|

|

市場調査レポート

商品コード

1217678

エチレンプロピレンジエンモノマー(EPDM)ゴムの世界市場:市場規模、市場シェア、動向分析、機会、予測:タイプ別、用途別、エンドユーザー別、地域別(2019年~2029年)Ethylene Propylene Diene Monomer Rubber Market - Global Size, Share, Trend Analysis, Opportunity and Forecast Report, 2019-2029, Segmented By Type ; By Application ; By End User ; By Region |

||||||

| エチレンプロピレンジエンモノマー(EPDM)ゴムの世界市場:市場規模、市場シェア、動向分析、機会、予測:タイプ別、用途別、エンドユーザー別、地域別(2019年~2029年) |

|

出版日: 2023年02月09日

発行: Blueweave Consulting

ページ情報: 英文 175 Pages

納期: 2~3営業日

|

- 全表示

- 概要

- 目次

世界のエチレンプロピレンジエンモノマー(EPDM)ゴムの市場規模は、2022年の49億8,000万米ドルから2029年には72億2,000万米ドルに達し、2023年から2029年までの予測期間(2022年~2028年)中に5.52%のCAGRで成長すると予測されています。中国やインドなどの新興国における自動車分野への財政支援の拡大、自動車や建築・建設などの用途の拡大は、市場の成長を促進しています。

当レポートでは、世界のエチレンプロピレンジエンモノマー(EPDM)ゴム市場について調査しており、市場概要、市場分析、企業プロファイルなど、包括的な情報を提供しています。

目次

第1章 調査の枠組み

第2章 エグゼクティブサマリー

第3章 世界のエチレンプロピレンジエンモノマー(EPDM)ゴム市場の洞察

- 業界バリューチェーン分析

- DROC分析

- 促進要因

- ブレンド製品におけるエチレンプロピレンジエンモノマー(EPDM)ゴムの使用の増加

- 建設セクターにおけるエチレンプロピレンジエンモノマー(EPDM)ゴムの需要の増加

- 抑制要因

- 市場に伴う高コスト

- 機会

- 政府投資の増加

- 環境に配慮した生産技術の開発

- 課題

- エチレンプロピレンジエンモノマー(EPDM)のリサイクルの困難さ

- 技術の進歩/最近の開発

- 規制の枠組み

- ポーターのファイブフォース分析

- 供給企業の交渉力

- 買い手の交渉力

- 新規参入業者の脅威

- 代替品の脅威

- 競争の激しさ

第4章 世界のエチレンプロピレンジエンモノマー(EPDM)ゴム市場概要

- 市場規模と予測(2019年~2029年)

- 金額別(100万米ドル)

- 市場シェアと予測

- タイプ別

- 溶液重合

- 懸濁重合

- その他

- 用途別

- 自動車

- 建築・建設

- タイヤ・チューブ

- ワイヤー・ケーブル

- 潤滑油添加剤

- エンドユーザー別

- 自動車

- 航空宇宙・防衛

- 消費財

- 建築・建設

- その他

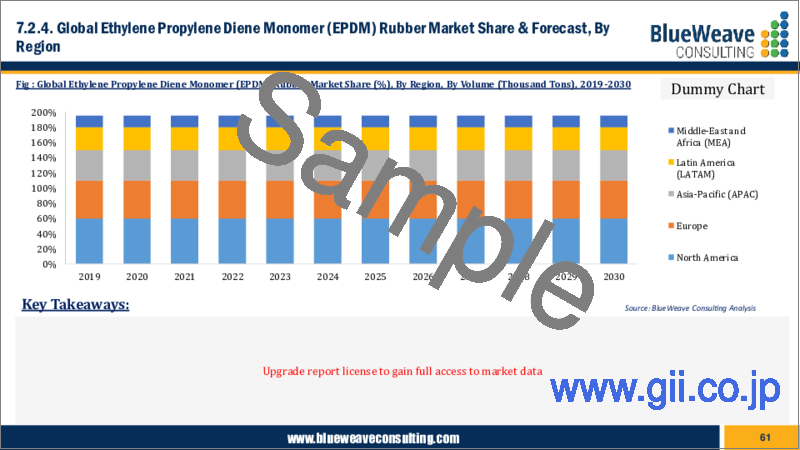

- 地域別

- 北米

- 欧州

- アジア太平洋

- ラテンアメリカ

- 中東およびアフリカ

- タイプ別

第5章 北米のエチレンプロピレンジエンモノマー(EPDM)ゴム市場

第6章 欧州のエチレンプロピレンジエンモノマー(EPDM)ゴム市場

第7章 アジア太平洋のエチレンプロピレンジエンモノマー(EPDM)ゴム市場

第8章 ラテンアメリカのエチレンプロピレンジエンモノマー(EPDM)ゴム市場

第9章 中東およびアフリカのエチレンプロピレンジエンモノマー(EPDM)ゴム市場

第10章 競合情勢

- 主要企業とその製品のリスト

- 世界のエチレンプロピレンジエンモノマー(EPDM)ゴム企業の市場シェア分析(2022年)

- 競合ベンチマーキング:操作パラメータ別

- 主要な戦略的展開(合併、買収、パートナーシップなど)

第11章 世界のエチレンプロピレンジエンモノマー(EPDM)ゴム市場に対するCOVID-19の影響

第12章 企業プロファイル(企業概要、財務マトリックス、競合情勢、主要な人材、主要な競合、連絡先、戦略的展望、SWOT分析)

- DuPont

- Exxon Mobil Corporation

- Lanxess

- Mitsui Chemicals, Inc

- Sumitomo chemical co. Ltd

- SK geo centric Co., Ltd.

- china petrochemical corporation

- Johns Manville.

- Berkshire Hathaway Inc.

- JSR Corporation

- KUMHO POLYCHEM

- Lion Elastomers

- PJSC"Nizhnekamskneftekhim''

- American Rubber

- Rotadyne Tools Pvt. Ltd.

- American Urethane,

- Argonics, Inc.

- Griffith Rubber Mills

- HINDUSTAN RUBBER INDUSTRIES

- その他

第13章 主要な戦略的推奨事項

第14章 調査手法

Global Ethylene Propylene Diene Monomer (EPDM) Rubber Market Size to Cross USD 7.2 Billion by 2029

Global ethylene propylene diene monomer (EPDM) rubber market is flourishing owing to growing product demand, R&D investment growth, and the demand for bio-based products.

BlueWeave Consulting, a leading strategic consulting and market research firm, in its recent study, estimates global ethylene propylene diene monomer (EPDM) rubber market size at USD 4.98 billion in 2022. During the forecast period between 2023 and 2029, BlueWeave expects global ethylene propylene diene monomer (EPDM) rubber market size to grow at a CAGR of 5.52% reaching a value of USD 7.22 billion by 2029. Major factors for the expansion of global EPDM rubber market include rising financial support for the automotive sector in emerging nations like China, India, and others. Throughout the forecast period, there is expected to be a significant rise in demand for ethylene propylene diene monomer (EPDM) rubber due to the rapid expansion of application sectors like automotive and building & construction. Rapid growth in the U.S. construction and automotive industries has resulted in a sharp increase in the demand for EPDM in the North American region. However, high cost associated with market is anticipated to restrain the overall market expansion.

Global Ethylene Propylene Diene Monomer (EPDM) Rubber Market - Overview:

EPDM is also known as ethylene propylene diene monomer (M-class) rubber. To produce cross-linking sites that allow for vulcanization, ethylene, propylene, and a small amount of non-conjugated diene monomers (between 3 and 9 percent) are copolymerized. It is an elastic material with a wide variety of uses. The majority of applications for EPDM include electrical insulation, lamination, and gaskets. This is due to its high resistance to tearing, solvents, abrasives, and temperatures. It has excellent low- and high-temperature elasticity as well as good resistance to common dilute acids, ketones, and alkalis. It also exhibits good electrical insulating properties.

Opportunity: Expanding government spending

The demand for ethylene propylene diene monomer is expected to rise as a result of the projected increase in government spending on the healthcare industry (EPDM). Because they are waterproof, ethylene propylene diene monomer (EPDM) coatings are increasingly used on medical equipment. This is a significant factor that, over the forecast period, is expected to greatly expand the ethylene propylene diene monomer (EPDM) market's potential.

Challenge: High Market Prices

Global ethylene propylene diene monomer (EPDM) rubber market is expected to grow more slowly as a result of the process' high cost. Given the presence of other market alternatives, ownership is expensive. These are some of the key elements preventing the ethylene propylene diene monomer (EPDM) rubber market from expanding over the anticipated time frame. One of the main factors holding back market expansion is the rise in environmental concerns brought on by VOC emissions during EPDM manufacturing.

Impact of COVID-19 on Global Ethylene Propylene Diene Monomer (EPDM) Rubber Market

The COVID-19 pandemic had a detrimental impact on global market for ethylene propylene diene monomer (EPDM) rubber market. Due to the closure of manufacturing facilities, manufacturing companies are dealing with the disruption of the demand and product supply chains caused by the pandemic. In the post-pandemic era, expansion in the medical and healthcare industries is expected to support the global market for ethylene propylene diene monomer (EPDM) rubber, as it helps to improve the efficiency of the equipment. Therefore, coronavirus is significantly affecting the growth of the ethylene propylene diene monomer market (EPDM).

Global Ethylene Propylene Diene Monomer (EPDM) Rubber Market - By End User:

Global ethylene diene monomer (EPDM) rubber market is segmented by end-user into Automotive, Aerospace and Defense, Consumer Goods, Building and Construction, and Others. EPDM is a high-density synthetic rubber with properties that make it superior to natural and synthetic alternatives for automotive applications. Furthermore, due to its flexibility, resiliency, and excellent weather resistance, EPDM is the most commonly used material in the automotive industry. It's used in weather stripping, seals, sealant, wire and cable harnesses, and vehicle brake systems.

Competitive Landscape:

Global ethylene diene monomer (EPDM) rubber market is fiercely competitive, with DuPont, Exxon Mobil Corporation, Lanxess, Mitsui Chemicals, Inc, Sumitomo chemical co. Ltd, SK geo centric Co., Ltd., China Petrochemical Corporation, Johns Manville., Berkshire Hathaway Inc., JSR Corporation, KUMHO POLYCHEM, Lion Elastomers, PJSC "Nizhnekamskneftekhim'', American Rubber, Rotadyne Tools Pvt. Ltd., American Urethane, Argonics, Inc., Griffith Rubber Mills, and HINDUSTAN RUBBER INDUSTRIES. companies use various strategies, including increasing investments in their R&D activities, mergers, and acquisitions, joint ventures, collaborations, licensing agreements, and new product and service releases to further strengthen their position in the global ethylene diene monomer (EPDM) market.

The in-depth analysis of the report provides information about growth potential, upcoming trends, and statistics of Global Ethylene Diene Monomer (EPDM) Rubber Market. It also highlights the factors driving forecasts of total market size. The report promises to provide recent technology trends in Global Ethylene Diene Monomer (EPDM) Rubber Market and industry insights to help decision-makers make sound strategic decisions. Furthermore, the report also analyzes the growth drivers, challenges, and competitive dynamics of the market.

Table of Contents

1. Research Framework

- 1.1. Research Objective

- 1.2. Product Overview

- 1.3. Market Segmentation

2. Executive Summary

3. Global Ethylene Propylene Diene Monomer (EPDM) Rubber Market Insights

- 3.1. Industry Value Chain Analysis

- 3.1.1. DROC Analysis

- 3.1.2. Growth Drivers

- 3.1.2.1. Growing Use of EPDM Polymer in Blended Products

- 3.1.2.2. Growing Demand of Ethylene Propylene Diene Monomer (EPDM) In Construction Sector

- 3.1.3. Restraints

- 3.1.3.1. High Cost Associated with Market

- 3.1.4. Opportunities

- 3.1.4.1. Increasing Government Investments

- 3.1.4.2. Development of Environment Friendly Technology for Production

- 3.1.5. Challenges

- 3.1.5.1. Difficulty in Recycling of EPDM

- 3.2. Technological Advancement/Recent Developments

- 3.3. Regulatory Framework

- 3.4. Porter's Five Forces Analysis

- 3.4.1. Bargaining Power of Suppliers

- 3.4.2. Bargaining Power of Buyers

- 3.4.3. Threat of New Entrants

- 3.4.4. Threat of Substitutes

- 3.4.5. Intensity of Rivalry

4. Global Ethylene Propylene Diene Monomer (EPDM) Rubber Market Overview

- 4.1. Market Size & Forecast, 2019-2029

- 4.1.1. By Value (USD Million)

- 4.2. Market Share & Forecast

- 4.2.1. By Type

- 4.2.1.1. Solution Polymerization

- 4.2.1.2. Suspension Polymerization

- 4.2.1.3. Others

- 4.2.2. By Application

- 4.2.2.1. Automotive

- 4.2.2.2. Building and Construction

- 4.2.2.3. Tires and Tubes

- 4.2.2.4. Wires and Cables

- 4.2.2.5. Lubricant Additives

- 4.2.3. By End User

- 4.2.3.1. Automotive

- 4.2.3.2. Aerospace and Defence

- 4.2.3.3. Consumer goods

- 4.2.3.4. Building and Construction

- 4.2.3.5. Others

- 4.2.4. By Region

- 4.2.4.1. North America

- 4.2.4.2. Europe

- 4.2.4.3. Asia Pacific (APAC)

- 4.2.4.4. Latin America (LATAM)

- 4.2.4.5. Middle East and Africa (MEA)

- 4.2.1. By Type

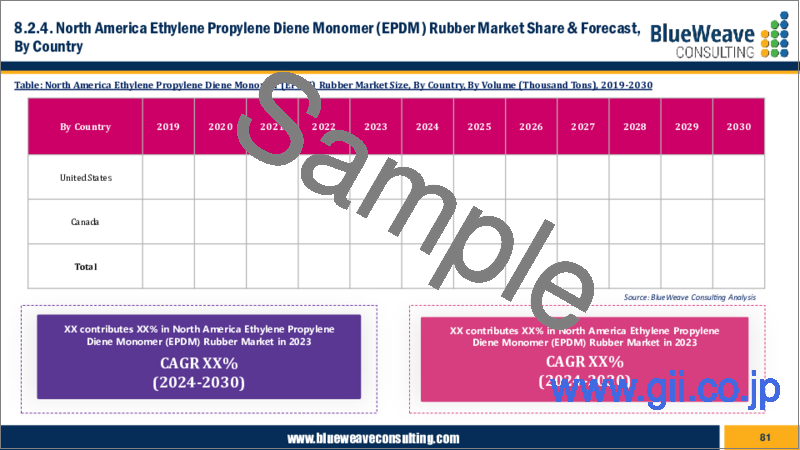

5. North America Ethylene Propylene Diene Monomer (EPDM) Rubber Market

- 5.1. Market Size & Forecast, 2019-2029

- 5.1.1. By Value (USD Million)

- 5.2. Market Share & Forecast

- 5.2.1. By Type

- 5.2.2. By Application

- 5.2.3. By End User

- 5.2.4. By Country

- 5.2.4.1. US

- 5.2.4.1.1. By Type

- 5.2.4.1.2. By Application

- 5.2.4.1.3. By End User

- 5.2.4.2. Canada

- 5.2.4.2.1. By Type

- 5.2.4.2.2. By Application

- 5.2.4.2.3. By End User

6. Europe Ethylene Propylene Diene Monomer (EPDM) Rubber Market

- 6.1. Market Size & Forecast, 2019-2029

- 6.1.1. By Value (USD Million)

- 6.2. Market Share & Forecast

- 6.2.1. By Type

- 6.2.2. By Application

- 6.2.3. By End User

- 6.2.4. By Country

- 6.2.4.1. Germany

- 6.2.4.1.1. By Type

- 6.2.4.1.2. By Application

- 6.2.4.1.3. By End User

- 6.2.4.2. UK

- 6.2.4.2.1. By Type

- 6.2.4.2.2. By Application

- 6.2.4.2.3. By End User

- 6.2.4.3. Italy

- 6.2.4.3.1. By Type

- 6.2.4.3.2. By Application

- 6.2.4.3.3. By End User

- 6.2.4.4. France

- 6.2.4.4.1. By Type

- 6.2.4.4.2. By Application

- 6.2.4.4.3. By End User

- 6.2.4.5. Spain

- 6.2.4.5.1. By Type

- 6.2.4.5.2. By Application

- 6.2.4.5.3. By End User

- 6.2.4.6. The Netherlands

- 6.2.4.6.1. By Type

- 6.2.4.6.2. By Application

- 6.2.4.6.3. By End User

- 6.2.4.7. Rest of Europe

- 6.2.4.7.1. By Type

- 6.2.4.7.2. By Application

- 6.2.4.7.3. By End User

7. Asia Pacific Ethylene Propylene Diene Monomer (EPDM) Rubber Market

- 7.1. Market Size & Forecast, 2019-2029

- 7.1.1. By Value (USD Million)

- 7.2. Market Share & Forecast

- 7.2.1. By Type

- 7.2.2. By Application

- 7.2.3. By End User

- 7.2.4. By Country

- 7.2.4.1. China

- 7.2.4.1.1. By Type

- 7.2.4.1.2. By Application

- 7.2.4.1.3. By End User

- 7.2.4.2. India

- 7.2.4.2.1. By Type

- 7.2.4.2.2. By Application

- 7.2.4.2.3. By End User

- 7.2.4.3. Japan

- 7.2.4.3.1. By Type

- 7.2.4.3.2. By Application

- 7.2.4.3.3. By End User

- 7.2.4.4. South Korea

- 7.2.4.4.1. By Type

- 7.2.4.4.2. By Application

- 7.2.4.4.3. By End User

- 7.2.4.5. Australia & New Zealand

- 7.2.4.5.1. By Type

- 7.2.4.5.2. By Application

- 7.2.4.5.3. By End User

- 7.2.4.6. Indonesia

- 7.2.4.6.1. By Type

- 7.2.4.6.2. By Application

- 7.2.4.6.3. By End User

- 7.2.4.7. Malaysia

- 7.2.4.7.1. By Type

- 7.2.4.7.2. By Application

- 7.2.4.7.3. By End User

- 7.2.4.8. Singapore

- 7.2.4.8.1. By Type

- 7.2.4.8.2. By Application

- 7.2.4.8.3. By End User

- 7.2.4.9. Philippines

- 7.2.4.9.1. By Type

- 7.2.4.9.2. By Application

- 7.2.4.9.3. By End User

- 7.2.4.10. Vietnam

- 7.2.4.10.1. By Type

- 7.2.4.10.2. By Application

- 7.2.4.10.3. By End User

- 7.2.4.11. Rest of APAC

- 7.2.4.11.1. By Type

- 7.2.4.11.2. By Application

- 7.2.4.11.3. By End User

8. Latin America Ethylene Propylene Diene Monomer (EPDM) Rubber Market

- 8.1. Market Size & Forecast, 2019-2029

- 8.1.1. By Value (USD Million)

- 8.2. Market Share & Forecast

- 8.2.1. By Type

- 8.2.2. By Application

- 8.2.3. By End User

- 8.2.4. By Country

- 8.2.4.1. Brazil

- 8.2.4.1.1. By Type

- 8.2.4.1.2. By Application

- 8.2.4.1.3. By End User

- 8.2.4.2. Mexico

- 8.2.4.2.1. By Type

- 8.2.4.2.2. By Application

- 8.2.4.2.3. By End User

- 8.2.4.3. Argentina

- 8.2.4.3.1. By Type

- 8.2.4.3.2. By Application

- 8.2.4.3.3. By End User

- 8.2.4.4. Peru

- 8.2.4.4.1. By Type

- 8.2.4.4.2. By Application

- 8.2.4.4.3. By End User

- 8.2.4.5. Rest of LATAM

- 8.2.4.5.1. By Type

- 8.2.4.5.2. By Application

- 8.2.4.5.3. By End User

9. Middle East & Africa Ethylene Propylene Diene Monomer (EPDM) Rubber Market

- 9.1. Market Size & Forecast, 2019-2029

- 9.1.1. By Value (USD Million)

- 9.2. Market Share & Forecast

- 9.2.1. By Type

- 9.2.2. By Application

- 9.2.3. By End User

- 9.2.4. By Country

- 9.2.4.1. Saudi Arabia

- 9.2.4.1.1. By Type

- 9.2.4.1.2. By Application

- 9.2.4.1.3. By End User

- 9.2.4.2. UAE

- 9.2.4.2.1. By Type

- 9.2.4.2.2. By Application

- 9.2.4.2.3. By End User

- 9.2.4.3. Qatar

- 9.2.4.3.1. By Type

- 9.2.4.3.2. By Application

- 9.2.4.3.3. By End User

- 9.2.4.4. Kuwait

- 9.2.4.4.1. By Type

- 9.2.4.4.2. By Application

- 9.2.4.4.3. By End User

- 9.2.4.5. South Africa

- 9.2.4.5.1. By Type

- 9.2.4.5.2. By Application

- 9.2.4.5.3. By End User

- 9.2.4.6. Nigeria

- 9.2.4.6.1. By Type

- 9.2.4.6.2. By Application

- 9.2.4.6.3. By End User

- 9.2.4.7. Algeria

- 9.2.4.7.1. By Type

- 9.2.4.7.2. By Application

- 9.2.4.7.3. By End User

- 9.2.4.8. Rest of MEA

- 9.2.4.8.1. By Type

- 9.2.4.8.2. By Application

- 9.2.4.8.3. By End User

10. Competitive Landscape

- 10.1. List of Key Players and Their Offerings

- 10.2. Global Ethylene Propylene Diene Monomer (EPDM) Rubber Company Market Share Analysis, 2022

- 10.3. Competitive Benchmarking, By Operating Parameters

- 10.4. Key Strategic Developments (Mergers, Acquisitions, Partnerships, etc.)

11. Impact of Covid-19 on Global Ethylene Propylene Diene Monomer (EPDM) Rubber Market

12. Company Profile (Company Overview, Financial Matrix, Competitive Landscape, Key Personnel, Key Competitors, Contact Address, Strategic Outlook, SWOT Analysis)

- 12.1. DuPont

- 12.2. Exxon Mobil Corporation

- 12.3. Lanxess

- 12.4. Mitsui Chemicals, Inc

- 12.5. Sumitomo chemical co. Ltd

- 12.6. SK geo centric Co., Ltd.

- 12.7. china petrochemical corporation

- 12.8. Johns Manville.

- 12.9. Berkshire Hathaway Inc.

- 12.10. JSR Corporation

- 12.11. KUMHO POLYCHEM

- 12.12. Lion Elastomers

- 12.13. PJSC "Nizhnekamskneftekhim''

- 12.14. American Rubber

- 12.15. Rotadyne Tools Pvt. Ltd.

- 12.16. American Urethane,

- 12.17. Argonics, Inc.

- 12.18. Griffith Rubber Mills

- 12.19. HINDUSTAN RUBBER INDUSTRIES

- 12.20. Other Prominent Players

13. Key Strategic Recommendations

14. Research Methodology

- 14.1. Qualitative Research

- 14.1.1. Primary & Secondary Research

- 14.2. Quantitative Research

- 14.3. Market Breakdown & Data Triangulation

- 14.3.1. Secondary Research

- 14.3.2. Primary Research

- 14.4. Breakdown of Primary Research Respondents, By Region

- 14.5. Assumptions & Limitations