|

市場調査レポート

商品コード

1640431

熱可塑性プラスチック:市場シェア分析、産業動向と統計、成長予測(2025~2030年)Thermoplastics - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

カスタマイズ可能

適宜更新あり

|

|||||||

| 熱可塑性プラスチック:市場シェア分析、産業動向と統計、成長予測(2025~2030年) |

|

出版日: 2025年01月05日

発行: Mordor Intelligence

ページ情報: 英文 150 Pages

納期: 2~3営業日

|

全表示

- 概要

- 目次

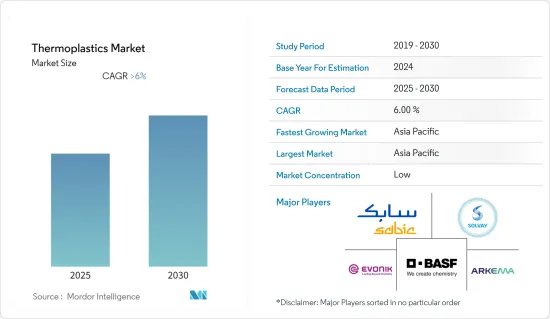

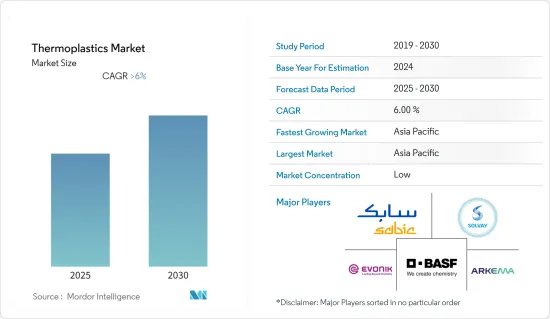

熱可塑性プラスチック市場は予測期間中にCAGR 6%超を記録すると予想されます。

COVID-19の発生は世界の封鎖、製造活動と供給網の混乱、生産停止を引き起こし、これらすべてが2020年の市場に打撃を与えました。しかし、2021年には状況が改善し始め、予測期間を通じて市場の成長軌道が再開しました。

主要ハイライト

- 下流加工における生産能力増強の拡大と、消費財とエレクトロニクスセグメントの成長が、検討中の市場に利益をもたらすと予測されます。

- しかし、熱可塑性プラスチックに関連する環境問題への懸念が市場成長の妨げになると予想されます。

- バイオベース製品の人気の高まりは、市場にとって好機となることが予想されます。

- アジア太平洋が市場を独占し、予測期間中に最も高いCAGRで推移すると予想されます。

熱可塑性プラスチック市場の動向

自動車・輸送セグメントでの需要の増加

- 熱可塑性プラスチックは、さまざまな自動車と輸送用途に広く採用されています。自動車のエアバッグ、ボンネットの下での使用、自動車の電気・電子機器などは、エンジニアリングプラスチックの用途の一部です。

- 自動車産業では、経済性の向上と設計の柔軟性を実現するために軽量材料の需要が高まっており、これが熱可塑性プラスチック市場の拡大を後押ししています。

- 厳しいCOVID時代を経て、自動車産業は中国、インド、インドネシア、マレーシアなどのアジア太平洋諸国を中心に投資と生産が復活し始めました。

- 国際エネルギー機関(IEA)も2022年の世界EV展望で、電気自動車の販売台数が飛躍的に増加していると述べています。2021年の電気自動車(EV)販売台数は前年比2倍の660万台となり、過去最高を記録しました。2022年も電気自動車の販売台数は力強く増加し続けており、第1四半期の販売台数は200万台で、2021年同期比75%増となりました。

- 中国汽車工業協会によると、中国では2022年の自動車生産台数が前年比で約3.4%増加しました。2021年の生産台数が2,608万台であったのに対し、2022年には約2,700万台の自動車が生産されました。

- 北米では、高品質で低燃費の自動車に対する消費者の嗜好の高まりにより、軽量化自動車に対する大きな需要が見られます。そのため、同地域では自動車製造用エンジニアリング・プラスチックの利用が急速に増加しています。

- さらに、欧州には自動車大手が存在し、欧州企業や政府による自動車研究開発産業への大規模な投資が、同地域の熱可塑性プラスチックの成長を後押ししています。

アジア太平洋の市場成長を支配する中国

- アジア太平洋が市場を独占すると予想されます。中国は最も急速に台頭している経済国のひとつであり、自動車、プラスチック、エレクトロニクス、建築の世界最大の生産国のひとつとなりました。

- 中国自動車工業協会によると、2022年の新エネルギー車の販売台数は2021年比で93.4%増加しました。2022年末の新エネルギー車全体の販売台数は約680万台で、2021年通年では約350万台に過ぎなかった。

- 中国は建設部門で大きな成長を遂げています。中国国家統計局によると、2022年第4四半期の中国の建設生産高は約2,760億人民元(約400億米ドル)で、前四半期(約276億米ドル)に比べ約50%の伸びを示しました。

- 中国国家統計局によると、2022年1~8月の中国におけるプラスチック製品の総生産量は5,307万トンとなり、前年同期の5,332万トンと比較しました。

- 中国はまた、2022年度の国防予算として、2021年度比7.1%増の約1兆4,500億人民元(2,300億米ドル)を提案しました。また、中国航空産業開発研究センターの報告書によると、2025年までに中国の航空機総数は5,343機に達すると予想されており、調査された市場はさらに拡大しています。

- そのため、予測期間中、様々なエンドユーザー産業からの熱可塑性プラスチックの需要が増加すると予想されます。

熱可塑性プラスチック産業概要

熱可塑性プラスチック市場はセグメント化されており、少数の参入企業が大きなシェアを占めています。熱可塑性プラスチック市場の主要企業(順不同)には、BASF SE、Evonik Industries AG、Solvay、SABIC、Arkemaが含まれます。

その他の特典

- エクセル形式の市場予測(ME)シート

- 3ヶ月のアナリストサポート

目次

第1章 イントロダクション

- 調査の前提条件

- 調査範囲

第2章 調査手法

第3章 エグゼクティブサマリー

第4章 市場力学

- 促進要因

- 下流の加工能力増強の急増

- 消費財産業とエレクトロニクス産業の成長

- 抑制要因

- 熱可塑性プラスチックに関する環境問題

- その他の抑制要因

- 産業バリューチェーン分析

- ポーターのファイブフォース分析

- 供給企業の交渉力

- 消費者の交渉力

- 新規参入業者の脅威

- 代替品の脅威

- 競合の程度

第5章 市場セグメンテーション(市場規模(数量ベース))

- 製品タイプ

- 汎用熱可塑性プラスチック

- ポリエチレン(PE)

- ポリプロピレン(PP)

- ポリ塩化ビニル(PVC)

- ポリスチレン(PS)

- エンジニアリング熱可塑性プラスチック

- ポリアミド(PA)

- ポリカーボネート(PC)

- ポリメチルメタクリレート(PMMA)

- ポリオキシメチレン(POM)

- ポリエチレンテレフタレート(PET)

- ポリブチレンテレフタレート(PBT)

- アクリロニトリル・ブタジエン・スチレン(ABS)/スチレン・アクリロニトリル(SAN)

- 高機能エンジニアリング熱可塑性プラスチック

- ポリエーテルエーテルケトン(PEEK)

- 液晶ポリマー(LCP)

- ポリテトラフルオロエチレン(PTFE)

- ポリイミド(PI)

- その他の製品タイプ(PPE、PSU、PEI、PPS、ETFE、PFA、FEP、PBI)

- 汎用熱可塑性プラスチック

- エンドユーザー産業

- 包装

- 建築・建設

- 自動車・輸送

- 電気・電子

- スポーツ・レジャー

- 医療

- その他のエンドユーザー産業(農業、消費財)

- 地域

- アジア太平洋

- 中国

- インド

- 日本

- 韓国

- その他のアジア太平洋

- 北米

- 米国

- カナダ

- メキシコ

- 欧州

- ドイツ

- 英国

- フランス

- イタリア

- その他の欧州

- 南米

- ブラジル

- アルゼンチン

- その他の南米

- 中東・アフリカ

- サウジアラビア

- 南アフリカ

- その他の中東・アフリカ

- アジア太平洋

第6章 競合情勢

- M&A、合弁事業、提携、協定

- 市場シェア/ランキング分析

- 主要企業の戦略

- 企業プロファイル

- 3M(incl. Dyneon LLC)

- Arkema

- Asahi Kasei Corporation

- BASF SE

- Celanese Corporation

- Chevron Phillips Chemical Company

- Covestro AG

- Daicel Corporation

- DuPont

- DSM

- Eastman Chemical Company

- Evonik Industries AG

- INEOS AG

- LANXESS

- LG Chem

- LyondellBasell Industries Holdings BV(incl. A. Schulman Inc.)

- Mitsubishi Engineering-Plastics Corporation

- Polyplastics Co. Ltd

- SABIC

- Solvay

- TEIJIN LIMITED

第7章 市場機会と今後の動向

- バイオベース製品の人気の高まり

The Thermoplastics Market is expected to register a CAGR of greater than 6% during the forecast period.

The COVID-19 outbreak caused worldwide lockdown, disruption in manufacturing activity and supply networks, and production halts, all of which harmed the market in 2020. However, conditions began to improve in 2021, resuming the market's growth trajectory throughout the projection period.

Key Highlights

- The expanding capacity additions in downstream processing and the growing consumer goods and electronic sectors are projected to benefit the market under consideration.

- However, environmental concerns related to thermoplastics are expected to hinder the market's growth.

- The growing popularity of bio-based products is expected to act as an opportunity for the market.

- The Asia-Pacific region is expected to dominate the market and will likely witness the highest CAGR during the forecast period.

Thermoplastic Market Trends

Increasing Demand from Automotive and Transportation

- Thermoplastics are widely employed in a variety of automotive and transportation applications. Automobile airbags, under-the-hood uses, and automotive electrical and electronics are some engineering plastics applications.

- The growing demand for lightweight materials in the automotive industry to improve the economy and provide design flexibility is driving the thermoplastics market's expansion.

- After a difficult COVID era, the automobile sector began to see a resurgence in investments and production, particularly in Asia-Pacific countries such as China, India, Indonesia, and Malaysia.

- The International Energy Agency, in its global EV Outlook of 2022, also stated that there had been an exponential increase in the sales of electric vehicles. The sales of electric vehicles (EVs) doubled in 2021 from the previous year to a new record of 6.6 million units. Sales of electric cars have kept rising strongly in 2022 as well, with 2 million units sold in the first quarter, up 75% from the same period in 2021.

- According to the China Association of Automobile Manufacturers, China saw an increase in automotive production in the country of around 3.4% in the year 2022 compared to the previous year. Around 27 million units of automobiles were produced in the year 2022 as compared to 26.08 million units produced in 2021.

- North America is witnessing a huge demand for lightweight automobiles, driven by the growing consumer preference for high-quality, fuel-efficient automobiles. Therefore, the region's utilization of engineering plastics for manufacturing automobiles is rapidly increasing.

- Furthermore, the presence of automotive giants in the European region and massive investments in the automotive R&D industry by European firms and governments are fueling the region's thermoplastics growth.

China to Dominate the Market Growth in Asia-Pacific

- The Asia-Pacific region is expected to dominate the market. China is one of the fastest emerging economies and became one of the world's biggest production houses for automobiles, plastics, electronics, and construction.

- According to the China Association of Automobile Manufacturers, sales of New Energy Vehicles increased by 93.4% in 2022 compared to 2021. The overall sales of new energy cars at the end of 2022 were around 6.8 million, compared to only approximately 3.5 million sales for the entire year in 2021.

- China is experiencing massive growth in its construction sector. According to the National Bureau of Statistics of China, in the fourth quarter of 2022, the construction output in China was valued at approximately CNY 276 billion (~USD 40 billion), a growth of approximately 50% compared to the previous quarter (~USD 27.6 billion).

- According to the National Bureau of Statistics of China, in the first eight months of 2022, the total plastic production in China stood at 53.07 million metric tons, compared to the previous year's 53.32 million metric tons of plastic products for the same period.

- China also proposed its FY 2022 defense budget of around CNY 1.45 trillion (USD 230 billion), a 7.1% year-on-year increase from 2021. Also, by 2025, China's total number of aircraft is expected to reach 5,343, according to the reports issued by the Aviation Industry Development Research Center of China, thus augmenting the market studied.

- Therefore, the demand for thermoplastics from various end-user industries is expected to increase during the forecast period.

Thermoplastic Industry Overview

The thermoplastics market is fragmented, with few players holding the major share in the market. Key players in the thermoplastics market (not in any particular order) include BASF SE, Evonik Industries AG, Solvay, SABIC, and Arkema.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Drivers

- 4.1.1 Rapid Increase in Downstream Processing Capacity Additions

- 4.1.2 Growing Consumer Goods and Eelctronics Industries

- 4.2 Restraints

- 4.2.1 Environmental Concerns Related to thermoplastics

- 4.2.2 Other Restraints

- 4.3 Industry Value-chain Analysis

- 4.4 Porter's Five Forces Analysis

- 4.4.1 Bargaining Power of Suppliers

- 4.4.2 Bargaining Power of Consumers

- 4.4.3 Threat of New Entrants

- 4.4.4 Threat of Substitute Products and Services

- 4.4.5 Degree of Competition

5 MARKET SEGMENTATION (Market Size in Volume)

- 5.1 Product Type

- 5.1.1 Commodity Thermoplastics

- 5.1.1.1 Polyethylene (PE)

- 5.1.1.2 Polypropylene (PP)

- 5.1.1.3 Polyvinyl chloride (PVC)

- 5.1.1.4 Polystyrene (PS)

- 5.1.2 Engineering Thermoplastics

- 5.1.2.1 Polyamide (PA)

- 5.1.2.2 Polycarbonates (PC)

- 5.1.2.3 Polymethyl methacrylate (PMMA)

- 5.1.2.4 Polyoxymethylene (POM)

- 5.1.2.5 Polyethylene terephthalate (PET)

- 5.1.2.6 Polybutylene terephthalate (PBT)

- 5.1.2.7 Acrylonitrile Butadiene Styrene (ABS)/Styrene Acrylonitrile (SAN)

- 5.1.3 High-performance Engineering Thermoplastics

- 5.1.3.1 Polyether Ether Ketone (PEEK)

- 5.1.3.2 Liquid Crystal Polymer (LCP)

- 5.1.3.3 Polytetrafluoroethylene (PTFE)

- 5.1.3.4 Polyimide (PI)

- 5.1.4 Other Product Types (PPE, PSU, PEI, PPS, ETFE, PFA, FEP, PBI)

- 5.1.1 Commodity Thermoplastics

- 5.2 End-user Industry

- 5.2.1 Packaging

- 5.2.2 Building and Construction

- 5.2.3 Automotive and Transportation

- 5.2.4 Electrical and Electronics

- 5.2.5 Sports and Leisure

- 5.2.6 Medical

- 5.2.7 Other End-user Industries (Agriculture, Consumer Goods)

- 5.3 Geography

- 5.3.1 Asia-Pacific

- 5.3.1.1 China

- 5.3.1.2 India

- 5.3.1.3 Japan

- 5.3.1.4 South Korea

- 5.3.1.5 Rest of Asia-Pacific

- 5.3.2 North America

- 5.3.2.1 United States

- 5.3.2.2 Canada

- 5.3.2.3 Mexico

- 5.3.3 Europe

- 5.3.3.1 Germany

- 5.3.3.2 United Kingdom

- 5.3.3.3 France

- 5.3.3.4 Italy

- 5.3.3.5 Rest of Europe

- 5.3.4 South America

- 5.3.4.1 Brazil

- 5.3.4.2 Argentina

- 5.3.4.3 Rest of South America

- 5.3.5 Middle-East and Africa

- 5.3.5.1 Saudi Arabia

- 5.3.5.2 South Africa

- 5.3.5.3 Rest of Middle-East and Africa

- 5.3.1 Asia-Pacific

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Market Share/Ranking Analysis

- 6.3 Strategies Adopted by Leading Players

- 6.4 Company Profiles

- 6.4.1 3M (incl. Dyneon LLC)

- 6.4.2 Arkema

- 6.4.3 Asahi Kasei Corporation

- 6.4.4 BASF SE

- 6.4.5 Celanese Corporation

- 6.4.6 Chevron Phillips Chemical Company

- 6.4.7 Covestro AG

- 6.4.8 Daicel Corporation

- 6.4.9 DuPont

- 6.4.10 DSM

- 6.4.11 Eastman Chemical Company

- 6.4.12 Evonik Industries AG

- 6.4.13 INEOS AG

- 6.4.14 LANXESS

- 6.4.15 LG Chem

- 6.4.16 LyondellBasell Industries Holdings BV (incl. A. Schulman Inc.)

- 6.4.17 Mitsubishi Engineering-Plastics Corporation

- 6.4.18 Polyplastics Co. Ltd

- 6.4.19 SABIC

- 6.4.20 Solvay

- 6.4.21 TEIJIN LIMITED

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Growing Popularity of Bio-based Products