|

|

市場調査レポート

商品コード

1749590

工業用ガスケットの世界市場 (~2030年):材質 (半金属・非金属・金属)・製品タイプ (ソフトガスケット・渦巻きガスケット)・エンドユーザー産業 (製油所・発電・化学処理・パルプ&製紙)・地域別Industrial Gaskets Market by Material Type (Semi-metallic, Non-metallic, Metallic), Product Type (Soft Gaskets, Spiral Wound), End-use Industry (Refineries, Power Generation, Chemical Processing, Pulp & Paper), and Region - Global Forecast to 2030 |

||||||

カスタマイズ可能

|

|||||||

| 工業用ガスケットの世界市場 (~2030年):材質 (半金属・非金属・金属)・製品タイプ (ソフトガスケット・渦巻きガスケット)・エンドユーザー産業 (製油所・発電・化学処理・パルプ&製紙)・地域別 |

|

出版日: 2025年06月04日

発行: MarketsandMarkets

ページ情報: 英文 255 Pages

納期: 即納可能

|

全表示

- 概要

- 図表

- 目次

工業用ガスケットの市場規模は、2025年の127億6,000万米ドルから、予測期間中はCAGR 5.7%で推移し、2030年には168億4,000万米ドルに達すると予測されています。

中国、インド、東南アジア諸国などの新興経済国で産業化が加速する中、石油・ガス、化学加工、発電、水処理、製造業といった重要分野では、信頼性の高いシーリングソリューションへのニーズが高まっています。工業用ガスケットは、パイプライン、原子炉、コンプレッサー、その他の機械において、漏れを防ぎ、圧力を維持し、運転の安全性を確保することで、これらの産業において重要な役割を果たしています。また、環境・安全規制の強化も需要に拍車をかけており、産業界は排出ガスの管理、危険な漏れの防止、世界標準の遵守をますます求められるようになっています。同時に、風力、太陽光、水素システムといった再生可能エネルギープロジェクトの成長によって、高性能かつ耐腐食性に優れたガスケットの新たな用途分野が広がっています。拡張PTFE、グラファイト、金属強化複合材料などの材料における技術革新は、ガスケットの耐久性と耐薬品性を大幅に向上させました。これに加えて、CNC切削、レーザー加工、3Dプリントといった先進的な製造技術の導入により、より高度にカスタマイズされた精密なガスケットの製造が可能となり、複雑で特殊な用途への対応力が高まっています。さらに、老朽化する産業インフラにおいて、メンテナンスや交換用ガスケットへのニーズが増加していることも市場拡大の要因となっており、特に重工業が根付いた地域ではその傾向が顕著です。

| 調査範囲 | |

|---|---|

| 調査対象年 | 2021-2030年 |

| 基準年 | 2024年 |

| 予測期間 | 2025-2030年 |

| 単位 | 金額(米ドル)/数量(キロトン) |

| セグメント | 材質・製品タイプ・エンドユーザー産業・地域 |

| 対象地域 | 北米、欧州、アジア太平洋、その他の地域 |

"材質別では、半金属ガスケットが予測期間中、2番目に急成長するセグメントに"

半金属ガスケットは、金属材料と非金属材料を組み合わせて設計されたシーリング部品であり、強度、柔軟性、シール性能のバランスの取れた性能を提供します。これらは、ソフトガスケットよりも高い耐久性が求められる一方で、完全なメタルガスケットほどの硬さを必要としない用途に適しており、石油・ガス、石油化学、発電、海洋工学といった産業で広く使用されています。これらのガスケットは、変動する条件や化学薬品にさらされ、堅牢で信頼性の高いシーリングが要求される中高圧・高温環境に特に適しています。最も一般的なタイプの一つが渦巻きガスケットで、これは金属(通常ステンレス鋼)の層とグラファイトやPTFEといった柔らかい充填材の層を交互に重ねた構造を持っています。半金属ガスケットは優れた回復性と荷重保持能力を備えており、熱サイクルや圧力変動があってもシールを維持できます。その汎用性により、フランジ接合部、熱交換器、ボイラー、圧力容器などでの使用に最適です。産業界がより高い安全性と性能を求める中で、耐久性、シール効率、厳しい規制要件を満たす能力により、半金属ガスケットの人気は高まり続けています。

”エンドユーザー産業別では、発電セグメント予測期間中2番目に急成長する見通し"

ガスケットは発電産業において、幅広い機器・システムの安全で効率的かつ漏れのない運用を実現するために重要な役割を担っています。化石燃料発電所、原子力施設、再生可能エネルギーシステムのいずれにおいても、ガスケットはボイラー、タービン、コンプレッサー、熱交換器、フランジ、バルブ、配管ネットワークなどの接合部のシールに欠かせません。これらの部品は、高圧蒸気やガス、液体の漏れを防ぎ、運転効率だけでなく作業員の安全や環境保護にも貢献します。発電所では、極端な温度、高圧、腐食性物質への曝露といった過酷な条件が一般的であるため、高い耐久性、熱サイクルへの耐性、長期にわたるシール性の維持に優れた渦巻きガスケットやカムプロファイルガスケットなどの半金属および金属ガスケットが重用されています。原子力用途では、放射線に耐性のある高仕様のガスケットが求められ、材料の高度化や厳格な品質管理が不可欠となります。また、世界的なクリーンエネルギーへの転換や老朽化したインフラの近代化が進む中で、先進的なガスケットソリューションへの需要は高まっています。 地熱、バイオマス、水素プラントといった再生可能エネルギー施設でも、熱回収システムや燃料電池などの設備に高性能なガスケットが必要とされます。このような変化の中で、ガスケットはシステムの信頼性向上、ダウンタイムの削減、厳格な環境・安全規制の遵守に大きく寄与しています。

当レポートでは、世界の工業用ガスケットの市場を調査し、市場概要、市場成長への各種影響因子の分析、技術・特許の動向、法規制環境、ケーススタディ、市場規模の推移・予測、各種区分・地域/主要国別の詳細分析、競合情勢、主要企業のプロファイルなどをまとめています。

目次

第1章 イントロダクション

第2章 調査手法

第3章 エグゼクティブサマリー

第4章 重要考察

第5章 市場概要

- 市場力学

- 促進要因

- 抑制要因

- 機会

- 課題

- バリューチェーン分析

- ポーターのファイブフォース分析

- エコシステム分析

- マクロ経済指標

- 価格分析

- 貿易分析

- 主要なステークホルダーと購入基準

- 投資と資金調達のシナリオ

- 特許分析

- 2025-2026年の主な会議とイベント

- AI/生成AIの影響

- ケーススタディ分析

- 規制状況

- 技術分析

- 顧客の事業に影響を与える動向/混乱

- 米国関税の影響

第6章 工業用ガスケット市場:材質別

- 半金属

- 非金属

- PTFE

- フレキシブルグラファイト

- EPDM

- 圧縮非アスベスト

- その他

- 金属

- ステンレス鋼

- アルミニウム

- 銅

- チタン

- その他

第7章 工業用ガスケット市場:製品タイプ別

- ソフトガスケット

- 渦巻きガスケット

- リングジョイントガスケット

- カムプロファイルガスケット

- ジャケットガスケット

- 波形ガスケット

- その他

- Oリングガスケット

- 圧縮アスベスト繊維ガスケット

第8章 工業用ガスケット市場:エンドユーザー産業別

- 製油所

- 発電

- リチウム産業

- 化学処理

- 水素産業

- 産業機械

- パルプ・紙

- 食品・医薬品

- 半導体

- その他

- 繊維

- 水処理

第9章 工業用ガスケット市場:地域別

- アジア太平洋

- 中国

- インド

- 日本

- 韓国

- タイ

- オーストラリア

- その他

- 欧州

- ドイツ

- フランス

- スペイン

- 英国

- イタリア

- ロシア

- オランダ

- その他

- 北米

- 米国

- カナダ

- メキシコ

- 中東・アフリカ

- GCC諸国

- 南アフリカ

- その他

- 南米

- ブラジル

- アルゼンチン

- その他

第10章 競合情勢

- 概要

- 主要参入企業の戦略/強み

- 収益分析

- 市場シェア分析

- 企業評価と財務指標

- ブランド/製品比較分析

- 企業評価マトリックス:主要企業

- 企業評価マトリックス:スタートアップ/中小企業

- 競合シナリオ

第11章 企業プロファイル

- 主要企業

- KLINGER GROUP

- W.L. GORE & ASSOCIATES, INC.

- GARLOCK

- TEADIT

- PARKER HANNIFIN CORP.

- FLEXITALLIC

- LAMONS

- GOODRICH GASKET

- JAMES WALKER GROUP

- FREUDENBERG SEALING TECHNOLOGIES

- DONIT TESNIT, D.O.O.

- DATWYLER HOLDING INC.

- その他の企業

- IGP

- 3M

- TRELLEBORG GROUP

- SPIRA POWER

- PGE INDUSTRIES PVT. LTD.

- CENTAURO S.R.L.

- DENVER RUBBER COMPANY

- HENNIG GASKET & SEALS

- HYDRO SILICA

- PHELPS

- REDCO

- KENT RUBBER

- VSP TECHNOLOGIES

- NATIONAL RUBBER CORPORATION

- GARDICO

第12章 付録

List of Tables

- TABLE 1 INCLUSIONS & EXCLUSIONS OF STUDY

- TABLE 2 WORLD CRUDE OIL & LIQUID FUEL PRODUCTION, BY COUNTRY, 2022-2025 (MILLION BARRELS PER DAY)

- TABLE 3 INDUSTRIAL GASKETS MARKET: PORTER'S FIVE FORCES ANALYSIS

- TABLE 4 INDUSTRIAL GASKETS MARKET: ROLE OF PLAYERS IN ECOSYSTEM

- TABLE 5 PROJECTED REAL GDP GROWTH (ANNUAL PERCENTAGE CHANGE) OF KEY COUNTRIES, 2019-2023

- TABLE 6 ANNUAL GDP PERCENTAGE CHANGE AND PROJECTION OF KEY COUNTRIES, 2024-2029

- TABLE 7 ELECTRICITY NET GENERATION OF KEY COUNTRIES, 2019-2023 (BILLION KWH)

- TABLE 8 AVERAGE SELLING PRICE OF INDUSTRIAL GASKETS, BY REGION, 2022-2030 (USD/KG)

- TABLE 9 AVERAGE SELLING PRICE OF INDUSTRIAL GASKETS, BY MATERIAL TYPE, 2024 (USD/KG)

- TABLE 10 AVERAGE SELLING PRICE OF INDUSTRIAL GASKETS OFFERED BY KEY PLAYERS, BY END-USE INDUSTRY, 2024 (USD/KG)

- TABLE 11 INFLUENCE OF STAKEHOLDERS ON BUYING PROCESS FOR TOP THREE END-USE INDUSTRIES

- TABLE 12 KEY BUYING CRITERIA FOR TOP THREE END-USE INDUSTRIES

- TABLE 13 INDUSTRIAL GASKETS MARKET: KEY CONFERENCES AND EVENTS, 2025-2026

- TABLE 14 INDUSTRIAL GASKETS MARKET: LIST OF REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 15 US ADJUSTED RECIPROCAL TARIFF RATES

- TABLE 16 INDUSTRIAL GASKETS MARKET, BY MATERIAL TYPE, 2022-2024 (USD MILLION)

- TABLE 17 INDUSTRIAL GASKETS MARKET, BY MATERIAL TYPE, 2025-2030 (USD MILLION)

- TABLE 18 INDUSTRIAL GASKETS MARKET, BY MATERIAL TYPE, 2022-2024 (KILOTON)

- TABLE 19 INDUSTRIAL GASKETS MARKET, BY MATERIAL TYPE, 2025-2030 (KILOTON)

- TABLE 20 INDUSTRIAL GASKETS MARKET, BY PRODUCT TYPE, 2022-2024 (USD MILLION)

- TABLE 21 INDUSTRIAL GASKETS MARKET, BY PRODUCT TYPE, 2025-2030 (USD MILLION)

- TABLE 22 INDUSTRIAL GASKETS MARKET, BY PRODUCT TYPE, 2022-2024 (KILOTON)

- TABLE 23 INDUSTRIAL GASKETS MARKET, BY PRODUCT TYPE, 2025-2030 (KILOTON)

- TABLE 24 INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 25 INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 26 INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 27 INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 28 INDUSTRIAL GASKETS MARKET, BY REGION, 2022-2024 (USD MILLION)

- TABLE 29 INDUSTRIAL GASKETS MARKET, BY REGION, 2025-2030 (USD MILLION)

- TABLE 30 INDUSTRIAL GASKETS MARKET, BY REGION, 2022-2024 (KILOTON)

- TABLE 31 INDUSTRIAL GASKETS MARKET, BY REGION, 2025-2030 (KILOTON)

- TABLE 32 ASIA PACIFIC: INDUSTRIAL GASKETS MARKET, BY COUNTRY, 2022-2024 (USD MILLION)

- TABLE 33 ASIA PACIFIC: INDUSTRIAL GASKETS MARKET, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 34 ASIA PACIFIC: INDUSTRIAL GASKETS MARKET, BY COUNTRY, 2022-2024 (KILOTON)

- TABLE 35 ASIA PACIFIC: INDUSTRIAL GASKETS MARKET, BY COUNTRY, 2025-2030 (KILOTON)

- TABLE 36 ASIA PACIFIC: INDUSTRIAL GASKETS MARKET, BY MATERIAL TYPE, 2022-2024 (USD MILLION)

- TABLE 37 ASIA PACIFIC: INDUSTRIAL GASKETS MARKET, BY MATERIAL TYPE, 2025-2030 (USD MILLION)

- TABLE 38 ASIA PACIFIC: INDUSTRIAL GASKETS MARKET, BY MATERIAL TYPE, 2022-2024 (KILOTON)

- TABLE 39 ASIA PACIFIC: INDUSTRIAL GASKETS MARKET, BY MATERIAL TYPE, 2025-2030 (KILOTON)

- TABLE 40 ASIA PACIFIC: INDUSTRIAL GASKETS MARKET, BY PRODUCT TYPE, 2022-2024 (USD MILLION)

- TABLE 41 ASIA PACIFIC: INDUSTRIAL GASKETS MARKET, BY PRODUCT TYPE, 2025-2030 (USD MILLION)

- TABLE 42 ASIA PACIFIC: INDUSTRIAL GASKETS MARKET, BY PRODUCT TYPE, 2022-2024 (KILOTON)

- TABLE 43 ASIA PACIFIC: INDUSTRIAL GASKETS MARKET, BY PRODUCT TYPE, 2025-2030 (KILOTON)

- TABLE 44 ASIA PACIFIC: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 45 ASIA PACIFIC: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 46 ASIA PACIFIC: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 47 ASIA PACIFIC: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 48 CHINA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 49 CHINA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 50 CHINA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 51 CHINA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 52 INDIA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 53 INDIA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 54 INDIA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 55 INDIA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 56 JAPAN: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 57 JAPAN: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 58 JAPAN: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 59 JAPAN: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 60 SOUTH KOREA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 61 SOUTH KOREA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 62 SOUTH KOREA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 63 SOUTH KOREA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 64 THAILAND: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 65 THAILAND: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 66 THAILAND: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 67 THAILAND: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 68 AUSTRALIA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 69 AUSTRALIA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 70 AUSTRALIA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 71 AUSTRALIA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 72 REST OF ASIA PACIFIC: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 73 REST OF ASIA PACIFIC: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 74 REST OF ASIA PACIFIC: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 75 REST OF ASIA PACIFIC: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 76 EUROPE: INDUSTRIAL GASKETS MARKET, BY COUNTRY, 2022-2024 (USD MILLION)

- TABLE 77 EUROPE: INDUSTRIAL GASKETS MARKET, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 78 EUROPE: INDUSTRIAL GASKETS MARKET, BY COUNTRY, 2022-2024 (KILOTON)

- TABLE 79 EUROPE: INDUSTRIAL GASKETS MARKET, BY COUNTRY, 2025-2030 (KILOTON)

- TABLE 80 EUROPE: INDUSTRIAL GASKETS MARKET, BY MATERIAL TYPE, 2022-2024 (USD MILLION)

- TABLE 81 EUROPE: INDUSTRIAL GASKETS MARKET, BY MATERIAL TYPE, 2025-2030 (USD MILLION)

- TABLE 82 EUROPE: INDUSTRIAL GASKETS MARKET, BY MATERIAL TYPE, 2022-2024 (KILOTON)

- TABLE 83 EUROPE: INDUSTRIAL GASKETS MARKET, BY MATERIAL TYPE, 2025-2030 (KILOTON)

- TABLE 84 EUROPE: INDUSTRIAL GASKETS MARKET, BY PRODUCT TYPE, 2022-2024 (USD MILLION)

- TABLE 85 EUROPE: INDUSTRIAL GASKETS MARKET, BY PRODUCT TYPE, 2025-2030 (USD MILLION)

- TABLE 86 EUROPE: INDUSTRIAL GASKETS MARKET, BY PRODUCT TYPE, 2022-2024 (KILOTON)

- TABLE 87 EUROPE: INDUSTRIAL GASKETS MARKET, BY PRODUCT TYPE, 2025-2030 (KILOTON)

- TABLE 88 EUROPE: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 89 EUROPE: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 90 EUROPE: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 91 EUROPE: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 92 GERMANY: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 93 GERMANY: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 94 GERMANY: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 95 GERMANY: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 96 FRANCE: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 97 FRANCE: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 98 FRANCE: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 99 FRANCE: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 100 SPAIN: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 101 SPAIN: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 102 SPAIN: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 103 SPAIN: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 104 UK: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 105 UK: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 106 UK: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 107 UK: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 108 ITALY: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 109 ITALY: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 110 ITALY: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 111 ITALY: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 112 RUSSIA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 113 RUSSIA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 114 RUSSIA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 115 RUSSIA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 116 NETHERLANDS: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 117 NETHERLANDS: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 118 NETHERLANDS: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 119 NETHERLANDS: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 120 REST OF EUROPE: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 121 REST OF EUROPE: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 122 REST OF EUROPE: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 123 REST OF EUROPE: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 124 NORTH AMERICA: INDUSTRIAL GASKETS MARKET, BY COUNTRY, 2022-2024 (USD MILLION)

- TABLE 125 NORTH AMERICA: INDUSTRIAL GASKETS MARKET, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 126 NORTH AMERICA: INDUSTRIAL GASKETS MARKET, BY COUNTRY, 2022-2024 (KILOTON)

- TABLE 127 NORTH AMERICA: INDUSTRIAL GASKETS MARKET, BY COUNTRY, 2025-2030 (KILOTON)

- TABLE 128 NORTH AMERICA: INDUSTRIAL GASKETS MARKET, BY MATERIAL TYPE, 2022-2024 (USD MILLION)

- TABLE 129 NORTH AMERICA: INDUSTRIAL GASKETS MARKET, BY MATERIAL TYPE, 2025-2030 (USD MILLION)

- TABLE 130 NORTH AMERICA: INDUSTRIAL GASKETS MARKET, BY MATERIAL TYPE, 2022-2024 (KILOTON)

- TABLE 131 NORTH AMERICA: INDUSTRIAL GASKETS MARKET, BY MATERIAL TYPE, 2025-2030 (KILOTON)

- TABLE 132 NORTH AMERICA: INDUSTRIAL GASKETS MARKET, BY PRODUCT TYPE, 2022-2024 (USD MILLION)

- TABLE 133 NORTH AMERICA: INDUSTRIAL GASKETS MARKET, BY PRODUCT TYPE, 2025-2030 (USD MILLION)

- TABLE 134 NORTH AMERICA: INDUSTRIAL GASKETS MARKET, BY PRODUCT TYPE, 2022-2024 (KILOTON)

- TABLE 135 NORTH AMERICA: INDUSTRIAL GASKETS MARKET, BY PRODUCT TYPE, 2025-2030 (KILOTON)

- TABLE 136 NORTH AMERICA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 137 NORTH AMERICA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 138 NORTH AMERICA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 139 NORTH AMERICA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 140 US: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 141 US: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 142 US: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 143 US: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 144 CANADA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 145 CANADA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 146 CANADA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 147 CANADA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 148 MEXICO: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 149 MEXICO: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 150 MEXICO: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 151 MEXICO: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 152 MIDDLE EAST & AFRICA: INDUSTRIAL GASKETS MARKET, BY COUNTRY, 2022-2024 (USD MILLION)

- TABLE 153 MIDDLE EAST & AFRICA: INDUSTRIAL GASKETS MARKET, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 154 MIDDLE EAST & AFRICA: INDUSTRIAL GASKETS MARKET, BY COUNTRY, 2022-2024 (KILOTON)

- TABLE 155 MIDDLE EAST & AFRICA: INDUSTRIAL GASKETS MARKET, BY COUNTRY, 2025-2030 (KILOTON)

- TABLE 156 MIDDLE EAST & AFRICA: INDUSTRIAL GASKETS MARKET, BY MATERIAL TYPE, 2022-2024 (USD MILLION)

- TABLE 157 MIDDLE EAST & AFRICA: INDUSTRIAL GASKETS MARKET, BY MATERIAL TYPE, 2025-2030 (USD MILLION)

- TABLE 158 MIDDLE EAST & AFRICA: INDUSTRIAL GASKETS MARKET, BY MATERIAL TYPE, 2022-2024 (KILOTON)

- TABLE 159 MIDDLE EAST & AFRICA: INDUSTRIAL GASKETS MARKET, BY MATERIAL TYPE, 2025-2030 (KILOTON)

- TABLE 160 MIDDLE EAST & AFRICA: INDUSTRIAL GASKETS MARKET, BY PRODUCT TYPE, 2022-2024 (USD MILLION)

- TABLE 161 MIDDLE EAST & AFRICA: INDUSTRIAL GASKETS MARKET, BY PRODUCT TYPE, 2025-2030 (USD MILLION)

- TABLE 162 MIDDLE EAST & AFRICA: INDUSTRIAL GASKETS MARKET, BY PRODUCT TYPE, 2022-2024 (KILOTON)

- TABLE 163 MIDDLE EAST & AFRICA: INDUSTRIAL GASKETS MARKET, BY PRODUCT TYPE, 2025-2030 (KILOTON)

- TABLE 164 MIDDLE EAST & AFRICA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 165 MIDDLE EAST & AFRICA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 166 MIDDLE EAST & AFRICA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 167 MIDDLE EAST & AFRICA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 168 SAUDI ARABIA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 169 SAUDI ARABIA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 170 SAUDI ARABIA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 171 SAUDI ARABIA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 172 UAE: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 173 UAE: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 174 UAE: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 175 UAE: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 176 REST OF GCC COUNTRIES: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 177 REST OF GCC COUNTRIES: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 178 REST OF GCC COUNTRIES: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 179 REST OF GCC COUNTRIES: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 180 SOUTH AFRICA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 181 SOUTH AFRICA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 182 SOUTH AFRICA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 183 SOUTH AFRICA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 184 REST OF MIDDLE EAST & AFRICA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 185 REST OF MIDDLE EAST & AFRICA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 186 REST OF MIDDLE EAST & AFRICA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 187 REST OF MIDDLE EAST & AFRICA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 188 SOUTH AMERICA: INDUSTRIAL GASKETS MARKET, BY COUNTRY, 2022-2024 (USD MILLION)

- TABLE 189 SOUTH AMERICA: INDUSTRIAL GASKETS MARKET, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 190 SOUTH AMERICA: INDUSTRIAL GASKETS MARKET, BY COUNTRY, 2022-2024 (KILOTON)

- TABLE 191 SOUTH AMERICA: INDUSTRIAL GASKETS MARKET, BY COUNTRY, 2025-2030 (KILOTON)

- TABLE 192 SOUTH AMERICA: INDUSTRIAL GASKETS MARKET, BY MATERIAL TYPE, 2022-2024 (USD MILLION)

- TABLE 193 SOUTH AMERICA: INDUSTRIAL GASKETS MARKET, BY MATERIAL TYPE, 2025-2030 (USD MILLION)

- TABLE 194 SOUTH AMERICA: INDUSTRIAL GASKETS MARKET, BY MATERIAL TYPE, 2022-2024 (KILOTON)

- TABLE 195 SOUTH AMERICA: INDUSTRIAL GASKETS MARKET, BY MATERIAL TYPE, 2025-2030 (KILOTON)

- TABLE 196 SOUTH AMERICA: INDUSTRIAL GASKETS MARKET, BY PRODUCT TYPE, 2022-2024 (USD MILLION)

- TABLE 197 SOUTH AMERICA: INDUSTRIAL GASKETS MARKET, BY PRODUCT TYPE, 2025-2030 (USD MILLION)

- TABLE 198 SOUTH AMERICA: INDUSTRIAL GASKETS MARKET, BY PRODUCT TYPE, 2022-2024 (KILOTON)

- TABLE 199 SOUTH AMERICA: INDUSTRIAL GASKETS MARKET, BY PRODUCT TYPE, 2025-2030 (KILOTON)

- TABLE 200 SOUTH AMERICA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 201 SOUTH AMERICA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 202 SOUTH AMERICA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 203 SOUTH AMERICA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 204 BRAZIL: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 205 BRAZIL: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 206 BRAZIL: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 207 BRAZIL: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 208 ARGENTINA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 209 ARGENTINA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 210 ARGENTINA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 211 ARGENTINA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 212 REST OF SOUTH AMERICA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 213 REST OF SOUTH AMERICA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 214 REST OF SOUTH AMERICA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 215 REST OF SOUTH AMERICA: INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 216 INDUSTRIAL GASKETS MARKET: OVERVIEW OF MAJOR STRATEGIES ADOPTED BY KEY PLAYERS, 2020-2025

- TABLE 217 INDUSTRIAL GASKETS MARKET: DEGREE OF COMPETITION, 2024

- TABLE 218 INDUSTRIAL GASKETS MARKET: END-USE INDUSTRY FOOTPRINT

- TABLE 219 INDUSTRIAL GASKETS MARKET: MATERIAL TYPE FOOTPRINT

- TABLE 220 INDUSTRIAL GASKETS MARKET: REGION FOOTPRINT

- TABLE 221 INDUSTRIAL GASKETS MARKET: DETAILED LIST OF KEY STARTUPS/SMES

- TABLE 222 INDUSTRIAL GASKETS MARKET: COMPETITIVE BENCHMARKING OF KEY STARTUPS/SMES

- TABLE 223 INDUSTRIAL GASKETS MARKET: PRODUCT LAUNCHES, JANUARY 2020-MAY 2025

- TABLE 224 INDUSTRIAL GASKETS MARKET: DEALS, JANUARY 2020-MAY 2025

- TABLE 225 INDUSTRIAL GASKETS MARKET: EXPANSIONS, JANUARY 2020-MAY 2025

- TABLE 226 KLINGER GROUP: COMPANY OVERVIEW

- TABLE 227 KLINGER GROUP: PRODUCTS OFFERED

- TABLE 228 KLINGER GROUP: PRODUCT LAUNCHES

- TABLE 229 KLINGER GROUP: DEALS

- TABLE 230 KLINGER GROUP: EXPANSIONS

- TABLE 231 W.L. GORE & ASSOCIATES, INC.: COMPANY OVERVIEW

- TABLE 232 W.L. GORE & ASSOCIATES, INC.: PRODUCTS OFFERED

- TABLE 233 GARLOCK: COMPANY OVERVIEW

- TABLE 234 GARLOCK: PRODUCTS OFFERED

- TABLE 235 TEADIT: COMPANY OVERVIEW

- TABLE 236 TEADIT: PRODUCTS OFFERED

- TABLE 237 TEADIT: EXPANSIONS

- TABLE 238 PARKER HANNIFIN CORP.: COMPANY OVERVIEW

- TABLE 239 PARKER HANNIFIN CORP.: PRODUCTS OFFERED

- TABLE 240 FLEXITALLIC: COMPANY OVERVIEW

- TABLE 241 FLEXITALLIC: PRODUCTS OFFERED

- TABLE 242 FLEXITALLIC: PRODUCT LAUNCHES

- TABLE 243 FLEXITALLIC: DEALS

- TABLE 244 FLEXITALLIC.: EXPANSIONS

- TABLE 245 LAMONS: COMPANY OVERVIEW

- TABLE 246 LAMONS: PRODUCTS OFFERED

- TABLE 247 LAMONS: PRODUCT LAUNCHES

- TABLE 248 GOODRICH GASKET: COMPANY OVERVIEW

- TABLE 249 GOODRICH GASKET: PRODUCTS OFFERED

- TABLE 250 JAMES WALKER GROUP: COMPANY OVERVIEW

- TABLE 251 JAMES WALKER GROUP: PRODUCTS OFFERED

- TABLE 252 JAMES WALKER GROUP: DEALS

- TABLE 253 FREUDENBERG SEALING TECHNOLOGIES: COMPANY OVERVIEW

- TABLE 254 FREUDENBERG SEALING TECHNOLOGIES: PRODUCTS OFFERED

- TABLE 255 FREUDENBERG SEALING TECHNOLOGIES: EXPANSIONS

- TABLE 256 DONIT TESNIT, D.O.O.: COMPANY OVERVIEW

- TABLE 257 DONIT TESNIT, D.O.O.: PRODUCTS OFFERED

- TABLE 258 DONIT TESNIT, D.O.O.: PRODUCT LAUNCHES

- TABLE 259 DATWYLER HOLDING INC.: COMPANY OVERVIEW

- TABLE 260 DATWYLER HOLDING INC.: PRODUCTS OFFERED

- TABLE 261 IGP: COMPANY OVERVIEW

- TABLE 262 3M: COMPANY OVERVIEW

- TABLE 263 TRELLEBORG GROUP: COMPANY OVERVIEW

- TABLE 264 SPIRA POWER: COMPANY OVERVIEW

- TABLE 265 PGE INDUSTRIES PVT. LTD.: COMPANY OVERVIEW

- TABLE 266 CENTAURO S.R.L.: COMPANY OVERVIEW

- TABLE 267 DENVER RUBBER COMPANY: COMPANY OVERVIEW

- TABLE 268 HENNIG GASKET & SEALS: COMPANY OVERVIEW

- TABLE 269 HYDRO SILICA: COMPANY OVERVIEW

- TABLE 270 PHELPS: COMPANY OVERVIEW

- TABLE 271 REDCO: COMPANY OVERVIEW

- TABLE 272 KENT RUBBER: COMPANY OVERVIEW

- TABLE 273 VSP TECHNOLOGIES: COMPANY OVERVIEW

- TABLE 274 NATIONAL RUBBER CORPORATION: COMPANY OVERVIEW

- TABLE 275 GARDICO: COMPANY OVERVIEW

List of Figures

- FIGURE 1 RESEARCH DESIGN

- FIGURE 2 TOP-DOWN APPROACH

- FIGURE 3 BOTTOM-UP APPROACH

- FIGURE 4 DATA TRIANGULATION

- FIGURE 5 SEMI-METALLIC SEGMENT TO ACCOUNT FOR LARGEST MARKET SHARE IN 2025

- FIGURE 6 SOFT GASKETS SEGMENT TO REGISTER HIGHEST GROWTH BETWEEN 2025 & 2030

- FIGURE 7 REFINERIES SEGMENT ACCOUNTED FOR LARGEST MARKET SHARE IN 2024

- FIGURE 8 ASIA PACIFIC ACCOUNTED FOR LARGEST MARKET SHARE IN 2024

- FIGURE 9 EMERGING ECONOMIES TO OFFER LUCRATIVE OPPORTUNITIES FOR MARKET GROWTH

- FIGURE 10 NON-METALLIC MATERIAL SEGMENT TO REGISTER HIGHEST GROWTH DURING FORECAST PERIOD

- FIGURE 11 SOFT GASKETS SEGMENT TO WITNESS HIGH GROWTH DURING FORECAST PERIOD

- FIGURE 12 REFINERIES SEGMENT TO LEAD MARKET IN 2025

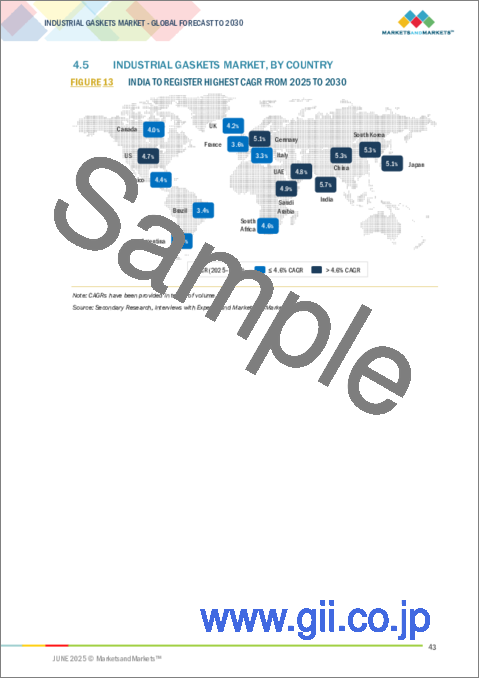

- FIGURE 13 INDIA TO REGISTER HIGHEST CAGR FROM 2025 TO 2030

- FIGURE 14 INDUSTRIAL GASKETS MARKET: DRIVERS, RESTRAINTS, OPPORTUNITIES, AND CHALLENGES

- FIGURE 15 INDUSTRIAL GASKETS MARKET: VALUE CHAIN ANALYSIS

- FIGURE 16 INDUSTRIAL GASKETS MARKET: PORTER'S FIVE FORCES ANALYSIS

- FIGURE 17 INDUSTRIAL GASKETS MARKET: ECOSYSTEM

- FIGURE 18 AVERAGE SELLING PRICE TREND OF INDUSTRIAL GASKETS, BY REGION, 2022-2030 (USD/KG)

- FIGURE 19 EXPORT TRADE DATA FOR HS CODE 401693-COMPLIANT PRODUCTS, BY COUNTRY (USD THOUSAND)

- FIGURE 20 IMPORT TRADE DATA FOR HS CODE 401693-COMPLIANT PRODUCTS, BY COUNTRY (USD THOUSAND)

- FIGURE 21 INFLUENCE OF STAKEHOLDERS ON BUYING PROCESS FOR TOP THREE END-USE INDUSTRIES

- FIGURE 22 KEY BUYING CRITERIA FOR TOP THREE END-USE INDUSTRIES

- FIGURE 23 INVESTMENT AND FUNDING SCENARIO, 2020-2023 (USD MILLION)

- FIGURE 24 PATENTS APPLIED AND GRANTED, 2014-2024

- FIGURE 25 LEGAL STATUS OF PATENTS, 2014-2024

- FIGURE 26 TOP JURISDICTIONS

- FIGURE 27 INDUSTRIAL GASKETS MARKET: TRENDS/DISRUPTIONS IMPACTING CUSTOMER BUSINESS

- FIGURE 28 SEMI-METALLIC INDUSTRIAL GASKETS TO DOMINATE MARKET DURING FORECAST PERIOD

- FIGURE 29 SOFT GASKETS SEGMENT TO DOMINATE MARKET DURING FORECAST PERIOD

- FIGURE 30 REFINERIES SEGMENT WILL DOMINATE MARKET DURING FORECAST PERIOD

- FIGURE 31 ASIA PACIFIC TO REGISTER HIGHEST GROWTH DURING FORECAST PERIOD

- FIGURE 32 ASIA PACIFIC: INDUSTRIAL GASKETS MARKET SNAPSHOT

- FIGURE 33 EUROPE: INDUSTRIAL GASKETS MARKET SNAPSHOT

- FIGURE 34 INDUSTRIAL GASKETS MARKET: REVENUE ANALYSIS OF KEY PLAYERS, 2022-2024 (USD BILLION)

- FIGURE 35 INDUSTRIAL GASKETS MARKET SHARE ANALYSIS, 2024

- FIGURE 36 INDUSTRIAL GASKETS MARKET: COMPANY VALUATION OF LEADING COMPANIES, 2024 (USD MILLION)

- FIGURE 37 INDUSTRIAL GASKETS MARKET: FINANCIAL METRICS OF LEADING COMPANIES, 2024

- FIGURE 38 INDUSTRIAL GASKETS MARKET: BRAND/PRODUCT COMPARISON

- FIGURE 39 INDUSTRIAL GASKETS MARKET: COMPANY EVALUATION MATRIX (KEY PLAYERS), 2024

- FIGURE 40 INDUSTRIAL GASKETS MARKET: COMPANY FOOTPRINT

- FIGURE 41 INDUSTRIAL GASKETS MARKET: COMPANY EVALUATION MATRIX (STARTUPS/SMES), 2024

- FIGURE 42 KLINGER GROUP: COMPANY SNAPSHOT

- FIGURE 43 PARKER HANNIFIN CORP.: COMPANY SNAPSHOT

- FIGURE 44 DATWYLER HOLDING INC.: COMPANY SNAPSHOT

The industrial gaskets market is projected to reach USD 16.84 billion by 2030 from USD 12.76 billion in 2025, at a CAGR of 5.7% during the forecast period. As emerging economies like China, India, and Southeast Asian nations undergo accelerated industrialization, there is a rising need for reliable sealing solutions in critical sectors such as oil & gas, chemical processing, power generation, water treatment, and manufacturing. Industrial gaskets play a vital role in these industries by preventing leaks, maintaining pressure, and ensuring operational safety across pipelines, reactors, compressors, and other machinery. Stricter environmental and safety regulations are also fueling demand, as industries are increasingly required to control emissions, prevent hazardous leaks, and adhere to global standards. Gaskets help achieve compliance by offering dependable, leak-proof sealing performance. Simultaneously, the growth of renewable energy projects, like wind, solar, and hydrogen systems, has opened new application areas for high-performance, corrosion-resistant gaskets. Technological innovations in materials, such as expanded PTFE, graphite, and metal-reinforced composites, have significantly enhanced gasket durability and chemical resistance. Alongside this, modern manufacturing techniques like CNC cutting, laser fabrication, and 3D printing allow for greater customization and precision, making gaskets suitable for more complex and specialized applications. The growing need for maintenance and replacement gaskets in aging industrial infrastructure further contributes to market expansion, especially in regions with established heavy industries.

| Scope of the Report | |

|---|---|

| Years Considered for the Study | 2021-2030 |

| Base Year | 2024 |

| Forecast Period | 2025-2030 |

| Units Considered | Value (USD Million)/Volume (Kiloton) |

| Segments | Volume (Kiloton) |

| Regions covered | North America, Europe, APAC, RoW |

"Semi-metallic gaskets is the second-fastest-growing segment in the industrial gaskets market during the forecast period."

Semi-metallic gaskets are engineered sealing components that combine both metallic and non-metallic materials to deliver a balanced performance of strength, flexibility, and sealing effectiveness. Designed for applications that require greater resilience than soft gaskets but more adaptability than fully metallic ones, semi-metallic gaskets are widely used in industries such as oil & gas, petrochemicals, power generation, and marine engineering. These gaskets are particularly suitable for medium-to-high-pressure and temperature environments where fluctuating conditions and chemical exposure demand robust and reliable sealing. One of the most common types of semi-metallic gaskets is the spiral wound gasket, which consists of alternating layers of metal winding (typically stainless steel) and soft filler material like graphite or PTFE. Semi-metallic gaskets offer excellent recovery and load-bearing properties, allowing them to maintain a seal even under thermal cycling and pressure variations. Their versatility makes them ideal for use in flange joints, heat exchangers, boilers, and pressure vessels. As industries demand higher safety and performance standards, the popularity of semi-metallic gaskets continues to rise due to their durability, sealing efficiency, and ability to meet stringent regulatory requirements.

.

"Power generation end-use industry is the second fastest-growing segment in the industrial gaskets market during the forecast period."

Gaskets play a critical role in the power generation industry by ensuring safe, efficient, and leak-free operations across a wide range of equipment and systems. Whether in fossil fuel-based plants, nuclear facilities, or renewable energy systems, gaskets are essential for sealing joints in boilers, turbines, compressors, heat exchangers, flanges, valves, and piping networks. These components prevent the leakage of high-pressure steam, gases, and liquids, which is vital not only for operational efficiency but also for worker safety and environmental protection. In power plants, conditions often involve extreme temperatures, high pressures, and exposure to corrosive substances. As such, the industry relies heavily on semi-metallic and metallic gaskets, such as spiral wound gaskets and kammprofile gaskets, due to their superior durability, resistance to thermal cycling, and ability to maintain sealing integrity over long periods. In nuclear applications, the demand for high-specification, radiation-resistant gaskets adds an additional layer of complexity, requiring advanced materials and stringent quality control. With the global shift toward cleaner energy and the modernization of aging power infrastructure, the demand for advanced gasket solutions is increasing. Renewable energy facilities such as geothermal, biomass, and hydrogen plants also require high-performance gaskets for equipment like heat recovery systems and fuel cells. In this evolving landscape, gaskets contribute significantly to enhancing system reliability, reducing downtime, and ensuring compliance with strict environmental and safety regulations.

"North America is projected to account for the second-largest market share in the industrial gaskets market."

The industrial gaskets market in North America is experiencing consistent growth, driven by strong demand from key industries such as power generation, refineries, and chemical processing. These sectors depend heavily on reliable sealing solutions to ensure safe and efficient operations under harsh conditions involving high pressure, extreme temperatures, and corrosive chemicals. In the US, which leads the regional market, the presence of extensive power infrastructure, large-scale oil refineries, and a robust chemical manufacturing base fuels significant demand for high-performance gaskets. The country's ongoing shift toward cleaner energy and the modernization of aging plants further amplify the need for durable, compliant sealing systems. Canada contributes to the market with its emphasis on energy production, particularly through oil sands, natural gas, and hydroelectric power. The focus on environmental sustainability and industrial safety drives demand for advanced gasket technologies that can withstand aggressive operating conditions while meeting stringent regulatory standards. Meanwhile, Mexico is emerging as a key growth area, supported by expanding industrial capacity and investment in oil refining, petrochemicals, and manufacturing. The country's growing role as a production hub increases the use of gaskets in assembly and equipment operations. With ongoing infrastructure upgrades, environmental regulations, and technological advancements shaping industry requirements, North America presents strong opportunities for innovation and expansion in the industrial gaskets market.

Extensive primary interviews were conducted to determine and verify the market size for several segments and subsegments, and the information was gathered through secondary research.

The break-up of primary interviews is given below:

- By Department: Tier 1: 40%, Tier 2: 25%, and Tier 3: 35%

- By Designation: C Level: 35%, Director Level: 30%, and Executives: 35%

- By Region: North America: 25%, Europe: 35%, Asia Pacific: 30%, South America: 5%, and the Middle East & Africa 5%

Klinger Group (Austria), W.L. Gore & Associates, Inc. (US), Garlock (US), Goodrich Gasket (India), James Walker Group (UK), Freudenberg Sealing Technologies (Germany), Donit Tesnit (Slovenia), Datwyler Holdings Inc. (Switzerland), Teadit (Brazil), and Parker Hannifin Corp. (US) are some of the key players in the industrial gaskets market.

The study includes an in-depth competitive analysis of these key players, with their company profiles, recent developments, and key market strategies.

Research Coverage

The market study covers the industrial gaskets market across various segments. It aims to estimate the market size and the growth potential of this market across different segments based on material type, product type, end-use industry, and region. The study also includes an in-depth competitive analysis of key players in the market, their company profiles, key observations related to their products and business offerings, recent developments undertaken by them, and key growth strategies adopted by them to improve their position in the industrial gaskets market.

Key Benefits of Buying the Report

The report aims to assist market leaders and new entrants in approximating the revenue figures for the overall industrial gaskets market, including its segments and sub-segments. This report is projected to help stakeholders understand the competitive landscape of the market, gain insights to improve the position of their businesses and plan suitable go-to-market strategies. The report also aims to help stakeholders understand the pulse of the market and provide them with information on the key market drivers, restraints, challenges, and opportunities.

The report provides insights on the following pointers:

- Analysis of key drivers (industrial growth & infrastructure expansion and rising demand from oil & gas and power generation sectors), restraints (fluctuating raw material prices), opportunities (emerging markets and industrial zones and expansion in renewable and hydrogen energy), challenges (complex operating environments)

- Market Development: Comprehensive information about lucrative markets - the report analyses the industrial gaskets market across varied regions

Market Diversification: Exhaustive information about new products & services, untapped geographies, recent developments, and investments in the industrial gaskets market

- Competitive Assessment: In-depth assessment of market shares, growth strategies, and product and service offerings of leading players like Klinger Group (Austria), W.L. Gore & Associates, Inc. (US), Garlock (US), Goodrich Gasket (India), James Walker Group (UK), Freudenberg Sealing Technologies (Germany), Donit Tesnit (Slovenia), Datwyler Holdings Inc. (Switzerland), Teadit (Brazil), and Parker Hannifin Corp. (US).

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 STUDY OBJECTIVES

- 1.2 MARKET DEFINITION

- 1.3 STUDY SCOPE

- 1.3.1 MARKET SEGMENTATION & REGIONAL SCOPE

- 1.3.2 INCLUSIONS & EXCLUSIONS OF STUDY

- 1.3.3 YEARS CONSIDERED

- 1.4 CURRENCY CONSIDERED

- 1.5 UNITS CONSIDERED

- 1.6 STAKEHOLDERS

- 1.7 SUMMARY OF CHANGES

2 RESEARCH METHODOLOGY

- 2.1 RESEARCH DATA

- 2.1.1 SECONDARY DATA

- 2.1.1.1 Key data from secondary sources

- 2.1.2 PRIMARY DATA

- 2.1.2.1 Key data from primary sources

- 2.1.2.2 Breakdown of primary interviews

- 2.1.2.3 Key industry insights

- 2.1.1 SECONDARY DATA

- 2.2 MARKET SIZE ESTIMATION

- 2.2.1 TOP-DOWN APPROACH

- 2.2.2 BOTTOM-UP APPROACH

- 2.3 DATA TRIANGULATION

- 2.4 RESEARCH ASSUMPTIONS

3 EXECUTIVE SUMMARY

4 PREMIUM INSIGHTS

- 4.1 ATTRACTIVE OPPORTUNITIES FOR PLAYERS IN INDUSTRIAL GASKETS MARKET

- 4.2 INDUSTRIAL GASKETS MARKET, BY MATERIAL TYPE

- 4.3 INDUSTRIAL GASKETS MARKET, BY PRODUCT TYPE

- 4.4 INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY

- 4.5 INDUSTRIAL GASKETS MARKET, BY COUNTRY

5 MARKET OVERVIEW

- 5.1 INTRODUCTION

- 5.2 MARKET DYNAMICS

- 5.2.1 DRIVERS

- 5.2.1.1 Increasing demand from oil & gas industry

- 5.2.1.2 Increasing focus on plant safety and reliability

- 5.2.1.3 Rapid industrialization and infrastructure development

- 5.2.2 RESTRAINTS

- 5.2.2.1 Fluctuating raw material prices

- 5.2.2.2 Availability of alternative sealing solutions

- 5.2.3 OPPORTUNITIES

- 5.2.3.1 Growth in eco-friendly and sustainable gasket solutions

- 5.2.3.2 Technological advancements and digitalization

- 5.2.4 CHALLENGES

- 5.2.4.1 Supply chain disruptions and workforce shortages

- 5.2.4.2 Competition from low-cost manufacturers

- 5.2.1 DRIVERS

- 5.3 VALUE CHAIN ANALYSIS

- 5.3.1 RAW MATERIAL SUPPLIERS

- 5.3.2 MANUFACTURERS

- 5.3.3 DISTRIBUTORS

- 5.3.4 END USERS

- 5.4 PORTER'S FIVE FORCES ANALYSIS

- 5.4.1 THREAT OF NEW ENTRANTS

- 5.4.2 THREAT OF SUBSTITUTES

- 5.4.3 BARGAINING POWER OF SUPPLIERS

- 5.4.4 BARGAINING POWER OF BUYERS

- 5.4.5 INTENSITY OF COMPETITIVE RIVALRY

- 5.5 ECOSYSTEM ANALYSIS

- 5.6 MACROECONOMIC INDICATORS

- 5.6.1 GDP TRENDS AND FORECASTS

- 5.7 PRICING ANALYSIS

- 5.7.1 AVERAGE SELLING PRICE TREND, BY REGION

- 5.7.2 AVERAGE SELLING PRICE, BY MATERIAL TYPE

- 5.7.3 AVERAGE SELLING PRICE OF INDUSTRIAL GASKETS OFFERED BY KEY PLAYERS, BY END-USE INDUSTRY

- 5.8 TRADE ANALYSIS

- 5.8.1 EXPORT SCENARIO (HS CODE 401693)

- 5.8.2 IMPORT SCENARIO (HS CODE 401693)

- 5.9 KEY STAKEHOLDERS AND BUYING CRITERIA

- 5.9.1 KEY STAKEHOLDERS IN BUYING PROCESS

- 5.9.2 QUALITY

- 5.9.3 SERVICE

- 5.9.4 BUYING CRITERIA

- 5.10 INVESTMENT AND FUNDING SCENARIO

- 5.11 PATENT ANALYSIS

- 5.11.1 INTRODUCTION

- 5.11.2 LEGAL STATUS OF PATENTS

- 5.11.3 JURISDICTION ANALYSIS

- 5.12 KEY CONFERENCES AND EVENTS, 2025-2026

- 5.13 IMPACT OF AI/GEN AI

- 5.14 CASE STUDY ANALYSIS

- 5.14.1 CASE STUDY ON USE OF INDUSTRIAL GASKETS IN NUCLEAR REACTORS

- 5.14.2 CASE STUDY ON INDUSTRIAL GASKET APPLICATIONS IN HIGH-PRESSURE STEAM SYSTEMS

- 5.15 REGULATORY LANDSCAPE

- 5.15.1 REGULATIONS

- 5.15.1.1 Europe

- 5.15.1.2 Asia Pacific

- 5.15.1.3 North America

- 5.15.2 STANDARDS

- 5.15.2.1 ISO 7483

- 5.15.2.2 ISO 15848-1

- 5.15.3 REGULATORY BODIES, GOVERNMENT BODIES, AND OTHER AGENCIES

- 5.15.1 REGULATIONS

- 5.16 TECHNOLOGY ANALYSIS

- 5.16.1 KEY TECHNOLOGIES

- 5.16.1.1 Sealing simulation and finite element analysis

- 5.16.1.2 High-temperature and high-pressure technology

- 5.16.2 COMPLEMENTARY TECHNOLOGIES

- 5.16.2.1 Thermal imaging and IR monitoring

- 5.16.3 ADJACENT TECHNOLOGIES

- 5.16.3.1 Sustainable manufacturing & green materials

- 5.16.1 KEY TECHNOLOGIES

- 5.17 TRENDS/DISRUPTIONS IMPACTING CUSTOMER BUSINESS

- 5.18 IMPACT OF 2025 US TARIFF - INDUSTRIAL GASKETS MARKET

- 5.18.1 INTRODUCTION

- 5.18.2 KEY TARIFF RATES

- 5.18.3 PRICE IMPACT ANALYSIS

- 5.18.4 IMPACT ON COUNTRY/REGION

- 5.18.4.1 US

- 5.18.4.2 Europe

- 5.18.4.3 Asia Pacific

- 5.18.5 IMPACT ON END-USE INDUSTRIES

6 INDUSTRIAL GASKETS MARKET, BY MATERIAL TYPE

- 6.1 INTRODUCTION

- 6.2 SEMI-METALLIC

- 6.2.1 RESILIENCE AND DURABILITY IN AGGRESSIVE ENVIRONMENTS TO DRIVE ADOPTION

- 6.3 NON-METALLIC

- 6.3.1 EASY INSTALLATION & COST-EFFECTIVENESS TO DRIVE MARKET

- 6.3.2 PTFE

- 6.3.3 FLEXIBLE GRAPHITE

- 6.3.4 EPDM

- 6.3.5 COMPRESSED NON-ASBESTOS

- 6.3.6 OTHER NON-METALLIC INDUSTRIAL GASKETS

- 6.4 METALLIC

- 6.4.1 USAGE IN EXTREMELY HIGH-PRESSURE AND HIGH-TEMPERATURE APPLICATIONS TO PROPEL ADOPTION

- 6.4.2 STAINLESS STEEL

- 6.4.3 ALUMINUM

- 6.4.4 COPPER

- 6.4.5 TITANIUM

- 6.4.6 OTHER METALLIC INDUSTRIAL GASKETS

7 INDUSTRIAL GASKETS MARKET, BY PRODUCT TYPE

- 7.1 INTRODUCTION

- 7.2 SOFT GASKETS

- 7.2.1 INCREASED USAGE IN HVAC SYSTEMS AND LOW-PRESSURE CHEMICAL PROCESSING EQUIPMENT TO DRIVE ADOPTION

- 7.3 SPIRAL WOUND GASKETS

- 7.3.1 INCREASED USAGE IN INDUSTRIAL APPLICATIONS TO DRIVE MARKET

- 7.4 RING JOINT GASKETS

- 7.4.1 INCREASED DEMAND IN HIGH-PRESSURE AND HIGH-TEMPERATURE ENVIRONMENTS TO DRIVE ADOPTION

- 7.5 KAMMPROFILE GASKETS

- 7.5.1 SUPERIOR SEALING AT LOWER BOLT LOADS-KEY FACTOR DRIVING ADOPTION IN MARKET

- 7.6 JACKETED GASKETS

- 7.6.1 GOOD RESILIENCE OF JACKETED GASKETS TO DRIVE ADOPTION

- 7.7 CORRUGATED GASKETS

- 7.7.1 APPLICATIONS REQUIRING FLANGE MOVEMENT OF THERMAL CYCLING TO DRIVE MARKET

- 7.8 OTHER PRODUCT TYPES

- 7.8.1 O-RING GASKETS

- 7.8.2 COMPRESSED ASBESTOS FIBER GASKETS

8 INDUSTRIAL GASKETS MARKET, BY END-USE INDUSTRY

- 8.1 INTRODUCTION

- 8.2 REFINERIES

- 8.2.1 INCREASED ADOPTION IN PIPELINES, HEAT EXCHANGERS, AND DISTILLATION COLUMNS TO DRIVE MARKET

- 8.3 POWER GENERATION

- 8.3.1 NEED TO MAINTAIN EFFICIENT WATER FLOW AND COOLING IN HYDROELECTRIC POWER PLANTS TO PROPEL MARKET

- 8.3.2 LITHIUM INDUSTRY

- 8.4 CHEMICAL PROCESSING

- 8.4.1 GROWING CHEMICAL PROCESSING SECTOR TO DRIVE DEMAND FOR INDUSTRIAL GASKETS

- 8.4.2 HYDROGEN INDUSTRY

- 8.5 INDUSTRIAL MACHINERY

- 8.5.1 GROWTH IN MINING SECTOR TO PROPEL MARKET.

- 8.6 PULP & PAPER

- 8.6.1 FLEXIBILITY AND ABILITY TO ABSORB VIBRATIONS TO DRIVE ADOPTION

- 8.7 FOOD & PHARMACEUTICAL

- 8.7.1 GROWING PHARMACEUTICAL INDUSTRY IN INDIA TO SUPPORT MARKET GROWTH

- 8.8 SEMICONDUCTOR

- 8.8.1 DEVELOPMENTS IN SEMICONDUCTOR MANUFACTURING TO DRIVE MARKET

- 8.9 OTHER END-USE INDUSTRIES

- 8.9.1 TEXTILE

- 8.9.2 WATER TREATMENT

9 INDUSTRIAL GASKETS MARKET, BY REGION

- 9.1 INTRODUCTION

- 9.2 ASIA PACIFIC

- 9.2.1 CHINA

- 9.2.1.1 Strong growth in chemical and semiconductor industries to propel market

- 9.2.2 INDIA

- 9.2.2.1 Government investments and initiatives to support market growth

- 9.2.3 JAPAN

- 9.2.3.1 Rapid growth of various industries to drive market

- 9.2.4 SOUTH KOREA

- 9.2.4.1 High-tech manufacturing strength and presence of innovation-driven end-use industries to drive market

- 9.2.5 THAILAND

- 9.2.5.1 High focus on infrastructure development and modernization to drive market

- 9.2.6 AUSTRALIA

- 9.2.6.1 Expansion in power sector to propel market

- 9.2.7 REST OF ASIA PACIFIC

- 9.2.1 CHINA

- 9.3 EUROPE

- 9.3.1 GERMANY

- 9.3.1.1 Strong growth in chemical industry to drive market

- 9.3.2 FRANCE

- 9.3.2.1 Favorable business ecosystem and high investment in end-use industries to drive market

- 9.3.3 SPAIN

- 9.3.3.1 National policies aimed at industrial modernization to support market growth

- 9.3.4 UK

- 9.3.4.1 High investments in healthcare sector to drive market

- 9.3.5 ITALY

- 9.3.5.1 Wide industrial base to drive demand for reliable gasket solutions

- 9.3.6 RUSSIA

- 9.3.6.1 Substantial power generation infrastructure to propel market

- 9.3.7 NETHERLANDS

- 9.3.7.1 Strong growth in semiconductor industry to drive market

- 9.3.8 REST OF EUROPE

- 9.3.1 GERMANY

- 9.4 NORTH AMERICA

- 9.4.1 US

- 9.4.1.1 Expanding industrial base and increasing demand across key end-use industries to drive market

- 9.4.2 CANADA

- 9.4.2.1 Robust chemical industry to drive market growth

- 9.4.3 MEXICO

- 9.4.3.1 Continuous investment in energy sector to drive market

- 9.4.1 US

- 9.5 MIDDLE EAST & AFRICA

- 9.5.1 GCC COUNTRIES

- 9.5.1.1 Saudi Arabia

- 9.5.1.1.1 Strong industrial growth to drive market

- 9.5.1.2 UAE

- 9.5.1.2.1 Strong refining, power, and chemical sectors to drive market

- 9.5.1.3 Rest of GCC Countries

- 9.5.1.1 Saudi Arabia

- 9.5.2 SOUTH AFRICA

- 9.5.2.1 Growth in refining & power generation sectors to boost market

- 9.5.3 REST OF MIDDLE EAST & AFRICA

- 9.5.1 GCC COUNTRIES

- 9.6 SOUTH AMERICA

- 9.6.1 BRAZIL

- 9.6.1.1 Strong growth in end-use industries to drive market

- 9.6.2 ARGENTINA

- 9.6.2.1 Investment and modernization in chemical and refining sectors to drive market

- 9.6.3 REST OF SOUTH AMERICA

- 9.6.1 BRAZIL

10 COMPETITIVE LANDSCAPE

- 10.1 OVERVIEW

- 10.2 KEY PLAYER STRATEGIES/RIGHT TO WIN

- 10.3 REVENUE ANALYSIS

- 10.4 MARKET SHARE ANALYSIS

- 10.5 COMPANY VALUATION AND FINANCIAL METRICS

- 10.6 BRAND/PRODUCT COMPARISON ANALYSIS

- 10.7 COMPANY EVALUATION MATRIX: KEY PLAYERS, 2024

- 10.7.1 STARS

- 10.7.2 EMERGING LEADERS

- 10.7.3 PERVASIVE PLAYERS

- 10.7.4 PARTICIPANTS

- 10.7.5 COMPANY FOOTPRINT: KEY PLAYERS, 2023

- 10.7.5.1 Company footprint

- 10.7.5.2 End-use industry footprint

- 10.7.5.3 Material footprint

- 10.7.5.4 Region footprint

- 10.8 COMPANY EVALUATION MATRIX: STARTUPS/SMES, 2024

- 10.8.1 PROGRESSIVE COMPANIES

- 10.8.2 RESPONSIVE COMPANIES

- 10.8.3 DYNAMIC COMPANIES

- 10.8.4 STARTING BLOCKS

- 10.8.5 COMPETITIVE BENCHMARKING: STARTUPS/SMES, 2024

- 10.8.5.1 Detailed list of key startups/SMEs

- 10.8.5.2 Competitive benchmarking of key startups/SMEs

- 10.9 COMPETITIVE SCENARIO

- 10.9.1 PRODUCT LAUNCHES

- 10.9.2 DEALS

- 10.9.3 EXPANSIONS

11 COMPANY PROFILES

- 11.1 KEY PLAYERS

- 11.1.1 KLINGER GROUP

- 11.1.1.1 Business overview

- 11.1.1.2 Products offered

- 11.1.1.3 Recent developments

- 11.1.1.3.1 Product launches

- 11.1.1.3.2 Deals

- 11.1.1.3.3 Expansions

- 11.1.1.4 MnM view

- 11.1.1.4.1 Key strengths

- 11.1.1.4.2 Strategic choices

- 11.1.1.4.3 Weaknesses and competitive threats

- 11.1.2 W.L. GORE & ASSOCIATES, INC.

- 11.1.2.1 Business overview

- 11.1.2.2 Products offered

- 11.1.2.3 MnM view

- 11.1.2.3.1 Key strengths

- 11.1.2.3.2 Strategic choices

- 11.1.2.3.3 Weaknesses and competitive threats

- 11.1.3 GARLOCK

- 11.1.3.1 Business overview

- 11.1.3.2 Products offered

- 11.1.3.3 MnM view

- 11.1.3.3.1 Key strengths

- 11.1.3.3.2 Strategic choices

- 11.1.3.3.3 Weaknesses and competitive threats

- 11.1.4 TEADIT

- 11.1.4.1 Business overview

- 11.1.4.2 Products offered

- 11.1.4.3 Recent developments

- 11.1.4.3.1 Expansions

- 11.1.4.4 MnM view

- 11.1.4.4.1 Key strengths

- 11.1.4.4.2 Strategic choices

- 11.1.4.4.3 Weaknesses and competitive threats

- 11.1.5 PARKER HANNIFIN CORP.

- 11.1.5.1 Business overview

- 11.1.5.2 Products offered

- 11.1.5.3 MnM view

- 11.1.5.3.1 Key strengths

- 11.1.5.3.2 Strategic choices

- 11.1.5.3.3 Weaknesses and competitive threats

- 11.1.6 FLEXITALLIC

- 11.1.6.1 Business overview

- 11.1.6.2 Products offered

- 11.1.6.3 Recent developments

- 11.1.6.3.1 Product launches

- 11.1.6.3.2 Deals

- 11.1.6.3.3 Expansions

- 11.1.6.4 MnM view

- 11.1.7 LAMONS

- 11.1.7.1 Business overview

- 11.1.7.2 Products offered

- 11.1.7.3 Recent developments

- 11.1.7.3.1 Product launches

- 11.1.7.4 MnM view

- 11.1.8 GOODRICH GASKET

- 11.1.8.1 Business overview

- 11.1.8.2 Products offered

- 11.1.8.3 MnM view

- 11.1.9 JAMES WALKER GROUP

- 11.1.9.1 Business overview

- 11.1.9.2 Products offered

- 11.1.9.3 Recent developments

- 11.1.9.3.1 Deals

- 11.1.9.4 MnM view

- 11.1.10 FREUDENBERG SEALING TECHNOLOGIES

- 11.1.10.1 Business overview

- 11.1.10.2 Products offered

- 11.1.10.3 Recent developments

- 11.1.10.3.1 Expansions

- 11.1.10.4 MnM view

- 11.1.11 DONIT TESNIT, D.O.O.

- 11.1.11.1 Business overview

- 11.1.11.2 Products offered

- 11.1.11.3 Recent developments

- 11.1.11.3.1 Product launches

- 11.1.11.4 MnM view

- 11.1.12 DATWYLER HOLDING INC.

- 11.1.12.1 Business overview

- 11.1.12.2 Products offered

- 11.1.12.3 MnM view

- 11.1.1 KLINGER GROUP

- 11.2 OTHER PLAYERS

- 11.2.1 IGP

- 11.2.2 3M

- 11.2.3 TRELLEBORG GROUP

- 11.2.4 SPIRA POWER

- 11.2.5 PGE INDUSTRIES PVT. LTD.

- 11.2.6 CENTAURO S.R.L.

- 11.2.7 DENVER RUBBER COMPANY

- 11.2.8 HENNIG GASKET & SEALS

- 11.2.9 HYDRO SILICA

- 11.2.10 PHELPS

- 11.2.11 REDCO

- 11.2.12 KENT RUBBER

- 11.2.13 VSP TECHNOLOGIES

- 11.2.14 NATIONAL RUBBER CORPORATION

- 11.2.15 GARDICO

12 APPENDIX

- 12.1 DISCUSSION GUIDE

- 12.2 KNOWLEDGESTORE: MARKETSANDMARKETS' SUBSCRIPTION PORTAL

- 12.3 CUSTOMIZATION OPTIONS

- 12.4 RELATED REPORTS

- 12.5 AUTHOR DETAILS