|

|

市場調査レポート

商品コード

1373064

プレハブ木造建築市場:パネルシステム別、用途別、地域別、競合予測・機会、2018-2028年Prefab Wood Building Market By Panel Systems, By Application, By Region, By Competition Forecast & Opportunities, 2018-2028F |

||||||

カスタマイズ可能

|

|||||||

| プレハブ木造建築市場:パネルシステム別、用途別、地域別、競合予測・機会、2018-2028年 |

|

出版日: 2023年10月03日

発行: TechSci Research

ページ情報: 英文 188 Pages

納期: 2~3営業日

|

- 全表示

- 概要

- 目次

プレハブ木造建築の世界市場は、2022年に120億8,000万米ドルの評価額を達成し、2028年までの年間平均成長率(CAGR)は7.19%と予測され、予測期間中に力強い成長が見込まれています。

プレハブ木造建築市場は、プレハブ木造建築市場の略称であり、製造済みまたはプレハブ木造部品を使用した建築物や構造物の設計、製造、組み立てを専門とする建設業界の一分野です。この市場では、壁、床、屋根トラス、さらには建物のモジュールやセクション全体を含む様々な建築要素が、グルーラミネート・ティンバー(グルラム)、ラミネート・ベニア・ランバー(LVL)、その他の木製材料などのエンジニアリング木材製品を使用して、管理された工場環境で製造されます。これらのプレハブ部材は、建設現場に運ばれ、組み立てられます。

プレハブ・ウッド・ビルディングは、小規模な住宅やキャビンから、集合住宅、商業ビル、学校など、規模も複雑さも様々です。プレハブ木造建築市場は、効率性、持続可能性、費用対効果を重視しているのが特徴です。プレハブ木造建築市場は、再生可能で環境に優しい素材である木材の自然な特質を活かし、迅速に組み立てられ、建設廃棄物を削減し、多くの場合、優れた断熱性とエネルギー効率を提供する建築物を生み出します。

| 市場概要 | |

|---|---|

| 予測期間 | 2024-2028 |

| 市場規模 | 120億8,000万米ドル |

| 2028年の市場規模 | 192億4,000万米ドル |

| CAGR 2023-2028 | 7.19% |

| 急成長セグメント | クロスラミネートティンバー(CLT)パネル |

| 最大市場 | 北米 |

この市場は、世界中の様々な建築分野において、持続可能で、手頃な価格で、カスタマイズ可能な建築ソリューションに対する需要の高まりに応える上で極めて重要な役割を果たしています。

耐久性への懸念

木材の耐久性に関する主な懸念事項の一つは、湿気や腐朽に弱いことです。湿度が高い地域や湿気に頻繁にさらされる地域では、木材は腐りやすく、時間の経過とともに劣化しやすくなります。しかし、この課題に対処するため、集成材(グルーラム)や単板積層材(LVL)のような人工木材製品が開発されています。これらの製品は、湿気や虫、腐敗に耐えるよう処理されており、長期にわたって構造的な完全性を保つことができます。

さらに、木材の腐朽に関する問題を防ぐには、適切なメンテナンスと定期的な検査が不可欠です。建築業者やオーナーは、劣化の兆候をいち早く察知し、対処するよう用心しなければならないです。教育や啓蒙キャンペーンは、木材の耐久性に関する誤解を解き、プレハブ建築における人工木材製品の利点を強調するのに役立ちます。

火災安全性への懸念:

プレハブ木造建築市場にとってのもうひとつの重要な課題は、火災安全性です。木材の燃えやすさに関する懸念から、建築業者や規制当局は、特に高層・大規模構造物の主要な建築材料として木材を採用することに躊躇しています。

火災安全性の懸念を軽減するため、多くの国では、高層木造建築物に耐火材料や工法を義務付ける厳しい建築基準法や規格を採用しています。これらの基準では通常、木造建築に耐火コーティング、スプリンクラーシステム、耐火バリアの使用を義務付けています。

火災安全に関する懸念に対処するためには、教育的取り組みと調査が不可欠です。火災試験を実施し、その結果を共有することで、実際の火災シナリオにおける人工木材製品の安全性を実証することができます。さらに、建築家や建設業者は、火災安全対策に配慮したプレハブ木造建築物を設計することで、地域の規制への適合を確保することができます。

まとめると、耐久性と火災安全性への懸念という課題が、プレハブ木造建築物の普及に大きな障害となっています。これらの懸念に対処するには、プレハブ木造建築が最高水準の安全性と耐久性を満たすよう、技術革新、教育、規制の調整を組み合わせる必要があります。

サプライチェーンの混乱と材料コスト

世界のプレハブ木造建築市場が直面する2つ目の顕著な課題は、サプライチェーンの混乱と材料費の変動です。これらの課題は近年特に顕著になってきており、業界の増大する需要に効果的かつ手頃な価格で対応する能力に影響を及ぼしています。

サプライチェーンの混乱

プレハブ木造建築市場は、木材、人工木材製品、接着剤、仕上げ材を含む資材の複雑な世界・サプライ・チェーンに大きく依存しています。自然災害、輸送問題、COVID-19パンデミックのような世界の健康危機などによるサプライチェーンの混乱は、生産の遅れやコスト増につながる可能性があります。

例えば、COVID-19パンデミックの際には、ロックダウンや規制が労働力や輸送手段の確保に影響を与え、材料や部品の納入が遅れました。こうした混乱は建設プロセス全体に波及し、プロジェクトのスケジュールや予算に影響を及ぼします。

サプライチェーンの混乱に対処するため、建設業者やメーカーは、現地調達の選択肢を模索し、サプライヤーベースを多様化することで、単一の供給元への依存を減らしています。また、不測の事態による影響を最小限に抑えるため、高度な在庫管理システムや緊急時対応計画も採用されています。

材料費の変動:

材料費、特に木材や関連建材の価格変動は、プレハブ木造建築市場にとってもう一つの大きな課題です。木材や人工木材製品の価格は、需要の変化、サプライチェーンの混乱、木材伐採に関する規制の変更などの要因により大きく変動する可能性があります。

こうした変動はプロジェクトの予算や計画を混乱させ、建設業者やデベロッパーがコストを正確に見積もり、収益性を維持することを困難にします。さらに、材料費の変動は、プレハブ木造建築への投資を躊躇させる可能性があります。

変動する材料費の影響を軽減するため、建設業者やデベロッパーは、サプライヤーとの長期契約、ヘッジ戦略、価格を固定するための金融商品を求めることが多いです。さらに、価格変動の影響を受けにくい代替建材や代替戦略を模索することもあるが、その場合、木材を使用する利点が制限されることもあります。

結論として、サプライチェーンの混乱と材料費の変動は、世界のプレハブ木造建築市場に大きな課題を突きつけています。建設業者とメーカーは、業界の成長と競合を維持するために、弾力的なサプライチェーン戦略を実施し、代替材料を模索し、積極的なコスト管理に取り組むことによって、これらの課題に適応しなければならないです。

セグメント別の洞察

CLTパネルに関する洞察

CLTパネルは、2022年に最大の市場シェアを獲得し、予測期間中もその地位を維持する見込みです。CLTパネルは、その卓越した構造強度で有名です。CLTパネルは、複数の木材ボードを互いに垂直に積み重ね、接着剤で接合したものです。この交差積層により高い耐荷重性を持つパネルが作られるため、CLTは多層ビル、集合住宅、商業構造物、さらには工業施設など、さまざまな建築用途に汎用性の高い材料となっています。より大きく、より高い構造物を支える能力により、CLTは他のパネルシステムとは一線を画しています。CLTパネルは管理された工場でプレハブ加工され、この精密な製造工程が現場での迅速で効率的な建設工程につながります。パネルは組み立ての準備が整った状態で建設現場に到着するため、現場での大がかりな切断や加工の必要性が軽減されます。この結果、工期、人件費、天候による遅延の可能性が削減され、CLTはタイトなスケジュールのプロジェクトに適した選択肢となります。持続可能性は建設業界における重要な推進力であり、CLTはこうした環境目標に完全に合致しています。木材は再生可能な資源であり、CLTの製造には通常、持続可能な方法で調達された木材が使用されます。さらに、木材は二酸化炭素を吸収・貯蔵するため、他の建材に比べて二酸化炭素排出量の削減に貢献します。このような環境への配慮は、環境意識の高い建設業者、建築家、顧客にアピールします。CLTの設計の柔軟性により、建築家や建設業者は幅広い建築設計を行うことができます。特定の要件に合わせて簡単に切断・成形できるため、ユニークで美観に優れた建築物の建設が可能です。CLTの多用途性は、耐荷重用途と非耐荷重用途の両方で使用され、設計の可能性をさらに広げます。CLTパネルは優れた断熱性を持ち、建物のエネルギー効率を高めます。その結果、冷暖房のエネルギー消費量が削減され、CLT構造は長期的に費用対効果が高く、環境にも配慮したものとなります。エネルギー効率は現代の建築において重要な考慮事項であり、CLTの人気の一因となっています。多くの国や地域が、高層化・大型化した木造建築を含むCLT建築に対応するため、建築基準法や規格を適応させています。このような規制上の支援により、建設業者やデベロッパーは、CLTが安全性と性能の要件を満たしていることを知っているため、プロジェクトにCLTを選択するようになりました。CLTの自然な美しさとむき出しの木肌は、建築家やデザイナーの間で人気を博しています。露出した木材仕上げは、温かみと美的魅力を提供し、建物全体の視覚的魅力に貢献します。これは、天然素材と持続可能性が重視される現代の建築動向に特に関連しています。

一戸建て住宅に関する洞察

一戸建て住宅分野は2022年に最大の市場シェアを占め、予測期間中も急速な成長が見込まれます。一戸建て住宅は、住宅所有者の好みやニーズに合わせて高度なカスタマイズを必要とすることが多いです。プレハブ木造建築システムは、効率性とカスタマイズ性のバランスに優れています。住宅所有者は、幅広いデザイン、レイアウト、仕上げ、機能から選択できるため、ライフスタイルに合った、パーソナライズされた審美的な住宅を作ることができます。プレハブの木製部材は、管理された工場環境で製造されるため、材料の無駄や人件費が削減されます。効率的な生産プロセスにより、コスト削減が実現し、住宅所有者に還元されます。さらに、コストの予測可能性と建設期間の短縮により、プレハブ木造住宅は、予算内で夢の家を建てたい人にとって魅力的な選択肢となります。プレハブ木造住宅は、従来の木造住宅よりもはるかに早く組み立てることができます。オフサイトで部材を製作するため、現場での同時作業が可能になり、工期が大幅に短縮されます。この迅速な建設プロセスは、できるだけ早く新しい家に引っ越したい住宅所有者にとって特に魅力的です。プレハブ木造住宅は断熱性に優れていることが多く、エネルギー効率と光熱費の削減に貢献します。CLT(Cross-Laminated Timber)やLVL(Laminated Veneer Lumber)のようなエンジニアードウッド製品は断熱性に優れ、プレハブ木造住宅を一年中快適にします。木材は再生可能で持続可能な建築材料です。プレハブ木造住宅は、持続可能な方法で調達された木材を使って建てられることが多く、環境意識や持続可能性の目標に合致しています。さらに、木材には炭素を貯蔵する能力があるため、環境に優しい選択となります。木材の自然な美しさと温もりは、一戸建て住宅にとって魅力的な選択肢です。むき出しの木材仕上げ、木材の梁、木製の被覆材は、居心地の良い心地よい雰囲気を作り出し、住宅の視覚的魅力に貢献します。この美的魅力は、一戸建て住宅市場でプレハブ木造住宅が好まれる大きな要因となっています。プレハブ木造建築システムは汎用性が高く、幅広い建築スタイルやデザインに対応できます。伝統的な外観、モダンな外観、現代的な外観など、住宅所有者がどのような外観を望むかにかかわらず、プレハブ木造建築は設計の好みに合わせることができます。プレハブ木造部材は、管理された環境で製造されるため、一貫した品質と業界標準の遵守が保証されます。住宅所有者は、プレハブ木造住宅の構造的完全性と耐久性に自信を持つことができます。多くの地域では、一戸建て住宅のプレハブ木造建築に対応するため、建築基準法や規制を適応させています。規制当局の支援は、住宅所有者や建設業者が主要な建築材料として木材を選択することをさらに後押ししています。

地域別インサイト

北米

北米は、2022年の世界市場におけるプレハブ木造建築の最大市場でした。この地域の市場成長の原動力は、持続可能でエネルギー効率の高い建物に対する需要の高まり、迅速かつ容易な建設に対するニーズの高まり、プレハブ建築物の使用に対する政府支援の高まりです。北米におけるプレハブ木造建築物の最大市場は米国であり、カナダがこれに続く。

欧州

2022年のプレハブ木造建築物の世界市場において、欧州は第2位の市場規模を有しています。この地域の市場成長の原動力は、北米と同様の要因に加え、モジュール式建物の人気の高まりです。ドイツは欧州最大のプレハブ木造建築市場であり、英国、フランスがこれに続く。

アジア太平洋:

アジア太平洋地域は、予測期間中プレハブ木造建築物の市場として最も急成長すると予想されます。この地域の市場成長の原動力は、急速な都市化、中間層人口の増加、持続可能な建築材料の使用に対する政府支援の増加です。プレハブ木造建築物市場は、アジア太平洋地域では中国が最大で、インド、日本がこれに続く。

目次

第1章 概要

第2章 調査手法

第3章 エグゼクティブサマリー

第4章 顧客の声

第5章 木造プレハブ建築の世界市場展望

- 市場規模と予測

- 金額別

- 市場シェアと予測

- パネルシステム別(CLT(Cross-laminated timber)パネル、NLT(Nail-laminated timber)パネル、DLT(Dowel-laminated timber)パネル、GLT(Glue-laminated timber)柱・梁)

- 用途別(一戸建て住宅、集合住宅、オフィス、ホスピタリティ、その他)

- 地域別

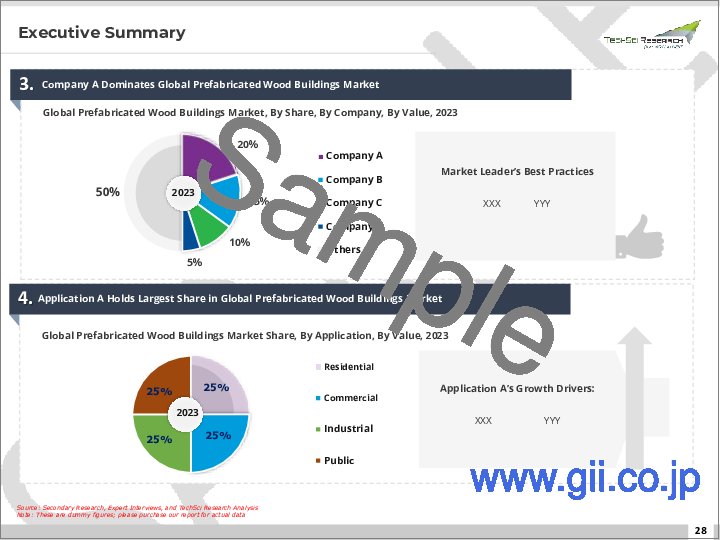

- 企業別(2022年)

- 市場マップ

第6章 北米プレハブ木造建築市場の展望

- 市場規模・予測

- 金額別

- 市場シェアと予測

- パネルシステム別

- 用途別

- 国別

- 北米国別分析

- 米国

- カナダ

- メキシコ

第7章 欧州プレハブ木造建築市場の展望

- 市場規模と予測

- 金額別

- 市場シェアと予測

- パネルシステム別

- 用途別

- 国別

- 欧州国別分析

- ドイツ

- 英国

- イタリア

- フランス

- スペイン

第8章 アジア太平洋プレハブ木造建築市場の展望

- 市場規模・予測

- 金額別

- 市場シェアと予測

- パネルシステム別

- 用途別

- 国別

- アジア太平洋:国別分析

- 中国

- インド

- 日本

- 韓国

- オーストラリア

第9章 南米プレハブ木造建築市場の展望

- 市場規模と予測

- 金額別

- 市場シェアと予測

- パネルシステム別

- 用途別

- 国別

- 南米::国別分析

- ブラジル

- アルゼンチン

- コロンビア

第10章 中東・アフリカのプレハブ木造建築市場の展望

- 市場規模・予測

- 金額別

- 市場シェアと予測

- パネルシステム別

- 用途別

- 国別

- MEA:国別分析

- 南アフリカ

- サウジアラビア

- アラブ首長国連邦

- クウェート

- トルコ

第11章 市場力学

第12章 市場動向と発展

第13章 競合情勢

- Skyline Champion Corporation

- American Homestar Corp

- Southland Log Homes

- Fertighaus Weiss Gmbh

- American Modular Systems

- Palm Harbor Homes Inc

- Lester Building Systems

- Bouygues Construction SA

- Fleetwood Pty Ltd.

- Clayton Homes, Inc

第14章 戦略的提言

第15章 調査会社について・免責事項

The Global Prefab Wood Building Market achieved a valuation of USD 12.08 billion in 2022 and is expected to experience robust growth in the forecast period, with a projected Compound Annual Growth Rate (CAGR) of 7.19% through 2028.

The Prefab Wood Building market, which is an abbreviation for the Prefabricated Wood Building market, represents a segment within the construction industry that specializes in designing, producing, and assembling buildings and structures using pre-manufactured or prefabricated wooden components. In this market, various building elements, including walls, floors, roof trusses, and even entire modules or sections of buildings, are manufactured in controlled factory environments using engineered wood products such as glue-laminated timber (glulam), laminated veneer lumber (LVL), and other wooden materials. These pre-made components are then transported to construction sites and assembled to create complete structures.

Prefab Wood Buildings can vary widely in size and complexity, ranging from small residential homes and cabins to multi-story residential complexes, commercial buildings, schools, and more. The Prefab Wood Building market is characterized by its focus on efficiency, sustainability, and cost-effectiveness. It leverages the natural qualities of wood, a renewable and environmentally friendly material, to create structures that can be assembled quickly, reduce construction waste, and often offer superior insulation and energy efficiency.

| Market Overview | |

|---|---|

| Forecast Period | 2024-2028 |

| Market Size 2022 | USD 12.08 Billion |

| Market Size 2028 | USD 19.24 Billion |

| CAGR 2023-2028 | 7.19% |

| Fastest Growing Segment | Cross-laminated Timber (CLT) Panels |

| Largest Market | North America |

This market plays a pivotal role in meeting the growing demand for sustainable, affordable, and customizable building solutions across various construction sectors worldwide.

Key Market Drivers

Sustainability and Environmental Concerns

The global Prefab Wood Building market is experiencing robust growth due to the increasing emphasis on sustainability and environmental concerns. As the world grapples with the challenges of climate change and resource depletion, there is a growing demand for eco-friendly construction solutions, and prefab wood buildings are at the forefront of this trend. Wood is a renewable resource that can be sourced sustainably, and the manufacturing process for prefab wood components tends to have a lower carbon footprint compared to traditional construction methods. Additionally, wood has excellent thermal insulation properties, reducing energy consumption and greenhouse gas emissions over a building's lifespan. This alignment with sustainability goals has led to incentives and regulations favoring wood construction in many regions, further propelling the prefab wood building market forward.

Cost Efficiency and Time Savings

Another significant driver for the prefab wood building market is its cost efficiency and time-saving advantages. Prefabricated wood components are manufactured in controlled environments, reducing the risk of weather-related delays and material waste. This precision and efficiency translate to cost savings for builders, making prefab wood construction an attractive option for both residential and commercial projects. Furthermore, the reduced construction time associated with prefab wood buildings allows for quicker occupancy and a faster return on investment. This time-saving aspect is particularly appealing for urban developers and those in need of rapid construction solutions, such as disaster relief housing.

Design Flexibility and Customization

Prefab wood building technology has evolved significantly, offering a wide range of design flexibility and customization options. Gone are the days when prefab meant cookie-cutter buildings with limited design choices. Modern prefab wood construction allows architects and builders to create unique and aesthetically pleasing structures, catering to various architectural styles and preferences. The versatility of wood as a building material allows for creative and innovative designs, making prefab wood buildings a favorite among those seeking both functionality and aesthetics. This design flexibility has expanded the market's appeal to a broader range of clients, from homeowners looking for custom-built homes to commercial developers seeking eye-catching, sustainable structures.

Urbanization and Housing Demand

Global urbanization trends are driving the demand for efficient and affordable housing solutions, and prefab wood buildings are well-suited to meet this demand. In densely populated urban areas, where space is limited and construction timelines are critical, prefab wood buildings offer a practical solution. Additionally, the affordability of prefab wood construction makes it an attractive option for governments and organizations looking to address housing shortages and provide affordable housing to their populations. This driver has led to an increased focus on modular and prefab housing projects in urban centers worldwide.

Technological Advancements

Advancements in technology, including computer-aided design (CAD) software, robotics, and automated manufacturing processes, have played a crucial role in the growth of the prefab wood building market. These technologies have improved the precision and efficiency of prefab wood component production, resulting in higher quality and more cost-effective solutions. Furthermore, the integration of smart building technologies into prefab wood structures enhances their functionality, energy efficiency, and overall appeal. This synergy between technology and prefab wood construction continues to drive innovation in the industry, attracting both builders and clients looking for cutting-edge solutions.

Regulatory Support and Incentives

Governments and regulatory bodies worldwide are recognizing the environmental benefits of prefab wood construction and are providing support and incentives to encourage its adoption. These incentives may include tax breaks, grants, and streamlined permitting processes for wood-based construction projects. Additionally, building codes and standards are evolving to accommodate and promote the use of wood in construction, further facilitating the growth of the prefab wood building market. These regulatory changes and incentives create a favorable environment for builders and developers to choose prefab wood as a sustainable and cost-effective building option.

In conclusion, the global Prefab Wood Building market is being propelled forward by a convergence of factors, including sustainability concerns, cost efficiency, design flexibility, urbanization, technological advancements, and regulatory support. These drivers are collectively shaping the future of construction, making prefab wood buildings a pivotal player in the evolving landscape of sustainable and efficient building practices.

Government Policies are Likely to Propel the Market

Subsidies for Sustainable Timber Sourcing

One key government policy that significantly impacts the global Prefab Wood Building market is the provision of subsidies and incentives for sustainable timber sourcing. Many governments worldwide are increasingly recognizing the importance of sustainable forestry practices to combat deforestation and promote environmental conservation. Under this policy, governments provide financial support and incentives to timber producers who adopt sustainable harvesting methods. These methods ensure that the rate of timber extraction does not exceed the rate of regeneration in forests. Incentives may include tax breaks, grants, or preferential treatment in government procurement for timber sourced from certified sustainable forests. By encouraging sustainable timber sourcing, governments contribute to the availability of responsibly harvested wood, which is a fundamental resource for the prefab wood building industry. This policy not only supports the industry's raw material supply but also aligns with global efforts to combat climate change and protect natural ecosystems.

Green Building Certification and Standards

Another crucial government policy influencing the prefab wood building market revolves around green building certification and standards. Governments and regulatory bodies around the world are establishing and enforcing stringent standards for energy efficiency, environmental sustainability, and overall building performance. These standards often require builders to meet specific sustainability criteria, including the use of eco-friendly materials such as certified sustainably sourced wood. Builders and developers who comply with these standards may receive various incentives, such as expedited permitting, tax incentives, or recognition for their environmentally friendly practices. In addition to promoting sustainable construction practices, these policies create a strong market pull for prefab wood buildings, as wood is a renewable and environmentally friendly building material that can help meet these stringent standards.

Timber Import Regulations

Timber import regulations are a vital government policy affecting the prefab wood building market, especially in regions with significant timber imports. Governments establish regulations to ensure that imported timber and wood products meet certain sustainability and legality standards. These policies often require importers to provide documentation proving that their timber products originate from legal and responsibly managed sources. Failure to comply with these regulations can result in fines or the prohibition of non-compliant timber products from entering the market. For the prefab wood building industry, such policies promote the use of legally sourced and sustainable wood, ensuring that the materials used in construction align with environmental and ethical principles. This strengthens the reputation of prefab wood buildings as a responsible and eco-friendly construction option.

Research and Development Funding

Government investment in research and development (R&D) is a critical policy driver for innovation in the prefab wood building market. Governments often allocate funds to support R&D initiatives focused on improving prefab wood construction methods, materials, and technologies. These R&D investments enable the industry to develop advanced techniques, such as digital fabrication, robotics, and innovative wood treatments, which enhance the efficiency, quality, and sustainability of prefab wood building processes. Government-funded research initiatives also lead to the creation of new building designs and systems that increase the versatility and marketability of prefab wood buildings. By facilitating innovation and technological advancement, government policies related to R&D funding contribute to the long-term growth and competitiveness of the prefab wood building market on a global scale.

Building Code Updates and Incentives

Governments regularly update building codes and regulations to reflect the latest industry practices and safety standards. In recent years, many governments have revised building codes to include provisions that specifically support and incentivize the use of wood in construction, including prefab wood buildings. These updates may include adjustments to height and area limitations, allowing taller and larger wooden structures, as well as fire safety standards that recognize the excellent performance of engineered wood products in fire-resistant applications. Additionally, some governments offer financial incentives or tax benefits to builders and developers who choose wood as a primary building material, further promoting the prefab wood building market. These policies not only encourage the use of wood but also help dispel outdated misconceptions about wood's safety and durability in construction, fostering greater acceptance of prefab wood buildings in the market.

Housing Affordability Initiatives

Government policies aimed at addressing housing affordability often have a significant impact on the prefab wood building market. In regions facing housing shortages and rising real estate prices, governments may implement various measures to stimulate affordable housing development. One common policy approach is to provide grants, tax credits, or subsidies to developers who construct affordable housing units using cost-effective methods, such as prefab wood construction. This financial support helps reduce the overall construction costs, making it possible for developers to offer affordable housing options to a wider range of income groups. Moreover, prefab wood buildings' quick construction timelines can help alleviate housing shortages more rapidly than traditional construction methods, making them a preferred choice for governments looking to address pressing housing needs.

In conclusion, government policies play a crucial role in shaping the global Prefab Wood Building market by influencing the sustainability of timber sourcing, promoting green building standards, regulating timber imports, supporting research and development, updating building codes, and addressing housing affordability challenges. These policies collectively contribute to the growth and sustainability of the prefab wood building industry while aligning with broader goals of environmental conservation and economic development.

Key Market Challenges

Perceived Durability and Fire Safety Concerns

One significant challenge confronting the global Prefab Wood Building market is the perception of durability and fire safety concerns associated with wood as a building material. While modern engineered wood products are designed to be highly durable and meet stringent fire safety standards, there are still persistent misconceptions that hinder the widespread acceptance of prefab wood buildings.

Durability Concerns:

One of the primary durability concerns associated with wood is its susceptibility to moisture and decay. In regions with high humidity levels or frequent exposure to moisture, wood can be prone to rot and deterioration over time. However, to address this challenge, engineered wood products like glue-laminated timber (glulam) and laminated veneer lumber (LVL) have been developed. These products are treated to resist moisture, insects, and decay, ensuring long-term structural integrity.

Additionally, proper maintenance and regular inspections are essential to prevent issues related to wood decay. Builders and owners must be vigilant in identifying and addressing any signs of deterioration promptly. Education and awareness campaigns can help dispel misconceptions about wood's durability and highlight the benefits of engineered wood products in prefab construction.

Fire Safety Concerns:

Another critical challenge for the prefab wood building market is fire safety. Concerns about wood's flammability have led to hesitancy among builders and regulators in adopting wood as a primary building material, especially for taller and larger structures.

To mitigate fire safety concerns, many countries have adopted stringent building codes and standards that require fire-resistant materials and construction methods for tall wood buildings. These codes typically mandate the use of fire-resistant coatings, sprinkler systems, and fire-resistant barriers in wood construction.

Educational initiatives and research are vital in addressing fire safety concerns. Conducting fire tests and sharing the results can help demonstrate the safety of engineered wood products in real-world fire scenarios. Additionally, architects and builders can design prefab wood buildings with fire safety measures in mind, ensuring compliance with local regulations.

In summary, the challenge of perceived durability and fire safety concerns poses a significant obstacle to the widespread adoption of prefab wood buildings. Addressing these concerns requires a combination of engineering innovation, education, and regulatory adjustments to ensure that prefab wood construction meets the highest standards of safety and durability.

Supply Chain Disruptions and Material Costs

The second prominent challenge facing the global Prefab Wood Building market is supply chain disruptions and fluctuating material costs. These challenges have become particularly pronounced in recent years, affecting the industry's ability to meet growing demand effectively and affordably.

Supply Chain Disruptions:

The Prefab Wood Building market heavily relies on a complex global supply chain for materials, including timber, engineered wood products, adhesives, and finishing materials. Disruptions in this supply chain, such as those caused by natural disasters, transportation issues, or global health crises like the COVID-19 pandemic, can lead to delays in production and increased costs.

For example, during the COVID-19 pandemic, lockdowns and restrictions impacted the availability of labor and transportation, delaying the delivery of materials and components. These disruptions ripple through the entire construction process, affecting project timelines and budgets.

To address supply chain disruptions, builders and manufacturers are exploring local sourcing options and diversifying their supplier base to reduce dependency on a single source. Advanced inventory management systems and contingency planning are also being employed to minimize the impact of unforeseen disruptions.

Fluctuating Material Costs:

Fluctuations in material costs, especially for wood and related construction materials, present another significant challenge for the Prefab Wood Building market. Prices for timber and engineered wood products can vary significantly due to factors such as changes in demand, supply chain disruptions, and regulatory changes related to timber harvesting.

These fluctuations can disrupt project budgets and planning, making it difficult for builders and developers to accurately estimate costs and maintain profitability. Moreover, volatile material costs can deter potential clients from investing in prefab wood buildings.

To mitigate the impact of fluctuating material costs, builders and developers often seek long-term agreements with suppliers, hedging strategies, and financial instruments to lock in prices. Additionally, they may explore alternative building materials or strategies that are less susceptible to price fluctuations, although this can sometimes limit the advantages of using wood.

In conclusion, supply chain disruptions and fluctuating material costs pose significant challenges to the global Prefab Wood Building market. Builders and manufacturers must adapt to these challenges by implementing resilient supply chain strategies, exploring alternative materials, and engaging in proactive cost management to maintain the industry's growth and competitiveness.

Segmental Insights

Cross-laminated Timber (CLT) Panels Insights

The Cross-laminated Timber (CLT) Panels segment had the largest market share in 2022 & expected to maintain it in the forecast period. CLT panels are renowned for their exceptional structural strength. They consist of multiple layers of wood boards stacked perpendicular to each other and bonded with adhesive. This cross-layering creates panels with high load-bearing capacity, making CLT a versatile material for various building applications, including multi-story buildings, residential complexes, commercial structures, and even industrial facilities. The ability to support larger and taller structures sets CLT apart from some other panel systems. CLT panels are prefabricated in controlled factory settings, and this precision manufacturing process leads to a quicker and more efficient construction process on-site. The panels arrive at the construction site ready for assembly, reducing the need for extensive on-site cutting and alterations. This results in reduced construction time, labor costs, and potential weather-related delays, making CLT a preferred choice for projects with tight schedules. Sustainability is a key driver in the construction industry, and CLT aligns perfectly with these environmental goals. Wood is a renewable resource, and CLT manufacturing typically involves using sustainably sourced timber. Additionally, wood captures and stores carbon dioxide, contributing to a reduced carbon footprint compared to other building materials. This eco-friendliness appeals to environmentally conscious builders, architects, and clients. CLT's design flexibility allows architects and builders to create a wide range of architectural designs. Its ability to be easily cut and shaped to specific requirements enables the construction of unique and aesthetically pleasing structures. CLT's versatility extends to its use in both load-bearing and non-load-bearing applications, further expanding its design possibilities. CLT panels offer excellent thermal insulation properties, which enhance a building's energy efficiency. This results in reduced energy consumption for heating and cooling, making CLT structures cost-effective and environmentally responsible in the long term. Energy efficiency is a critical consideration in modern construction and contributes to CLT's popularity. Many countries and regions have adapted their building codes and standards to accommodate CLT construction, including taller and larger wood buildings. This regulatory support has encouraged builders and developers to choose CLT for their projects, knowing that it complies with safety and performance requirements. CLT's natural beauty and exposed wood surfaces have gained popularity among architects and designers. Exposed wood finishes offer warmth and aesthetic appeal, contributing to the overall visual appeal of buildings. This is particularly relevant in contemporary architectural trends where natural materials and sustainability are valued.

Single-family residential Insights

The Single-family residential segment had the largest market share in 2022 and is projected to experience rapid growth during the forecast period. Single-family residential homes often require a high degree of customization to meet the unique preferences and needs of homeowners. Prefab wood building systems offer an excellent balance between efficiency and customization. Homeowners can choose from a wide range of designs, layouts, finishes, and features, allowing them to create a personalized and aesthetically pleasing home that suits their lifestyle. Prefabricated wood components are manufactured in controlled factory environments, which reduces material waste and labor costs. The efficient production process results in cost savings that can be passed on to homeowners. Additionally, the predictability of costs and reduced construction time make prefab wood homes an attractive choice for those looking to build their dream home on a budget. Prefabricated wood homes can be assembled much faster than traditional stick-built homes. The off-site fabrication of components allows for concurrent on-site work, significantly shortening construction timelines. This rapid construction process is especially appealing to homeowners who want to move into their new homes as quickly as possible. Prefab wood homes often feature excellent thermal insulation properties, which contribute to energy efficiency and lower utility bills. Engineered wood products like Cross-laminated Timber (CLT) and laminated veneer lumber (LVL) provide superior insulation, making prefab wood homes comfortable year-round. Wood is a renewable and sustainable building material. Prefabricated wood homes are often constructed using sustainably sourced timber, aligning with environmental consciousness and sustainability goals. Moreover, wood has the ability to store carbon, making it an environmentally friendly choice. Wood's natural beauty and warmth make it an attractive choice for single-family homes. Exposed wood finishes, timber beams, and wooden cladding create a cozy and inviting atmosphere, contributing to the visual appeal of the home. This aesthetic appeal is a significant driver for the preference of prefab wood homes in the single-family residential market. Prefab wood building systems are highly versatile, accommodating a wide range of architectural styles and designs. Whether homeowners desire a traditional, modern, or contemporary look, prefab wood construction can be tailored to meet their design preferences. Prefabricated wood components are manufactured in controlled environments, ensuring consistent quality and adherence to industry standards. Homeowners can have confidence in the structural integrity and durability of their prefab wood homes. Many regions have adapted building codes and regulations to accommodate prefab wood construction for single-family homes. Regulatory support has further encouraged homeowners and builders to choose wood as a primary building material.

Regional Insights

North America

North America had the largest market for prefab wood buildings in the global market in 2022. The growth of the market in this region is driven by the increasing demand for sustainable and energy-efficient buildings, the rising need for quick and easy construction, and the growing government support for the use of prefabricated buildings. The United States is the largest market for prefab wood buildings in North America, followed by Canada.

Europe:

Europe had the second-largest market for prefab wood buildings in the global market in 2022. The growth of the market in this region is driven by similar factors as in North America, as well as the increasing popularity of modular buildings. Germany is the largest market for prefab wood buildings in Europe, followed by the United Kingdom and France.

Asia Pacific:

Asia Pacific is expected to be the fastest-growing market for prefab wood buildings during the forecast period. The growth of the market in this region is driven by rapid urbanization, the growing middle-class population, and the increasing government support for the use of sustainable building materials. China is the largest market for prefab wood buildings in the Asia Pacific, followed by India and Japan.

Key Market Players

Skyline Champion Corporation

American Homestar Corp

Southland Log Homes

Fertighaus Weiss Gmbh

American Modular Systems

Palm Harbor Homes Inc

Lester Building Systems

Bouygues Construction SA

Fleetwood Pty Ltd.

Clayton Homes, Inc

Report Scope:

In this report, the Global Prefab Wood Building Market has been segmented into the following categories, in addition to the industry trends which have also been detailed below:

Prefab Wood Building Market, By Panel Systems:

- Cross-laminated timber (CLT) panels

- Nail-laminated timber (NLT) panels

- Dowel-laminated timber (DLT) panels

- Glue-laminated timber (GLT) columns and beams

Prefab Wood Building Market, By Application:

- Single Family Residential

- Multi-family Residential

- Office

- Hospitality

- Others

Prefab Wood Building Market, By Region:

- North America

- United States

- Canada

- Mexico

- Europe

- France

- United Kingdom

- Italy

- Germany

- Spain

- Asia-Pacific

- China

- India

- Japan

- Australia

- South Korea

- South America

- Brazil

- Argentina

- Colombia

- Middle East & Africa

- South Africa

- Saudi Arabia

- UAE

- Kuwait

- Turkey

Competitive Landscape

- Company Profiles: Detailed analysis of the major companies present in the Global Prefab Wood Building Market.

Available Customizations:

- Global Prefab Wood Building market report with the given market data, Tech Sci Research offers customizations according to a company's specific needs. The following customization options are available for the report:

Company Information

- Detailed analysis and profiling of additional market players (up to five).

Table of Contents

1. Product Overview

2. Research Methodology

3. Executive Summary

4. Voice of Customer

5. Global Prefab Wood Building Market Outlook

- 5.1. Market Size & Forecast

- 5.1.1. By Value

- 5.2. Market Share & Forecast

- 5.2.1. By Panel Systems (Cross-laminated timber (CLT) panels, Nail-laminated timber (NLT) panels, Dowel-laminated timber (DLT) panels, and Glue-laminated timber (GLT) columns and beams)

- 5.2.2. By Application (Single Family Residential, Multi-family Residential, Office, Hospitality, and Others)

- 5.2.3. By Region

- 5.2.4. By Company (2022)

- 5.3. Market Map

6. North America Prefab Wood Building Market Outlook

- 6.1. Market Size & Forecast

- 6.1.1. By Value

- 6.2. Market Share & Forecast

- 6.2.1. By Panel Systems

- 6.2.2. By Application

- 6.2.3. By Country

- 6.3. North America: Country Analysis

- 6.3.1. United States Prefab Wood Building Market Outlook

- 6.3.1.1. Market Size & Forecast

- 6.3.1.1.1. By Value

- 6.3.1.2. Market Share & Forecast

- 6.3.1.2.1. By Panel Systems

- 6.3.1.2.2. By Application

- 6.3.1.1. Market Size & Forecast

- 6.3.2. Canada Prefab Wood Building Market Outlook

- 6.3.2.1. Market Size & Forecast

- 6.3.2.1.1. By Value

- 6.3.2.2. Market Share & Forecast

- 6.3.2.2.1. By Panel Systems

- 6.3.2.2.2. By Application

- 6.3.2.1. Market Size & Forecast

- 6.3.3. Mexico Prefab Wood Building Market Outlook

- 6.3.3.1. Market Size & Forecast

- 6.3.3.1.1. By Value

- 6.3.3.2. Market Share & Forecast

- 6.3.3.2.1. By Panel Systems

- 6.3.3.2.2. By Application

- 6.3.3.1. Market Size & Forecast

- 6.3.1. United States Prefab Wood Building Market Outlook

7. Europe Prefab Wood Building Market Outlook

- 7.1. Market Size & Forecast

- 7.1.1. By Value

- 7.2. Market Share & Forecast

- 7.2.1. By Panel Systems

- 7.2.2. By Application

- 7.2.3. By Country

- 7.3. Europe: Country Analysis

- 7.3.1. Germany Prefab Wood Building Market Outlook

- 7.3.1.1. Market Size & Forecast

- 7.3.1.1.1. By Value

- 7.3.1.2. Market Share & Forecast

- 7.3.1.2.1. By Panel Systems

- 7.3.1.2.2. By Application

- 7.3.1.1. Market Size & Forecast

- 7.3.2. United Kingdom Prefab Wood Building Market Outlook

- 7.3.2.1. Market Size & Forecast

- 7.3.2.1.1. By Value

- 7.3.2.2. Market Share & Forecast

- 7.3.2.2.1. By Panel Systems

- 7.3.2.2.2. By Application

- 7.3.2.1. Market Size & Forecast

- 7.3.3. Italy Prefab Wood Building Market Outlook

- 7.3.3.1. Market Size & Forecast

- 7.3.3.1.1. By Value

- 7.3.3.2. Market Share & Forecast

- 7.3.3.2.1. By Panel Systems

- 7.3.3.2.2. By Application

- 7.3.3.1. Market Size & Forecast

- 7.3.4. France Prefab Wood Building Market Outlook

- 7.3.4.1. Market Size & Forecast

- 7.3.4.1.1. By Value

- 7.3.4.2. Market Share & Forecast

- 7.3.4.2.1. By Panel Systems

- 7.3.4.2.2. By Application

- 7.3.4.1. Market Size & Forecast

- 7.3.5. Spain Prefab Wood Building Market Outlook

- 7.3.5.1. Market Size & Forecast

- 7.3.5.1.1. By Value

- 7.3.5.2. Market Share & Forecast

- 7.3.5.2.1. By Panel Systems

- 7.3.5.2.2. By Application

- 7.3.5.1. Market Size & Forecast

- 7.3.1. Germany Prefab Wood Building Market Outlook

8. Asia-Pacific Prefab Wood Building Market Outlook

- 8.1. Market Size & Forecast

- 8.1.1. By Value

- 8.2. Market Share & Forecast

- 8.2.1. By Panel Systems

- 8.2.2. By Application

- 8.2.3. By Country

- 8.3. Asia-Pacific: Country Analysis

- 8.3.1. China Prefab Wood Building Market Outlook

- 8.3.1.1. Market Size & Forecast

- 8.3.1.1.1. By Value

- 8.3.1.2. Market Share & Forecast

- 8.3.1.2.1. By Panel Systems

- 8.3.1.2.2. By Application

- 8.3.1.1. Market Size & Forecast

- 8.3.2. India Prefab Wood Building Market Outlook

- 8.3.2.1. Market Size & Forecast

- 8.3.2.1.1. By Value

- 8.3.2.2. Market Share & Forecast

- 8.3.2.2.1. By Panel Systems

- 8.3.2.2.2. By Application

- 8.3.2.1. Market Size & Forecast

- 8.3.3. Japan Prefab Wood Building Market Outlook

- 8.3.3.1. Market Size & Forecast

- 8.3.3.1.1. By Value

- 8.3.3.2. Market Share & Forecast

- 8.3.3.2.1. By Panel Systems

- 8.3.3.2.2. By Application

- 8.3.3.1. Market Size & Forecast

- 8.3.4. South Korea Prefab Wood Building Market Outlook

- 8.3.4.1. Market Size & Forecast

- 8.3.4.1.1. By Value

- 8.3.4.2. Market Share & Forecast

- 8.3.4.2.1. By Panel Systems

- 8.3.4.2.2. By Application

- 8.3.4.1. Market Size & Forecast

- 8.3.5. Australia Prefab Wood Building Market Outlook

- 8.3.5.1. Market Size & Forecast

- 8.3.5.1.1. By Value

- 8.3.5.2. Market Share & Forecast

- 8.3.5.2.1. By Panel Systems

- 8.3.5.2.2. By Application

- 8.3.5.1. Market Size & Forecast

- 8.3.1. China Prefab Wood Building Market Outlook

9. South America Prefab Wood Building Market Outlook

- 9.1. Market Size & Forecast

- 9.1.1. By Value

- 9.2. Market Share & Forecast

- 9.2.1. By Panel Systems

- 9.2.2. By Application

- 9.2.3. By Country

- 9.3. South America: Country Analysis

- 9.3.1. Brazil Prefab Wood Building Market Outlook

- 9.3.1.1. Market Size & Forecast

- 9.3.1.1.1. By Value

- 9.3.1.2. Market Share & Forecast

- 9.3.1.2.1. By Panel Systems

- 9.3.1.2.2. By Application

- 9.3.1.1. Market Size & Forecast

- 9.3.2. Argentina Prefab Wood Building Market Outlook

- 9.3.2.1. Market Size & Forecast

- 9.3.2.1.1. By Value

- 9.3.2.2. Market Share & Forecast

- 9.3.2.2.1. By Panel Systems

- 9.3.2.2.2. By Application

- 9.3.2.1. Market Size & Forecast

- 9.3.3. Colombia Prefab Wood Building Market Outlook

- 9.3.3.1. Market Size & Forecast

- 9.3.3.1.1. By Value

- 9.3.3.2. Market Share & Forecast

- 9.3.3.2.1. By Panel Systems

- 9.3.3.2.2. By Application

- 9.3.3.1. Market Size & Forecast

- 9.3.1. Brazil Prefab Wood Building Market Outlook

10. Middle East and Africa Prefab Wood Building Market Outlook

- 10.1. Market Size & Forecast

- 10.1.1. By Value

- 10.2. Market Share & Forecast

- 10.2.1. By Panel Systems

- 10.2.2. By Application

- 10.2.3. By Country

- 10.3. MEA: Country Analysis

- 10.3.1. South Africa Prefab Wood Building Market Outlook

- 10.3.1.1. Market Size & Forecast

- 10.3.1.1.1. By Value

- 10.3.1.2. Market Share & Forecast

- 10.3.1.2.1. By Panel Systems

- 10.3.1.2.2. By Application

- 10.3.1.1. Market Size & Forecast

- 10.3.2. Saudi Arabia Prefab Wood Building Market Outlook

- 10.3.2.1. Market Size & Forecast

- 10.3.2.1.1. By Value

- 10.3.2.2. Market Share & Forecast

- 10.3.2.2.1. By Panel Systems

- 10.3.2.2.2. By Application

- 10.3.2.1. Market Size & Forecast

- 10.3.3. UAE Prefab Wood Building Market Outlook

- 10.3.3.1. Market Size & Forecast

- 10.3.3.1.1. By Value

- 10.3.3.2. Market Share & Forecast

- 10.3.3.2.1. By Panel Systems

- 10.3.3.2.2. By Application

- 10.3.3.1. Market Size & Forecast

- 10.3.4. Kuwait Prefab Wood Building Market Outlook

- 10.3.4.1. Market Size & Forecast

- 10.3.4.1.1. By Value

- 10.3.4.2. Market Share & Forecast

- 10.3.4.2.1. By Panel Systems

- 10.3.4.2.2. By Application

- 10.3.4.1. Market Size & Forecast

- 10.3.5. Turkey Prefab Wood Building Market Outlook

- 10.3.5.1. Market Size & Forecast

- 10.3.5.1.1. By Value

- 10.3.5.2. Market Share & Forecast

- 10.3.5.2.1. By Panel Systems

- 10.3.5.2.2. By Application

- 10.3.5.1. Market Size & Forecast

- 10.3.1. South Africa Prefab Wood Building Market Outlook

11. Market Dynamics

12. Market Trends & Developments

13. Competitive Landscape

- 13.1. Skyline Champion Corporation

- 13.2. American Homestar Corp

- 13.3. Southland Log Homes

- 13.4. Fertighaus Weiss Gmbh

- 13.5. American Modular Systems

- 13.6. Palm Harbor Homes Inc

- 13.7. Lester Building Systems

- 13.8. Bouygues Construction SA

- 13.9. Fleetwood Pty Ltd.

- 13.10. Clayton Homes, Inc