|

|

市場調査レポート

商品コード

1835564

マイクロキャリア市場:製品タイプ、用途、エンドユーザー別-2025~2032年の世界予測Microcarriers Market by Product, Type, Application, End-User - Global Forecast 2025-2032 |

||||||

カスタマイズ可能

適宜更新あり

|

|||||||

| マイクロキャリア市場:製品タイプ、用途、エンドユーザー別-2025~2032年の世界予測 |

|

出版日: 2025年09月30日

発行: 360iResearch

ページ情報: 英文 186 Pages

納期: 即日から翌営業日

|

概要

マイクロキャリア市場は、2032年までにCAGR 10.28%で44億3,000万米ドルの成長が予測されています。

| 主要市場の統計 | |

|---|---|

| 基準年 2024年 | 20億2,000万米ドル |

| 推定年 2025年 | 22億2,000万米ドル |

| 予測年 2032年 | 44億3,000万米ドル |

| CAGR(%) | 10.28% |

マイクロキャリア技術の基礎的概要と、細胞培養とバイオプロセス環境での採用を促進する戦略的必須事項

マイクロキャリアは、細胞培養とバイオプロセスのインフラの成長セグメントを支えており、接着細胞株の大規模な拡大をサポートする不可欠な基質を提供しています。先端治療、ワクチンプラットフォーム、バイオ製造プロセスが進化するにつれ、マイクロキャリアシステムはニッチな実験室ツールから産業用細胞培養操作の重要な要素へと移行しています。この変化により、消耗品や装置のカテゴリー全体に対する関心が高まり、探索、スケールアップ、商業生産の架け橋となる首尾一貫した戦略の必要性が強まっています。

過去数年間、メーカーとエンドユーザーは、再現性、スループット、規制との整合性を優先してきました。その結果、製品設計では、材料科学、表面工学、閉鎖系バイオリアクタとの適合性がますます重視されるようになっています。同時に、濾過から細胞計数に至るまで、下流のワークフローと分析は、マイクロキャリア上で培養される細胞の明確な物理的特性に適応し、サプライチェーン全体にわたって新たな相互依存関係を生み出しています。このような力学は、プロジェクトがベンチトップでの概念実証から商業生産に移行する際に、一貫した成果を確保するために、調達、プロセス開発、品質保証にわたる統合的な計画を必要としています。

将来を見据え、企業の意思決定者は、製品の性能だけでなく、サプライヤーの多様化、製造拠点、規制のチャネルなどのレジリエンス要因も考慮しなければなりません。業務の継続性と技術適合性を重視することで、企業は開発リスクを低減し、細胞ベース製品の開発期間を短縮することができます。このエグゼクティブサマリーでは、マイクロキャリアの採用を形作る構造的変化と戦略的選択を統合し、リーダーがこれらの実現技術を採用する際に技術、商業、コンプライアンスの優先順位を調整するためのフレームワークを記載しています。

材料科学の進歩、統合されたシステム設計、進化する規制への期待が、マイクロキャリアの採用とサプライチェーン戦略をどのように再構築しているか

マイクロキャリアの情勢は、科学的、商業的、規制的な力の収束によって変化しており、調達の決定や製品設計を再構築しています。材料科学の進歩により、表面化学的性質の調整、生体適合性の向上、機械的特性の最適化が可能になり、その結果、より高い細胞密度と予測可能な細胞採取速度論がサポートされるようになりました。バイオリアクタ工学とクローズドシステムワークフローの並行的な改善により、コンタミネーションリスクが軽減され、スケールアップが合理化されたため、学術ラボや受託製造業者の初期採用者以外にも広く採用されるようになりました。

製薬会社やバイオテクノロジー企業が、細胞治療や遺伝子治療の臨床応用までの時間を短縮し、組換えタンパク質やワクチンの生産能力を拡大しようとしているため、商業的力学も変化しています。このため、マイクロキャリア、培地、装置が個による商品としてではなく、相互運用可能なシステムとして機能する統合ソリューションへの需要が高まっています。その結果、材料スペシャリスト、装置メーカー、受託開発業者間の戦略的提携が頻繁に行われるようになり、バリデーションやサプライチェーン管理を簡素化するバンドル提供が可能になりました。

規制当局の期待も並行して進化しており、当局は製品の一貫性を確保するプロセスの理解と管理戦略をより重視しています。このような規制の明確化により、サプライヤーは文書化、適格性確認プロトコル、拡大可能な製造方法に投資するインセンティブを与えられています。その結果、強固な技術データ包装と、実証されたプロセス再現性を併せ持つ市場参入企業は、採用企業のニーズを満たす上で有利な立場に立つことになります。これらの変革的シフトを総合すると、マイクロキャリアの主流バイオプロセスへの統合はさらに深まり、経営陣は研究開発、オペレーション、規制業務にまたがる機能横断的戦略を採用する必要があります。

2025年米国関税改正がマイクロキャリアのサプライチェーンと調達戦略に及ぼす広範な業務上と戦略上の影響を評価します

2025年の米国の措置に端を発した関税措置と貿易施策の転換は、マイクロキャリアのエコシステムの調達と製造の意思決定に新たな変数を導入しました。投入品と完成品に対する輸入関税は、一部のサプライヤーの陸揚げコストを上昇させ、調達戦略に影響を与え、組織にサプライヤーとの契約、在庫施策、総陸揚げコスト計算の見直しを促しています。これを受けて、調達部門は多層サプライチェーン全体の透明性を優先し、貿易措置による直接的・間接的なコスト影響を緩和するための代替ルートを模索しています。

その結果、メーカーとバイヤーは、可能な限りニアショアリングと地域化の取り組みを加速させ、越境関税変動にさらされるリスクを最小限に抑えるため、地元または地域の製造能力を持つサプライヤーを選好するようになりました。このような動きは、生産能力計画や資本配分に影響を及ぼし、地域製造ラインの構築や認定にはリードタイムと投資が必要となります。同時に、供給の継続性が重要な選択基準となり、消耗品、機器、特殊試薬への優先的なアクセスを確保するための長期購入契約や戦略的サプライヤーパートナーシップなどの提携モデルの強化が推進されています。

また、在庫ヘッジ、二重調達戦略、貿易施策シナリオを組み込んだサプライヤーリスク評価の強化など、経営上の対応も行われています。利幅を確保し、顧客に対して競合価格設定を維持するために、一部のベンダーはプロセスの改善や、製品の包装やロジスティクスの再設計を通じてコストの最適化を追求し、関税の影響を減らしてきました。規制当局や税関当局は逆に、正確な分類と準拠した書類作成を重視し、輸出業者と輸入業者の事務負担を増大させています。全体として、2025年の関税改正の累積的な影響により、サプライチェーンの弾力性と敏捷性は取締役会レベルの優先事項へと昇格し、地域能力への長期的な投資と目先の緩和のバランスを取るよう指導者に迫っています。

詳細なセグメンテーション分析により、調達パターンと技術採用の選択肢を形成する製品、タイプ、用途、エンドユーザーの微妙な違いが明らかになります

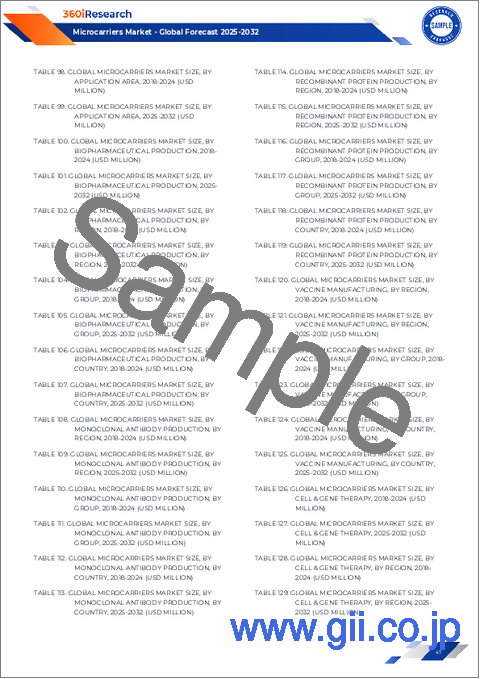

セグメントレベルの分析により、製品ポートフォリオと市場参入アプローチを設計する利害関係者にとって重要な意思決定のノードが明らかになります。製品別では、市場参入企業は消耗品と機器を区別する必要があります。これは、それぞれに異なる調達手順と品質管理が課されるためです。消耗品は、継続的な供給とバッチ間の厳格な一貫性を必要とし、消耗品カテゴリーはさらに、厳格な品質保証とロットのトレーサビリティを要求する培地と試薬に区分されます。機器類はさらにアクセサリ、バイオリアクタ、セルカウンター、培養容器、濾過システムにサブセグメンテーションされ、それぞれがマイクロキャリアの性能パラメーターやプロセス統合要件と相互作用します。

よくあるご質問

目次

第1章 序文

第2章 調査手法

第3章 エグゼクティブサマリー

第4章 市場概要

第5章 市場洞察

- 高度表面機能化技術により幹細胞の接着と増殖率が向上

- 革新的な生分解性マイクロキャリアがサステイナブル細胞治療の製造プロセスを強化

- ナノエンジニアリングの新たな動向により、細胞微小環境の精密な制御が可能になる

- マイクロキャリアベースバイオリアクタの統合により、ウイルスベクタ生産用懸濁細胞培養が効率化されます。

- シングルユースマイクロキャリアの採用により、バイオ医薬品における無菌大規模細胞増殖が加速

- カスタマイズ可能なマイクロキャリア製剤は、cGMP哺乳類細胞培養における規制遵守を満たす

- デジタルモニタリングと自動化ツールは、マイクロキャリアのバイオプロセスパラメータをリアルタイムで最適化

- 戦略的パートナーシップがマイクロキャリア技術プロバイダのグローバルサプライチェーン拡大を促進

第6章 米国の関税の累積的な影響、2025年

第7章 AIの累積的影響、2025年

第8章 マイクロキャリア市場:製品別

- 消耗品

- 培地

- 試薬

- 装置

- 付属品

- バイオリアクタ

- 細胞カウンター

- 培養容器

- 濾過システム

第9章 マイクロキャリア市場:タイプ別

- マイクロキャリア

- 微孔性

- 非多孔性

第10章 マイクロキャリア市場:用途別

- バイオ医薬品製造

- 組み換えタンパク質の生産

- ワクチン製造

- 細胞治療

- 研究開発

- 組織工学

第11章 マイクロキャリア市場:エンドユーザー別

- 学術研究機関

- 契約研究機関

- 製薬バイオテクノロジー企業

第12章 マイクロキャリア市場:地域別

- 南北アメリカ

- 北米

- ラテンアメリカ

- 欧州・中東・アフリカ

- 欧州

- 中東

- アフリカ

- アジア太平洋

第13章 マイクロキャリア市場:グループ別

- ASEAN

- GCC

- EU

- BRICS

- G7

- NATO

第14章 マイクロキャリア市場:国別

- 米国

- カナダ

- メキシコ

- ブラジル

- 英国

- ドイツ

- フランス

- ロシア

- イタリア

- スペイン

- 中国

- インド

- 日本

- オーストラリア

- 韓国

第15章 競合情勢

- 市場シェア分析、2024年

- FPNVポジショニングマトリックス、2024年

- 競合分析

- Aber Instruments Ltd.

- Avantor, Inc.

- Bangs Laboratories, Inc.

- Bio-Rad Laboratories, Inc.

- Carroucell

- ChemoMetec A/S

- Cole-Parmer Instrument Company

- Corning Inc.

- denovoMATRIX GmbH

- Entegris, Inc.

- Eppendorf AG

- Esco Vaccixcell

- FUJIFILM Holdings Corporation

- Getinge AB

- Global Life Sciences Solutions USA LLC

- Kuraray Co., Ltd.

- Lonza Group AG

- Matrix F.T.

- Merck KGaA

- Pall Corporation

- Polysciences Inc.

- PromoCell GmbH

- RoosterBio, Inc.

- Sartorius AG

- Sunresin New Materials Co.Ltd.

- Teijin Limited

- Thermo Fisher Scientific Inc.