|

|

市場調査レポート

商品コード

1255883

植物工場の世界市場-2023-2030Global Plant Factory Market - 2023-2030 |

||||||

|

● お客様のご希望に応じて、既存データの加工や未掲載情報(例:国別セグメント)の追加などの対応が可能です。 詳細はお問い合わせください。 |

|||||||

| 植物工場の世界市場-2023-2030 |

|

出版日: 2023年04月11日

発行: DataM Intelligence

ページ情報: 英文 210 Pages

納期: 約2営業日

|

- 全表示

- 概要

- 目次

市場概要

世界の植物工場市場は、予測期間中(2023年~2030年)のCAGRは7.8%と予想されています。

植物工場と呼ばれる閉鎖型農業システムにより、年間を通じて継続的に野菜を生産することが可能になります。植物工場は、作物の出力時間を短縮し、水や肥料を節約し、無農薬で生産することができます。工場では、光、温度、水分、二酸化炭素のレベルを人工的な手段で調整します。

植物工場は、高品質で化学物質を含まない食品の生産に役立ちます。現代の製造業、養液栽培、バイオテクノロジー、IT技術が融合した植物工場では、工場内の気候を精密に調整しています。植物工場では、人工的な熟成剤や農薬が使用されないため、より栄養価の高い野菜ができます。

市場力学

従来の農法に比べ、より大きな収量を実現

植物工場は農家の資源消費を減少させるため、裏庭の庭師から商業栽培者、スーパーマーケットからレストランまで、ほとんどの栽培者がこの農法を実施することを可能にします。数多くの国連研究が、水耕栽培システムが作物の収量と食料生産を増加させる可能性を強調しています。2018年の国連報告書によると、水耕栽培システムで生産された植物は、従来の農業で栽培されたものに比べ、収量が20~25%高く、生産性は2~5倍になるとされています。

2019年のFAOの調査によると、水耕栽培システムは、最適化された栽培条件と効率的な資源利用により、従来の農業システムよりも最大で5倍生産性が高い可能性があります。

生産者は機械故障のリスクや導入率の遅れに直面する

他の高度な技術と同様に、植物工場も機器故障のリスクと無縁ではありません。工場やプラントで使用される複雑で高度に自動化されたシステムを効率的に稼働させるためには、専門的な修理や維持管理が必要です。万が一、機器の故障が発生した場合、修理や交換に費用がかかる可能性があり、すぐに対処しなければ、作物の損失につながる可能性があります。

機器の故障リスクが高まると生産量が制限されるため、さらに導入率が低下し、市場拡大を阻害する難しい要因となっています。例えば、システム内の水ポンプが壊れると、結果として植物が数時間で枯れてしまうかもしれないです。

COVID-19の影響度分析

COVID-19の分析には、Pre-COVIDシナリオ、COVIDシナリオ、Post-COVIDシナリオに加えて、価格力学(パンデミック時およびパンデミック後の価格変動、COVID前のシナリオとの比較)、需要-供給スペクトラム(取引制限、ロックダウンおよびその後の問題による需要と供給のシフト)、政府の取り組み(政府組織による市場、セクター、産業の再生への取り組み)、メーカー戦略的取り組み(COVID問題を軽減するためにメーカーは何を行ったか)、があります。

目次

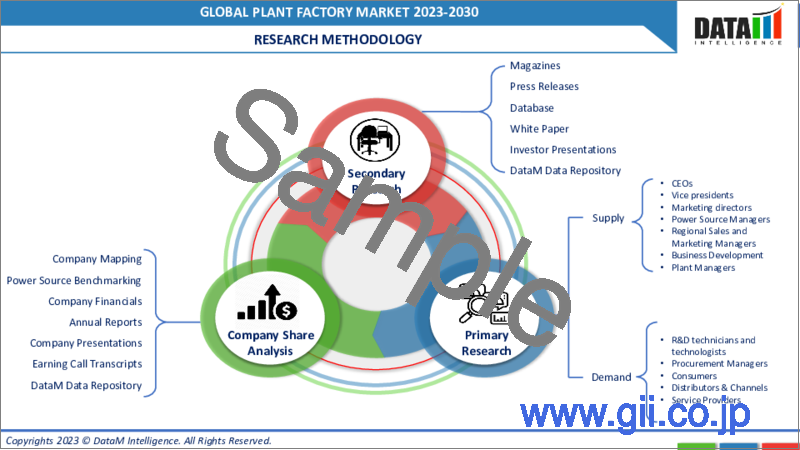

第1章 調査手法とスコープ

- 調査手法

- 調査目的および調査範囲について

第2章 定義と概要

第3章 エグゼクティブサマリー

- 市場内訳、施設別

- 市場内訳、光源別

- 市場内訳:栽培システム別

- 市場内訳、作物別

- 市場内訳、地域別

第4章 市場力学

- 影響要因

- 促進要因

- 植物工場のメリットに関する認知度向上

- 従来の農法に比べ、より大きな収量を実現

- 抑制要因

- 高い設備投資額

- 機会

- 影響度分析

- 促進要因

第5章 産業分析

- ポーターのファイブフォース分析

- サプライチェーン分析

- 価格アナリシス

- レギュラトリー・アナリシス

第6章 COVID-19の分析

- COVID-19の解析について

- COVID-19シナリオ前

- 現在のCOVID-19シナリオ

- ポストCOVID-19またはフューチャーシナリオ

- COVID-19における価格ダイナミクス

- 需給スペクトル

- パンデミック時の市場に関連する政府の取り組み

- メーカーの戦略的な取り組み

- 結論

第7章 施設別

- 温室

- インドアファーム

- その他

第8章 光別

- 太陽光

- 完全人工光

第9章 育成システム別

- ノンソイルベース

- ソイルベース

- ハイブリッド

第10章 作物別

- フルーツ

- 野菜類

- フラワー&オーナメンタル

- その他

第11章 地域別

- 北米

- 米国

- カナダ

- メキシコ

- 欧州

- ドイツ

- 英国

- フランス

- スペイン

- イタリア

- その他欧州

- 南米

- ブラジル

- アルゼンチン

- その他南米地域

- アジア太平洋地域

- 中国

- インド

- 日本

- オーストラリア

- その他アジア太平洋地域

- 中東・アフリカ地域

第12章 競合情勢

- 競合シナリオ

- 市況分析・シェア分析

- M&A分析

第13章 企業プロファイル

- Plenty Unlimited Inc.

- 会社概要

- 製品ポートフォリオと説明

- 主なハイライト

- 財務概要

- Bright Farms

- Bowery Farming

- AppHarvest

- AeroFarms

- Crop One

- Mirai Co. Ltd

- Gotham Greens

- Sky Greens

- Oishee

第14章 付録

Market Overview

The global plant factory market reached US$ XX million in 2022 and is projected to witness lucrative growth by reaching up to US$ XX million by 2030. The market is expected to exhibit a CAGR of 7.8% during the forecast period (2023-2030).

A closed-growing agriculture system called a 'plant factory' makes it possible to produce vegetables continuously all year long. Plant factories reduce crop output time, conserve water and fertilizer, and provide pesticide-free production. The factory uses artificial means to regulate the levels of light, temperature, moisture and carbon dioxide.

Plant factories help in the production of high-quality, chemical-free food. Modern manufacturing, nutrient farming, biotechnology and information technology are all combined in plant factories, which precisely regulate the internal climate of a factory. In plant farms, artificial ripening agents and pesticides are not used, resulting in vegetables that are more nutritious.

Market Dynamics

A greater yield compared to conventional farming methods

As plant factories decrease the farmer's resource consumption, plant factories make it possible for most cultivators from backyard gardeners to commercial growers, supermarkets to restaurants to implement this farming method. Numerous UN studies have emphasized the potential of hydroponic systems to increase crop yields and food production. According to a 2018 UN report, plants produced in hydroponic systems have a 20%-25% higher yield and a productivity that is 2-5 times higher than those grown in traditional agriculture.

According to a 2019 FAO study, hydroponic agriculture systems may be up to five times more productive than traditional agriculture systems because of the optimized growing conditions and efficient resource use.

Growers face the risk of machinery breakdown and slow adoption rate

Like any other sophisticated technology, plant factories are not immune to the risk of equipment failure. Specialized repair and upkeep are required to keep the intricate and highly automated systems used in factories and plants operating efficiently. If equipment failure does occur, it might be costly to fix or replace and if it is not taken care of right away, it may result in crop loss.

Higher equipment failure risks restrict output, which further lowers adoption rates and is a difficult factor that inhibits market expansion. For instance, if a water pump in the system breaks, the plants might die in a matter of hours as a consequence.

COVID-19 Impact Analysis

The COVID-19 analysis includes Pre-COVID Scenario, COVID Scenario and Post-COVID Scenario along with Pricing Dynamics (including pricing change during and post-pandemic comparing it with pre-COVID scenarios), Demand-Supply Spectrum (shift in demand and supply owing to trading restrictions, lockdown and subsequent issues), Government Initiatives (initiatives to revive market, sector or Industry by Government Bodies) and Manufacturers' Strategic Initiatives (what manufacturers did to mitigate the COVID issues will be covered here).

Segment Analysis

The global plant factory market is segmented based on facility, light, growing system, crop and region.

The high reliance on sunlight drives the sunlight segment growth

The high reliance of plant factory on sunlight is expected to drive the segment growth over the forecast period. The plant factories depend heavily on sunlight, a natural source of light that is essential for plant growth and development. It offers a wide range of wavelengths of light that are essential to photosynthesis and other physiological functions in plants. Plant factories can lower their energy expenses and boost their profitability by utilizing natural light.

Geographical Analysis

The growing government initiatives in Asia-Pacific

The market in Asia-Pacific is expected to grow at the fastest rate over the forecast period, owing to the rapidly expanding agriculture sector and support from government. Government actions and incentives would be needed to support farmers, ensure widespread acceptance of different relief solutions and help India achieve food security. The government hopes to have doubled the output in horticulture and therefore, there is strong support for new greenhouse building. Moreover, the government assists farmers and horticulturists in producing safe food.

Competitive Landscape

The major global players in the market are: Plenty Unlimited Inc., Bright Farms, Bowery Farming, AppHarvest, AeroFarms, Crop One, Mirai Co. Ltd, Gotham Greens, Crop One, and Sky Greens.

Why Purchase the Report?

- To visualize the global plant factory- market segmentation based on facility, light, growing system, crop and region, as well as understand key commercial assets and players.

- Identify commercial opportunities by analyzing trends and co-development.

- Excel data sheet with numerous data points of plant factory market-level with all segments.

- PDF report consists of a comprehensive analysis after exhaustive qualitative interviews and an in-depth study.

- Product mapping available as Excel consisting of key products of all the major players.

The global plant factory market report would provide approximately 69 tables, 67 figures and 210 pages.

Target Audience 2023

- Manufacturers/ Buyers

- Industry Investors/Investment Bankers

- Research Professionals

- Emerging Companies

Table of Contents

1. Methodology and Scope

- 1.1. Research Methodology

- 1.2. Research Objective and Scope of the Report

2. Definition and Overview

3. Executive Summary

- 3.1. Market Snippet, By Facility

- 3.2. Market Snippet, By Light

- 3.3. Market Snippet, By Growing System

- 3.4. Market Snippet, By Crop

- 3.5. Market Snippet, By Region

4. Dynamics

- 4.1. Impacting Factors

- 4.1.1. Drivers

- 4.1.1.1. Increasing awareness regarding the benefits of plant factory

- 4.1.1.2. A greater yield compared to conventional farming methods

- 4.1.2. Restraints

- 4.1.2.1. High capital investments

- 4.1.2.2. XX

- 4.1.3. Opportunity

- 4.1.3.1. XX

- 4.1.4. Impact Analysis

- 4.1.1. Drivers

5. Industry Analysis

- 5.1. Porter's Five Forces Analysis

- 5.2. Supply Chain Analysis

- 5.3. Pricing Analysis

- 5.4. Regulatory Analysis

6. COVID-19 Analysis

- 6.1. Analysis of COVID-19

- 6.1.1. Before COVID-19 Scenario

- 6.1.2. Present COVID-19 Scenario

- 6.1.3. Post COVID-19 or Future Scenario

- 6.2. Pricing Dynamics Amid COVID-19

- 6.3. Demand-Supply Spectrum

- 6.4. Government Initiatives Related to the Market During Pandemic

- 6.5. Manufacturers Strategic Initiatives

- 6.6. Conclusion

7. By Facility

- 7.1. Introduction

- 7.1.1. Market Size Analysis and Y-o-Y Growth Analysis (%), By Facility

- 7.1.2. Market Attractiveness Index, By Facility

- 7.2. Greenhouses*

- 7.2.1. Introduction

- 7.2.2. Market Size Analysis and Y-o-Y Growth Analysis (%)

- 7.3. Indoor Farms

- 7.4. Others

8. By Light

- 8.1. Introduction

- 8.1.1. Market Size Analysis and Y-o-Y Growth Analysis (%), By Light

- 8.1.2. Market Attractiveness Index, By Light

- 8.2. Sunlight*

- 8.2.1. Introduction

- 8.2.2. Market Size Analysis and Y-o-Y Growth Analysis (%)

- 8.3. Fully Artificial Light

9. By Growing System

- 9.1. Introduction

- 9.1.1. Market Size Analysis and Y-o-Y Growth Analysis (%), By Growing System

- 9.1.2. Market Attractiveness Index, By Growing System

- 9.2. Non-Soil-Based*

- 9.2.1. Introduction

- 9.2.2. Market Size Analysis and Y-o-Y Growth Analysis (%)

- 9.3. Soil-Based

- 9.4. Hybrid

10. By Crop

- 10.1. Introduction

- 10.1.1. Market Size Analysis and Y-o-Y Growth Analysis (%), By Crop

- 10.1.2. Market Attractiveness Index, By Crop

- 10.2. Fruits*

- 10.2.1. Introduction

- 10.2.2. Market Size Analysis and Y-o-Y Growth Analysis (%)

- 10.3. Vegetables

- 10.4. Flowers & ornamental

- 10.5. Others

11. By Region

- 11.1. Introduction

- 11.2. Market Size Analysis and Y-o-Y Growth Analysis (%), By Region

- 11.3. Market Attractiveness Index, By Region

- 11.4. North America

- 11.4.1. Introduction

- 11.4.2. Key Region-Specific Dynamics

- 11.4.3. Market Size Analysis and Y-o-Y Growth Analysis (%), By Facility

- 11.4.4. Market Size Analysis and Y-o-Y Growth Analysis (%), By Light

- 11.4.5. Market Size Analysis and Y-o-Y Growth Analysis (%), By Growing System

- 11.4.6. Market Size Analysis and Y-o-Y Growth Analysis (%), By Crop

- 11.4.7. Market Size Analysis and Y-o-Y Growth Analysis (%), By Country

- 11.4.7.1. The U.S.

- 11.4.7.2. Canada

- 11.4.7.3. Mexico

- 11.5. Europe

- 11.5.1. Introduction

- 11.5.2. Key Region-Specific Dynamics

- 11.5.3. Market Size Analysis and Y-o-Y Growth Analysis (%), By Facility

- 11.5.4. Market Size Analysis and Y-o-Y Growth Analysis (%), By Light

- 11.5.5. Market Size Analysis and Y-o-Y Growth Analysis (%), By Growing System

- 11.5.6. Market Size Analysis and Y-o-Y Growth Analysis (%), By Crop

- 11.5.7. Market Size Analysis and Y-o-Y Growth Analysis (%), By Country

- 11.5.7.1. Germany

- 11.5.7.2. The U.K.

- 11.5.7.3. France

- 11.5.7.4. Spain

- 11.5.7.5. Italy

- 11.5.7.6. Rest of Europe

- 11.6. South America

- 11.6.1. Introduction

- 11.6.2. Key Region-Specific Dynamics

- 11.6.3. Market Size Analysis and Y-o-Y Growth Analysis (%), By Facility

- 11.6.4. Market Size Analysis and Y-o-Y Growth Analysis (%), By Light

- 11.6.5. Market Size Analysis and Y-o-Y Growth Analysis (%), By Growing System

- 11.6.6. Market Size Analysis and Y-o-Y Growth Analysis (%), By Crop

- 11.6.7. Market Size Analysis and Y-o-Y Growth Analysis (%), By Country

- 11.6.7.1. Brazil

- 11.6.7.2. Argentina

- 11.6.7.3. Rest of South America

- 11.7. Asia-Pacific

- 11.7.1. Introduction

- 11.7.2. Key Region-Specific Dynamics

- 11.7.3. Market Size Analysis and Y-o-Y Growth Analysis (%), By Facility

- 11.7.4. Market Size Analysis and Y-o-Y Growth Analysis (%), By Light

- 11.7.5. Market Size Analysis and Y-o-Y Growth Analysis (%), By Growing System

- 11.7.6. Market Size Analysis and Y-o-Y Growth Analysis (%), By Crop

- 11.7.7. Market Size Analysis and Y-o-Y Growth Analysis (%), By Country

- 11.7.7.1. China

- 11.7.7.2. India

- 11.7.7.3. Japan

- 11.7.7.4. Australia

- 11.7.7.5. Rest of Asia-Pacific

- 11.8. Middle East and Africa

- 11.8.1. Introduction

- 11.8.2. Key Region-Specific Dynamics

- 11.8.3. Market Size Analysis and Y-o-Y Growth Analysis (%), By Facility

- 11.8.4. Market Size Analysis and Y-o-Y Growth Analysis (%), By Light

- 11.8.5. Market Size Analysis and Y-o-Y Growth Analysis (%), By Growing System

- 11.8.6. Market Size Analysis and Y-o-Y Growth Analysis (%), By Crop

12. Competitive Landscape

- 12.1. Competitive Scenario

- 12.2. Market Positioning/Share Analysis

- 12.3. Mergers and Acquisitions Analysis

13. Company Profiles

- 13.1. Plenty Unlimited Inc.

- 13.1.1. Company Overview

- 13.1.2. Product Portfolio and Description

- 13.1.3. Key Highlights

- 13.1.4. Financial Overview

- 13.2. Bright Farms

- 13.3. Bowery Farming

- 13.4. AppHarvest

- 13.5. AeroFarms

- 13.6. Crop One

- 13.7. Mirai Co. Ltd

- 13.8. Gotham Greens

- 13.9. Sky Greens

- 13.10. Oishee

LIST NOT EXHAUSTIVE

14. Appendix

- 14.1. About Us and Services

- 14.2. Contact Us