|

市場調査レポート

商品コード

1849866

機械状態監視:市場シェア分析、産業動向、統計、成長予測(2025年~2030年)Machine Condition Monitoring - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

カスタマイズ可能

適宜更新あり

|

|||||||

| 機械状態監視:市場シェア分析、産業動向、統計、成長予測(2025年~2030年) |

|

出版日: 2025年06月17日

発行: Mordor Intelligence

ページ情報: 英文 120 Pages

納期: 2~3営業日

|

概要

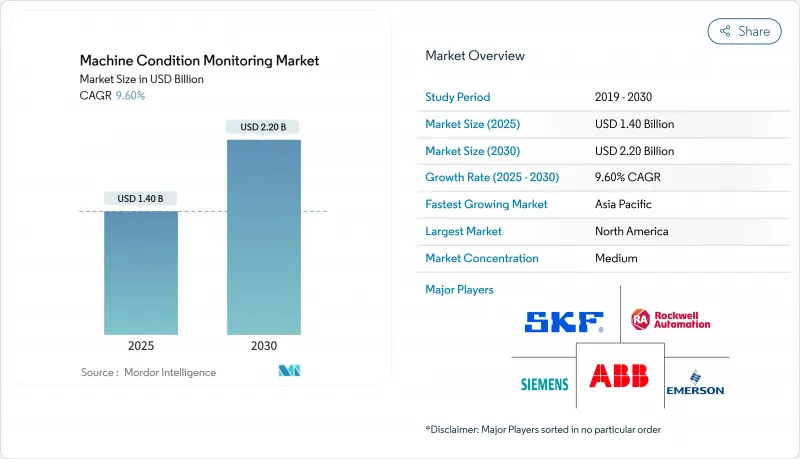

機械状態監視市場は2025年に14億米ドルに達し、CAGR 9.6%を反映して2030年には22億米ドルに達する勢いです。

この勢いを支えているのは、ワイヤレスIIoTセンサーの導入拡大と、意思決定サイクルを短縮するAI対応診断プラットフォームです。工業生産者は、労働力の制約とアップタイム目標の引き上げに直面しており、自動故障検出システムの需要が高まっています。ワイヤレス・センサ・ノードとエッジ・アナリティクスを組み合わせることで、総所有コストが削減され、これまで監視されていなかった小規模な資産もカバーできるようになります。エネルギー性能に関する継続的な洞察は、メーカーが排出量開示規則を満たすのに役立つため、持続可能性の義務化は採用をさらに促進します。競合の激しさは、既存企業がインストールベースの規模に依存する一方で、AIを中心とした参入企業が高度な分析とSaaSの提供を通じて価値を競うため、緩やかなままです。

世界の機械状態監視市場の動向と洞察

計画外ダウンタイムの削減に向けた予知保全の重視

製造業では、突発的な停止により毎年500億米ドルの損失が発生しているため、企業はカレンダーベースのサービスに代わって、ダウンタイムを20~50%削減し、メンテナンス費用を5~10%削減する予測アプローチを導入しています。機械学習アルゴリズムは、マルチセンサーデータストリームを利用して数週間先の故障を特定し、予定された休止時間中にチームが介入できるようにします。自動車工場では、BMWとテスラがリアルタイム分析を使って機器のライフサイクルを延ばし、成功を収めています。デジタルツインモデルは、摩耗シナリオをシミュレートし、部品調達を最適化することで、スケジュールを改善します。

インダストリー4.0エッジ分析プラットフォームの採用

エッジ処理は、アナリティクスをセンサーノードに移し、遅延をなくすと同時に、ネットワーク停止中も洞察を維持します。STマイクロエレクトロニクスは、秒以下の検出を必要とする状態監視の使用事例にマイクロコントローラを位置付けています。シーメンスのSIMOCODE M-CPは、シングルペアイーサネットを介してモーターコントロールセンター内にモニタリングを組み込み、配線の手間を削減し、診断をより小型のモーターに拡張します。早期導入企業からは、ミリ秒レベルの異常検知と最大50%の帯域幅削減が報告されています。

レガシーなブラウンフィールド資産の改修コスト

古い施設にはセンサーマウントやネットワークバックボーンがほとんどないため、導入にはエンジニアリングの変更、安全承認、段階的なシャットダウンが必要となり、その期間は1年半以上に及ぶこともあります。米国海兵隊は、コンディション・ベースド・メンテナンス・プラスを採用する際の障壁として、相反するレガシー・ポリシーを挙げており、これは民間のプロセス・プラントにおける同様の苦闘を反映しています。ワイヤレス機器は配線の痛みを和らげるが、電力供給と危険区域認証は依然として予算を引き上げており、企業は重要度によってプロジェクトを段階的に進めるよう促しています。

セグメント分析

ハードウェアは2024年の売上高の45%を占め、センサー、ゲートウェイ、収集ユニットがあらゆる設備で不可欠な役割を担っていることを強調しています。このセグメントは、消費電力を抑えながら感度を向上させるマイクロエレクトロメカニカルシステムの着実な進歩から利益を得ています。シーメンスは、SIMOCODE M-CPでハードウェアとライセンシング可能な分析モジュールを融合させ、配電盤ユーザーへの導入を簡素化しました。SKFがLKABと締結した6,000万米ドルの契約は、振動測定と遠隔診断を複数年契約にパッケージ化したものです。

ワイヤレスIIoTセンサーネットワークは年率12.4%で成長すると予測され、手間のかからない改修を好む顧客の好みを裏付けています。導入が拡大するにつれ、統合プラットフォームは未加工のストリームをメンテナンスチケットに変換し、定期的なSaaS収入を創出します。これらの要因は、分析サブスクリプションに新たなマージン・プールを導入する一方で、既存事業者にとってのスケールメリットを維持するものです。

振動解析は2024年に34.2%のシェアを維持。専門家は回転資産の豊富な故障シグネチャライブラリを信頼し、機器メーカーは加速度計を購入時にバンドルし、ネットワーク効果を強化しています。超音波放射は、工場が高騒音エリアでもベアリングの早期故障検出や圧縮空気漏れの特定を重視することから、年率11.8%の拡大が予測されます。

サーモグラフィは、Teledyne FLIRとRealWearのパートナーシップのようなウェアラブル統合によって支援されるクラウドダッシュボードで熱異常のフラグを立てるAIによって採用が増加します。モーター電流シグネチャーとオイル分析は、診断の信頼性を高め、電気および潤滑システムにまで範囲を広げるマルチモーダルなスイートを完成させます。

地域分析

北米は2024年の売上高の32.4%を占め、厳しい安全規制とインダストリー4.0の早期展開に支えられています。米国証券取引委員会(SEC)の排出量報告とカリフォルニア州法253条は、企業を継続的な効率測定へと導いています。成熟した設置ベースは、エッジ対応センサーへのアップグレードサイクルをさらに促進します。

アジア太平洋地域の年間成長率は9.9%に達します。中国とインドのスマート製造補助金が初期費用を軽減し、日本のセンサー・イノベーション・ハブがIEEE SENSORS 2024で専門知識を披露します。バッテリー、半導体、再生可能機器の工場が急拡大し、構想段階から予知保全が組み込まれます。

欧州はESGフレームワークを活用して投資を正当化し、中東は石油・ガスのメガプロジェクトと監視を連携させる。ラテンアメリカでは、鉱山会社がコンベヤフリートをデジタル化し、水力発電所が信頼性の向上を求めているため、新たな成長を記録しています。

その他の特典:

- エクセル形式の市場予測(ME)シート

- 3ヶ月間のアナリストサポート

よくあるご質問

目次

第1章 イントロダクション

- 調査の前提条件と市場の定義

- 調査範囲

第2章 調査手法

第3章 エグゼクティブサマリー

第4章 市場情勢

- 市場概要

- 市場促進要因

- 予知保全に重点を置き、計画外のダウンタイムを削減

- インダストリー4.0エッジ分析プラットフォームの導入

- 新興アジアにおける資産集約型セクターの急成長

- ワイヤレスIIoTセンサーが総所有コストを大幅に削減

- ESG主導によるエネルギー効率の高い工場運営の推進

- ゼロフォールトトレランスを要求する軍事および宇宙プログラム(目立たない)

- 市場抑制要因

- ブラウンフィールド資産の改修費用

- 振動解析専門家の不足

- 常時接続システムにおけるサイバーセキュリティの懸念

- 貿易障壁の高まりがハードウェアサプライチェーンを制限している(目立たない)

- バリュー/サプライチェーン分析

- 規制情勢

- テクノロジーの展望

- ポーターのファイブフォース

- 新規参入業者の脅威

- 買い手の交渉力

- 供給企業の交渉力

- 代替品の脅威

- 競争企業間の敵対関係

第5章 市場規模と成長予測

- 提供別

- ハードウェア

- ソフトウェア

- サービス

- 監視手法別

- 振動解析

- サーモグラフィー

- 超音波放射

- 潤滑油分析

- モーター電流シグネチャ

- 腐食および摩耗破片

- その他のテクニック

- 展開別

- オンライン/継続システム

- ポータブル/周期的計測器

- ワイヤレスIIoTセンサーネットワーク

- エンドユーザー業界別

- 石油・ガス

- 発電

- 金属・鉱業

- 化学・石油化学製品

- 自動車・輸送

- 航空宇宙および防衛

- 飲食品

- 海洋

- その他の産業

- 地域別

- 北米

- 米国

- カナダ

- 南米

- ブラジル

- アルゼンチン

- 欧州

- ドイツ

- 英国

- フランス

- ロシア

- アジア

- 中国

- 日本

- インド

- 韓国

- 中東・アフリカ

- 中東

- サウジアラビア

- アラブ首長国連邦

- アフリカ

- 南アフリカ

- 北米

第6章 競合情勢

- 市場集中度

- 戦略的動向

- 市場シェア分析

- 企業プロファイル

- SKF AB

- Emerson Electric Co.(Bently Nevada)

- Rockwell Automation Inc.

- ABB Ltd.

- Siemens AG

- Meggitt PLC

- Bruel and Kjaer Vibro

- Fluke Corporation

- FLIR Systems Inc.

- Parker Hannifin Corp.(Kittiwake)

- AMETEK Inc.(Spectro Scientific)

- Thermo Fisher Scientific Inc.

- Bentley Nevada(Baker Hughes)

- Schaeffler Group

- Azima DLI

- Honeywell International Inc.

- National Instruments Corp.

- Schneider Electric SE

- Gastops Ltd.

- Wilcoxon Sensing Technologies