|

|

市場調査レポート

商品コード

1642519

サーボモーター・ドライブの市場レポート:製品タイプ別、電圧範囲別、システム別、通信プロトコル別、最終用途産業別、地域別、2025年~2033年Servo Motors and Drives Market Report by Product Type, Voltage Range, System, Communication Protocol, End Use Industry, and Region 2025-2033 |

||||||

カスタマイズ可能

|

|||||||

| サーボモーター・ドライブの市場レポート:製品タイプ別、電圧範囲別、システム別、通信プロトコル別、最終用途産業別、地域別、2025年~2033年 |

|

出版日: 2025年01月18日

発行: IMARC

ページ情報: 英文 131 Pages

納期: 2~3営業日

|

- 全表示

- 概要

- 図表

- 目次

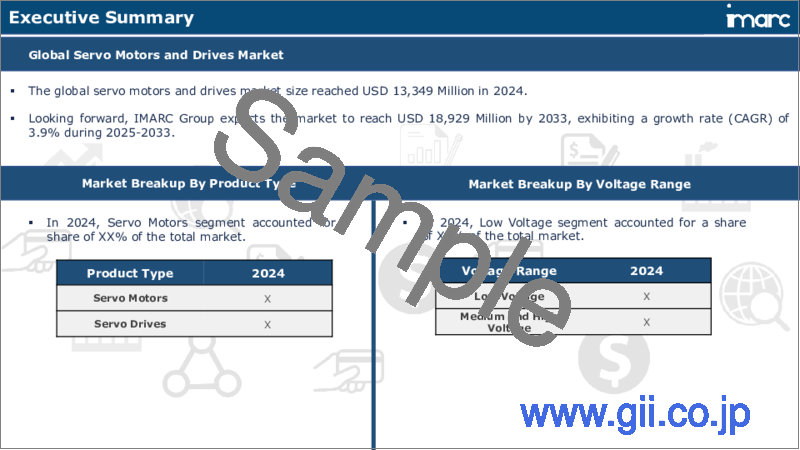

世界のサーボモーター・ドライブの市場規模は、2024年に133億米ドルに達しました。今後、IMARC Groupは、市場は2033年までに189億米ドルに達し、2025年から2033年にかけて3.9%の成長率(CAGR)を示すと予測しています。運用コストと消費電力を削減するためのエネルギー効率に対する需要の高まり、オートメーションとロボット工学の人気の高まり、産業用モノのインターネット(IIoT)の進歩は、市場を推進する主な要因の一部です。

サーボモーターは高精度で効率的な回転アクチュエーターであり、角度位置、速度、加速度の制御を行います。正確で応答性の高い運動制御が可能なため、製造機械からロボットまで、さまざまな用途で広く利用されています。一方、サーボドライブは、サーボモーターに電力を供給し、制御する電子アンプです。通常、電圧または電流の形で入力信号を受信し、サーボモーターによって実行される正確な動きに変換します。その結果、サーボモーター・ドライブは世界中の自動車、包装、ロボット、半導体、電子機器、ゴム・プラスチック産業で採用されています。

現在、サーボモーター・ドライブの採用が増加しており、精度と再現性の向上が市場の成長に寄与しています。これに伴い、再生可能エネルギーの生産にサーボモーター・ドライブの採用が増加しており、市場の成長を強化しています。さらに、世界中のさまざまな産業で、精度、速度、信頼性に対する需要が高まっていることも、市場にプラスの影響を与えています。さらに、メンテナンスコストとダウンタイムの削減を支援するアクチュエータの採用が増加しており、業界の投資家に有利な成長機会を提供しています。さらに、高度なカスタマイズ性と適応性を提供するサーボモーター・ドライブの需要の増加が、市場の成長を支えています。このほか、多くの国の政府機関が再生可能エネルギー源の採用を支援しており、これが市場の成長を後押ししています。

サーボモーター・ドライブの市場傾向 / 促進要因:

自動化とロボット工学の人気の高まり

さまざまな産業で自動化とロボット工学の人気が高まっていることが、市場の成長を後押ししています。製造業では、これらの技術は高精度と柔軟性を提供することで生産工程の増加に役立っています。サーボモーター・ドライブは、ピックアンドプレース作業、溶接、組み立てなどの作業に必要な精度と応答性を提供するロボットの重要なコンポーネントです。さらに、eコマース産業の急成長により、物流や倉庫管理における自動化ソリューションの需要が高まっていることも、市場の成長を後押ししています。さらに、コンベアベルト、仕分け機、無人搬送車(AGV)に電力を供給するサーボシステムの需要も増加しています。

運用コスト削減のためのエネルギー効率化需要の増加

環境とコストへの配慮から、エネルギー効率は産業界全体で大きな関心事となっています。これに伴い、これらのモーターとドライブは高いエネルギー効率で知られており、電力消費と運用コストの削減を目指す企業に適した選択肢となっています。これらのシステムは、必要なときに正確に電力を供給するように設計されており、アイドル時や低負荷時のエネルギー浪費を最小限に抑えます。これとは別に、持続可能性とカーボンフットプリントの削減への注目の高まりにより、エネルギー効率の高いサーボソリューションの採用が増加していることも、市場の成長に寄与しています。さらに、さまざまな産業で環境に優しい慣行や規制への対応が進んでおり、これが市場にプラスの影響を与えています。

産業用モノのインターネット(IIoT)の進歩

産業用モノのインターネット(IIoT)とインダストリー4.0のコンセプトの統合によるスマート製造の実現が、市場の成長を後押ししています。さらに、これらのモーターとドライブは、高度なセンサーと通信機能を備えているため、接続された製造環境内で相互作用することができ、重要な役割を果たしています。これに加えて、これらの先進技術の統合は、リアルタイムでのデータ収集と分析を提供し、予知保全を可能にし、ダウンタイムを削減し、装置全体の有効性を向上させます。サーボモーターを遠隔で監視・制御できるため、作業効率が向上し、現場作業員の必要性が減少します。この統合は生産性を向上させるだけでなく、市場の変動や変化する顧客の需要に迅速に対応することができます。

目次

第1章 序文

第2章 調査範囲と調査手法

- 調査の目的

- ステークホルダー

- データソース

- 一次情報

- 二次情報

- 市場推定

- ボトムアップアプローチ

- トップダウンアプローチ

- 予測調査手法

第3章 エグゼクティブサマリー

第4章 イントロダクション

- 概要

- 主要業界動向

第5章 世界のサーボモーター・ドライブ市場

- 市場概要

- 市場実績

- COVID-19の影響

- 市場予測

第6章 市場内訳:製品タイプ別

- サーボモーター

- 市場動向

- 市場内訳:タイプ別

- 市場予測

- サーボドライブ

- 市場動向

- 市場内訳:タイプ別

- 市場予測

第7章 市場内訳:電圧範囲別

- 低電圧

- 市場動向

- 市場予測

- 中電圧・高電圧

- 市場動向

- 市場予測

第8章 市場内訳:システム別

- 線形システム

- 市場動向

- 市場予測

- ロータリーシステム

- 市場動向

- 市場予測

第9章 市場内訳:通信プロトコル別

- フィールドバス

- 市場動向

- 市場予測

- 産業用イーサネット

- 市場動向

- 市場予測

- 無線

- 市場動向

- 市場予測

第10章 市場内訳:最終用途産業別

- 工作機械

- 市場動向

- 市場予測

- パッケージ

- 市場動向

- 市場予測

- ロボット工学

- 市場動向

- 市場予測

- 半導体

- 市場動向

- 市場予測

- エレクトロニクス

- 市場動向

- 市場予測

- ゴム・プラスチック

- 市場動向

- 市場予測

- その他

- 市場動向

- 市場予測

第11章 市場内訳:地域別

- アジア太平洋

- 日本

- 中国

- 韓国

- インド

- オーストラリア

- インドネシア

- その他

- 欧州

- ドイツ

- イタリア

- スペイン

- フランス

- 英国

- ロシア

- その他

- 北米

- 米国

- カナダ

- ラテンアメリカ

- ブラジル

- メキシコ

- その他

- 中東・アフリカ

- 市場動向

- 市場内訳:国別

- 市場予測

第12章 SWOT分析

- 概要

- 強み

- 弱み

- 機会

- 脅威

第13章 バリューチェーン分析

第14章 ポーターのファイブフォース分析

- 概要

- 買い手の交渉力

- 供給企業の交渉力

- 競合の程度

- 新規参入業者の脅威

- 代替品の脅威

第15章 価格分析

第16章 競合情勢

- 市場構造

- 主要企業

- 主要企業のプロファイル

- ABB Ltd.

- Bosch Rexroth AG

- Delta Electronics, Inc.

- Emerson Electric Co.

- Fanuc Corporation

- Mitsubishi Electric Corporation

- Nidec Corporation

- Rockwell Automation Inc.

- Schneider Electric SE

- Siemens AG

- Yaskawa Electric Corporation

List of Figures

- Figure 1: Global: Servo Motors and Drives Market: Major Drivers and Challenges

- Figure 2: Global: Servo Motors and Drives Market: Sales Value (in Billion USD), 2019-2024

- Figure 3: Global: Servo Motors and Drives Market Forecast: Sales Value (in Billion USD), 2025-2033

- Figure 4: Global: Servo Motors Market: Sales Value (in Million USD), 2019 & 2024

- Figure 5: Global: Servo Motors Market: Breakup by Type (in %), 2024

- Figure 6: Global: Servo Motors Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 7: Global: Servo Drives Market: Sales Value (in Million USD), 2019 & 2024

- Figure 8: Global: Servo Drives Market: Breakup by Type (in %), 2024

- Figure 9: Global: Servo Drives Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 10: Global: Low Voltage Servo Motors and Drives Market: Sales Value (in Million USD), 2019 & 2024

- Figure 11: Global: Low Voltage Servo Motors and Drives Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 12: Global: Medium and High Voltage Servo Motors and Drives Market: Sales Value (in Million USD), 2019 & 2024

- Figure 13: Global: Medium and High Voltage Servo Motors and Drives Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 14: Global: Rotary Servo Motors and Drives Market: Sales Value (in Million USD), 2019 & 2024

- Figure 15: Global: Rotary Servo Motors and Drives Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 16: Global: Linear Servo Motors and Drives Market: Sales Value (in Million USD), 2019 & 2024

- Figure 17: Global: Linear Servo Motors and Drives Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 18: Global: Servo Motors and Drives (Fieldbus) Market: Sales Value (in Million USD), 2019 & 2024

- Figure 19: Global: Servo Motors and Drives (Fieldbus) Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 20: Global: Servo Motors and Drives (Industrial Ethernet) Market: Sales Value (in Million USD), 2019 & 2024

- Figure 21: Global: Servo Motors and Drives (Industrial Ethernet) Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 22: Global: Servo Motors and Drives (Wireless) Market: Sales Value (in Million USD), 2019 & 2024

- Figure 23: Global: Servo Motors and Drives (Wireless) Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 24: Global: Servo Motors and Drives (Machine Tools) Market: Sales Value (in Million USD), 2019 & 2024

- Figure 25: Global: Servo Motors and Drives (Machine Tools) Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 26: Global: Servo Motors and Drives (Packaging) Market: Sales Value (in Million USD), 2019 & 2024

- Figure 27: Global: Servo Motors and Drives (Packaging) Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 28: Global: Servo Motors and Drives (Robotics) Market: Sales Value (in Million USD), 2019 & 2024

- Figure 29: Global: Servo Motors and Drives (Robotics) Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 30: Global: Servo Motors and Drives (Semiconductors) Market: Sales Value (in Million USD), 2019 & 2024

- Figure 31: Global: Servo Motors and Drives (Semiconductors) Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 32: Global: Servo Motors and Drives (Electronics) Market: Sales Value (in Million USD), 2019 & 2024

- Figure 33: Global: Servo Motors and Drives (Electronics) Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 34: Global: Servo Motors and Drives (Rubber and Plastics) Market: Sales Value (in Million USD), 2019 & 2024

- Figure 35: Global: Servo Motors and Drives (Rubber and Plastics) Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 36: Global: Servo Motors and Drives (Others) Market: Sales Value (in Million USD), 2019 & 2024

- Figure 37: Global: Servo Motors and Drives (Others) Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 38: Asia Pacific: Servo Motors and Drives Market: Sales Value (in Million USD), 2019 & 2024

- Figure 39: Asia Pacific: Servo Motors and Drives Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 40: Japan: Servo Motors and Drives Market: Sales Value (in Million USD), 2019 & 2024

- Figure 41: Japan: Servo Motors and Drives Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 42: China: Servo Motors and Drives Market: Sales Value (in Million USD), 2019 & 2024

- Figure 43: China: Servo Motors and Drives Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 44: South Korea: Servo Motors and Drives Market: Sales Value (in Million USD), 2019 & 2024

- Figure 45: South Korea: Servo Motors and Drives Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 46: India: Servo Motors and Drives Market: Sales Value (in Million USD), 2019 & 2024

- Figure 47: India: Servo Motors and Drives Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 48: Australia: Servo Motors and Drives Market: Sales Value (in Million USD), 2019 & 2024

- Figure 49: Australia: Servo Motors and Drives Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 50: Indonesia: Servo Motors and Drives Market: Sales Value (in Million USD), 2019 & 2024

- Figure 51: Indonesia: Servo Motors and Drives Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 52: Others: Servo Motors and Drives Market: Sales Value (in Million USD), 2019 & 2024

- Figure 53: Others: Servo Motors and Drives Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 54: Europe: Servo Motors and Drives Market: Sales Value (in Million USD), 2019 & 2024

- Figure 55: Europe: Servo Motors and Drives Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 56: Germany: Servo Motors and Drives Market: Sales Value (in Million USD), 2019 & 2024

- Figure 57: Germany: Servo Motors and Drives Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 58: Italy: Servo Motors and Drives Market: Sales Value (in Million USD), 2019 & 2024

- Figure 59: Italy: Servo Motors and Drives Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 60: Spain: Servo Motors and Drives Market: Sales Value (in Million USD), 2019 & 2024

- Figure 61: Spain: Servo Motors and Drives Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 62: France: Servo Motors and Drives Market: Sales Value (in Million USD), 2019 & 2024

- Figure 63: France: Servo Motors and Drives Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 64: United Kingdom: Servo Motors and Drives Market: Sales Value (in Million USD), 2019 & 2024

- Figure 65: United Kingdom: Servo Motors and Drives Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 66: Russia: Servo Motors and Drives Market: Sales Value (in Million USD), 2019 & 2024

- Figure 67: Russia: Servo Motors and Drives Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 68: Others: Servo Motors and Drives Market: Sales Value (in Million USD), 2019 & 2024

- Figure 69: Others: Servo Motors and Drives Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 70: North America: Servo Motors and Drives Market: Sales Value (in Million USD), 2019 & 2024

- Figure 71: North America: Servo Motors and Drives Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 72: United States: Servo Motors and Drives Market: Sales Value (in Million USD), 2019 & 2024

- Figure 73: United States: Servo Motors and Drives Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 74: Canada: Servo Motors and Drives Market: Sales Value (in Million USD), 2019 & 2024

- Figure 75: Canada: Servo Motors and Drives Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 76: Latin America: Servo Motors and Drives Market: Sales Value (in Million USD), 2019 & 2024

- Figure 77: Latin America: Servo Motors and Drives Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 78: Brazil: Servo Motors and Drives Market: Sales Value (in Million USD), 2019 & 2024

- Figure 79: Brazil: Servo Motors and Drives Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 80: Mexico: Servo Motors and Drives Market: Sales Value (in Million USD), 2019 & 2024

- Figure 81: Mexico: Servo Motors and Drives Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 82: Others: Servo Motors and Drives Market: Sales Value (in Million USD), 2019 & 2024

- Figure 83: Others: Servo Motors and Drives Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 84: Middle East and Africa: Servo Motors and Drives Market: Sales Value (in Million USD), 2019 & 2024

- Figure 85: Middle East and Africa: Servo Motors and Drives Market Forecast: Sales Value (in Million USD), 2025-2033

- Figure 86: Middle East and Africa: Servo Motors and Drives Market: Breakup by Country (in %), 2024

- Figure 87: Global: Servo Motors and Drives Industry: SWOT Analysis

- Figure 88: Global: Servo Motors and Drives Industry: Value Chain Analysis

- Figure 89: Global: Servo Motors and Drives Industry: Porter's Five Analysis

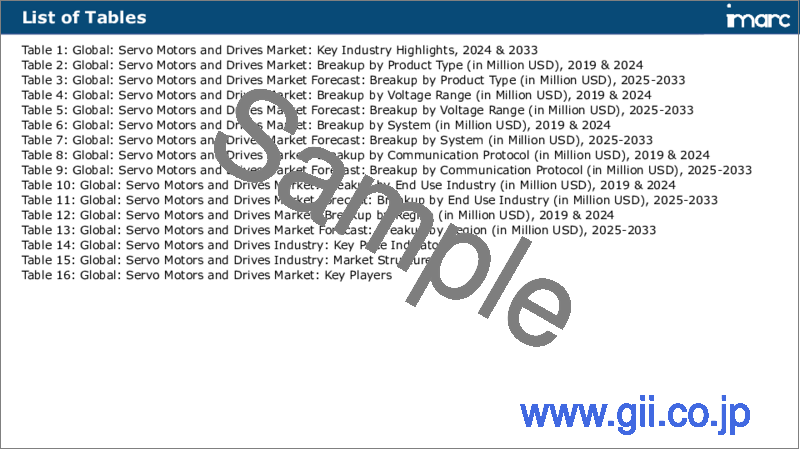

List of Tables

- Table 1: Global: Servo Motors and Drives Market: Key Industry Highlights, 2024 & 2033

- Table 2: Global: Servo Motors and Drives Market: Breakup by Product Type (in Million USD), 2019 & 2024

- Table 3: Global: Servo Motors and Drives Market Forecast: Breakup by Product Type (in Million USD), 2025-2033

- Table 4: Global: Servo Motors and Drives Market: Breakup by Voltage Range (in Million USD), 2019 & 2024

- Table 5: Global: Servo Motors and Drives Market Forecast: Breakup by Voltage Range (in Million USD), 2025-2033

- Table 6: Global: Servo Motors and Drives Market: Breakup by System (in Million USD), 2019 & 2024

- Table 7: Global: Servo Motors and Drives Market Forecast: Breakup by System (in Million USD), 2025-2033

- Table 8: Global: Servo Motors and Drives Market: Breakup by Communication Protocol (in Million USD), 2019 & 2024

- Table 9: Global: Servo Motors and Drives Market Forecast: Breakup by Communication Protocol (in Million USD), 2025-2033

- Table 10: Global: Servo Motors and Drives Market: Breakup by End Use Industry (in Million USD), 2019 & 2024

- Table 11: Global: Servo Motors and Drives Market Forecast: Breakup by End Use Industry (in Million USD), 2025-2033

- Table 12: Global: Servo Motors and Drives Market: Breakup by Region (in Million USD), 2019 & 2024

- Table 13: Global: Servo Motors and Drives Market Forecast: Breakup by Region (in Million USD), 2025-2033

- Table 14: Global: Servo Motors and Drives Industry: Key Price Indicator

- Table 15: Global: Servo Motors and Drives Industry: Market Structure

- Table 16: Global: Servo Motors and Drives Market: Key Players

The global servo motors and drives market size reached USD 13.3 Billion in 2024. Looking forward, IMARC Group expects the market to reach USD 18.9 Billion by 2033, exhibiting a growth rate (CAGR) of 3.9% during 2025-2033. The growing demand for energy efficiency to reduce operational costs and power consumption, rising popularity of automation and robotics, and advancements in the Industrial Internet of Things (IIoT) are some of the major factors propelling the market.

Servo motors are highly precise and efficient rotary actuators that provide control over angular position, velocity, and acceleration. They are widely utilized in various applications, ranging from manufacturing machinery to robotics, due to their ability to provide precise and responsive movement control. On the other hand, servo drives are electronic amplifiers that power and control the servo motors. They receive input signals, typically in the form of voltage or current, and translate them into the precise movements executed by the servo motor. As a result, servo motors and drives are employed in the automotive, packaging, robotics, semiconductors, electronics, and rubber and plastic industries worldwide.

At present, the rising adoption of servo motors and drives, as they ensure enhanced accuracy and repeatability, is contributing to the growth of the market. In line with this, the increasing employment of servo motors and drives to produce renewable energy is strengthening the growth of the market. Moreover, the growing demand for precision, speed, and reliability in various industries across the globe is positively influencing the market. In addition, the rising adoption of actuators that assist in reducing maintenance costs and downtime is providing lucrative growth opportunities to industry investors. Furthermore, the increasing demand for servo motors and drives, as they offer a high degree of customization and adaptability, is supporting the growth of the market. Besides this, governing agencies of numerous countries are supporting the adoption of renewable energy sources, which is bolstering the growth of the market.

Servo Motors and Drives Market Trends/Drivers:

Rising popularity of automation and robotics

The rising popularity of automation and robotics in various industries is bolstering the growth of the market. In the manufacturing sector, these technologies help in increasing production processes by offering high precision and flexibility. Servo motors and drivers are vital components of robots that provide the accuracy and responsiveness required for tasks, such as pick-and-place operations, welding, and assembly. Furthermore, the increasing demand for automated solutions in logistics and warehousing due to the burgeoning e-commerce industry is propelling the growth of the market. In addition, there is a rise in the demand for servo systems to power conveyor belts, sorters, and automated guided vehicles (AGVs).

Increasing demand for energy efficiency to reduce operational costs

Energy efficiency is a major concern across industries due to environmental and cost considerations. In line with this, these motors and drives are renowned for their high energy efficiency, which makes them a suitable choice for businesses aiming to reduce power consumption and operational costs. These systems are designed to deliver power precisely when needed, minimizing energy wastage during idle or low-load conditions. Apart from this, the rising adoption of energy-efficient servo solutions due to the increasing focus on sustainability and reduced carbon footprint is contributing to the growth of the market. Furthermore, various industries are increasingly aligning with eco-friendly practices and regulations, which is positively influencing the market.

Advancements in the Industrial Internet of Things (IIoT)

The integration of the Industrial Internet of Things (IIoT) and Industry 4.0 concepts to offer smart manufacturing is bolstering the growth of the market. In addition, these motors and drives play a vital role as they are equipped with advanced sensors and communication capabilities, which allow them to interact within connected manufacturing environments. Besides this, integration of these advanced technologies provides real-time data collection and analysis that enables predictive maintenance, reduces downtime, and improves the overall equipment effectiveness. The ability to monitor and control servo motors remotely enhances operational efficiency and reduces the need for on-site personnel. This integration not only enhances productivity but also positions industries to respond quickly to market fluctuations and changing customer demands.

Servo Motors and Drives Industry Segmentation:

Breakup by Product Type:

Servo Motors

Servo Drives

Servo motors represent the largest market segment

Breakup by Voltage Range:

Low Voltage

Medium and High Voltage

Low voltage accounts for the majority of the market share

Breakup by System:

Linear System

Rotary System

Rotary system holds the largest market share

Breakup by Communication Protocol:

Fieldbus

Industrial Ethernet

Wireless

Fieldbus dominates the market segment

Breakup by End Use Industry:

Machine Tools

Packaging

Robotics

Semiconductors

Electronics

Rubber and Plastics

Others

Machine tools represent the biggest market share

Breakup by Region:

Asia Pacific

Japan

China

South Korea

India

Australia

Indonesia

Others

Europe

Germany

France

United Kingdom

Italy

Spain

Russia

Others

North America

United States

Canada

Latin America

Brazil

Mexico

Others

Middle East and Africa

Asia Pacific exhibits a clear dominance, accounting for the largest servo motors and drives market share

The market research report has also provided a comprehensive analysis of all the major regional markets, which include Asia Pacific (Japan, China, South Korea, India, Australia, Indonesia, and others); Europe (Germany, Italy, Spain, France, the United Kingdom, Russia, and others); North America (the United States and Canada); Latin America (Brazil, Mexico, and others); and the Middle East and Africa. According to the report, Asia Pacific accounted for the largest market share.

Asia Pacific held the biggest market share due to the increasing adoption of advanced manufacturing technologies. Besides this, the rising focus on industrial automation in various sectors is strengthening the growth of the market in the Asia Pacific region. Moreover, the increasing need for servo technology in packaging and processing equipment is offering a positive market outlook. In line with this, the rising focus on renewable energy sources and electric vehicles (EVs) among individuals is supporting the growth of the market in the region.

Competitive Landscape:

Key players are investing in research and development (R&D) activities to introduce advanced solutions. This includes developing motors with higher power density, improved efficiency, and enhanced precision. Innovations in feedback systems, control algorithms, and connectivity features are common to meet Industry 4.0 requirements. In addition, many companies are offering customized solutions to cater to specific customer requirements. This allows industries to have tailored solutions that precisely match their application needs and enhance efficiency and performance. Apart from this, they are focusing on designing energy-efficient systems to meet environmental regulations and reduce operational costs for end-users. Energy-efficient motors not only save electricity but produce less heat and extend the lifespan of the product.

The report has provided a comprehensive analysis of the competitive landscape in the market. Detailed profiles of all major companies have also been provided. Some of the key players in the market include:

ABB Ltd.

Bosch Rexroth AG

Delta Electronics, Inc.

Emerson Electric Co.

Fanuc Corporation

Mitsubishi Electric Corporation

Nidec Corporation

Rockwell Automation Inc.

Schneider Electric SE

Siemens AG

Yaskawa Electric Corporation

Key Questions Answered in This Report

- 1. What was the size of the global servo motors and drives market in 2024?

- 2. What is the expected growth rate of the global servo motors and drives market during 2025-2033?

- 3. What are the key factors driving the global servo motors and drives market?

- 4. What has been the impact of COVID-19 on the global servo motors and drives market?

- 5. What is the breakup of the global servo motors and drives market based on the product type?

- 6. What is the breakup of the global servo motors and drives market based on the voltage range?

- 7. What is the breakup of the global servo motors and drives market based on the system?

- 8. What is the breakup of the global servo motors and drives market based on the communication protocol?

- 9. What is the breakup of the global servo motors and drives market based on the end use industry?

- 10. What are the key regions in the global servo motors and drives market?

- 11. Who are the key players/companies in the global servo motors and drives market?

Table of Contents

1 Preface

2 Scope and Methodology

- 2.1 Objectives of the Study

- 2.2 Stakeholders

- 2.3 Data Sources

- 2.3.1 Primary Sources

- 2.3.2 Secondary Sources

- 2.4 Market Estimation

- 2.4.1 Bottom-Up Approach

- 2.4.2 Top-Down Approach

- 2.5 Forecasting Methodology

3 Executive Summary

4 Introduction

- 4.1 Overview

- 4.2 Key Industry Trends

5 Global Servo Motors and Drives Market

- 5.1 Market Overview

- 5.2 Market Performance

- 5.3 Impact of COVID-19

- 5.4 Market Forecast

6 Market Breakup by Product Type

- 6.1 Servo Motors

- 6.1.1 Market Trends

- 6.1.2 Market Breakup by Type

- 6.1.3 Market Forecast

- 6.2 Servo Drives

- 6.2.1 Market Trends

- 6.2.2 Market Breakup by Type

- 6.2.3 Market Forecast

7 Market Breakup by Voltage Range

- 7.1 Low Voltage

- 7.1.1 Market Trends

- 7.1.2 Market Forecast

- 7.2 Medium and High Voltage

- 7.2.1 Market Trends

- 7.2.2 Market Forecast

8 Market Breakup by System

- 8.1 Linear System

- 8.1.1 Market Trends

- 8.1.2 Market Forecast

- 8.2 Rotary System

- 8.2.1 Market Trends

- 8.2.2 Market Forecast

9 Market Breakup by Communication Protocol

- 9.1 Fieldbus

- 9.1.1 Market Trends

- 9.1.2 Market Forecast

- 9.2 Industrial Ethernet

- 9.2.1 Market Trends

- 9.2.2 Market Forecast

- 9.3 Wireless

- 9.3.1 Market Trends

- 9.3.2 Market Forecast

10 Market Breakup by End Use Industry

- 10.1 Machine Tools

- 10.1.1 Market Trends

- 10.1.2 Market Forecast

- 10.2 Packaging

- 10.2.1 Market Trends

- 10.2.2 Market Forecast

- 10.3 Robotics

- 10.3.1 Market Trends

- 10.3.2 Market Forecast

- 10.4 Semiconductors

- 10.4.1 Market Trends

- 10.4.2 Market Forecast

- 10.5 Electronics

- 10.5.1 Market Trends

- 10.5.2 Market Forecast

- 10.6 Rubber and Plastics

- 10.6.1 Market Trends

- 10.6.2 Market Forecast

- 10.7 Others

- 10.7.1 Market Trends

- 10.7.2 Market Forecast

11 Market Breakup by Region

- 11.1 Asia Pacific

- 11.1.1 Japan

- 11.1.1.1 Market Trends

- 11.1.1.2 Market Forecast

- 11.1.2 China

- 11.1.2.1 Market Trends

- 11.1.2.2 Market Forecast

- 11.1.3 South Korea

- 11.1.3.1 Market Trends

- 11.1.3.2 Market Forecast

- 11.1.4 India

- 11.1.4.1 Market Trends

- 11.1.4.2 Market Forecast

- 11.1.5 Australia

- 11.1.5.1 Market Trends

- 11.1.5.2 Market Forecast

- 11.1.6 Indonesia

- 11.1.6.1 Market Trends

- 11.1.6.2 Market Forecast

- 11.1.7 Others

- 11.1.7.1 Market Trends

- 11.1.7.2 Market Forecast

- 11.1.1 Japan

- 11.2 Europe

- 11.2.1 Germany

- 11.2.1.1 Market Trends

- 11.2.1.2 Market Forecast

- 11.2.2 Italy

- 11.2.2.1 Market Trends

- 11.2.2.2 Market Forecast

- 11.2.3 Spain

- 11.2.3.1 Market Trends

- 11.2.3.2 Market Forecast

- 11.2.4 France

- 11.2.4.1 Market Trends

- 11.2.4.2 Market Forecast

- 11.2.5 United Kingdom

- 11.2.5.1 Market Trends

- 11.2.5.2 Market Forecast

- 11.2.6 Russia

- 11.2.6.1 Market Trends

- 11.2.6.2 Market Forecast

- 11.2.7 Others

- 11.2.7.1 Market Trends

- 11.2.7.2 Market Forecast

- 11.2.1 Germany

- 11.3 North America

- 11.3.1 United States

- 11.3.1.1 Market Trends

- 11.3.1.2 Market Forecast

- 11.3.2 Canada

- 11.3.2.1 Market Trends

- 11.3.2.2 Market Forecast

- 11.3.1 United States

- 11.4 Latin America

- 11.4.1 Brazil

- 11.4.1.1 Market Trends

- 11.4.1.2 Market Forecast

- 11.4.2 Mexico

- 11.4.2.1 Market Trends

- 11.4.2.2 Market Forecast

- 11.4.3 Others

- 11.4.3.1 Market Trends

- 11.4.3.2 Market Forecast

- 11.4.1 Brazil

- 11.5 Middle East and Africa

- 11.5.1 Market Trends

- 11.5.2 Market Breakup by Country

- 11.5.3 Market Forecast

12 SWOT Analysis

- 12.1 Overview

- 12.2 Strengths

- 12.3 Weaknesses

- 12.4 Opportunities

- 12.5 Threats

13 Value Chain Analysis

14 Porters Five Forces Analysis

- 14.1 Overview

- 14.2 Bargaining Power of Buyers

- 14.3 Bargaining Power of Suppliers

- 14.4 Degree of Competition

- 14.5 Threat of New Entrants

- 14.6 Threat of Substitutes

15 Price Analysis

16 Competitive Landscape

- 16.1 Market Structure

- 16.2 Key Players

- 16.3 Profiles of Key Players

- 16.3.1 ABB Ltd.

- 16.3.1.1 Company Overview

- 16.3.1.2 Product Portfolio

- 16.3.1.3 Financials

- 16.3.1.4 SWOT Analysis

- 16.3.2 Bosch Rexroth AG

- 16.3.2.1 Company Overview

- 16.3.2.2 Product Portfolio

- 16.3.2.3 SWOT Analysis

- 16.3.3 Delta Electronics, Inc.

- 16.3.3.1 Company Overview

- 16.3.3.2 Product Portfolio

- 16.3.3.3 Financials

- 16.3.3.4 SWOT Analysis

- 16.3.4 Emerson Electric Co.

- 16.3.4.1 Company Overview

- 16.3.4.2 Product Portfolio

- 16.3.4.3 Financials

- 16.3.4.4 SWOT Analysis

- 16.3.5 Fanuc Corporation

- 16.3.5.1 Company Overview

- 16.3.5.2 Product Portfolio

- 16.3.5.3 Financials

- 16.3.5.4 SWOT Analysis

- 16.3.6 Mitsubishi Electric Corporation

- 16.3.6.1 Company Overview

- 16.3.6.2 Product Portfolio

- 16.3.6.3 Financials

- 16.3.6.4 SWOT Analysis

- 16.3.7 Nidec Corporation

- 16.3.7.1 Company Overview

- 16.3.7.2 Product Portfolio

- 16.3.7.3 Financials

- 16.3.7.4 SWOT Analysis

- 16.3.8 Rockwell Automation Inc.

- 16.3.8.1 Company Overview

- 16.3.8.2 Product Portfolio

- 16.3.8.3 Financials

- 16.3.8.4 SWOT Analysis

- 16.3.9 Schneider Electric SE

- 16.3.9.1 Company Overview

- 16.3.9.2 Product Portfolio

- 16.3.9.3 Financials

- 16.3.9.4 SWOT Analysis

- 16.3.10 Siemens AG

- 16.3.10.1 Company Overview

- 16.3.10.2 Product Portfolio

- 16.3.10.3 Financials

- 16.3.10.4 SWOT Analysis

- 16.3.11 Yaskawa Electric Corporation

- 16.3.11.1 Company Overview

- 16.3.11.2 Product Portfolio

- 16.3.11.3 Financials

- 16.3.1 ABB Ltd.