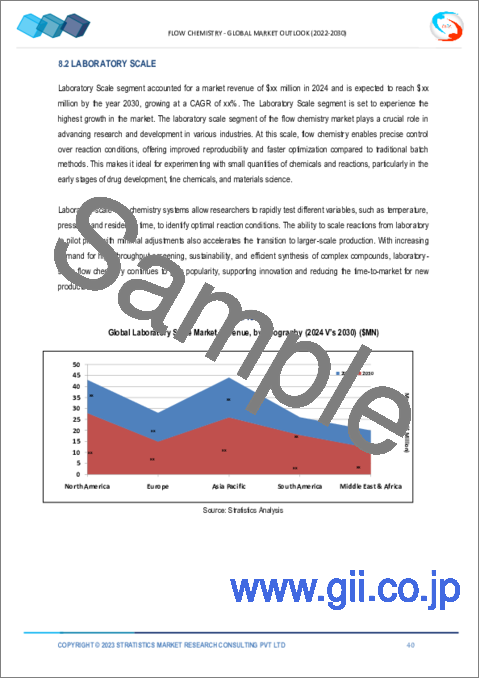

The laboratory scale segment is expected to be the largest during the forecast period

The laboratory scale segment is estimated to have a lucrative growth. Laboratory-scale flow chemistry involves conducting chemical reactions within a controlled, continuous flow of reagents through small-scale systems. It offers precise control over reaction parameters like temperature, pressure, and residence time, enhancing safety and efficiency compared to traditional batch methods. This approach enables rapid experimentation with reduced material consumption and waste production, making it ideal for process development, optimization, and synthesis of organic molecules in research and small-scale production settings.

The pharmaceutical segment is expected to have the highest CAGR during the forecast period

The pharmaceutical segment is anticipated to witness the fastest CAGR growth during the forecast period. Flow chemistry in pharmaceutical applications revolutionizes drug synthesis by enabling precise control over reaction conditions in continuous processes. It enhances efficiency, safety, and scalability, facilitating rapid synthesis of complex molecules and reducing production costs. This technology accelerates drug discovery, synthesis of APIs and development of novel drug formulations, contributing significantly to pharmaceutical innovation and efficiency.

Region with largest share:

The Flow Chemistry market in the Asia-Pacific region is experiencing robust growth driven by increasing industrialization, rapid expansion in pharmaceutical and chemical sectors, and government initiatives supporting sustainable manufacturing practices. Countries like China, India, Japan, and South Korea are prominent players due to their strong manufacturing capabilities and growing investments in research and development. The region benefits from lower labour costs, improving infrastructure, and rising adoption of advanced technologies.

Region with highest CAGR:

In North America, the Flow Chemistry market is characterized by strong adoption in pharmaceuticals, chemicals, and academia. The region benefits from advanced infrastructure, a robust research ecosystem, and a high concentration of key market players and innovators. North America's market is dynamic, with continuous advancements in flow reactor technology and increasing investments in R&D enhancing its position in the global flow chemistry landscape.

Key players in the market

Some of the key players profiled in the Flow Chemistry Market include Corning Incorporated, ThalesNano, AGI Group, Vapourtec Limited, FutureChemistry Holding BV, Uniqsis Limited, Little Things Factory GmbH, H.E.L Group, Milestone Srl, Chemtrix BV, Biotage AB, Cambridge Reactor Design Ltd., Parr Instrument Company, Lonza Group AG, and Advion Interchim Scientific, Syrris Limited.

Key Developments:

In December 2023, AGI Group acquired Chemtrix B.V. This acquisition of Chemtrix B.V. is anticipated to scale up AGI Group's capabilities in the flow chemistry market for application in the pilot as well as the manufacturing field.

In July 2023, H.E.L Group announced a collaboration with IIT Kanpur to leverage sustainable energy driven by the institute. The objective of this initiative was to create new testing labs for conducting research in new chemistry development, battery storage, and thermal characteristics study.

Products Covered:

- Continuous Flow Reactors

- Microreactors

- Continuous Stirred Tank Reactors (CSTR)

- Plug Flow Reactors (PFR)

- Microwave Flow Reactors

- Other Products

Chemical Reactions Types Covered:

- Homogeneous Reactions

- Heterogeneous Reactions

- Gas-Liquid Reactions

- Liquid-Liquid Reactions

- Solid-Liquid Reactions

Mode of Operations Covered:

- Continuous Flow Chemistry

- Semi-continuous Flow Chemistry

Scale of Operations Covered:

- Laboratory Scale

- Pilot Plant Scale

- Industrial Scale

Technologies Covered:

- Photochemical Flow Reactors

- Electrochemical Flow Reactors

- Thermal Flow Reactors

Applications Covered:

- Pharmaceutical

- Chemical

- Petrochemical

- Food & Beverage

- Water Treatment

- Other Applications

Regions Covered:

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- UK

- Italy

- France

- Spain

- Rest of Europe

- Asia Pacific

- Japan

- China

- India

- Australia

- New Zealand

- South Korea

- Rest of Asia Pacific

- South America

- Argentina

- Brazil

- Chile

- Rest of South America

- Middle East & Africa

- Saudi Arabia

- UAE

- Qatar

- South Africa

- Rest of Middle East & Africa

What our report offers:

- Market share assessments for the regional and country-level segments

- Strategic recommendations for the new entrants

- Covers Market data for the years 2022, 2023, 2024, 2026, and 2030

- Market Trends (Drivers, Constraints, Opportunities, Threats, Challenges, Investment Opportunities, and recommendations)

- Strategic recommendations in key business segments based on the market estimations

- Competitive landscaping mapping the key common trends

- Company profiling with detailed strategies, financials, and recent developments

- Supply chain trends mapping the latest technological advancements

Free Customization Offerings:

All the customers of this report will be entitled to receive one of the following free customization options:

- Company Profiling

- Comprehensive profiling of additional market players (up to 3)

- SWOT Analysis of key players (up to 3)

- Regional Segmentation

- Market estimations, Forecasts and CAGR of any prominent country as per the client's interest (Note: Depends on feasibility check)

- Competitive Benchmarking

- Benchmarking of key players based on product portfolio, geographical presence, and strategic alliances

Table of Contents

1 Executive Summary

2 Preface

- 2.1 Abstract

- 2.2 Stake Holders

- 2.3 Research Scope

- 2.4 Research Methodology

- 2.4.1 Data Mining

- 2.4.2 Data Analysis

- 2.4.3 Data Validation

- 2.4.4 Research Approach

- 2.5 Research Sources

- 2.5.1 Primary Research Sources

- 2.5.2 Secondary Research Sources

- 2.5.3 Assumptions

3 Market Trend Analysis

- 3.1 Introduction

- 3.2 Drivers

- 3.3 Restraints

- 3.4 Opportunities

- 3.5 Threats

- 3.6 Product Analysis

- 3.7 Technology Analysis

- 3.8 Application Analysis

- 3.9 Emerging Markets

- 3.10 Impact of Covid-19

4 Porters Five Force Analysis

- 4.1 Bargaining power of suppliers

- 4.2 Bargaining power of buyers

- 4.3 Threat of substitutes

- 4.4 Threat of new entrants

- 4.5 Competitive rivalry

5 Global Flow Chemistry Market, By Product

- 5.1 Introduction

- 5.2 Continuous Flow Reactors

- 5.3 Microreactors

- 5.4 Continuous Stirred Tank Reactors (CSTR)

- 5.5 Plug Flow Reactors (PFR)

- 5.6 Microwave Flow Reactors

- 5.7 Other Products

6 Global Flow Chemistry Market, By Chemical Reactions Type

- 6.1 Introduction

- 6.2 Homogeneous Reactions

- 6.3 Heterogeneous Reactions

- 6.4 Gas-Liquid Reactions

- 6.5 Liquid-Liquid Reactions

- 6.6 Solid-Liquid Reactions

7 Global Flow Chemistry Market, By Mode of Operation

- 7.1 Introduction

- 7.2 Continuous Flow Chemistry

- 7.3 Semi-continuous Flow Chemistry

8 Global Flow Chemistry Market, By Scale of Operation

- 8.1 Introduction

- 8.2 Laboratory Scale

- 8.3 Pilot Plant Scale

- 8.4 Industrial Scale

9 Global Flow Chemistry Market, By Technology

- 9.1 Introduction

- 9.2 Photochemical Flow Reactors

- 9.3 Electrochemical Flow Reactors

- 9.4 Thermal Flow Reactors

10 Global Flow Chemistry Market, By Application

- 10.1 Introduction

- 10.2 Pharmaceutical

- 10.3 Chemical

- 10.4 Petrochemical

- 10.5 Food & Beverage

- 10.6 Water Treatment

- 10.7 Other Applications

11 Global Flow Chemistry Market, By Geography

- 11.1 Introduction

- 11.2 North America

- 11.2.1 US

- 11.2.2 Canada

- 11.2.3 Mexico

- 11.3 Europe

- 11.3.1 Germany

- 11.3.2 UK

- 11.3.3 Italy

- 11.3.4 France

- 11.3.5 Spain

- 11.3.6 Rest of Europe

- 11.4 Asia Pacific

- 11.4.1 Japan

- 11.4.2 China

- 11.4.3 India

- 11.4.4 Australia

- 11.4.5 New Zealand

- 11.4.6 South Korea

- 11.4.7 Rest of Asia Pacific

- 11.5 South America

- 11.5.1 Argentina

- 11.5.2 Brazil

- 11.5.3 Chile

- 11.5.4 Rest of South America

- 11.6 Middle East & Africa

- 11.6.1 Saudi Arabia

- 11.6.2 UAE

- 11.6.3 Qatar

- 11.6.4 South Africa

- 11.6.5 Rest of Middle East & Africa

12 Key Developments

- 12.1 Agreements, Partnerships, Collaborations and Joint Ventures

- 12.2 Acquisitions & Mergers

- 12.3 New Product Launch

- 12.4 Expansions

- 12.5 Other Key Strategies

13 Company Profiling

- 13.1 Corning Incorporated

- 13.2 ThalesNano

- 13.3 AGI Group

- 13.4 Vapourtec Limited

- 13.5 FutureChemistry Holding BV

- 13.6 Uniqsis Limited

- 13.7 Little Things Factory GmbH

- 13.8 H.E.L Group

- 13.9 Milestone Srl

- 13.10 Chemtrix BV

- 13.11 Biotage AB

- 13.12 Cambridge Reactor Design Ltd.

- 13.13 Parr Instrument Company

- 13.14 Lonza Group AG

- 13.15 Advion Interchim Scientific

- 13.16 Syrris Limited