|

|

市場調査レポート

商品コード

1400609

EMI/RFI:材料および技術EMI/RFI: Materials and Technologies |

||||||

|

|||||||

| EMI/RFI:材料および技術 |

|

出版日: 2023年12月26日

発行: BCC Research

ページ情報: 英文 255 Pages

納期: 即納可能

|

全表示

- 概要

- 図表

- 目次

世界のEMI/RFI材料および技術の市場規模は、2023年の74億米ドルから、予測期間中は4.6%のCAGRで推移し、2028年末には92億米ドルの規模に成長すると予測されています。

導電性コーティングの部門は2023年の28億米ドルから、3.6%のCAGRで推移し、2028年末には33億米ドルに達すると予測されています。また、ラミネート/テープ/フォイルの部門は2023年の4億3,450万米ドルから、5.8%のCAGRで推移し、2028年末には5億7,510万米ドルに達すると予測されています。

当レポートでは、世界のEMI/RFI材料および技術の市場を調査し、市場の定義・概要、市場影響因子および市場機会の分析、シールドメカニズム、シールド技術・材料の動向、市場規模の推移・予測、各種区分・地域別の詳細分析、ESGの展開、競合情勢、主要企業のプロファイルなどをまとめています。

目次

第1章 イントロダクション

第2章 サマリー・ハイライト

- 市場の見通し

- サマリーハイライト

- 市場規模

第3章 市場概要

- 概要

- EMI/RFI市場が直面する主な課題

- 市場に影響を与えるマクロ経済的要因

- 経済成長とパンデミック後の市場への影響

- 電磁的コンプライアンス

- 電子規格

- EMC規格/規制の目的

- 基本概念

- コンプライアンステストと認証

- 規制および標準化機関と指令

- FCC要件

- その他の環境規制

- Extended EMC規制

第4章 市場力学

- 市場促進要因

- 通信ネットワークの進歩により、EMI/RFIシールド需要が増加の見通し

- 防衛・航空宇宙向けのEMI/RFIシールドソリューション

- 医療機器向けEMI/RFIシールドに対する需要の高まり

- 電気自動車の普及と車両あたりの電子コンテンツの割合の増加

- 市場の課題

- さまざまな電子機器の小型化とEMI/RFIシールド間のトレードオフ

- 電子製品の廃棄に関する環境問題

- 世界のテストと認証の複雑さ

- 市場動向と機会

- データセンターの相互接続の拡大によるクラウドサービス需要の高まり

- 環境に優しいEMI/RFI材料

- リサイクル

第5章 EMI/RFI:基本概念

- 記号・用語

- 電磁エネルギー

- 放射線

- 伝導

- インピーダンス

- 静電放電

- 電磁場

- 電磁干渉・無線周波数干渉

- 定義・範囲

第6章 シールドメカニズム

- 概要

- 背景

- EMIシールドの概要

- シールド効果

- 減衰

- 電磁適合性

- 電磁波制御

- シールド性能

- 吸収

- 反射率

- 透過性

- ガルバニック腐食と金属の適合性

- 導電率と抵抗率の関係

- EMI/RFIおよび静電気の影響

- 無線周波数範囲の重要性

- EMI/RFIバックグラウンドの制御

第7章 シールド技術と材料

- 概要

- メタライゼーションプロセス:概要

- メタライゼーション材料

- シールド効果の概要:コーティングタイプ別

- 導電性プラスチック

- 背景

- 配合オプション

- 導電性プラスチック

- プラスチックの誘電特性

- プラスチックに導電性を持たせる技術

- 導電性材料のタイプ

- 機能

- 導電性添加剤の選択

- 導電率試験

- 導電性プラスチックの長所・短所

- 導電性プラスチックの配合

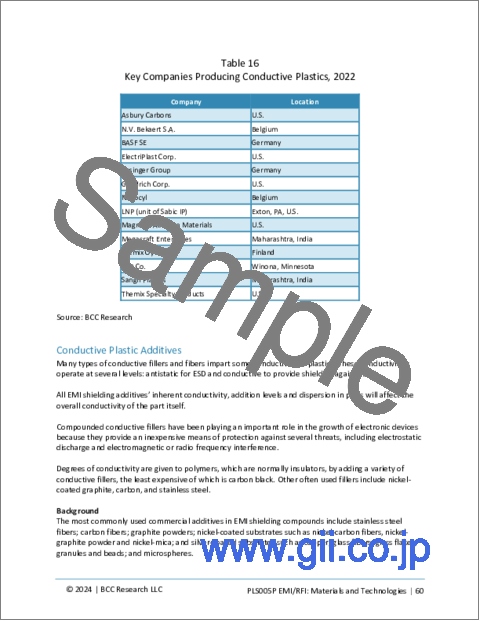

- 導電性プラスチックの製造企業

- 導電性プラスチック添加剤

- カーボンナノチューブ

- 導電性フィルム

- 導電性フィルム事業会社

- 導電性フィルムの最近の発展

- 固有導電性ポリマー

- ポリアニリン

- 展望

- ICPの導電率と金属、半導体、絶縁体の導電率の比較

- 処理オプション

- 最近のEMIシールドの開発

- 導電性エラストマー

- EMI関連の技術と用途

- 導電性コーティング

- 背景

- 導電性コーティングの用途

- EMIシールド化合物と他の導電性コーティングとの比較

- 導電性コーティングの問題

- 導電性コーティングの比較

- 代替導電性コーティングの性能

- 長所・短所

- コーティングバインダー

- 溶剤ベース導電性コーティングと水性導電性コーティングの比較

- 銅、ニッケル、銀の使用量

- 電気めっきコーティング

- 無電解めっき

- 概要

- シールド効果の測定

- ダイレクトプレート

- 無電解めっきに携わる企業

- 無電解めっきの環境問題

- 軍用仕様

- その他の仕様

- 真空蒸着

- 背景

- 技術

- 長所と短所

- 業界のテスト方法

- 真空蒸着プロセス

- 真空蒸着に携わる企業

- 導電性塗料

- 銅

- 銀

- ニッケル

- 関連技術

- 溶剤と水性の違い

- ペイントの厚さ

- その他の変数

- 導電性塗料の塗布

- シールド性能

- 導電性塗装プラスチック

- 導電性塗料の業種指定

- 導電性ペイント技術における厳選された技術的進歩

- プログラムをサポートするための世界にアクセス可能なインフラ

- 一般的な塗装プラスチック

- 溶射

- 技術

- 長所・短所

- プロセスの改善

- 国際溶射協会

- ラミネート・金属化フォイル・テープ

- フレキシブルフォイルラミネート

- 金属粘着テープ

- ファブリックテープ

- フェライト

- 背景

- プロパティ

- EMI抑制のためのフェライトの選択

- フェライトの形状と用途

- ソフトフェライト販売企業

- 最近の開発

- パフォーマンスの比較

- EMCシールドとエンドユーザーの要件

第8章 シールドコンポーネント

- ガスケット

- 技術

- EMIガスケットを評価する際の重要な機能

- プロパティ

- ガスケットタイプの選択

- ガスケットタイプ:材質別

- 技術的および商業的な考慮事項

- 設置費用

- 高周波用シールドガスケット

- テスト

- EMIシールドにおけるガスケットの設計上の考慮事項

- フィルター

- 追加の技術情報

- フィルター選択のガイドライン

- 用途

- 損失の多い線路または散逸フィルタ

- コネクタとケーブル

- ケーブル構造

- EMIケーブルのシールドおよび吸収材

- ウィンドウズ

- 材料

- シールド性能

- 材料の長所と短所

- メンテナンスとパフォーマンスの問題

- エンクロージャ

- 課題

- 技術の問題

- 美観

- 開口部のシールド

- EMI漏れ

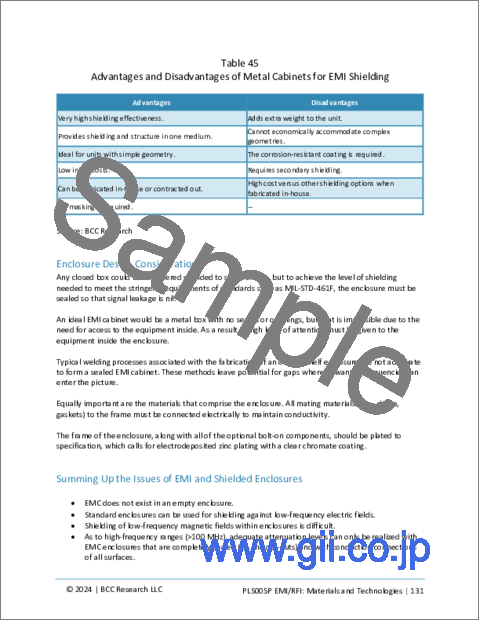

- 長所と短所

- エンクロージャ設計の考慮事項

- EMIとシールドされたエンクロージャの問題:サマリー

- 建築遮蔽

- 背景

- シールドルーム構造のタイプ

- コンポーネント

- その他のシールドコンポーネント

- 編組

- フォイルシールド

- 接着剤

第9章 EMI/RFI材料および技術市場:定量的側面

- 概要

- EMI/RFIシールド市場:手法別

- ボリューム

- 価値

- 金属キャビネット市場の予測

- 導電性プラスチック市場の予測

- その他のEMI/RFIシールド製品市場の予測

第10章 主なEMI/RFIシールド製品の追加パターン・使用法

- 導電性コーティング

- ラミネートとテープ

- 導電性プラスチックおよびエラストマー

- その他のシールド

第11章 産業/シールドインターフェース

- エレクトロニクス産業

- エレクトロニクス業界の動向

- EMIシールドの動向

- 輸送

- 自動車

- 航空機

- ドローン

- ヘルスケア産業

- 医療用インプラントの潜在的なEMI問題

- 医療業界におけるEMI問題を最小限に抑えるための取り組み

- 病院における携帯電話のリスクの最小化と利点の最大化

- 病院における無線電子機器の影響

- 病院の重要なEMIエリア

- 病院EMCの管理

- 医療機器のシールドに使用される素材

- 医療用EMC規格

- 家電製品

- 概要

- EMCコンプライアンス

- その他の消費者向け製品

- 軍事用途

- 高い干渉の可能性

- 脆弱なシステム

第12章 EMI/RFI材料および技術市場の持続可能性

- 二酸化炭素排出量を削減するためのエレクトロニクス分野の持続可能な製造

- EMI/RFI材料市場におけるESGの重要性

- ESG評価と指標:データの理解

- EMI/RFI材料および技術市場におけるESGの現状

- ESGスコア分析

- ESGリスク規模、エクスポージャー規模、管理規模

- BCCによる総論

第13章 競合情勢

- ベンダー分析

- 主な戦略的展開

- 最近の動向:主要企業別

第14章 企業プロファイル

- 主要企業のプロファイル

- 3M

- CTS CORP.

- THE DOW CHEMICAL CO.

- DUPONT DE NEMOURS INC.

- HENKEL AG & CO. KGAA

- LEADER TECH INC.

- PARKER HANNIFIN CORP.

- PPG INDUSTRIES INC.

- RTP CO.

- SCHAFFNER HOLDING AG

- Profiles of Other Key Players

- AD-VANCE MAGNETICS

- A.K. STAMPING CO. INC.

- ALCO TECHNOLOGIES

- AMUNEAL MANUFACTURING CORP.

- CHANG GU CHUAN TECHNOLOGY CO. LTD.

- CHANGZHOU PIONEER ELECTRONIC CO. LTD.

- CHINA EMI SHIELDING MATERIALS CO. LTD.

- COILCRAFT INC.

- CYBERSHIELD INC.

- ELASTOMERIC SPECIALTIES INC.

- ETS-LINDGREN L.P.

- FERRONICS INC.

- FUJIPOLY AMERICA CORP.

- GREENE RUBBER CO.

- JINAN EMI SHIELDING TECHNOLOGY CO. LTD.

- KITAGAWA INDUSTRIES AMERICA INC.

- MACDERMID ENTHONE INC.

- MAGNETIC SHIELD CORP.

- MAJR PRODUCTS

- MARIAN INC.

- MARTEK INC.

- MICROSORB TECHNOLOGIES

- MUSHIELD CO. INC.

- OMEGA SHIELDING PRODUCTS INC.

- ORION INDUSTRIES INC.

- PREMIX THERMOPLASTICS

- PRESSCUT INDUSTRIES INC.

- SAS INDUSTRIES INC.

- SCHLEGEL ELECTRONIC MATERIALS

- SHIELDEX US

- STOCKWELL ELASTOMERICS INC.

- SWIFT TEXTILE METALIZING LLC

- TDK RF SOLUTIONS INC.

- TECH-ETCH INC.

- THRUST INDUSTRIES

- VTI VACUUM TECHNOLOGIES

- THE ZIPPERTUBING CO.

第15章 付録:頭字語

List of Tables

- Summary Table : Global Market for EMI/RFI Materials and Technologies, by Method, Through 2028

- Table 1 : Electromagnetic Compatibility Cost Estimate

- Table 2 : Systeme International d'Unite (SI) and Their Symbols

- Table 3 : Systeme International d'Unite (SI) Prefixes and Their Symbols

- Table 4 : Frequency Levels and Band Names

- Table 5 : EMI Transmitters and Receivers

- Table 6 : Shielding Effectiveness Ratings

- Table 7 : Typical Low-Frequency Magnetic Shielding Materials and Their Properties

- Table 8 : Anodic Indices for Metals

- Table 9 : EMI Shielding Compounds Versus Conductive Coatings

- Table 10 : Metallization Material for Functional Coatings

- Table 11 : Shielding Effectiveness of Key Coatings

- Table 12 : Dielectric Constants for Selected Materials

- Table 13 : Options for Making Plastics Conductive

- Table 14 : Surface Resistivity for Electronic Device Substrates

- Table 15 : Resistance Spectrum of Methods for Making Plastics Conductive

- Table 16 : Key Companies Producing Conductive Plastics, 2022

- Table 17 : Advantages and Disadvantages of Stainless-Steel Fibers

- Table 18 : Key Suppliers of Carbon Nanotubes, 2022

- Table 19 : Companies Operating in the Conductive Films, 2022

- Table 20 : Conductivities of ICPs Compared with Metal, Semiconductors and Insulators

- Table 21 : Processing Types Employed for ICPs

- Table 22 : Stability and Processing Attributes of Key ICPs

- Table 23 : Shielding Effectiveness of Conductive Elastomers

- Table 24 : Comparative Testing of Conductive Elastomers for Galvanic Corrosion

- Table 25 : Comparing EMI Shielding Compounds and Conductive Coatings, by Several Key Variables

- Table 26 : Comparison of Conductive Coatings, by Conductivity and Shielding Effectiveness

- Table 27 : Advantages and Disadvantages of Conductive Coatings for EMI Shielding

- Table 28 : Global Conductive Coating Companies, 2022

- Table 29 : Electroless Plating Process

- Table 30 : Advantages and Disadvantages of Electroless Plating for EMI/RFI Shielding

- Table 31 : Applications Using Electroless Plating for EMI/RFI Shielding

- Table 32 : The Sequence of Steps for Electroless Plating of Plastics

- Table 33 : Relative Conductivity of Shielding Metals

- Table 34 : Key Suppliers of Electroless Plating Products

- Table 35 : Advantages and Disadvantages of Vacuum Metallization for EMI/RFI Shielding

- Table 36 : Vacuum Metallizing Companies

- Table 37 : Advantages and Disadvantages of Zinc Arc Spray for EMI/RFI Shielding

- Table 38 : Parameters for Ferrite Selection

- Table 39 : Ferrite Devices and Corresponding Applications

- Table 40 : Ferrite Applications by Shape

- Table 41 : Key Companies Marketing Soft Ferrites, 2022

- Table 42 : Strengths and Weaknesses of Key EMI Shielding Options

- Table 43 : Typical Shielding Effectiveness for Major Gasket Types

- Table 44 : Comparison of Window Shielding Materials

- Table 45 : Advantages and Disadvantages of Metal Cabinets for EMI Shielding

- Table 46 : Comparison of Architectural Shielding Technologies

- Table 47 : Global Market Volumes of EMI/RFI Materials and Technologies, by Method, Through 2028

- Table 48 : North American Market Volumes of EMI/RFI Materials and Technologies, by Method, Through 2028

- Table 49 : European Market Volumes of EMI/RFI Materials and Technologies, by Method, Through 2028

- Table 50 : Asia-Pacific Market Volumes of EMI/RFI Materials and Technologies, by Method, Through 2028

- Table 51 : Global Market Volumes of Conductive Coatings, by Type, Through 2028

- Table 52 : North American Market Volumes of Conductive Coatings, by Type, Through 2028

- Table 53 : European Market Volumes of Conductive Coatings, by Type, Through 2028

- Table 54 : Asia-Pacific Market Volumes of Conductive Coatings, by Type, Through 2028

- Table 55 : Average Estimated Costs of EMI/RFI Shielding Methods, 2022

- Table 56 : Global Market for EMI/RFI Materials and Technologies, by Method, Through 2028

- Table 57 : North American Market for EMI/RFI Materials and Technologies, by Method, Through 2028

- Table 58 : European Market for EMI/RFI Materials and Technologies, by Method, Through 2028

- Table 59 : Asia-Pacific Market for EMI/RFI Materials and Technologies, by Method, Through 2028

- Table 60 : Global Market for Conductive Coatings, by Type Through 2028

- Table 61 : North American Market for Conductive Coatings, by Type, Through 2028

- Table 62 : European Market for Conductive Coatings, by Type, Through 2028

- Table 63 : Asia-Pacific Market for Conductive Coatings, by Type, Through 2028

- Table 64 : Global Market for Metal Cabinets in EMI/RFI Materials and Technologies, by Volume and Value, Through 2028

- Table 65 : North American Market for Metal Cabinets in EMI/RFI Materials and Technologies, by Volume and Value, Through 2028

- Table 66 : European Market for Metal Cabinets in EMI/RFI Materials and Technologies, by Volume and Value, Through 2028

- Table 67 : Asia-Pacific Market for Metal Cabinets in EMI/RFI Materials and Technologies, by Volume and Value, Through 2028

- Table 68 : Global Market for Conductive Plastics in EMI/RFI Materials and Technologies, by Volume and Value, Through 2028

- Table 69 : North American Market for Conductive Plastics in EMI/RFI Materials and Technologies, by Volume and Value, Through 2028

- Table 70 : European Market for Conductive Plastics in EMI/RFI Materials and Technologies, by Volume and Value, Through 2028

- Table 71 : Asia-Pacific Market for Conductive Plastics in EMI/RFI Materials and Technologies, by Volume and Value, Through 2028

- Table 72 : Global Market for Miscellaneous Products in EMI/RFI Materials and Technologies, by Volume and Value, Through 2028

- Table 73 : North American Market for Miscellaneous Products in EMI/RFI Materials and Technologies, by Volume and Value, Through 2028

- Table 74 : European Market for Miscellaneous Products in EMI/RFI Materials and Technologies, by Volume and Value, Through 2028

- Table 75 : Asia-Pacific Market for Miscellaneous Products in EMI/RFI Materials and Technologies, by Volume and Value, Through 2028

- Table 76 : Typical Frequencies and Field Strengths for Types of Transmitters

- Table 77 : EMI/RFI Sources in the U.S.

- Table 78 : Components with EMI/RFI and ESD Solution and Industries Involved

- Table 79 : Automotive EMC Standards

- Table 80 : Selected European Automotive EMC Standards

- Table 81 : Selected SAE Automotive EMC Standards

- Table 82 : Medical EMC Standards, 2022

- Table 83 : IEC 60601-1 EMC Standard for Medical Electrical Equipment, General Requirements for Safety

- Table 84 : ESG Ratings and Metrics: Understanding the Data

- Table 85 : Current Status of ESG in the Market for EMI/RFI Materials and Technologies

- Table 86 : Risk Scale, Exposure Scale and Management Scale

- Table 87 : Recent Developments in Market for EMI/RFI Materials and Technologies, 2020 Through 2023

- Table 88 : 3M: Financial Measures, 2021 and 2022

- Table 89 : 3M: Market for EMI/RFI Materials and Technologies Product Portfolio

- Table 90 : CTS Corp.: Financial Measures, 2021 and 2022

- Table 91 : CTS Corp.: Market for EMI/RFI Materials and Technologies Product Portfolio

- Table 92 : The Dow Chemical Co.: Financial Measures, 2021 and 2022

- Table 93 : The Dow Chemical Co.: Market for EMI/RFI Materials and Technologies Product Portfolio

- Table 94 : DuPont de Nemours Inc.: Financial Measures, 2021 and 2022

- Table 95 : DuPont de Nemours Inc.: Market for EMI/RFI Materials and Technologies Product Portfolio

- Table 96 : Henkel AG & Co. KGAA: Financial Measures, 2021 and 2022

- Table 97 : Henkel AG & Co. KGAA: Market for EMI/RFI Materials and Technologies Product Portfolio

- Table 98 : HEICO Corp.: Financial Measures, 2021 and 2022

- Table 99 : Leader Tech Inc.: Market for EMI/RFI Materials and Technologies Product Portfolio

- Table 100 : Parker Hannifin Corp.: Financial Measures, 2021 and 2022

- Table 101 : Parker Hannifin Corp.: Market for EMI/RFI Materials and Technologies Product Portfolio

- Table 102 : PPG Industries Inc.: Financial Measures, 2021 and 2022

- Table 103 : PPG Industries Inc.: Market for EMI/RFI Materials and Technologies

- Table 104 : Schaffner Holding AG: Financial Measures, 2021 and 2022

- Table 105 : Schaffner Holding AG: Market for EMI/RFI Materials and Technologies Product Portfolio

- Table 106 : Acronyms and Glossary of Terms Used in This Report

List of Figures

- Summary Figure : Global Market Shares of EMI/RFI Materials and Technologies, by Method, 2022

Figure A : Research Methodology for Global Market for EMI/RFI Materials and Technologies

- Figure 1 : Environmental Score of Major Companies

- Figure 2 : Social Score of Major Companies

- Figure 3 : Governance Score of Major Companies

- Figure 4 : Total Score of Major Companies

- Figure 5 : Key Development Strategies in the Market for EMI/RFI Materials and Technologies, 2019 through 2023

- Figure 6 : Analysis of Key Development Strategies, by Key Players in the Market for EMI/RFI Materials and Technologies, 2019 through 2023

- Figure 7 : 3M: Financial Measures, 2021 and 2022

- Figure 8 : 3M: Revenue Share, by Business Unit, 2022

- Figure 9 : 3M: Revenue Share, by Country/Region, 2022

- Figure 10 : CTS Corp.: Financial Measures, 2021 and 2022

- Figure 11 : CTS Corp.: Revenue Share, by Business Unit, 2022

- Figure 12 : CTS Corp.: Revenue Share, by Country/Region, 2022

- Figure 13 : The Dow Chemical Co.: Financial Measures, 2021 and 2022

- Figure 14 : The Dow Chemical Co.: Revenue Share, by Business Unit, 2022

- Figure 15 : The Dow Chemical Co.: Revenue Share, by Country/Region, 2022

- Figure 16 : DuPont de Nemours Inc.: Financial Measures, 2021 and 2022

- Figure 17 : DuPont de Nemours Inc.: Revenue Share, by Business Unit, 2022

- Figure 18 : DuPont de Nemours Inc: Revenue Share, by Country/Region, 2022

- Figure 19 : Henkel AG & Co. KGAA: Financial Measures, 2021 and 2022

- Figure 20 : Henkel AG & Co. KGAA: Revenue Share, by Business Unit, 2022

- Figure 21 : Henkel AG & Co. KGAA: Revenue Share, by Country/Region, 2022

- Figure 22 : HEICO Corp.: Financial Measures, 2021 and 2022

- Figure 23 : HEICO Corp.: Revenue Share, by Business Unit, 2022

- Figure 24 : HEICO Corp.: Revenue Share, by Country/Region, 2022

- Figure 25 : Parker Hannifin Corp.: Financial Measures, 2021 and 2022

- Figure 26 : Parker Hannifin Corp.: Revenue Share, by Business Unit, 2022

- Figure 27 : Parker Hannifin Corp.: Revenue Share, by Country/Region, 2022

- Figure 28 : PPG Industries Inc.: Financial Measures, 2021 and 2022

- Figure 29 : PPG Industries Inc.: Revenue Share, by Business Unit, 2022

- Figure 30 : PPG Industries Inc: Revenue Share, by Country/Region, 2022

- Figure 31 : Schaffner Holding AG: Financial Measures, 2021 and 2022

- Figure 32 : Schaffner Holding AG: Revenue Share, by Business Unit, 2022

- Figure 33 : Schaffner Holding AG: Revenue Share, by Country/Region, 2022

Highlights:

The global market for EMI/RFI materials and technologies is expected to increase from $7.4 billion in 2023 to $9.2 billion by the end of 2028, with a compound annual growth rate (CAGR) of 4.6% during the forecast period of 2023-2028.

Conductive coatings market for EMI/RFI materials and technologies is expected to increase from $2.8 billion in 2023 to $3.3 billion by the end of 2028, with a CAGR of 3.6% during the forecast period of 2023-2028.

Laminates/tapes/foils market for EMI/RFI materials and technologies is expected to increase from $434.5 million in 2023 to $575.1 million by the end of 2028, with a CAGR of 5.8% during the forecast period of 2023-2028.

Report Scope:

This report segments the EMI/RFI materials and technologies market based on shielding method and region. The report provides an overview of the global EMI/RFI technologies market and analyzes market trends. Using 2022 as the base year, the report provides estimated market data for the forecast period 2023 through 2028.

The EMI/RFI materials and technologies market is segmented by shielding method and region into the following -

- Shielding method: conductive coatings, metal cabinets, conductive plastics, laminates/tapes/foils and miscellaneous.

- Region: North America, Europe and Asia-Pacific.

Technologies and materials specific to EMI/RFI shielding are also identified and analyzed in terms of their impact on plastics and the other materials. Trends in components and devices used in the electronics medical, automotive, and consumer products industries are also included in the report.

This report also discusses the current state of the electronics industry as well as other related industries, the market for plastics-based shielding options, key participants, shielding technologies, materials, shielding components, global developments, and examples of global regulatory standards and environmental issues confronting the electronic shielding business.

The report explains the relevant and upcoming technologies, and it covers the qualitative aspects of the market in broad detail. The scope of the report covers an overview of the global market for EMI/RFI materials and technologies and an analysis of the global market trends. The sales values are presented in U.S. dollars. The estimated values used are based on manufacturers' total revenues.

Furthermore, the study also discusses market dynamics such as drivers, restraints, opportunities and challenges. It also examines new and emerging trends and their impact on current and future market dynamics.

Report Includes:

- 39 data tables and 68 additional tables

- An overview of the global market landscape related to the materials and technologies of electromagnetic interference (EMI) and radio-frequency interference (RFI)

- In-depth analysis of global market trends, featuring historical revenue data for 2022, estimated figures for 2023, as well as forecasts for 2028. This analysis includes projections of Compound Annual Growth Rates (CAGRs) spanning through 2028

- Evaluation of the current market size and revenue growth prospects specific to materials and technologies of electromagnetic interference (EMI) and radio-frequency interference (RFI), accompanied by a comprehensive market share analysis categorized by type, and geographical region

- Coverage of issues surrounding the ever-increasing frequencies being encountered along with the proliferation of wireless devices that may result in the shifting of shielding options

- Assessment of the impact of other technologies, such as bluetooth, absorptive EMI, and fiber optics

- Discussion of trends in components and devices used in electronics and other industries, such as medical, automotive, and consumer products

- Examination of the current state of the electronics and other industries, the market for plastics-based shielding options, key participants, shielding technologies, patents, materials, shielding components, and a time line of global developments

- Information on basic concepts, compliance testing and certification related to the industry and insights into regulatory and standards bodies and directives and U.S. food and drug administration requirement

- Company profiles of major players within the industry, including 3M, The Dow Chemical Co., Parker-Hannifin Corp., and PPG Industries Inc.

Table of Contents

Chapter 1 Introduction

- Study Goals and Objectives

- Reasons for Doing This Study

- Scope of Report

- What's New in this Update?

- Methodology

- Information Sources

- Geographic Breakdown

- Segmentation Breakdown

Chapter 2 Summary and Highlights

- Market Outlook

- Summary Highlights

- Market Size

Chapter 3 Market Overview

- Overview

- Major Issues Confronting the EMI/RFI Market

- Macroeconomic Factors Impacting Market

- Economic Growth and Post-Pandemic Impact on the Market

- Electromagnetic Compliance

- Electronic Standards

- Purpose of EMC Standards/Regulations

- Basic Concepts

- Compliance Testing and Certification

- Regulatory and Standards Bodies and Directives

- The Federal Communications Commission Requirements

- Other Environmental Regulations

- Extended EMC Regulations

Chapter 4 Market Dynamics

- Market Drivers

- Advancement of Telecom Networks Will Increase EMI/RFI Shielding Demand

- EMI/RFI Shielding Solutions for Defense and Aerospace Applications

- Rising Demand for EMI/RFI Protection for Medical Devices and Equipment

- Rising Adoption of Electric Vehicles and Increasing Percentage of Electronic Content per Vehicle

- Market Challenges

- Trade-Off Between Miniaturization and EMI/RFI Shielding of Various Electronic Devices

- Environmental Issues Regarding Disposal of Electronic Items

- Complexities of Global Testing and Certifications

- Market Trends and Opportunities

- Rising Demand for Cloud Services Due to Growth in Data Center Interconnect

- Environmentally Friendly EMI/RFI Materials

- Recycling

Chapter 5 EMI/RFI: Basic Concepts

- Symbols and Terminology

- Electromagnetic Energy

- Radiation

- Conduction

- Impedance

- Electrostatic Discharge

- Electromagnetic Fields

- Electromagnetic and Radio Frequency Interference

- Definitions and Ranges

Chapter 6 Shielding Mechanisms

- Overview

- Background

- EMI Shielding Overview

- Shielding Effectiveness

- Attenuation

- Electromagnetic Compatibility

- EM Control

- Shielding Performance

- Absorption

- Reflectance

- Permeability

- Galvanic Corrosion and Metals Compatibility

- Relationship between Conductivity and Resistivity

- Effects of EMI/RFI and Static Electricity

- Importance of Radio Frequency Ranges

- Controlling EMI/RFI Background

Chapter 7 Shielding Technologies and Materials

- Overview

- Metallization Processes Overview

- Metallization Materials

- Shielding Effectiveness Overview, by Coating Type

- Conductive Plastics

- Background

- Formulation Options

- Conductive Plastics

- Dielectric Properties of Plastics

- Techniques for Making Plastics Conductive

- Conductive Material Types

- Functions

- Conductive Additive Selection

- Conductivity Tests

- Advantages and Disadvantages of Conductive Plastics

- Compounding Conductive Plastics

- Companies Producing Conductive Plastics

- Conductive Plastic Additives

- Carbon Nanotubes

- Conductive Films

- Companies Operating in Conductive Films

- Recent Developments in Conductive Films

- Inherently Conductive Polymers

- Polyanilines

- Prospects

- Conductivities of ICPs Compared with That of Metals, Semiconductors and Insulators

- Processing Options

- Recent EMI Shielding Developments

- Conductive Elastomers

- Technology and Applications Related to EMI

- Recent Developments

- Conductive Coatings

- Background

- Electrically Conductive Coating Applications

- EMI Shielding Compounds Compared with Other Conductive Coatings

- Conductive Coating Issues

- Comparison of Conductive Coatings

- Performance of Alternate Conductive Coatings

- Advantages and Disadvantages

- Coating Binders

- Solvent-Based versus Waterborne Conductive Coatings

- Copper, Nickel and Silver Usage

- Electroplated Coatings

- Recent Developments

- Electroless Plating

- Overview

- Measuring Shielding Effectiveness

- Direct Plate

- Companies Involved in Electroless Plating

- Environmental Issues with Electroless Plating

- Military Specifications

- Other Specifications

- Recent Developments

- Vacuum Metallization

- Background

- Technology

- Advantages and Disadvantages

- Industry Test Methods

- Vacuum Metallization Processes

- Companies Involved in Vacuum Metallizing

- Conductive Paints

- Copper

- Silver

- Nickel

- Technologies Involved

- Solvent Versus Waterborne

- Paint Thicknesses

- Other Variables

- Conductive Paint Application

- Shielding Performance

- Conductive Painted Plastics

- Conductive Paint Specifying Industries

- Selected Technical Advances in Conductive Paint Technology

- Globally Accessible Infrastructure to Support Programs

- Common Painted Plastics

- Thermal Spray

- Technology

- Advantages and Disadvantages

- Improvements in the Process

- International Thermal Spray Association

- Laminates, Metallized Foils and Tapes

- Flexible Foil Laminates

- Adhesive Metal Tapes

- Fabric Tapes

- Ferrites

- Background

- Properties

- Choosing Ferrites for EMI Suppression

- Ferrite Shapes and Applications

- Companies Marketing Soft Ferrites

- Recent Development

- Performance Comparisons

- EMC Shielding and End-User Requirements

Chapter 8 Shielding Components

- Gaskets

- Technology

- Essential Features When Evaluating EMI Gaskets

- Properties

- Selecting Gasket Types

- Gasket Types by Material

- Technical and Commercial Considerations

- Installation Costs

- Shielding Gaskets for Higher Frequencies

- Testing

- Design Considerations for Gaskets in EMI Shielding

- Filters

- Additional Technical Information

- Guidelines for Filter Selection

- Applications

- Lossy Line or Dissipative Filters

- Connectors and Cables

- Cable Construction

- EMI Cable Shielding and Absorbing Materials

- Windows

- Materials

- Shielding Performance

- Material Advantages and Disadvantages

- Maintenance and Performance Issues

- Enclosures

- Challenges

- Technology Issues

- Aesthetics

- Shielding of Apertures

- EMI Leakage

- Advantages and Disadvantages

- Enclosure Design Considerations

- Summing Up the Issues of EMI and Shielded Enclosures

- Architectural Shielding

- Background

- Shielded Room Construction Types

- Components

- Other Shielding Components

- Braids

- Foil Shields

- Adhesives

Chapter 9 Quantitative Aspects of EMI/RFI Materials and Technologies Market

- Overview

- EMI/RFI Shielding Market by Method

- Volumes

- Value

- Metal Cabinet Market Estimates

- Conductive Plastics Market Estimates

- Miscellaneous EMI/RFI Shielding Product Market Estimates

Chapter 10 Additional Patterns and Usage of Selected EMI/RFI Shielding Products

- Conductive Coatings

- Laminates and Tapes

- Conductive Plastics and Elastomers

- Miscellaneous Shielding

Chapter 11 Industry/Shielding Interface

- Electronics Industry

- Trends in the Electronics Industry

- EMI Shielding Trends

- Transportation Industry

- Automobiles

- Aircraft Industry

- Drones

- Healthcare Industry

- Potential EMI Problems with Medical Implants

- Efforts to Minimize EMI Problems in the Medical Industry

- Minimizing Risk and Maximizing Benefits of Mobile Phones in Hospitals

- Wireless Electronic Equipment Effects in Hospitals

- Critical Hospital EMI Areas

- Managing Hospital EMC

- Materials Used for Shielding Medical Devices

- Medical EMC Standards

- Recent Developments

- Appliances

- Overview

- EMC Compliance

- Other Consumer Products

- Military Applications

- High Potential for Interference

- Vulnerable Systems

Chapter 12 Sustainability in the EMI/RFI Materials and Technologies Market

- Sustainable Manufacturing for the Electronics Sector to Reduce Carbon Emissions

- Importance of ESG in the EMI/RFI Materials Market

- ESG Ratings and Metrics: Understanding the Data

- Current Status of ESG in the Market for EMI/RFI Materials and Technologies

- ESG Score Analysis

- ESG Risk Scale, Exposure Scale and Management Scale

- Concluding Remarks from BCC

Chapter 13 Competitive Landscape

- Introduction

- Vendor Analysis

- Major Strategic Developments

- Recent Developments by Key Players

Chapter 14 Company Profiles

- Profiles of Key Players

- 3M

- CTS CORP.

- THE DOW CHEMICAL CO.

- DUPONT DE NEMOURS INC.

- HENKEL AG & CO. KGAA

- LEADER TECH INC.

- PARKER HANNIFIN CORP.

- PPG INDUSTRIES INC.

- RTP CO.

- SCHAFFNER HOLDING AG

- Profiles of Other Key Players

- AD-VANCE MAGNETICS

- A.K. STAMPING CO. INC.

- ALCO TECHNOLOGIES

- AMUNEAL MANUFACTURING CORP.

- CHANG GU CHUAN TECHNOLOGY CO. LTD.

- CHANGZHOU PIONEER ELECTRONIC CO. LTD.

- CHINA EMI SHIELDING MATERIALS CO. LTD.

- COILCRAFT INC.

- CYBERSHIELD INC.

- ELASTOMERIC SPECIALTIES INC.

- ETS-LINDGREN L.P.

- FERRONICS INC.

- FUJIPOLY AMERICA CORP.

- GREENE RUBBER CO.

- JINAN EMI SHIELDING TECHNOLOGY CO. LTD.

- KITAGAWA INDUSTRIES AMERICA INC.

- MACDERMID ENTHONE INC.

- MAGNETIC SHIELD CORP.

- MAJR PRODUCTS

- MARIAN INC.

- MARTEK INC.

- MICROSORB TECHNOLOGIES

- MUSHIELD CO. INC.

- OMEGA SHIELDING PRODUCTS INC.

- ORION INDUSTRIES INC.

- PREMIX THERMOPLASTICS

- PRESSCUT INDUSTRIES INC.

- SAS INDUSTRIES INC.

- SCHLEGEL ELECTRONIC MATERIALS

- SHIELDEX US

- STOCKWELL ELASTOMERICS INC.

- SWIFT TEXTILE METALIZING LLC

- TDK RF SOLUTIONS INC.

- TECH-ETCH INC.

- THRUST INDUSTRIES

- VTI VACUUM TECHNOLOGIES

- THE ZIPPERTUBING CO.