|

市場調査レポート

商品コード

1904996

防衛用複合材料の世界市場:2026年~2036年Global Defense Composites Market 2026-2036 |

||||||

|

|||||||

| 防衛用複合材料の世界市場:2026年~2036年 |

|

出版日: 2026年01月10日

発行: Aviation & Defense Market Reports (A&D)

ページ情報: 英文 150+ Pages

納期: 3営業日

|

概要

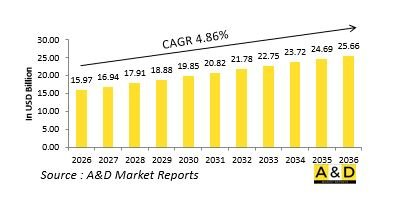

世界の防衛用複合材料の市場規模は、2026年に159億7,000万米ドルと推定され、2026年から2036年までの予測期間においてCAGR 4.86%で成長し、2036年までに256億6,000万米ドルに達すると見込まれています。

防衛用複合材料市場の導入

世界の防衛用複合材料市場は、物理的または化学的特性が大きく異なる2つ以上の構成材料を組み合わせ、個々の成分とは異なる特性を有する材料を製造するエンジニアリング材料を包含します。防衛用途では、通常、炭素、ガラス、アラミドなどの強化繊維をポリマー、金属、またはセラミックマトリックスに埋め込む技術が用いられます。複合材料は、アルミニウムや鋼などの従来材料と比較して、優れた強度重量比、耐食性、レーダー透過性、設計の柔軟性を提供します。その応用範囲は、航空機構造、無人システム、車両装甲、海軍艦艇、ミサイル部品、個人用防護装備など、あらゆる軍事分野に及びます。繊維配向、積層順序、樹脂配合を通じて材料特性を調整できる特性により、ステルス性、弾道防護、極限環境下での耐久性など、特定の要件に応じた最適化が可能となります。防衛プラットフォームが厳しい重量制約の中でより高い性能を追求する中、複合材料は特殊用途から、プラットフォーム全体の設計と能力に影響を与える基盤材料へと移行しています。

防衛用複合材料市場における技術的影響:

防衛用複合材料の技術進化は、製造効率、性能向上、多機能性に焦点を当てています。自動繊維配置装置やテープレイイング装置は、大規模で複雑な構造物の精密かつ再現性の高い製造を可能にし、人件費を削減します。オートクレーブ外硬化プロセスは、材料特性を維持しながら生産コストを低減します。カーボンナノチューブやグラフェン添加剤を含むナノテクノロジーの応用は、機械的特性、電気伝導性、損傷耐性を向上させます。多機能複合材料には、構造健全性監視用の埋め込みセンサー、電磁シールド用の導電性トレース、熱管理用の相変化材料などが組み込まれています。リサイクル可能かつバイオベースの樹脂システムは、環境問題とライフサイクルの持続可能性に対応します。デジタルツイン技術は複合材料の設計を最適化し、耐用年数を通じた性能を予測します。これらの進歩は、厳しい防衛環境における手頃な価格と信頼性を向上させながら、複合材料の応用範囲を拡大しています。

防衛用複合材料市場の主要促進要因:

あらゆる移動式防衛プラットフォームにおける重量削減の不断の追求は、積載量・航続距離・燃料効率の向上を目的として、複合材料の継続的な採用と進歩を促進しています。低観測性プラットフォームのステルス要件は、レーダー吸収性や形状制御能力を有する複合材料を有利にしています。装甲用途では、金属代替品と比較して軽量化を図りながら弾道保護を提供する複合材料の能力が評価されています。耐食性の優位性は、海軍および沿岸配備システムの保守コスト削減と稼働率向上に寄与します。設計の柔軟性により、複数の部品を単一の複合材部品に統合した構造が可能となり、組立の複雑さが軽減されます。無人システムの普及は、消耗品となる可能性のあるプラットフォーム向けに性能とコスト効率のバランスが取れた、コスト最適化された複合材ソリューションの需要を生み出しています。さらに、サプライチェーンの安全保障上の懸念から、戦略的に重要な地域における国内の複合材原料調達源と加工能力の開発が促進されています。

防衛用複合材料市場の地域別動向:

地域ごとの複合材技術力は、産業の優先順位、プラットフォーム計画、材料科学の専門知識の違いを反映しています。北米産業は先進的な航空宇宙用途、特に戦闘機やステルスプラットフォームにおいて主導的立場にあります。欧州の開発は、高度な航空宇宙技術と並行して、装甲車両用途向けの自動車由来技術を重視しています。アジア太平洋地域は急速な進展を見せており、日本と韓国は炭素繊維生産で優位性を発揮する一方、中国は自国プラットフォーム計画を支える包括的な複合材エコシステムを構築中です。イスラエル産業は装甲車両のアップグレードや無人システムといった特殊用途における革新性を示しています。中東諸国は先進航空機保有を支援するため、複合材修理・整備施設への投資を拡大しています。材料輸出規制や技術移転制限は、自国での材料生産能力を有する地域に競争優位性をもたらす一方、戦略的産業自律性を求める地域では現地開発を促進しています。

主要防衛複合材プログラム:

Bharat ForgeのATAGS 155mm牽引式榴弾砲契約(DAC承認済み、2025年末納入)では、砲身ジャケットと反動システムに先進炭素繊維複合材を採用。307門分(700億ルピー相当)の承認を得ており、鋼鉄製に比べ20%軽量化により、射程48kmの火力支援における機動性を向上させます。ハイデラバードのCFMRI(複合材料研究開発センター)が開発した国産材料により、60%の国産化率を確保。過酷な気象条件下での耐久性を実証済みです。2026年第2四半期より供給を開始し、ボフォース砲時代以降の砲兵装備不足を解消します。民間セクターによる生産拡大により、エルビット社などの世界的競合他社に対抗し、アルメニアへの輸出提案を支援します。複合材料はラダックのような高地展開における兵站負担を軽減します。

目次

防衛複合材料市場レポートの定義

防衛複合材料市場セグメンテーション

タイプ別

地域別

用途別

今後10年間の防衛複合材料市場分析

この章では、10年間の防衛複合材料市場の分析により、防衛複合材料市場の成長、変化する動向、技術採用の概要、および市場の魅力について詳細な概要が提供されます。

防衛複合材料市場の市場技術

このセグメントでは、この市場に影響を与えると予想される上位10の技術と、これらの技術が市場全体に与える可能性のある影響について説明します。

世界の防衛複合材料市場予測

この市場の10年間の防衛複合材料市場予測は、上記のセグメント全体で詳細にカバーされています。

地域防衛複合材料市場の動向と予測

このセグメントでは、地域別防衛複合材料市場の動向、促進要因、抑制要因、課題、そして政治、経済、社会、技術といった側面を網羅しています。また、地域別の市場予測とシナリオ分析も詳細に取り上げています。地域分析の最終段階では、主要企業のプロファイリング、サプライヤーの状況、企業ベンチマークなどについて分析しています。現在の市場規模は、通常のシナリオに基づいて推定されています。

北米

促進要因、抑制要因、課題

PEST

市場予測とシナリオ分析

主要企業

サプライヤー階層の状況

企業ベンチマーク

欧州

中東

アジア太平洋地域

南米

防衛複合材料市場の国別分析

この章では、この市場における主要な防衛プログラムを取り上げ、この市場で申請された最新のニュースや特許についても解説します。また、国レベルの10年間の市場予測とシナリオ分析についても解説します。

米国

防衛プログラム

最新ニュース

特許

この市場における現在の技術成熟度

市場予測とシナリオ分析

カナダ

イタリア

フランス

ドイツ

オランダ

ベルギー

スペイン

スウェーデン

ギリシャ

オーストラリア

南アフリカ

インド

中国

ロシア

韓国

日本

マレーシア

シンガポール

ブラジル

防衛複合材料市場の機会マトリックス

機会マトリックスは、読者がこの市場における機会の高いセグメントを理解するのに役立ちます。

防衛複合材料市場レポートに関する専門家の意見

この市場の可能性のある分析についての当社の専門家の意見をまとめています。