|

|

市場調査レポート

商品コード

1750233

ブラックマスリサイクルの市場規模、シェア、予測、動向分析:電池タイプ別、電池供給源別、リサイクルプロセス別 - 2032年までの世界予測Black Mass Recycling Market Size, Share, Forecast, & Trends Analysis by Battery Type, Battery Source, Recycling Process -Global Forecast to 2032 |

||||||

カスタマイズ可能

|

|||||||

| ブラックマスリサイクルの市場規模、シェア、予測、動向分析:電池タイプ別、電池供給源別、リサイクルプロセス別 - 2032年までの世界予測 |

|

出版日: 2025年06月17日

発行: Meticulous Research

ページ情報: 英文 148 Pages

納期: 即納可能

|

全表示

- 概要

- 図表

- 目次

この調査レポートは「ブラックマスリサイクルの市場規模、シェア、予測、動向分析:電池タイプ(NMC、LCO、LMO、NCA)、電池供給源(自動車用電池、コンシューマーエレクトロニクス、産業用)、リサイクルプロセス(湿式冶金、乾式冶金)別-2032年までの世界予測」を掲載し、ブラックマスリサイクル市場は2025年から2032年の調査期間中にCAGR22.5%で、2032年までに204億米ドルに達すると予測しています。当レポートでは、主要5地域にわたる世界のブラックマスリサイクル市場を詳細に分析し、現在の市場動向、市場規模、最近の市場開拓、2032年までの予測などをまとめています。

広範な2次調査と1次調査、市場シナリオの綿密な分析を経て、主要産業の促進要因、市場抑制要因、機会、動向の影響分析を実施しています。この市場の成長を牽引しているのは、電気自動車(EV)の普及が加速し、リサイクルを必要とする使用済みリチウムイオン電池の量が増加していることです。リチウム、コバルト、ニッケルといった重要な電池用金属に対する需要の高まりは、サプライチェーンの脆弱性と相まって、採掘への依存を減らすためにリサイクル材料を優先するようメーカーや政府に働きかけています。

さらに、バッテリーギガファクトリーの急速な開発が、効率的なリサイクルソリューションの必要性に拍車をかけています。特に湿式冶金や直接リサイクルプロセスにおける技術の進歩は、金属回収率とコスト効率を高め、市場の成長を支えています。こうした前向きな動向にもかかわらず、業界は不十分なリサイクルインフラ、多様なバッテリー化学物質の複雑さ、低コストの採掘材料との競合などの課題に直面しています。しかし、税額控除や補助金といった政府の優遇措置や、インドや東南アジアといった新興市場での需要拡大が、大きなチャンスをもたらしています。

特筆すべきは、湿式冶金技術とクローズドループリサイクルシステムへのシフトが、バッテリーリサイクルを廃棄物管理活動から持続可能なエネルギー貯蔵の重要な要素へと変化させ、新しいバッテリー生産における回収材料の直接的な再利用を可能にし、この分野での循環経済を促進していることです。

目次

第1章 イントロダクション

第2章 調査手法

第3章 エグゼクティブサマリー

- 概要

- セグメント別分析

- 市場分析:バッテリータイプ別

- 市場分析:電池供給源別

- 市場分析:リサイクルプロセス別

- 地域別分析

- 競合分析

第4章 市場洞察

- 市場概要

- 市場成長に影響を与える要因

- 促進要因

- 電気自動車需要の増加

- 使用済み電池の廃棄管理ニーズの高まり

- 重要鉱物のサプライチェーンセキュリティ

- 電池製造の成長

- リサイクル技術の進歩

- 抑制要因

- 適切なリサイクルインフラの欠如

- 機会

- バッテリーリサイクルに対する政府の奨励金

- 新興市場での拡大

- 副原料市場の成長

- 課題

- 電池リサイクルに対する政府の優遇措置

- 鉱業セクターとの競合

- 動向

- 湿式冶金プロセスの採用増加

- クローズドループ型電池リサイクルシステムの開発

- 促進要因

- バリューチェーン分析

- ポーターのファイブフォース分析

- ブラックマスリサイクルプロセス

- 廃リチウムイオン電池の前処理方法

- 前処理された廃リチウムイオン電池からのリチウム抽出技術

第5章 ブラックマスリサイクル市場評価-電池タイプ別

- 概要

- リチウムニッケル・マンガン・コバルト酸化物(NMC)

- コバルト酸リチウム(LCO)

- リチウムマンガン酸化物(LMO)

- リチウムニッケル・コバルト・アルミニウム酸化物(NCA)

- その他の電池

第6章 ブラックマスリサイクル市場評価-電池供給源別

- 概要

- 自動車用電池

- 民生用電子電池

- 産業用電池

- その他の電池供給源

第7章 ブラックマスリサイクル市場の評価-リサイクルプロセス別

- 概要

- 湿式冶金

- 乾式冶金

- その他のリサイクルプロセス

第8章 ブラックマスリサイクル市場の評価-地域別

- 概要

- 北米

- 米国

- カナダ

- 欧州

- ドイツ

- 英国

- フランス

- イタリア

- スペイン

- その他欧州

- アジア太平洋

- 中国

- 日本

- インド

- 韓国

- その他アジア太平洋

- ラテンアメリカ

- 中東・アフリカ

第9章 競合情勢

- 概要

- 主要成長戦略

- 競合ベンチマーキング

- 競合ダッシュボード

- 業界リーダー

- 市場差別化要因

- 先行企業

- 新興企業

- 市場シェア/市況分析

第10章 企業プロファイル

- BASF SE

- Umicore SA

- Tenova S.p.A.

- Li-Cycle Holdings Corp.

- Lithion Technologies Inc.

- AkkuSer Oy

- Duesenfeld GmbH

- Aqua Metals, Inc.

- SungEel Hitech Co., Ltd.

- Fortum Corporation

- Redwood Materials, Inc.

- Green Li-Ion Pte Ltd

- Tata Chemicals Limited

- Attero Recycling Pvt. Ltd.

- Exigo Recycling Pvt. Ltd.

第11章 付録

LIST OF TABLES

- Table 1 Global Black Mass Recycling Market, by Battery Type, 2023-2032 (USD Million)

- Table 2 Global Lithium Nickel Manganese Cobalt Oxide Recycling Market, by Region/Country, 2023-2032 (USD Million)

- Table 3 Global Lithium Cobalt Oxide (LCO) Recycling Market, by Region/Country, 2023-2032 (USD Million)

- Table 4 Global Lithium Manganese Oxide (LMO) Recycling Market, by Region/Country, 2023-2032 (USD Million)

- Table 5 Global Lithium Nickel Cobalt Aluminium Oxide (NCA) Recycling Market, by Region/Country, 2023-2032 (USD Million)

- Table 6 Global Other Batteries Recycling Market, by Region/Country, 2023-2032 (USD Million)

- Table 7 Global Black Mass Recycling Market, by Battery Source, 2023-2032 (USD Million)

- Table 8 Global Automotive Batteries Recycling Market, by Country/Region, 2023-2032 (USD Million)

- Table 9 Global Consumer Electronic Batteries Recycling Market, by Country/Region, 2023-2032 (USD Million)

- Table 10 Global Industrial Batteries Recycling Market, by Country/Region, 2023-2032 (USD Million)

- Table 11 Global Other Batteries Recycling Market, by Country/Region, 2023-2032 (USD Million)

- Table 12 Global Black Mass Recycling Market, by Recycling Process, 2023-2032 (USD Million)

- Table 13 Global Black Mass Recycling Market for Hydrometallurgy, by Country/Region, 2023-2032 (USD Million)

- Table 14 Global Black Mass Recycling Market for Pyrometallurgy, by Country/Region, 2023-2032 (USD Million)

- Table 15 Global Black Mass Recycling Market for Other Recycling Processes, by Country/Region, 2023-2032 (USD Million)

- Table 16 North America: Black Mass Recycling Market, by Country, 2023-2032 (USD Million)

- Table 17 North America: Black Mass Recycling Market, by Battery Type, 2023-2032 (USD Million)

- Table 18 North America: Black Mass Recycling Market, by Battery Source, 2023-2032 (USD Million)

- Table 19 North America: Black Mass Recycling Market, by Recycling Process, 2023-2032 (USD Million)

- Table 20 U.S.: Black Mass Recycling Market, by Battery Type, 2023-2032 (USD Million)

- Table 21 U.S.: Black Mass Recycling Market, by Battery Source, 2023-2032 (USD Million)

- Table 22 U.S.: Black Mass Recycling Market, by Recycling Process, 2023-2032 (USD Million)

- Table 23 Canada: Black Mass Recycling Market, by Battery Type, 2023-2032 (USD Million)

- Table 24 Canada: Black Mass Recycling Market, by Battery Source, 2023-2032 (USD Million)

- Table 25 Canada: Black Mass Recycling Market, by Recycling Process, 2023-2032 (USD Million)

- Table 26 Europe: Black Mass Recycling Market, by Country, 2023-2032 (USD Million)

- Table 27 Europe: Black Mass Recycling Market, by Battery Type, 2023-2032 (USD Million)

- Table 28 Europe: Black Mass Recycling Market, by Battery Source, 2023-2032 (USD Million)

- Table 29 Europe: Black Mass Recycling Market, by Recycling Process, 2023-2032 (USD Million)

- Table 30 Germany: Black Mass Recycling Market, by Battery Type, 2023-2032 (USD Million)

- Table 31 Germany: Black Mass Recycling Market, by Battery Source, 2023-2032 (USD Million)

- Table 32 Germany: Black Mass Recycling Market, by Recycling Process, 2023-2032 (USD Million)

- Table 33 U.K.: Black Mass Recycling Market, by Battery Type, 2023-2032 (USD Million)

- Table 34 U.K.: Black Mass Recycling Market, by Battery Source, 2023-2032 (USD Million)

- Table 35 U.K.: Black Mass Recycling Market, by Recycling Process, 2023-2032 (USD Million)

- Table 36 France: Black Mass Recycling Market, by Battery Type, 2023-2032 (USD Million)

- Table 37 France: Black Mass Recycling Market, by Battery Source, 2023-2032 (USD Million)

- Table 38 France: Black Mass Recycling Market, by Recycling Process, 2023-2032 (USD Million)

- Table 39 Italy: Black Mass Recycling Market, by Battery Type, 2023-2032 (USD Million)

- Table 40 Italy: Black Mass Recycling Market, by Battery Source, 2023-2032 (USD Million)

- Table 41 Italy: Black Mass Recycling Market, by Recycling Process, 2023-2032 (USD Million)

- Table 42 Spain: Black Mass Recycling Market, by Battery Type, 2023-2032 (USD Million)

- Table 43 Spain: Black Mass Recycling Market, by Battery Source, 2023-2032 (USD Million)

- Table 44 Spain: Black Mass Recycling Market, by Recycling Process, 2023-2032 (USD Million)

- Table 45 Rest of Europe: Black Mass Recycling Market, by Battery Type, 2023-2032 (USD Million)

- Table 46 Rest of Europe: Black Mass Recycling Market, by Battery Source, 2023-2032 (USD Million)

- Table 47 Rest of Europe: Black Mass Recycling Market, by Recycling Process, 2023-2032 (USD Million)

- Table 48 Asia-Pacific: Black Mass Recycling Market, by Country/Region, 2023-2032 (USD Million)

- Table 49 Asia-Pacific: Black Mass Recycling Market, by Battery Type, 2023-2032 (USD Million)

- Table 50 Asia-Pacific: Black Mass Recycling Market, by Battery Source, 2023-2032 (USD Million)

- Table 51 Asia-Pacific: Black Mass Recycling Market, by Recycling Process, 2023-2032 (USD Million)

- Table 52 China: Black Mass Recycling Market, by Battery Type, 2023-2032 (USD Million)

- Table 53 China: Black Mass Recycling Market, by Battery Source, 2023-2032 (USD Million)

- Table 54 China: Black Mass Recycling Market, by Recycling Process, 2023-2032 (USD Million)

- Table 55 Japan: Black Mass Recycling Market, by Battery Type, 2023-2032 (USD Million)

- Table 56 Japan: Black Mass Recycling Market, by Battery Source, 2023-2032 (USD Million)

- Table 57 Japan: Black Mass Recycling Market, by Recycling Process, 2023-2032 (USD Million)

- Table 58 India: Black Mass Recycling Market, by Battery Type, 2023-2032 (USD Million)

- Table 59 India: Black Mass Recycling Market, by Battery Source, 2023-2032 (USD Million)

- Table 60 India: Black Mass Recycling Market, by Recycling Process, 2023-2032 (USD Million)

- Table 61 South Korea: Black Mass Recycling Market, by Battery Type, 2023-2032 (USD Million)

- Table 62 South Korea: Black Mass Recycling Market, by Battery Source, 2023-2032 (USD Million)

- Table 63 South Korea: Black Mass Recycling Market, by Recycling Process, 2023-2032 (USD Million)

- Table 64 Rest of Asia-Pacific: Black Mass Recycling Market, by Battery Type, 2023-2032 (USD Million)

- Table 65 Rest of Asia-Pacific: Black Mass Recycling Market, by Battery Source, 2023-2032 (USD Million)

- Table 66 Rest of Asia-Pacific: Black Mass Recycling Market, by Recycling Process, 2023-2032 (USD Million)

- Table 67 Latin America: Black Mass Recycling Market, by Battery Type, 2023-2032 (USD Million)

- Table 68 Latin America: Black Mass Recycling Market, by Battery Source, 2023-2032 (USD Million)

- Table 69 Latin America: Black Mass Recycling Market, by Recycling Process, 2023-2032 (USD Million)

- Table 70 Middle East & Africa: Black Mass Recycling Market, by Battery Type, 2023-2032 (USD Million)

- Table 71 Middle East & Africa: Black Mass Recycling Market, by Battery Source, 2023-2032 (USD Million)

- Table 72 Middle East & Africa: Black Mass Recycling Market, by Recycling Process, 2023-2032 (USD Million)

- Table 73 Recent Developments, by Company, 2022-2025

LIST OF FIGURES

- Figure 1 Research Process

- Figure 2 Key Secondary Sources

- Figure 3 Primary Research Techniques

- Figure 4 Key Executives Interviewed

- Figure 5 Breakdown of Primary Interviews (Supply-Side & Demand-Side)

- Figure 6 Market Sizing and Growth Forecast Approach

- Figure 7 In 2025, The Lithium Nickel Manganese Cobalt Oxide (NMC) Segment Is Expected to Dominate The Black Mass Recycling Market

- Figure 8 In 2025, The Automotive Batteries Segment Is Expected to Dominate the Black Mass Recycling Market

- Figure 9 In 2025, The Hydrometallurgy Segment Is Expected to Dominate the Black Mass Recycling Market

- Figure 10 Black Mass Recycling Market, by Region, 2025 Vs. 2032

- Figure 11 Factors Affecting Market Growth

- Figure 12 Value Chain Analysis

- Figure 13 Porter's Five Forces Analysis

- Figure 14 Pre-Treatment Methods for Waste Lithium-Ion Battery

- Figure 15 Lithium Recycling from Pre-Treated Waste Lib Components by Pyrometallurgy Process

- Figure 16 Lithium-Ion Recycling from Pre-Treated Waste LiB Components by Hydrometallurgy Process

- Figure 17 Global Black Mass Recycling Market, by Battery Type, 2025 Vs. 2032 (USD Million)

- Figure 18 Global Black Mass Recycling Market, by Battery Source, 2025 Vs. 2032 (USD Million)

- Figure 19 Global Black Mass Recycling Market, by Recycle Process, 2025 Vs. 2032 (USD Million)

- Figure 20 Global Black Mass Recycling Market, by Region, 2025 Vs. 2032 (USD Million)

- Figure 21 North America: Black Mass Recycling Market Snapshot

- Figure 22 Europe: Black Mass Recycling Market Snapshot

- Figure 23 Asia-Pacific: Black Mass Recycling Market Snapshot

- Figure 24 Latin America: Black Mass Recycling Market Snapshot

- Figure 25 Middle East & Africa: Black Mass Recycling Market

- Figure 26 Key Growth Strategies Adopted by Leading Players, 2022-2025

- Figure 27 Black Mass Recycling Market: Competitive Benchmarking, by Region

- Figure 28 Competitive Dashboard: Black Mass Recycling Market

- Figure 29 Black Mass Recycling Market Position Analysis, 2024

- Figure 30 BASF SE: Financial Overview (2024)

- Figure 31 Umicore SA: Financial Overview (2024)

- Figure 32 Li-Cycle Holdings Corp.: Financial Overview (2024)

- Figure 33 Fortum Corporation: Financial Overview (2024)

- Figure 34 Tata Chemicals Limited: Financial Overview (2025)

Black Mass Recycling Market Size, Share, Forecast, & Trends Analysis by Battery Type (NMC, LCO, LMO, NCA), Battery Source (Automotive Batteries, Consumer Electronics, Industrial), Recycling Process (Hydrometallurgy, Pyrometallurgy)-Global Forecast to 2032

According to the research report titled, 'Black Mass Recycling Market Size, Share, Forecast, & Trends Analysis by Battery Type (NMC, LCO, LMO, NCA), Battery Source (Automotive Batteries, Consumer Electronics, Industrial), Recycling Process (Hydrometallurgy, Pyrometallurgy)-Global Forecast to 2032,' the black mass recycling market is projected to reach $20.4 billion by 2032, at a CAGR of 22.5% during the forecast period 2025-2032. The report provides an in-depth analysis of the global black mass recycling market across five major regions, emphasizing the current market trends, market sizes, recent developments, and forecasts till 2032.

Succeeding extensive secondary and primary research and an in-depth analysis of the market scenario, the report conducts the impact analysis of the key industry drivers, restraints, opportunities, and trends. The growth of this market is driven by the accelerating adoption of electric vehicles (EVs), which is increasing the volume of spent lithium-ion batteries requiring recycling. The rising demand for critical battery metals such as lithium, cobalt, and nickel, coupled with supply chain vulnerabilities, is encouraging manufacturers and governments to prioritize recycled materials to reduce dependence on mining.

Additionally, the rapid development of battery gigafactories is fueling the need for efficient recycling solutions. Technological advancements, particularly in hydrometallurgical and direct recycling processes, are enhancing metal recovery rates and cost-efficiency, supporting market growth. Despite these positive trends, the industry faces challenges including insufficient recycling infrastructure, the complexity of diverse battery chemistries, and competition from lower-cost mined materials. However, government incentives like tax credits and grants, along with expanding demand in emerging markets such as India and Southeast Asia, present substantial opportunities.

Notably, the shift toward hydrometallurgical techniques and closed-loop recycling systems is transforming battery recycling from a waste management activity into a vital component of sustainable energy storage, enabling direct reuse of recovered materials in new battery production and fostering a circular economy within the sector.

The key players operating in the black mass recycling market are BASF SE (Germany), Umicore SA (Belgium), Tenova S.p.A. (Italy), Li-Cycle Holdings Corp. (Canada), Lithion Recycling Inc. (Canada), AkkuSer Oy (Finland), Duesenfeld GmbH (Germany), Aqua Metals Inc. (U.S.), SungEel Hi-Tech. Co., Ltd. (South Korea), Fortum Corporation (Finland), Redwood Materials Inc. (U.S.), Green Li-ion Pte Ltd. (Singapore), Tata Chemicals Limited (India), Attero Recycling Pvt. Ltd. (India), Exigo Recycling Pvt. Ltd. (India).

The black mass recycling market is segmented by battery type (lithium cobalt oxide (LCO), lithium nickel manganese cobalt oxide (NMC), lithium manganese oxide (LMO), lithium nickel cobalt aluminum oxide (NCA), and other batteries), battery source (automotive batteries, industrial batteries, consumer electronics, and other battery sources), recycling process (hydrometallurgy, pyrometallurgy, and other recycling processes), and geography. The study also evaluates industry competitors and analyzes the country-level markets.

Based on battery type, the lithium nickel manganese cobalt oxide (NMC) segment is expected to account for the largest share of the black mass recycling market in 2025. The major share of this market is mainly attributed to the widespread use of NMC batteries in electric vehicles and electronics, driven by their high energy density, longer lifespan, and growing demand for sustainable battery recycling solutions. Additionally, the increasing adoption of electric vehicles globally and supportive government regulations promoting battery recycling further boost the demand for NMC recycling. Manufacturers are also investing in advanced recycling technologies to recover valuable metals like nickel, cobalt, and lithium efficiently. These factors collectively contribute to the growing market share of the NMC segment in black mass recycling.

Based on battery source, the consumer electronic batteries segment is projected to record the highest CAGR during the forecast period. The fast growth of this segment is mainly attributed to the global proliferation of smartphones, laptops, tablets, wearable devices, and other portable electronic gadgets, all of which utilize lithium-ion batteries. The shorter lifecycle of batteries in consumer electronics compared to automotive and industrial batteries leads to a quicker turnover and a continuous supply of spent batteries for recycling. Furthermore, increasing awareness about e-waste management and regulatory actions to properly dispose of electronic devices are further accelerating the recycling of consumer electronics batteries.

Based on recycling process, the hydrometallurgy segment is expected to account for the largest share of the black mass recycling market in 2025. The large share of this segment is attributed to the several advantages of hydrometallurgical method offers over traditional pyrometallurgical processes. Hydrometallurgy involves the use of aqueous chemical solutions to selectively leach and recover valuable metals such as lithium, cobalt, nickel, and manganese from the black mass. This method allows for higher recovery rates of these critical materials, particularly lithium, which is often lost during high-temperature pyrometallurgical processing. As a result, hydrometallurgy has become the preferred choice for battery recyclers seeking to maximize the economic value extracted from spent lithium-ion batteries.

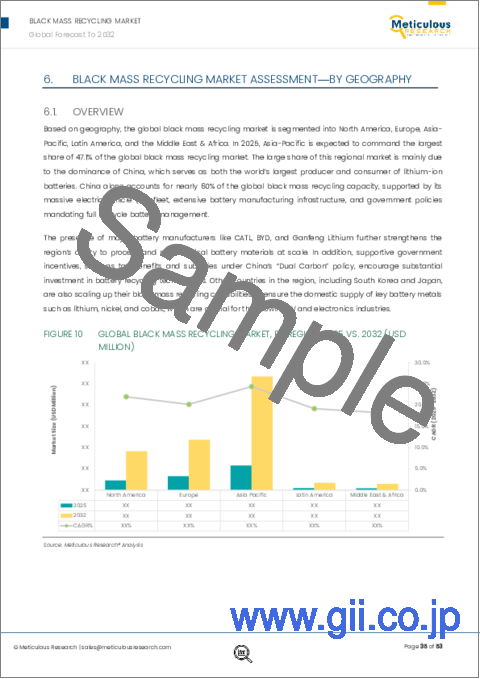

An in-depth geographic analysis of the industry provides detailed qualitative and quantitative insights into the five major regions (North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa) and the coverage of major countries in each region. Asia-Pacific is slated to register the highest CAGR during the forecast period, mainly due to the rapid industrialization, increasing adoption of electric vehicles, and strong government initiatives supporting sustainable practices. Countries like China, Japan, and South Korea are leading in battery production and consumption, driving demand for recycling. Additionally, growing awareness of environmental impacts and the need for resource recovery further accelerate the region's black mass recycling market growth.

Moreover, the presence of major battery manufacturers and recycling companies in the region enhances technological advancements and infrastructure development for efficient recycling processes. Favorable policies, subsidies, and strategic partnerships between public and private sectors are also contributing to market expansion. With the rising need to reduce dependency on raw material imports and ensure a stable supply of critical metals, Asia-Pacific is poised to lead the global growth in black mass recycling.

Key Questions Answered in the Report-

- What is the current revenue generated by black mass recycling globally?

- At what rate is the global black mass recycling demand projected to grow for the next 5-7 years?

- What are the historical market sizes and growth rates of the global black mass recycling market?

- What are the major factors impacting the growth of this market at the regional and country levels? What are the major opportunities for existing players and new entrants in the market?

- Which segments in terms of type and applications are expected to create major traction for the manufacturers in this market?

- What are the key geographical trends in this market? Which regions/countries are expected to offer significant growth opportunities for the manufacturers operating in the global black mass recycling market?

- Who are the major players in the global black mass recycling market? What are their specific product offerings in this market?

- What are the recent strategic developments in the global black mass recycling market? What are the impacts of these strategic developments on the market?

Scope of the Report:

Black Mass Recycling Market Assessment-by Battery Type

- Lithium Nickel Manganese Cobalt Oxide (NMC)

- Lithium Cobalt Oxide (LCO)

- Lithium Manganese Oxide (LMO)

- Lithium Nickel Cobalt Aluminium Oxide (NCA)

- Other Batteries

Black Mass Recycling Market Assessment-by Battery Source

- Automotive Batteries

- Consumer Electronic Batteries

- Industrial Batteries

- Other Battery Sources

Black Mass Recycling Market Assessment-by Recycling Process

- Hydrometallurgy

- Pyrometallurgy

- Other Recycling Processes

Black Mass Recyclings Market Assessment-by Geography

- North America

- U.S.

- Canada

- Europe

- Germany

- France

- U.K.

- Italy

- Spain

- Rest of Europe

- Asia-Pacific

- China

- Japan

- India

- South Korea

- Rest of Asia-Pacific

- Latin America

- Middle East & Africa

TABLE OF CONTENTS

1 Introduction

- 1.1. Market Definition & Scope

- 1.2. Market Ecosystem

- 1.3. Currency & Limitations

- 1.4. Key Stakeholders

2 Research Methodology

- 2.1. Research Approach

- 2.2. Data Collection & Validation

- 2.2.1. Secondary Research

- 2.2.2. Primary Research

- 2.3. Market Assessment

- 2.3.1. Market Size Estimation

- 2.3.2. Bottom-Up Approach

- 2.3.3. Top-Down Approach

- 2.3.4. Growth Forecast

- 2.4. Assumptions for the Study

3 Executive Summary

- 3.1. Overview

- 3.2. Segmental Analysis

- 3.2.1. Market Analysis, by Battery Type

- 3.2.2. Market Analysis, by Battery Source

- 3.2.3. Market Analysis, by Recycling Process

- 3.3. Regional Analysis

- 3.4. Competitive Analysis

4 Market Insights

- 4.1. Overview

- 4.2. Factors Affecting Market Growth

- 4.2.1. Drivers

- 4.2.1.1. Increasing Demand for Electric Vehicles

- 4.2.1.2. Growing Need to Manage the Disposal of Used Batteries

- 4.2.1.3. Supply Chain Security for Critical Minerals

- 4.2.1.4. Growth in Battery Manufacturing

- 4.2.1.5. Technological Advancements in Recycling

- 4.2.2. Restraints

- 4.2.2.1. Lack of Proper Recycling Infrastructure

- 4.2.3. Opportunities

- 4.2.3.1. Government Incentives for Battery Recycling

- 4.2.3.2. Expansion in Emerging Markets

- 4.2.3.3. Growing Secondary Raw Material Market

- 4.2.4. Challenges

- 4.2.4.1. Government Incentives for Battery Recycling

- 4.2.4.2. Competition from Mining Sector

- 4.2.5. Trends

- 4.2.5.1. Rising Adoption of Hydrometallurgical Processes

- 4.2.5.2. Development of Closed-Loop Battery Recycling Systems

- 4.2.1. Drivers

- 4.3. Value Chain Analysis

- 4.4. Porter's Five Forces Analysis

- 4.4.1. Competitive Rivalry (High)

- 4.4.2. Threat of New Entrants (Moderate-High)

- 4.4.3. Threat of Substitutes (Moderate)

- 4.4.4. Bargaining Power of Buyers (High)

- 4.4.5. Bargaining Power of Suppliers (Low-Moderate)

- 4.5. Black Mass Recycling Processes

- 4.5.1. Pre-Treatment Methods for Waste Lithium-Ion Battery

- 4.5.2. Lithium Extraction Technologies from Pre-Treated Waste Lithium-Ion Battery

5 Black Mass Recycling Market Assessment - by Battery Type

- 5.1. Overview

- 5.2. Lithium Nickel Manganese Cobalt Oxide (NMC)

- 5.3. Lithium Cobalt Oxide (LCO)

- 5.4. Lithium Manganese Oxide (LMO)

- 5.5. Lithium Nickel Cobalt Aluminium Oxide (NCA)

- 5.6. Other Batteries

6 Black Mass Recycling Market Assessment - by Battery Source

- 6.1. Overview

- 6.2. Automotive Batteries

- 6.3. Consumer Electronic Batteries

- 6.4. Industrial Batteries

- 6.5. Other Battery Sources

7 Black Mass Recycling Market Assessment - by Recycling Process

- 7.1. Overview

- 7.2. Hydrometallurgy

- 7.3. Pyrometallurgy

- 7.4. Other Recycling Processes

8 Black Mass Recycling Market Assessment-by Geography

- 8.1. Overview

- 8.2. North America

- 8.2.1. U.S.

- 8.2.2. Canada

- 8.3. Europe

- 8.3.1. Germany

- 8.3.2. U.K.

- 8.3.3. France

- 8.3.4. Italy

- 8.3.5. Spain

- 8.3.6. Rest of Europe

- 8.4. Asia Pacific

- 8.4.1. China

- 8.4.2. Japan

- 8.4.3. India

- 8.4.4. South Korea

- 8.4.5. Rest of Asia-Pacific

- 8.5. Latin America

- 8.6. Middle East & Africa

9 Competitive Landscape

- 9.1. Overview

- 9.2. Key Growth Strategies

- 9.3. Competitive Benchmarking

- 9.4. Competitive Dashboard

- 9.4.1. Industry Leaders

- 9.4.2. Market Differentiators

- 9.4.3. Vanguards

- 9.4.4. Emerging Companies

- 9.5. Market Share/Position Analysis

10 Company Profiles

- 10.1. BASF SE

- 10.2. Umicore SA

- 10.3. Tenova S.p.A.

- 10.4. Li-Cycle Holdings Corp.

- 10.5. Lithion Technologies Inc.

- 10.6. AkkuSer Oy

- 10.7. Duesenfeld GmbH

- 10.8. Aqua Metals, Inc.

- 10.9. SungEel Hitech Co., Ltd.

- 10.10. Fortum Corporation

- 10.11. Redwood Materials, Inc.

- 10.12. Green Li-Ion Pte Ltd

- 10.13. Tata Chemicals Limited

- 10.14. Attero Recycling Pvt. Ltd.

- 10.15. Exigo Recycling Pvt. Ltd.

11 Appendix

- 11.1. Available Customization

- 11.2. Related Reports