|

|

市場調査レポート

商品コード

1704029

統合型バッテリー(CTP、CTB、CTC、CTV)、バッテリー革新技術(2025年)Integrated Battery (CTP, CTB, CTC, and CTV)and Battery Innovation Technology Report 2025 |

||||||

|

|||||||

| 統合型バッテリー(CTP、CTB、CTC、CTV)、バッテリー革新技術(2025年) |

|

出版日: 2025年04月02日

発行: ResearchInChina

ページ情報: 英文 300 Pages

納期: 即日から翌営業日

|

全表示

- 概要

- 目次

1. 統合型バッテリー技術の応用が徐々に深化

統合型バッテリー技術には、バッテリーパック統合とボディ統合の2つの形式があります。前者はCTP(Cell to Pack)技術に反映され、ボディ統合はCTB(Cell to Body)/CTV(Cell to Vehicle)とCTC(Cell to Chassis)の形で存在します。

バッテリー統合技術は、バッテリーセルを直接シャーシに統合し、電気自動車の航続距離を伸ばし、ボディの剛性を高め、運転の快適性を向上させ、車内のZ軸スペースを最適化します。未完成の統計によると、最大17モデル(発売済みと発売予定を含む)に統合技術を応用されており、その応用は絶えず深まっています。

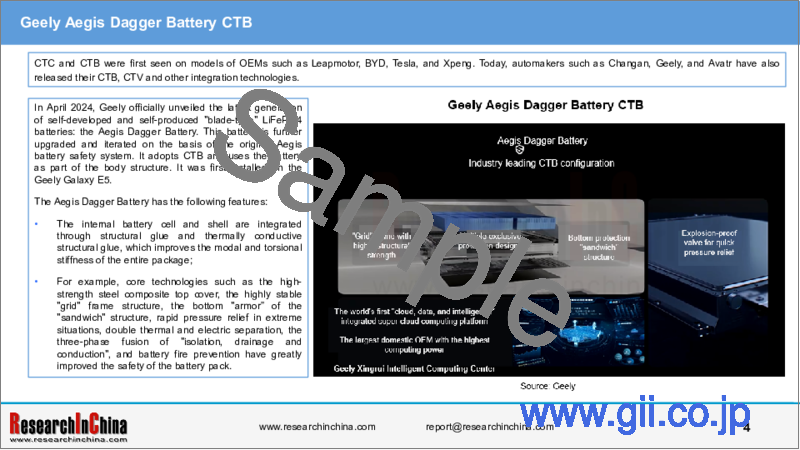

CTCとCTBは、Leapmotor、BYD、Tesla、XpengなどのOEMのモデルで初めて採用されました。現在、Changan、Geely、Avatrなどの自動車企業もCTB、CTVなどの統合技術を発表しています。

2024年4月、Geelyは自社開発・自社生産の最新世代の「ブレードタイプ」LiFePO4バッテリー、Aegis Dagger Batteryを正式に発表しました。このバッテリーは、オリジナルのAegisバッテリーの安全システムをベースに、さらにアップグレードされ、改良されたものです。CTBを採用し、バッテリーを車体構造の一部として使用しています。Geely Galaxy E5に初めて搭載されました。

Aegis Dagger Batteryの特徴

内部のバッテリーセルとシェルが構造用接着剤と熱伝導性構造用接着剤によって一体化されており、パッケージ全体のモード剛性とねじり剛性が向上しています。

例えば、高強度スチールコンポジットトップカバー、安定性の高い「グリッド」フレーム構造、「サンドイッチ」構造の底部「装甲」、極限状況での迅速な圧力開放、二重の熱と電気の分離、「絶縁・排水・伝導」の三相融合、バッテリー火災防止などのコア技術により、バッテリーパックの安全性が大幅に向上しています。

2025年3月、LeapmotorはCTC 2.0 Plusをリリースしました。CTC 2.0 Plusは、CTC 2.0に比べて安全性、統合性、インテリジェンスが向上しており、2025年4月に発売されるLeapmoon B10に初搭載されます。

Leapao CTC 2.0 Plusには以下の更新点があります。

より安全に:1,029回の安全テストと128回の性能テスト、50%高い側面衝撃係数、20%高い底面強度、極端なケースでも火災、爆発、熱拡散がない

より統合される:バッテリーパックのないバッテリーシャーシの統合設計、9-in-1超統合型バッテリー制御システム、同クラスで利用可能なパワーが19%向上

よりスマートに:アダプティブAI BMSバッテリー管理システムは、バッテリーの推定精度を1%向上させ、バッテリーの熱管理エネルギー消費を30%向上させ、車両の航続距離を2%向上させることができる

2. 2024年~2025年、バッテリーサプライヤーは34のバッテリー革新技術を相次いで発表しました。

2025年2月、BMWの第6世代パワーバッテリーが世界で初めて大型円筒形セルを採用しデビューしました。今年発表されるBMW初の次世代モデルや、2026年から量産される中国の次世代モデルにまず適用される予定です。BMWの大型円筒形バッテリーの工業的量産は、間違いなくこのようなバッテリーの開発を促進し、また革新的なパワーバッテリー技術の継続的なブレークスルーを示す貴重なデモンストレーションとなるとみられます。

不完全な統計によると、2024年以降、12のバッテリーメーカーが34の新しいバッテリー技術を相次いで発表しており、そのうちCATLは7つのバッテリー技術を発表し、小型/大型商用車、ハイブリッド車、バスなどに広く使用されています。また、CATLは6C LiFePO4バッテリーを発表しており、これはわずか10分の充電で350kmの航続距離を追加することが可能で、将来的にはUltium準900Vプラットフォームに搭載される予定です。

当レポートでは、中国の自動車産業について調査分析し、統合型バッテリー(CTP、CTB、CTC、CTVなど)とバッテリー革新技術の開発状況、搭載状況、供給レイアウトなどの情報を提供しています。

目次

第1章 新エネルギーバッテリーと統合型バッテリー産業の概要

- 新エネルギー車用バッテリーと産業の概要

- 統合型バッテリーと産業の概要

- 統合型バッテリー:CTP技術

- 統合型バッテリー:CTC技術

- 統合型バッテリー:CTB技術

第2章 バッテリー統合と革新的技術のTier 1サプライヤー

- CATL

- SVOLT Energy

- CALB

- AESC

- LG Energy Solution

- SK On

- Farasis Energy

- EVE

- SEVB

- REPT

- FinDreams Battery

- BAK Battery

- Lishen Battery

- Greater Bay Technology

第3章 OEMのバッテリー統合と革新的技術のレイアウト

- Leapmotor

- BYD

- Tesla

- SAIC

- BAIC BJEV

- Volkswagen

- JAC

- Ford

- Changan Automobile

- FAW

- GAC

- Xpeng

- Chery

- Geely

- NIO

- Xiaomi

- Avatr

- Great Wall Motor

第4章 新エネルギーバッテリーと統合型バッテリーの開発動向

- 動向1

- 動向2

- 動向3

- 動向4:大型円筒形バッテリーの量産が加速、一部企業は量産段階に突入

- 動向5

- 動向6

- 動向7

- 動向8

Power battery research: 17 vehicle models use integrated batteries, and 34 battery innovation technologies are released

ResearchInChina released Integrated Battery (CTP, CTB, CTC, and CTV)and Battery Innovation Technology Report 2025, which summarizes the development status, installation, supply layout, etc. of integrated batteries (such as CTP, CTB, CTC, and CTV) and battery innovation technologies, and predicts the development trends of integrated batteries and battery innovation technologies.

1. The application of integrated battery technologies is gradually deepening

- Integrated battery technologies include two forms: battery pack integration and body integration. The former is reflected in CTP (Cell to Pack) technology, and body integration exists in the form of CTB (Cell to Body)/CTV (Cell to Vehicle) and CTC (Cell to Chassis).

Integrated battery technologies integrate the battery cells directly into the chassis to increase the range of electric vehicles, enhance body rigidity, improve driving comfort and optimize the Z-axis space in the cabin. According to incomplete statistics, up to 17 models (including those that have been released and planned to be launched) have applied integrated technologies, whose application is constantly deepening.

CTC and CTB were first seen on models of OEMs such as Leapmotor, BYD, Tesla, and Xpeng. Today, car companies such as Changan, Geely, and Avatr have also released their CTB, CTV and other integration technologies.

In April 2024, Geely officially unveiled the latest generation of self-developed and self-produced "blade-type" LiFePO4 batteries: the Aegis Dagger Battery. This battery is further upgraded and iterated on the basis of the original Aegis battery safety system. It adopts CTB and uses the battery as part of the body structure. It was first installed on the Geely Galaxy E5.

The Aegis Dagger Battery has the following features:

The internal battery cell and shell are integrated through structural glue and thermally conductive structural glue, which improves the modal and torsional stiffness of the entire package;

For example, core technologies such as the high-strength steel composite top cover, the highly stable "grid" frame structure, the bottom "armor" of the "sandwich" structure, rapid pressure relief in extreme situations, double thermal and electric separation, the three-phase fusion of "isolation, drainage and conduction", and battery fire prevention have greatly improved the safety of the battery pack.

In March 2025,Leapmotor released CTC 2.0 Plus. CTC 2.0 Plus has improved safety, integration, and intelligence compared to CTC 2.0, and will first land on Leapmoon B10 which is to be launched in April 2025.

Leapao CTC 2.0 Plus has the following upgrades:

Safer: Six-fold ("source + vision + isolation + barrier + evacuation + cooling") safety design; 1,029 safety tests and 128 performance tests; 50% higher side impact coefficient; 20% higher bottom strength; no fire, no explosion, and no heat spread in extreme cases;

More integrated: Integrated design of battery chassis without battery pack; 9-in-1 ultra-integrated battery control system; 19% more power available in the same class;

Smarter: The adaptive AI BMS battery management system can improve battery estimation accuracy by 1%, battery thermal management energy consumption by 30%, and vehicle range by 2%.

2. From 2024 to 2025, battery suppliers successively released 34 battery innovation technologies

In February 2025, BMW's sixth-generation power battery debuted globally, using large cylindrical cells for the first time. It is planned to be first applied to BMW's first next-generation model to be unveiled this year, as well as the Chinese next-generation models that will be mass-produced from 2026. BMW's upcoming industrial mass production of large cylindrical batteries will undoubtedly fuel the development of such batteries, and also provide a valuable demonstration for the continued breakthroughs in innovative power battery technologies.

According to incomplete statistics, 12 battery suppliers have successively released 34 new battery technologies since 2024, of which CATL has unveiled 7 battery technologies, which are widely used in light/heavy commercial vehicles, hybrid vehicles, buses and other models. CATL has also launched a 6C LiFePO4 battery, which can provide an additional 350 kilometers of range for vehicles in just 10 minutes of charging and will be installed on the Ultium quasi-900V platform in the future.

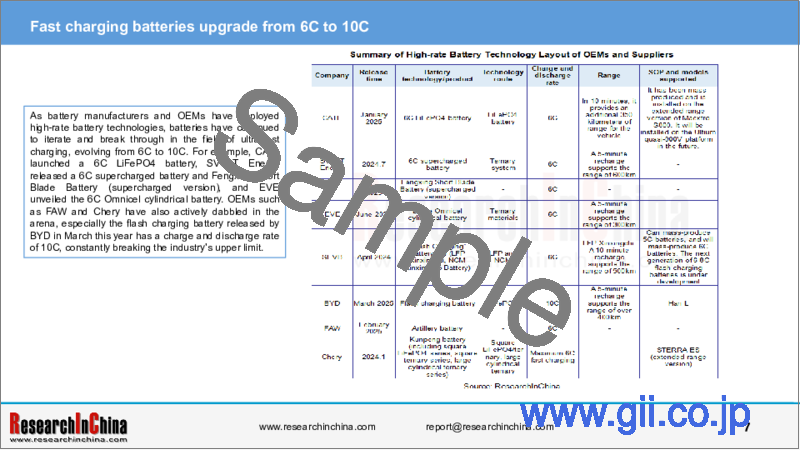

3. Fast charging batteries upgrade from 6C to 10C

As battery manufacturers and OEMs have deployed high-rate battery technologies, batteries have continued to iterate and break through in the field of ultra-fast charging, evolving from 6C to 10C. For example, CATL launched a 6C LiFePO4 battery, SVOLT Energy released a 6C supercharged battery and Fengxing Short Blade Battery (supercharged version), and EVE unveiled the 6C Omnicel cylindrical battery. OEMs such as FAW and Chery have also actively dabbled in the arena, especially the flash charging battery released by BYD in March this year has a charge and discharge rate of 10C, constantly breaking the industry's upper limit.

For example, in order to completely alleviate users' anxiety about charging, BYD's "flash charging battery" is comparable to "refueling" in charging speed. From the positive electrode to the negative electrode of the battery, it builds an ultra-high-speed ion channel in all directions, reducing the internal resistance of the battery by 50% with the charging current of 1000A and the charging rate of 10C. With the support of 1,000V and 1,000A, the charging power can reach 1 megawatt (1000kW), a 10-second charging offers a range up to 20 kilometers, and a 5-minute flash charging enables a range of 400 kilometers. In terms of performance, the single-module single-motor power reaches 580kW, and the maximum speed exceeds 300km/h. The "flash charging battery" was first available on Han L and Tang L which are expected to be officially launched in April.

4. Batteries for PHEVs and EREVs have become an important development direction for the power battery industry

Batteries tailored for PHEVs and EREVs aim to balance battery-electric range and fast recharging. In order to meet users' needs for daily commuting and long-distance mobility, such batteries not only should support high power output, but also must have fast charging and long lifespan. Given this, power battery manufacturers such as CATL, SVOLT Energy, and CALB are vigorously developing and launching special batteries for PHEVs and EREVs.

In January 2024, CATL released the Freevoy Super Hybrid Battery for the first time with Avatr 12. It plans to apply it to nearly 30 PHEV and EREV models from Geely, Chery, GAC, and Voyah in 2025. In July 2024, SVOLT Energy released the 800V 4C Dragon Scale Armor hybrid battery for PHEVs, which will be mass-produced in July 2025. In January 2025, SVOLT Energy released two types of batteries for PHEVs and EREVs, namely off-road batteries (for plug-in hybrid, extended-range off-road vehicles) and HEV batteries (for commercial vehicles and passenger cars). off-road batteries have been mass-produced and first installed on Tank 500 Hi4-Z.

Table of Contents

1 Overview of New Energy Battery and Integrated Battery Industry

Preface

Definition

- 1.1 Overview of New Energy Vehicle Batteries and Industry

- 1.1.1 Classification and Features of Batteries in New Energy Vehicle Industry

- 1.1.2 What Is a Ternary Lithium Battery

- 1.1.3 Advantages and Disadvantages of Ternary Lithium Batteries

- 1.1.4 Status Quo of Ternary Lithium Battery Industry

- 1.1.5 What Is a LiFePO4 Battery

- 1.1.6 Advantages and Disadvantages of LiFePO4 Batteries

- 1.1.7 Status Quo of LiFePO4 Battery Industry

- 1.1.8 What Is a Solid-state Battery

- 1.1.9 Advantages and disadvantages of Solid-state Batteries

- 1.1.10 Comparison between Solid-state Battery Development Paths

- 1.1.11 Innovative Battery Technology Layout of Battery Suppliers

- 1.1.12 Next-generation Battery Layout of Battery Suppliers

- 1.1.13 Innovative Battery Technology Layout and Next-generation Battery Layout of OEMs

- 1.1.14 Breakdown of Battery Types of Passenger Car Models launched from Jun 2024 to Mar 2025

- 1.1.15 Summary of Passenger Car Models Launched in February 2025

- 1.2 Overview of Integrated Batteries and Industry

- 1.2.1 Automotive Integrated Batteries and Industrial Development Background

- 1.2.2 Evolution of Automotive Integrated Batteries

- 1.2.3 China's Battery Integration Policies

- 1.2.4 Impact of Battery Pack Integration on the Number of Parts and Group Efficiency

- 1.2.5 Comparison among CTP, CTC and CTB Technologies

- 1.2.6 Integrated Battery Technology Industry Chain

- 1.2.7 Technology Layout of Battery Suppliers

- 1.2.8 Technology Layout of Integrated Battery OEMs

- 1.3 Integrated Batteries: CTP Technology

- 1.3.1 Definition of CTP

- 1.3.2 CTP Technology Route

- 1.3.3 Advantages of CTP Compared with Conventional Battery Packs

- 1.3.4 Disadvantages of CTP and Impact

- 1.3.5 Status Quo of CTP Industry

- 1.4 Integrated Batteries: CTC Technology

- 1.4.1 Definition of CTC

- 1.4.2 CTC Technology Route

- 1.4.3 CTC Technical Difficulties and Integration Solutions

- 1.4.4 Comparison between CTC and CTP

- 1.4.5 Advantages and Disadvantages of CTC

- 1.4.6 Status Quo of CTC Industry and Application Cases

- 1.4.7 Impact of CTC

- 1.5 Integrated Batteries: CTB Technology

- 1.5.1 Definition of CTB

- 1.5.2 Comparison between CTB and CTP

- 1.5.3 Comparison between CTB and CTC

- 1.5.4 Advantages and Disadvantages of CTB

2 Tier1 Suppliers of Battery Integration and Innovative Technologies

- 2.1 CATL

- Global layout

- Power Battery System Integration Technology Roadmap

- CTP Technology Development History

- Integrated Battery Technology Solution 1

- Integrated Battery Technology Solution 2

- Battery Technology Solution 1

- Battery Technology Solution 1: Applicable Models

- Battery Technology Solution 2

- Battery Technology Solution 3

- Battery Technology Solution 4

- Battery Technology Solution 5

- Battery Technology Solution 6

- New Battery Technology Plan 1

- New Battery Technology Plan 2

- Battery Cell Energy Density Technology Plan

- Strategic Cooperation

- Capacity Layout

- 2.2 SVOLT Energy

- Global Layout

- Development History of Power Batteries

- Flying Stack Technology Research Progress

- Integrated Battery Technology Solution

- Battery Cell Solution

- New Battery Technology Solution 1

- New Battery Technology Solution 2

- New Battery Technology Solution 3

- New Battery Technology Solution 4

- New Battery Technology Solution 5

- New Battery Technology Solution 6

- New Battery Technology Solution 7

- New Battery Technology Plan 1

- New Battery Technology Plan 2

- New Battery Technology Plan 2

- New Battery Technology Plan 2

- Customers

- 2.3 CALB

- Summary of Batteries

- Integrated Battery Technology Solution

- One-Stop

- Battery Technology Solution 1

- Battery Technology Solution 2

- New Battery Technology Solution 1

- New Battery Technology Solution 2

- New Battery Technology Solution 3

- Summary of Applicable Models

- Latest Factory Layout and Capacity Planning

- 2.4 AESC

- Global Layout and Capacity Layout

- Battery Technology Route

- Batteries and Customers

- Latest Patents for Solid-state Batteries

- 2.5 LG Energy Solution

- Global Layout

- Product Layout

- Battery Cell Solution

- Module Solution

- Integrated Battery Technology Solution 1

- Integrated Battery Technology Solution 2

- New Battery Technology Solution: Cylindrical Batteries

- Next-generation Battery Technology Solution: Solid-state Batteries, Lithium-sulfur Batteries

- Cumulative Delivery of Power Batteries (2009-2023)

- Future Technology Development Path

- Latest Cooperation

- 2.6 SK On

- Manufacturing Engineering

- Core Technology

- Integrated Battery Technology Solution

- New Battery Technology Solution 1

- New Battery Technology Solution 2

- Research Progress and Cooperation in All-solid-state batteries

- Latest Patents for All-solid-state batteries

- Next-generation Battery Technology Solution

- 2.7 Farasis Energy

- Global Layout

- Battery Technology Solution

- Battery Technology Patents

- New Battery Technology Solution

- Next-generation Battery Technology Solution

- Projects under Development

- Cooperation and Designation

- 2.8 EVE

- 2.9 SEVB

- 2.10 REPT

- 2.11 FinDreams Battery

- 2.12 BAK Battery

- 2.13 Lishen Battery

- 2.14 Greater Bay Technology

3 Battery Integration and Innovative Technology Layout of OEMs

- 3.1 Leapmotor

- Battery Technology Iteration Process

- Integrated Battery Technology Solution 1

- Integrated Battery Technology Solution 2

- Summary of and Comparison between Integrated Battery Technologies

- Models with Integrated Battery Technologies

- 3.2 BYD

- Battery Technology Progress

- Integrated Battery Technology Solution 1

- Integrated Battery Technology Solution 2

- Integrated Battery Technology Solution 2: Application Case 1

- Integrated Battery Technology Solution 2: Application Case 2

- Integrated Battery Technology Solution 3

- New Battery Technology Solution 1

- New Battery Technology Solution 2

- Next-generation Battery Technology Layout

- Next-generation Battery Feasibility Solution

- Next-generation Battery Technology Patents

- 3.3 Tesla

- Integrated Battery Technology Solution

- Battery Technology Solution

- New Battery Technology Planning

- Battery Technology Patents

- Battery Application Case

- 3.4 SAIC

- Battery Technology Solution

- Application Case of Battery Technology Solution

- Expandable Integrated Battery Platform Solution

- Cooperation in Integrated Batteries and Other Battery Technologies

- Next-generation Battery Technology Layout

- 3.5 BAIC BJEV

- Cooperation in Integrated Batteries and Next-generation Battery Technologies

- New Battery Technology Solution

- 3.6 Volkswagen

- Integrated Battery Technology Layout

- Cooperation in Next-generation Battery Technologies

- 3.7 JAC

- Integrated Battery Technology Application Case 1

- Integrated Battery Technology Application Case 2

- Integrated Battery Technology Application Case 3

- Cooperation in Integrated Batteries and Next-generation Battery Technologies

- 3.8 Ford

- Integrated Battery Technology Patents

- Integrated Battery Technology Cooperation and Applicable Models

- Next-generation Battery Technology Layout

- 3.9 Changan Automobile

- Integrated Battery Technology Solution

- Integrated Battery Application Case

- New Battery Technology Solution and Cooperation

- Next-generation Battery Technology Solution and Planning

- 3.10 FAW

- 3.11 GAC

- 3.12 Xpeng

- 3.13 Chery

- 3.14 Geely

- 3.15 NIO

- 3.16 Xiaomi

- 3.17 Avatr

- 3.18 Great Wall Motor

4 Development Trends of New Energy Batteries and Integrated Batteries

- 4.1 Trend 1

- 4.2 Trend 2

- 4.3 Trend 3

- 4.4 Trend 4: Mass production of Large Cylindrical Batteries Is Accelerating, and Some Companies Have Entered the Mass Production Stage

- 4.5 Trend 5

- 4.6 Trend 6

- 4.7 Trend 7

- 4.8 Trend 8