|

|

市場調査レポート

商品コード

1771351

短繊維強化複合材料(SFRC)の世界市場、需要、生産能力、数量、価格帯Short Fiber Reinforced Composites Market, Demand, Production Capacity, Volume and Price Range |

||||||

|

|||||||

| 短繊維強化複合材料(SFRC)の世界市場、需要、生産能力、数量、価格帯 |

|

出版日: 2025年07月10日

発行: Prismane Consulting

ページ情報: 英文 105 Pages

納期: 3~5営業日

|

全表示

- 概要

- 目次

市場のセグメンテーション:タイプ別

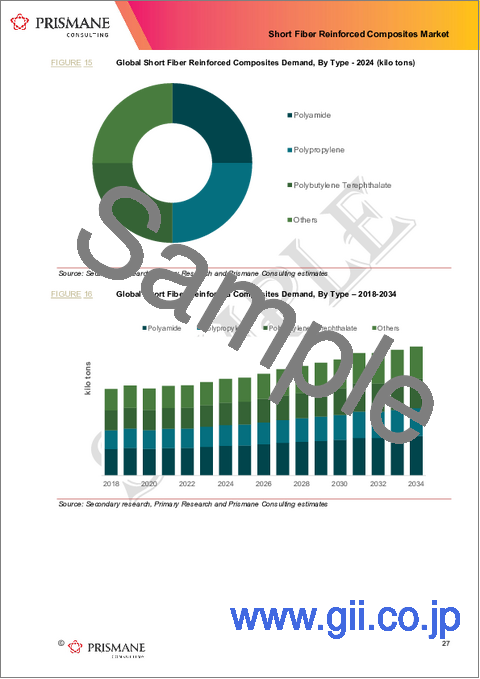

短繊維強化複合材料(SFRC)市場は、第一に母材によってポリアミド、ポリプロピレン、ポリブチレンテレフタレート(PBT)の3つのタイプに分けられます。このうち、ポリアミド系複合材料が市場を独占しています。ポリアミド系複合材料は、その優秀な機械的強度、耐熱性、化学的安定性で好まれています。ガラス繊維や炭素繊維のような短繊維で強化されたポリアミド複合材料は、強化されていないポリアミドと比較して、さらに高い強度、剛性、耐衝撃性を実現します。これらの特性により、ポリアミド複合材料は自動車、航空宇宙、電気、消費財産業などの要求の厳しい用途に適しています。

さまざまな産業における用途

短繊維強化複合材料(SFRC)は、機械的性能、コスト効率、加工の容易さといったその独自の組み合わせにより、複数の主要な産業で広く使用されています。輸送産業では、SFRCがバンパー、ダッシュボード、内装パネルなどの自動車部品に使用され、強度を損なうことなく大幅な軽量化を実現しています。航空宇宙産業では、高い強度対重量比が重要な翼構造などの部品にSFRCが使用されています。

地域市場の考察

アジア太平洋が世界のSFRC市場を主導しており、これは主にその強力な自動車部門と消費財部門によるものです。世界最大の自動車生産国である中国は、自動車の生産と売上の増加に伴い、SFRC材料の需要を大きく促進しています。インドや日本などにおける工業化の進行と可処分所得の増加も、同地域の市場成長に寄与しています。

北米や欧州などのその他の地域は、航空宇宙産業や自動車産業が発達しており、軽量で高性能な材料を重視しているため、重要なシェアを占めています。

主な市場企業と技術革新

SFRC市場の著名企業は、BASF、DSM Royal、DowDuPont、SABIC、Lanxessなどです。これらの企業は、需要の増加に対応するため、新材料の開発と生産能力の増強に注力しています。

SABICは、2021年発売のPBTコンパウンドや2022年発売のガラス繊維強化PPコンパウンドなど、カーボンフットプリントの削減を目的とした新しい短繊維強化コンパウンドを発表しました。これらの技術革新は、材料性能を向上させ、自動車産業の進化するニーズ、特に電気自動車に対するニーズを支えます。

市場促進要因

- 輸送産業からの需要の拡大

短繊維強化複合材料(SFRC)は、従来の材料に代わる軽量かつ強靭な材料を提供することで、輸送産業においてますます重要性を増しています。車両の軽量化により、SFRCは燃費の向上、排出ガスの削減、総合的な性能の向上に寄与します。これらをバンパー、ダッシュボード、ドアパネル、シート構造、ボンネット下部品などの重要な部品に使用することで、より安全で効率的な車両設計が可能になります。電気自動車(EV)の普及は、バッテリー効率と走行距離を最大化するために軽量化が不可欠であることから、需要をさらに加速させています。乗用車に加え、SFRCは商用トラック、バス、鉄道システムにも組み込まれ、同様の利点を実現しています。SFRCは複雑な形状に成形しやすいため、メーカーは生産を合理化しコストを削減できる一方、耐衝撃性、耐疲労性、耐環境性に優れているため、長期的な信頼性を確保できます。各国政府が燃料の経済性や排ガスの規制を強化し続けているため、輸送部門におけるSFRCの需要は着実に伸びると予測されます。

市場抑制要因

- 短い繊維長に起因する、限られた耐荷重

SFRCの欠点の1つは、繊維長が通常数ミリから数センチと短いために生じる固有の制限です。短繊維は複合材料全体に荷重を効果的に伝達する能力が低いため、長繊維や連続繊維複合材料に比べて剛性と強度が低くなります。また、短繊維の配向がランダムであるため、機械的性能にばらつきが生じます。

この制限により、SFRCは特定の高強度用途において長繊維複合材料に取って代わることができず、一部の要求の厳しい構造部品での使用が制限されます。

当レポートでは、世界の短繊維強化複合材料(SFRC)市場について調査分析し、市場力学と産業動向、各セグメントの需要、メーカーのプロファイルなどの情報を提供しています。

目次

第1章 イントロダクション

第2章 市場の要約

- 市場の進化

- 需要の概要

- 産業構造

- 戦略上の問題

- 最終用途の動向

- 成長予測

第3章 経済とエネルギーの見通し

- GDPと人口動態

- 金融政策と財政政策

- 原油生産と価格

- 天然ガス

- 電気料金

第4章 最終用途部門の実績

- 自動車

- 日用消費財

- 電気・電子

- その他

第5章 短繊維強化複合材料(SFRC)のイントロダクションと市場の概要

- 製品の説明

- グレードと特性

- 原材料

- 製造プロセス

- 環境問題

- バリューチェーン

- 用途

第6章 市場力学と産業動向

- 市場力学

- 促進要因

- 抑制要因

- 機会

- 課題

第7章 世界の短繊維強化複合材料(SFRC)の需要の分析:タイプ別、用途別(数量と金額)(2018年~2034年)

- 戦略上の問題とCOVID-19の影響

- 需要の分析と予測(2018年~2034年)

- 需要

- 需要成長率

- 促進要因の分析

- 世界の短繊維強化複合材料(SFRC)市場:タイプ別

- ポリアミド

- ポリプロピレン

- ポリブチレンテレフタレート

- その他

- 世界の短繊維強化複合材料(SFRC)市場:用途別

- 輸送

- 消費財

- 電気・電子

- その他

第8章 需要の分析と市場のレビュー:地域/国別(数量と金額)(2018年~2034年)

- 戦略上の問題とCOVID-19の影響

- 需要の分析と予測(2018年~2034年)

- 需要

- 需要成長率

- 短繊維強化複合材料(SFRC)市場:タイプ別

- 短繊維強化複合材料(SFRC)市場:用途別

- 北米

- 米国

- カナダ

- メキシコ

- 西欧

- ドイツ

- フランス

- イタリア

- 英国

- スペイン

- その他の西欧

- 中欧・東欧

- ロシア

- ポーランド

- その他の中欧・東欧

- アジア太平洋

- 中国

- 日本

- インド

- 韓国

- その他のアジア太平洋

- 中南米

- 中東・アフリカ

第9章 価格分析

第10章 主な戦略上の問題と事業機会の評価

- 市場の魅力の評価

- 見通しとターゲット市場の調査

第11章 戦略的推奨と提案

第12章 企業分析

- 短繊維強化複合材料(SFRC)メーカーのプロファイル/企業分析

- 基本詳細

- 本社、主要市場

- 所有

- 企業の財務

- 製造拠点

- 世界の売上

- 総従業員数

- 製品ポートフォリオ/サービス/ソリューション

- 採用された主な事業戦略とPrismane Consultingの概要

- 近年の発展

- 対象企業

- BASF

- DSM Royal

- SABIC

- Lanxess

- その他のメーカー

第13章 付録

Short fiber reinforced composites (SFRC) are advanced materials created by dispersing short fibers-typically glass, carbon, aramid, or natural fibers-into a polymer matrix such as thermoplastics or thermosets. These short fibers significantly enhance the mechanical properties of the base material, including tensile strength, stiffness, impact resistance, and dimensional stability. Unlike continuous fiber composites, SFRCs are easier to manufacture and mold, making them suitable for high-volume production with complex shapes.

SFRCs offer a balance between performance and cost, making them attractive for a wide range of applications across automotive, aerospace, electronics, construction, and consumer goods industries. In automotive parts, they help reduce weight while maintaining structural integrity. In electronics, they improve thermal and electrical performance. Their resistance to wear and environmental degradation also makes them suitable for outdoor and industrial applications. The ability to tailor fiber type, orientation, and loading levels provides designers with flexibility to meet specific performance requirements, further boosting their appeal in competitive markets.

Market Segmentation by Type

The SFRC market is primarily divided into three types based on the matrix material: Polyamide, Polypropylene, and Polybutylene Terephthalate (PBT). Among these, polyamide-based composites dominate the market. Polyamide composites are favored because of their excellent mechanical strength, heat resistance, and chemical stability. When reinforced with short fibers like glass or carbon fibers, polyamide composites achieve even higher strength, stiffness, and resistance to impact compared to unreinforced polyamide. These properties make them suitable for demanding applications in automotive, aerospace, electrical, and consumer goods industries.

Applications Across Industries

Short fiber reinforced composites (SFRC) are widely used across several key industries due to their unique combination of mechanical performance, cost efficiency, and ease of processing. The transportation sector represents the largest application area, where SFRCs are utilized in automotive components such as bumpers, dashboards, and interior panels, offering significant weight reduction without compromising strength. In the aerospace industry, SFRCs are used in components like wing structures, where high strength-to-weight ratios are critical.

In the consumer products sector, SFRCs are widely found in sporting goods such as tennis rackets, golf clubs, and bicycle frames, where durability, light weight, and strength are important. Additionally, the electrical and electronics industry benefits from SFRCs for components requiring mechanical integrity along with resistance to heat and chemicals. The versatility of SFRCs in meeting specific design and performance requirements makes them a popular and growing choice in both high-performance and everyday applications.

Regional Market Insights

The Asia Pacific region leads the global SFRC market, largely due to its strong automotive and consumer goods sectors. China, the world's largest automobile producer, drives significant demand for SFRC materials as vehicle production and sales grow. Increased industrialization and rising disposable incomes in countries like India and Japan also contribute to market growth in the region.

Other regions such as North America and Europe hold important shares due to their advanced aerospace and automotive industries and focus on lightweight, high-performance materials.

Key Market Players and Innovations

Prominent companies in the SFRC market include BASF, DSM Royal, DowDuPont, SABIC, and Lanxess. These firms focus on developing new materials and increasing production capacity to meet growing demand.

SABIC has introduced new short fiber reinforced compounds aimed at reducing carbon footprints, including PBT compounds launched in 2021, and new glass fiber reinforced PP compounds introduced in 2022. These innovations improve material performance and support the automotive industry's evolving needs, especially for electric vehicles.

Market Drivers

- Growing Demand from Transportation Industry:

Short Fiber Reinforced Composites (SFRC) are increasingly vital in the transportation industry, offering a lightweight yet strong alternative to traditional materials. By reducing vehicle weight, SFRCs help improve fuel efficiency, lower emissions, and enhance overall performance. Their use in critical components such as bumpers, dashboards, door panels, seat structures, and under-the-hood parts supports safer, more efficient vehicle designs. The growing adoption of electric vehicles (EVs) further accelerates demand, as weight reduction is essential to maximizing battery efficiency and driving range. In addition to passenger vehicles, SFRCs are also being integrated into commercial trucks, buses, and railway systems to achieve similar benefits. Their ability to be easily molded into complex shapes allows manufacturers to streamline production and reduce costs, while their excellent resistance to impact, fatigue, and environmental factors ensures long-term reliability. As governments continue to tighten fuel economy and emission standards, the demand for SFRC in the transportation sector is expected to grow steadily.

Market Restraint

- Limited Load-Bearing Capacity Due to Short Fiber Length

One drawback of SFRCs is the inherent limitation caused by the short fiber length, typically a few millimeters to centimeters. Short fibers have less ability to transfer load effectively throughout the composite, which results in lower stiffness and strength compared to long fiber or continuous fiber composites. The random orientation of short fibers can also lead to inconsistent mechanical performance.

This limitation restricts SFRCs from replacing long fiber composites in certain high-strength applications, limiting their use in some demanding structural components.

Table of Contents

1. Introduction

- Scope

- Market Coverage

- Types

- Applications

- Regions

- Countries

- Years Considered

- Historical - 2018 - 2023

- Base - 2024

- Forecast Period - 2025 - 2034

- Research Methodology

- Approach

- Research Methodology

- Prismane Consulting Market Models

- Assumptions & Limitations

- Abbreviations & Definitions

- Conversion Factors

- Data Sources

2. Market Synopsis

- Market Evolution

- Demand Overview

- Industry Structure

- Strategic Issues

- End-use Trends

- Growth Forecast

3. Economic & Energy Outlook

- GDP and Demographics

- Monetary & Fiscal Policies

- Crude Oil Production and prices

- Natural Gas

- Electricity Prices

4. End-use Sector Performance

- Automotive

- FMCG

- Electrical & Electronics

- Others

5. Introduction to Short Fiber Reinforced Composites and Market Overview

- Product Description

- Grades & Properties

- Raw Material

- Manufacturing Process

- Environmental Issues

- Value Chain

- Applications

6. Market Dynamics and Industry Trends

- Market Dynamics

- Drivers

- Restraints

- Opportunities

- Challenges

7. Global Short Fiber Reinforced Composites Demand Analysis, By Types, By Applications (Volume, Value) (2018-2034)

- Strategic Issues and COVID-19 Impact

- Demand Analysis and Forecast (2018- 2034)

- Demand

- Demand Growth Rate (%)

- Driving Force Analysis

- Global Short Fiber Reinforced Composites Market, By Types

- Polyamide

- Polypropylene

- Polybutylene Terephthalate

- Others

- Global Short Fiber Reinforced Composites Market, By Applications

- Transportation

- Consumer Products

- Electrical & Electronics

- Others

8. Demand Analysis and Market Review, By Region, By Country (Volume, Value), (2018- 2034)

- Strategic Issues and COVID-19 Impact

- Demand Analysis and Forecast (2018- 2034)

- Demand

- Demand Growth Rate (%)

- Short Fiber Reinforced Composites Market, By Types

- Short Fiber Reinforced Composites Market, By Applications

Note: Demand Analysis has been provided for all major Regions / Countries as mentioned below. The demand (consumption) split by types and applications have been provided for each of the countries / regions in Volume (Kilo tons) and Value (USD Million).

- North America

- USA

- Canada

- Mexico

- Western Europe

- Germany

- France

- Italy

- United Kingdom

- Spain

- Rest of Western Europe

- Central & Eastern Europe

- Russia

- Poland

- Rest of Central & Eastern Europe

- Asia-Pacific

- China

- Japan

- India

- South Korea

- Rest of Asia-Pacific

- Central & South America

- Middle East & Africa

Note: CAGR will be calculated for all types and applications to arrive at the regional / global demand growth for the forecast period (2025 - 2034)

9. Pricing Analysis

10. Key Strategic Issues and Business Opportunity Assessment

- Market Attractiveness Assessment

- Prospective & Target Market Study

11. Strategic Recommendation & Suggestions

12. Company Analysis

- Short Fiber Reinforced Composites Manufacturers Profiles/ Company Analysis

- Basic Details

- Headquarter, Key Markets

- Ownership

- Company Financial

- Manufacturing Bases

- Global Turnover

- Total Employee

- Product Portfolio / Services / Solutions

- Key Business Strategies adopted and Prismane Consulting Overview

- Recent Developments

- Companies Covered -

- BASF

- DSM Royal

- SABIC

- Lanxess

- Other Manufacturers

Note: This section includes company information, company financials, manufacturing bases and operating regions. Company financials have been mentioned only for those companies where financials were available in SEC Filings, annual reports, or company websites. All the reported financials in this report are in U.S. Dollars. Financials reported in other currencies have been converted using average currency conversion rates. Company profiles may include manufacturers, suppliers, and distributors.

13. Appendices

- Demand - Regions

- Demand - Countries