|

|

市場調査レポート

商品コード

1858245

スクラップ金属リサイクル市場:材質別、リサイクル工程別、スクラップ発生源別、リサイクル技術別、リサイクル設備別、最終用途産業別-世界予測(2025-2032年)Scrap Metal Recycling Market by Material Type, Recycling Process, Source of Scrap, Recycling Technology, Recycling Equipment, End-Use Industry - Global Forecast 2025-2032 |

||||||

カスタマイズ可能

適宜更新あり

|

|||||||

| スクラップ金属リサイクル市場:材質別、リサイクル工程別、スクラップ発生源別、リサイクル技術別、リサイクル設備別、最終用途産業別-世界予測(2025-2032年) |

|

出版日: 2025年09月30日

発行: 360iResearch

ページ情報: 英文 195 Pages

納期: 即日から翌営業日

|

概要

スクラップ金属リサイクル市場は、2032年までにCAGR6.45%で814億米ドル規模に成長すると予測されております。

| 主な市場の統計 | |

|---|---|

| 基準年2024 | 493億7,000万米ドル |

| 推定年2025 | 525億米ドル |

| 予測年2032 | 814億米ドル |

| CAGR(%) | 6.45% |

現代のスクラップ金属リサイクルを形作る、基礎的な促進要因、規制の潮流、物質フローの力学、戦略的要請を概説する簡潔なセクターの枠組み

金属スクラップリサイクル業界は、工業生産、資源管理、気候変動対策の重要な接点に位置しています。産業システムが進化する中、製造エコシステムへ材料価値を還元し、一次資源採掘の環境負荷を低減する同業界の役割は、より顕著になっております。本導入部では、今日の業界を形作る基盤的要因--変化する規制要件、二次原料への需要高まり、収率と材料純度を向上させる処理技術への投資加速--について説明し、読者の理解を深めます。

今後、業界関係者は貿易政策、持続可能性目標、資本配分決定という複雑化する相互作用を乗り切らねばなりません。サプライチェーンのレジリエンスが戦略的課題として浮上した結果、利害関係者はトレーサビリティ、上流工程におけるパートナーシップ、プロセス標準化を優先しています。これらの戦略的課題は、シュレッディング、選別、冶金学的回収における技術進歩によって強化され、循環型経済イニシアチブと組み合わせることで、材料と最終用途を横断した価値創出の明確な道筋を創出します。

したがって、既存企業と新規参入企業の双方にとって、材料フロー、処理経済性、規制枠組みを支える構造的ダイナミクスを理解することが不可欠です。本節では、後続の分析の基盤となる重要な文脈を提示し、スクラップ金属リサイクル業界における運営上の選択、投資優先順位、競争的ポジショニングを形成する体系的な力を読者が理解できるようにします。

金属スクラップリサイクルにおける脱炭素化、デジタル化、循環型モデル、協働的価値再配分を加速する変革的要因の魅力的な統合

金属スクラップリサイクル業界は、競争優位性と事業優先順位を再定義する複数の変革的シフトによって再構築されつつあります。第一に、製造業が低炭素原料を求める中、産業横断的な脱炭素化への取り組みが再生材の需要を増加させています。この需要側の圧力により、材料処理業者は厳格な品質仕様を満たし、確固たる管理連鎖保証を提供するため、高精度選別技術や冶金学的アプローチの導入を迫られています。

一方、デジタル化は業務効率と透明性を加速させています。高度なセンサーシステム、機械学習による選別、クラウドベースのトレーサビリティプラットフォームにより、処理業者は高価値分画の回収率向上と汚染率低減を実現しています。その結果、自動化への投資が労働力構成を変え、エネルギー消費量の相応な増加なしに処理能力向上の機会を創出しています。

同時に、循環型経済は理念的な取り組みから実践的な導入へと移行しつつあります。拡大生産者責任制度や買い手主導のリサイクル素材使用目標は、バリューチェーン内での価値の蓄積場所を変えつつあります。これにより、OEMメーカー、スクラップ収集業者、製錬所間の垂直的連携が促進され、原料確保と品質保証を両立させる「製品としてのサービス」や「回収プログラム」といった新たなビジネスモデルが奨励されています。これらの変化が相まって、業界全体における関係性、資本配分、技術能力の再構築が進んでいます。

2025年に米国が実施した関税措置が、スクラップ金属リサイクル業界の貿易パターン、調達慣行、国内価値保持戦略に与えた影響に関する詳細な分析

2025年に米国が実施した一連の関税措置は、金属スクラップリサイクル事業者の貿易フロー、価格シグナル、事業戦略に多層的な影響をもたらしました。直近の結果として、貿易業者や加工業者が国境コストの増加を軽減しようと努めた結果、輸出入パターンの再構築が生じました。これにより、輸送ルートの変更、地域調達契約の増加、関税耐性を優先した長期契約の再交渉が進んでいます。

さらに、関税は原料品質と国内で入手可能な二次材料への注目を高めました。特定の合金や非鉄金属分画の輸入コストが国内供給源に比べて上昇したため、一部の川下製造業者は、リサイクル原料の安定供給を確保すべく、地元の収集業者や加工業者との提携を加速させました。同時に、関税は国境を越えた裁定取引に依存する企業にとって利益率の圧縮をもたらし、規模の拡大によって貿易摩擦の増加を吸収できる分野において、業務効率化と統合を促進するインセンティブとなりました。

さらに、政策環境の変化により、在庫戦略と運転資金管理の見直しが促されています。市場参入企業は、関税変動リスクへの曝露を低減するため、動的ヘッジング、柔軟な調達期間設定、地域密着型前処理を積極的に活用しています。これらの対応策は総合的に、短期的なサプライチェーン継続性の重視を強化すると同時に、地域的自立化、サプライチェーンのマッピング、国内溶解・鋳造能力への投資といった戦略的動きを促進し、国境内でより大きな価値を創出する方向へと導いています。

材料クラス、加工ルート、スクラップの起源、技術的選択、設備構成、最終用途の需要パターンを統合した包括的なセグメンテーション分析により、機会領域を明らかにします

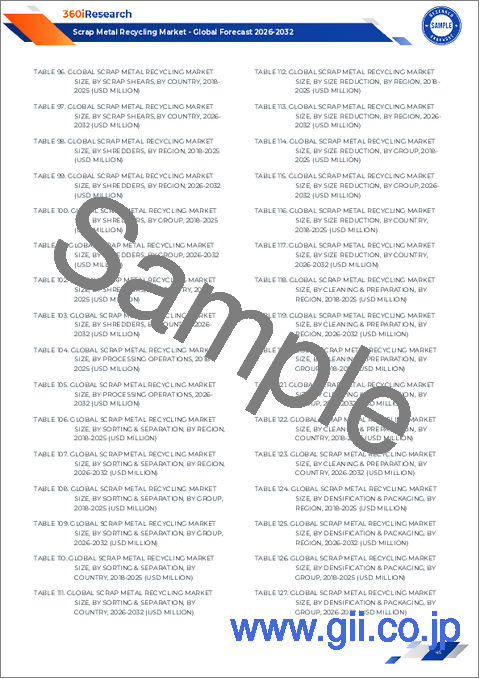

細分化されたセグメンテーションの視点により、材料タイプ、リサイクルプロセス、スクラップの供給源、技術、設備、最終用途産業の領域において、技術要件、運用能力、商業的機会が交差する領域が明らかになります。材料分類は基盤となります:合金は高速度鋼とステンレス鋼に区分され、鉄金属は主に鋳鉄と鋼、非鉄金属にはアルミニウム、真鍮、銅、鉛、ニッケル、亜鉛が含まれ、貴金属は金、パラジウム、プラチナ、銀を包含します。各材料グループは汚染への感受性、回収経路、下流顧客仕様が異なり、これらが処理業者の投資優先順位を決定します。

処理方法もビジネスモデルを決定づけます。シュレッダー処理や選別を含む収集・処理活動は、その後の溶解・鋳造工程の基盤となります。連続鋳造や溶解炉による溶解は、エネルギー消費特性や製品形状に影響を与えます。原料の特性も原料経済性に影響を与えます。自動車由来のスクラップは廃車から製造廃棄物まで多岐にわたり、建設・解体由来の原料はアルミニウムビームから構造用鋼材まで様々です。これにより汚染度、量、組成にばらつきが生じ、処理業者はそれぞれに適した前処理で対応する必要があります。

技術的アプローチも同様に差別化を生み出します。電解回収や浸出による湿式冶金処理は、特定の非鉄金属や貴金属分画の回収率を高めます。一方、解体やシュレッディングによる機械的リサイクルは、バルク処理と初期材料選別を支えます。梱包機やブリケッターからスクラップ処理用クレーン、剪断機、シュレッダーに至る設備の選択は、処理能力、材料密度、物流効率に影響を与え、梱包機の構成は密閉式と二ラム式に分かれます。最後に、最終用途の需要特性はセクターごとに異なります。自動車用途はOEM製造と修理・保守ニーズを包含し、建設業は構造用グレードの材料を必要とし、民生用電子機器は高純度非鉄金属原料に依存し、製造業は電子機器生産から機械製造まで多岐にわたります。これらのセグメンテーション要素の相互作用が、利益創出の源泉となる領域と、品質重視のマーケットプレースで評価される能力を決定します。

南北アメリカ、欧州、中東・アフリカ、アジア太平洋地域における差別化された政策枠組み、インフラ整備状況、需要主導の促進要因を明快に分析した地域別インテリジェンス

地域ごとの政策、インフラ、需要要因が大きく異なるため、地域動向は戦略的計画の核心となります。アメリカ大陸では、政策議論において国内産業の安全保障と再生材含有率の優遇措置が重視され、上流の回収ネットワークと下流の溶解能力への投資が促進されています。強力な自動車・製造業需要拠点と相まって、地域の物流構造は統合サプライチェーンを支える一方、加工業者を地域ごとの規制変動や労働市場格差に晒しています。

欧州・中東・アフリカ地域では、規制体制と市場成熟度がモザイク状に存在します。欧州の一部地域では、積極的な循環型経済法や製品管理プログラムにより、トレーサビリティと材料認証の重要性が高まり、サプライヤーは選別・追跡システムの強化を迫られています。一方、中東・アフリカの一部地域では、工業化とインフラ投資の拡大が進み、原料発生と処理能力の両面で新たなホットスポットが生まれています。ただし、環境基準や安全基準にばらつきがあるため、国際的な事業者はこうした課題を乗り越える必要があります。

アジア太平洋地域は、一次金属・二次金属双方に対する高い需要、密集した製造クラスター、自動化・デジタル選別技術の加速的な導入によって引き続き特徴づけられています。この地域の原材料消費パターンとエネルギーミックスは、リサイクル投資に対する差別化されたインセンティブを生み出しており、貿易政策や地域供給協定は、材料の流れが国内に留まるか、輸出市場を経由するかに影響を与えます。全地域を通じて、公共政策、インフラ整備状況、投資資本の可用性が、新たな生産能力とパートナーシップが形成される場所を形作る主要な変数です。

スクラップ金属リサイクル分野で高業績企業を差別化する戦略的行動、技術導入、垂直統合、パートナーシップモデルに関する実践的な企業情報

金属スクラップリサイクル業界をリードする主要企業は、垂直統合、選択的買収、技術主導の差別化、パートナーシップによる原料確保といった戦略的施策を組み合わせて実行しています。統合モデルへ転換する企業は原料品質と物流管理の強化を実現し、高度な冶金技術とプロセス最適化に注力する企業は、高い回収率と製品グレードの一貫性を通じて差別化を図っています。同時に、生産者が再生素材の含有率保証やトレーサビリティの確約を求める中、OEMメーカーや下流の加工業者との戦略的提携も増加傾向にあります。

技術投資も重要な特徴です。市場リーダー企業は、自動選別プラットフォーム、センサーベースの等級識別、デジタルトレーサビリティを導入し、汚染削減、処理コスト低減、認証済み再生材の高価格化を実現しています。こうした投資は、材料フローの最適化、エネルギー集約度の低減、労働安全の向上を目的とした業務再設計と組み合わされることが多いです。ただし、資本規律は依然として重要であり、企業は地域ごとの規制インセンティブや原料供給状況に応じて、新規設備投資と既存設備の改修をバランスよく進めています。

最後に、競合は能力格差と規制順守によって形成されます。新たな環境基準への適合性を実証し、文書化された管理連鎖を提供し、特注のリサイクル材料仕様を提示できる事業者は、長期契約を獲得する上で優位な立場にあります。一方、技術投資を拡大できない中小事業者は、ニッチ分野への特化や地域連携モデルを追求しない限り、低マージンの収集・前処理業務に限定される可能性があります。

経営陣がレジリエンス強化、原料品質の確保、技術とパートナーシップ別付加価値創出を加速するための実践的かつ優先順位付けされた戦略的提言

業界リーダーは、レジリエンス強化、利益率向上、進化する規制要件への適合を図るため、一連の実践的施策を優先すべきです。第一に、下流の認証要件を満たし顧客契約のリスクを低減するため、トレーサビリティと品質保証システムへの投資が必要です。これらの投資は、エネルギー消費削減と歩留まり向上を実現するプロセス最適化プログラムと並行して実施され、加工業者が持続可能性への取り組みを推進しつつ、より多くの価値を内部で保持することを可能にします。

次に、多様な地域収集ネットワークと高品質原料を確保する契約体系を組み合わせた柔軟な調達戦略を構築してください。同時に、OEMや大規模コンバーターとの戦略的提携を推進し、収益を安定化させ先進的加工能力への資本投資を正当化する長期販売契約を締結しましょう。第三に、自動化技術と湿式冶金技術については段階的導入を採用してください:高収益原料ストリームのアップグレードを優先し、新たな回収手法は制御環境下で試験運用した後、本格稼働へ拡大します。

最後に、ガバナンスとコンプライアンス体制を強化し、規制変化を予測するとともに、業界標準設定に積極的に参画すること。循環型経済の指標を企業計画と報告に組み込むことで、サステナビリティ連動型資金調達の機会が拡大し、利害関係者の信頼が向上します。これらの提言を総合すると、企業が価値を創出しつつ材料循環に貢献できる、一貫性のあるロードマップが形成されます。

信頼性が高く実践可能な知見を確保するため、一次インタビュー、二次検証、分析フレームワークを組み合わせた透明性の高い混合手法別研究アプローチを採用しております

本研究の統合は、定性的な一次調査と定量的な検証を組み合わせた混合調査手法に基づき、堅牢性と文脈的関連性を確保しています。1次調査では、回収業者、処理業者、製錬所、OEM調達責任者、規制アドバイザーなど、バリューチェーン全体の業界利害関係者に対する構造化インタビューを実施しました。これらの対話により、材料処理経路や商業契約慣行に影響を与える、運用上の制約、投資の合理性、買い手の仕様に関する直接的な知見が得られました。

2次調査では、技術文献、規制記録、貿易通知、運用上のベストプラクティスを包括的に精査し、一次調査結果を文脈化するとともに、共通するテーマを特定しました。複数の情報源にわたりデータの三角測量を実施し、異なる視点を調整するとともに、実証的に一貫したパターンを浮き彫りにしました。採用した分析フレームワークには、バリューチェーン分析、政策影響の感度マッピング、能力ギャップ評価が含まれ、投資によって運用面または商業面で特に大きな改善が期待できる領域を特定しました。

最後に、品質管理として、専門家による反復的な検証と事例のバックチェックを実施し、正確性を確保しました。特に急速に変化する政策環境や地域間の差異といった本手法の限界を明示的に考慮し、これらの注意点を結果解釈に組み込むことで、意思決定者に適切な条件付きインサイトを提供しました。

スクラップ金属リサイクルにおける持続可能な成長と循環性の強化に向けた戦略的要請と、規制・技術・商業動向を結びつける決定的な結論

要約しますと、金属スクラップリサイクル業界は、二次原料の商品化された取引から、循環型産業システムにおける戦略的に重要な拠点へと移行しつつあります。規制要因、技術進歩、低炭素原料への商業的需要が相互に作用し、新たなパフォーマンス期待と価値創出の機会を生み出しています。高精度選別、冶金学的回収、デジタルトレーサビリティへの投資を推進する利害関係者は、プレミアム価値の獲得と下流メーカーとの長期的なパートナーシップ構築において優位な立場を確立できるでしょう。

同時に、政策動向と貿易環境の変化に対応するためには、関税変動リスクへの曝露を軽減し地域優位性を活用する、機敏な調達・運営戦略が求められます。規律ある資本配分と、対象を絞った技術導入、協働調達を組み合わせる企業は、環境基準を損なうことなく、回復力を高め利益率を改善できるでしょう。持続可能性目標を、検証可能かつ経済的に実行可能な運営手法へと転換する能力こそが、リーダーシップの真価を定義します。

結局のところ、今後の道筋には、材料回収を環境上の要請であると同時に戦略的なビジネス機会として捉える統合的思考が求められます。循環性を制度化し、セクター横断的な協力を促進し、材料品質への明確な焦点を維持する組織こそが、産業脱炭素化と資源効率化の次の波を主導する可能性が高いでしょう。

よくあるご質問

目次

第1章 序文

第2章 調査手法

第3章 エグゼクティブサマリー

第4章 市場の概要

第5章 市場洞察

- 人工知能とロボット工学の統合による金属スクラップ選別精度と効率性の向上

- 自動車および建設分野における持続可能性の要請により、再生鋼材への需要が高まっています。

- オンデマンドでの回収と価格の透明性を提供する電子商取引型金属廃棄物リサイクルプラットフォームの成長

- 金属スクラップの調達・販売におけるサプライチェーンのトレーサビリティ向上のためのブロックチェーン導入

- 製造業におけるクローズドループ金属リサイクルを促進する循環型経済モデルへの移行

- 金属スクラップ輸出に対する規制圧力の増大と環境コンプライアンス基準の強化

- 高度な破砕・剪断技術の導入による材料回収率の最大化

第6章 米国の関税の累積的な影響, 2025

第7章 AIの累積的影響, 2025

第8章 スクラップ金属リサイクル市場:素材タイプ別

- 合金

- 高速度鋼

- ステンレス鋼

- 鉄金属

- 鋳鉄

- 鋼鉄

- 非鉄金属

- アルミニウム

- 真鍮

- 銅

- 鉛

- ニッケル

- 亜鉛

- 貴金属

- 金

- パラジウム

- プラチナ

- 銀

第9章 スクラップ金属リサイクル市場リサイクル工程別

- 収集・処理

- シュレッディング

- 選別

- 溶解・鋳造

- 常用鋳造

- 溶解炉による溶解

第10章 スクラップ金属リサイクル市場スクラップの供給源別

- 自動車

- 使用済み自動車

- 製造廃棄物

- 建設・解体

- アルミニウムビーム

- 構造用鋼材

第11章 スクラップ金属リサイクル市場リサイクル技術別

- 湿式冶金処理

- 電解精錬

- 浸出

- 機械的リサイクル

- 解体

- シュレッディング

第12章 スクラップ金属リサイクル市場リサイクル設備別

- ベーラー

- 密閉式ベール圧縮機

- ツーラム式圧縮機

- ブリケッター

- スクラップハンドリングクレーン

- スクラップ用シアー

- シュレッダー

第13章 スクラップ金属リサイクル市場:最終用途産業別

- 自動車

- OEM製造

- 修理・保守

- 建設

- 家電製品

- 製造

- 電子機器製造

- 機械生産

第14章 スクラップ金属リサイクル市場:地域別

- 南北アメリカ

- 北米

- ラテンアメリカ

- 欧州・中東・アフリカ

- 欧州

- 中東

- アフリカ

- アジア太平洋地域

第15章 スクラップ金属リサイクル市場:グループ別

- ASEAN

- GCC

- EU

- BRICS

- G7

- NATO

第16章 スクラップ金属リサイクル市場:国別

- 米国

- カナダ

- メキシコ

- ブラジル

- 英国

- ドイツ

- フランス

- ロシア

- イタリア

- スペイン

- 中国

- インド

- 日本

- オーストラリア

- 韓国

第17章 競合情勢

- 市場シェア分析, 2024

- FPNVポジショニングマトリックス, 2024

- 競合分析

- Al Habari Engineering

- Alcoa Corporation

- Andritz AG

- ArcelorMittal S.A.

- Arfin India Limited

- Audubon Metals LLC by Koch Industries, Inc.

- Aurubis AG

- Baosteel Co., Ltd.

- CASS, Inc.

- Commercial Metals Company

- Constellium SE

- Crestwood Metal Corp.

- European Metal Recycling Limited

- Ferrous Processing & Trading

- Great Lakes Electronics Corporation

- Hindalco Industries Limited

- Hulamin Limited

- Kuusakoski Oy

- Metalico, Inc. by Ye Chiu Metal Recycling(China)Ltd.

- Norsk Hydro ASA

- Nucor Corporation

- Nupur Recyclers Limited

- OmniSource, LLC

- Palco Recycle Industries Limited

- Prime Materials Recovery Inc.

- Radius Recycling

- Real Alloy Recycling, LLC

- Remondis SE & Co. KG

- Rio Tinto PLC

- Scepter, Inc.

- Sims Limited

- Tom Martin & Company Ltd.

- Tri-Arrows Aluminum, Inc.

- TRIMET SE