|

|

市場調査レポート

商品コード

1747193

3Dプリンティングロボットの世界市場:コンポーネント・サービス別、ロボットタイプ別、用途別 - 予測(~2030年)3D Printing Robot Market by Component & Service, Robot Type, Application - Global Forecast to 2030 |

||||||

カスタマイズ可能

|

|||||||

| 3Dプリンティングロボットの世界市場:コンポーネント・サービス別、ロボットタイプ別、用途別 - 予測(~2030年) |

|

出版日: 2025年06月06日

発行: MarketsandMarkets

ページ情報: 英文 297 Pages

納期: 即納可能

|

全表示

- 概要

- 図表

- 目次

世界の3Dプリンティングロボットの市場規模は、2025年の20億米ドルから2030年までに31億4,000万米ドルに達すると予測され、CAGRで9.5%の成長が見込まれます。

| 調査範囲 | |

|---|---|

| 調査対象年 | 2020年~2030年 |

| 基準年 | 2024年 |

| 予測期間 | 2025年~2030年 |

| 単位 | 10億米ドル |

| セグメント | コンポーネント・サービス、ロボットタイプ、用途、地域 |

| 対象地域 | 北米、欧州、アジア太平洋、その他の地域 |

3Dプリンティングロボット市場は、オートメーションの採用が進み、さまざまな産業でカスタマイズされコスト最適化された製造ソリューションに対する需要が高まっていることから、急成長が見込まれています。複雑な形状を実現するため、材料の無駄を省くため、また生産サイクルを最適化するために、ロボット3Dプリンティングシステムを採用する企業が増えています。次世代ロボットと積層造形技術の融合により、大規模で精度の高い、需要に応じたコンポーネントの生産が可能になります。機能部品メーカーやツーリング・プロトタイプサービスプロバイダーは、リードタイムを劇的に短縮することで業務を変革し、市場の需要に迅速に対応し、顧客に卓越した価値を提供することを可能にしています。さらに、インダストリー4.0プロジェクト設計の変革とスマートファクトリーの進化が、主に航空宇宙、自動車、建設産業におけるロボット3Dプリンティング技術の採用を後押ししています。この市場には、ロボットシステムや積層造形にかかる高額な初期資本支出などの抑制要因があり、中小企業が3Dプリンティングロボットを採用する意欲をそぐ可能性があります。さらに、複雑なロボット3Dプリンティング装置の運転と保守を行う熟練労働者の不足が、大規模採用の大きなハードルとなっています。

「用途別では、ツーリングセグメントが予測期間に2番目に高いCAGRを記録する見込みです。」

ツーリング用途は、自動車、航空宇宙・防衛、建設などのさまざまな産業において、迅速でコスト効率の高い、カスタマイズされたツールの生産へのニーズが高まっているため、予測期間に3Dプリンティングロボット市場で2番目に高いCAGRを示す見込みです。従来のツーリング方法は、特に少量生産コンポーネントや複雑なコンポーネントの場合、時間とコストがかかります。ロボット3Dプリンティングは、リードタイムを大幅に短縮し、無駄を最小化するとともに、従来の方法では困難な複雑な形状の生産を可能にします。この技術は、主に自動車、航空宇宙、産業機械の部門で、治具、固定具、金型、加工補助具の製造に使用され、製造環境における柔軟性と応答性を高めています。

ロボットアームはツーリング部品の製造を自動化および最適化できるため、特にマスカスタマイゼーションやリーン生産が重視される環境で需要が高まっています。さらに、高性能材料と多軸ロボットシステムの進歩により、3Dプリンティングロボットを使用して実現できるツーリング用途の範囲が広がっています。企業が生産性を向上させながらコスト削減を目指す中、ツーリングにおけるロボット3Dプリンティングへのニーズは高まると予測され、産業でもっとも急成長している用途の1つとなっています。

「航空宇宙・防衛セグメントが2030年に第2位の市場シェアを記録」

エンドユーザー別では、高性能で軽量で複雑なコンポーネントを重視しているため、航空宇宙・防衛部門が予測期間に3Dプリンティングロボット市場で2番目に大きなシェアを占める見込みです。航空宇宙・防衛産業は、材料への期待が高く、生産レベルが低いことが特徴であり、従来の製造は実現可能性が低いです。ロボットを用いた積層造形は、拡張性、カスタマイズ性、一貫した品質を提供することで、こうした課題に容易に対処できます。

当レポートでは、世界の3Dプリンティングロボット市場について調査分析し、主な促進要因と抑制要因、競合情勢、将来の動向などの情報を提供しています。

目次

第1章 イントロダクション

第2章 調査手法

第3章 エグゼクティブサマリー

第4章 主な調査結果

- 3Dプリンティングロボット市場の企業にとって魅力的な機会

- 3Dプリンティングロボット市場:最終用途産業別

- 3Dプリンティングロボット市場:ロボットタイプ別

- 3Dプリンティングロボット市場:用途別

- 3Dプリンティングロボット市場:地域別

- 3Dプリンティングロボット市場:国別

第5章 市場の概要

- イントロダクション

- 市場力学

- 促進要因

- 抑制要因

- 機会

- 課題

- ポーターのファイブフォース分析

- エコシステム分析

- バリューチェーン分析

- 規制情勢

- 規制機関、政府機関、その他の組織

- 標準

- 貿易分析

- 輸入データ(HSコード844311)

- 輸出シナリオ(HSコード844311)

- 価格分析

- 3Dプリンティングロボットコンポーネントの平均販売価格:主要企業別(2024年)

- 3Dプリンティングロボットの価格帯:主要企業別(2024年)

- 3Dプリンティングロボットコンポーネントの平均販売価格の動向:地域別(2021年~2024年)

- 技術分析

- 主要技術

- 隣接技術

- 補完技術

- 特許分析

- ケーススタディ分析

- 主なステークホルダーと購入基準

- 主な会議とイベント(2025年~2026年)

- 投資と資金調達シナリオ(2013年~2024年)

- 顧客ビジネスに影響を与える動向/混乱

- 2025年の米国関税の影響の分析

- イントロダクション

- 主な関税率

- 国/地域に対する影響

- 最終用途産業に対する影響

- 3Dプリンティング市場に対するAIの影響

第6章 3Dプリンティングロボット市場:コンポーネント・サービス別

- イントロダクション

- ロボットアーム

- 3Dプリントヘッド

- ソフトウェア

- サービス

第7章 3Dプリンティングロボット市場:ロボットタイプ別

- イントロダクション

- 多関節

- カルテジアン

- SCARA

- 極座標

- デルタ

- その他のロボットタイプ

第8章 3Dプリンティングロボット市場:用途別

- イントロダクション

- プロトタイピング

- ツーリング

- 機能部品製造

第9章 3Dプリンティングロボット市場:最終用途産業別

- イントロダクション

- 自動車

- 日用消費財

- 航空宇宙・防衛

- 建設

- 料理

- その他の最終用途産業

第10章 3Dプリンティングロボット市場:地域別

- イントロダクション

- 北米

- 北米のマクロ経済の見通し

- 米国

- カナダ

- メキシコ

- 欧州

- 欧州のマクロ経済の見通し

- ドイツ

- 英国

- フランス

- イタリア

- スペイン

- ポーランド

- 北欧

- その他の欧州

- アジア太平洋

- アジア太平洋のマクロ経済の見通し

- 中国

- 韓国

- 日本

- インド

- オーストラリア

- インドネシア

- マレーシア

- タイ

- ベトナム

- その他のアジア太平洋

- その他の地域

- その他の地域のマクロ経済の見通し

- 南米

- アフリカ

- 中東

第11章 競合情勢

- 概要

- 主要参入企業の戦略/強み(2021年~2025年)

- 収益分析(2021年~2024年)

- 市場シェア分析(2024年)

- 企業の評価と財務指標(2025年)

- ブランド/製品の比較

- 企業の評価マトリクス:主要企業(2024年)

- 企業の評価マトリクス:スタートアップ/中小企業(2024年)

- 競合シナリオ

第12章 企業プロファイル

- 主要企業

- KUKA AG

- ABB

- YASKAWA ELECTRIC CORPORATION

- FANUC CORPORATION

- UNIVERSAL ROBOTS A/S

- MASSIVE DIMENSION

- CEAD B.V.

- CARACOL

- WEBER MASCHINENFABRIK

- MELTIO3D

- COMAU

- その他の企業

- BAUBOT GMBH

- MX3D

- TWENTE ADDITIVE MANUFACTURING

- DOBOT

- DYZE DESIGN

- REV3RD S.R.L.

- ADAXIS SAS

- ORBITAL COMPOSITES INC.

- AI BUILD LIMITED

- OCTOPUZ INDUSUITE

- HYPERION ROBOTICS

- HYPERTHERM, INC.

- INGERSOLL MACHINE TOOLS, INC.

- 3D MINERALS

第13章 付録

List of Tables

- TABLE 1 3D PRINTING ROBOT MARKET: RISK ANALYSIS

- TABLE 2 3D PRINTING ROBOT MARKET: PORTER'S FIVE FORCES ANALYSIS

- TABLE 3 ROLE OF PLAYERS IN 3D PRINTING ROBOT ECOSYSTEM

- TABLE 4 INTERNATIONAL: REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 5 NORTH AMERICA: LIST OF REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 6 EUROPE: LIST OF REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 7 ASIA PACIFIC: LIST OF REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 8 ROW: LIST OF REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 9 IMPORT DATA FOR HS CODE 844311-COMPLIANT PRODUCTS, BY COUNTRY, 2020-2024 (USD MILLION)

- TABLE 10 EXPORT DATA FOR HS CODE 844311-COMPLIANT PRODUCTS, BY COUNTRY, 2020-2024 (USD MILLION)

- TABLE 11 AVERAGE SELLING PRICE OF ROBOTIC ARMS OFFERED BY KEY PLAYERS, 2024 (USD)

- TABLE 12 AVERAGE SELLING PRICE OF 3D PRINTING HEADS OFFERED BY KEY PLAYERS, 2024 (USD)

- TABLE 13 PRICING RANGE OF 3D PRINTING ROBOTS, BY KEY PLAYER, 2024

- TABLE 14 PRICING RANGE OF ROBOT ARMS, BY REGION, 2021-2024 (USD)

- TABLE 15 PRICING RANGE OF 3D PRINTING HEADS, BY REGION, 2021-2024 (USD)

- TABLE 16 LIST OF GRANTED PATENTS RELATED TO 3D PRINTING ROBOT, 2019-2022

- TABLE 17 INFLUENCE OF STAKEHOLDERS ON BUYING PROCESS FOR TOP 3 END-USE INDUSTRIES (%)

- TABLE 18 KEY BUYING CRITERIA FOR TOP 3 END-USE INDUSTRIES

- TABLE 19 KEY CONFERENCES AND EVENTS, 2025-2026

- TABLE 20 US-ADJUSTED RECIPROCAL TARIFF RATES

- TABLE 21 3D PRINTING ROBOT MARKET, BY COMPONENT & SERVICE, 2021-2024 (USD MILLION)

- TABLE 22 3D PRINTING ROBOT MARKET, BY COMPONENT & SERVICE, 2025-2030 (USD MILLION)

- TABLE 23 3D PRINTING ROBOT MARKET, BY HARDWARE COMPONENT, 2021-2024 (THOUSAND UNITS)

- TABLE 24 3D PRINTING ROBOT MARKET, BY HARDWARE COMPONENT, 2025-2030 (THOUSAND UNITS)

- TABLE 25 ROBOT ARMS: 3D PRINTING ROBOT MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 26 ROBOT ARMS: 3D PRINTING ROBOT MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 27 ROBOT ARMS: 3D PRINTING ROBOT MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 28 ROBOT ARMS: 3D PRINTING ROBOT MARKET, BY REGION, 2025-2030 (USD MILLION)

- TABLE 29 3D PRINTING HEADS: 3D PRINTING ROBOT MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 30 3D PRINTING HEADS: 3D PRINTING ROBOT MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 31 3D PRINTING HEADS: 3D PRINTING ROBOT MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 32 3D PRINTING HEADS: 3D PRINTING ROBOT MARKET, BY REGION, 2025-2030 (USD MILLION)

- TABLE 33 SOFTWARE: 3D PRINTING ROBOT MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 34 SOFTWARE: 3D PRINTING ROBOT MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 35 SOFTWARE: 3D PRINTING ROBOT MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 36 SOFTWARE: 3D PRINTING ROBOT MARKET, BY REGION, 2025-2030 (USD MILLION)

- TABLE 37 LIST OF MAJOR 3D PRINTING RAAS PROVIDERS

- TABLE 38 3D PRINTING ROBOT MARKET, BY ROBOT TYPE, 2021-2024 (USD MILLION)

- TABLE 39 3D PRINTING ROBOT MARKET, BY ROBOT TYPE, 2025-2030 (USD MILLION)

- TABLE 40 ARTICULATED: 3D PRINTING ROBOT MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 41 ARTICULATED: 3D PRINTING ROBOT MARKET, BY REGION, 2025-2030 (USD MILLION)

- TABLE 42 CARTESIAN: 3D PRINTING ROBOT MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 43 CARTESIAN: 3D PRINTING ROBOT MARKET, BY REGION, 2025-2030 (USD MILLION)

- TABLE 44 SCARA: 3D PRINTING ROBOT MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 45 SCARA: 3D PRINTING ROBOT MARKET, BY REGION, 2025-2030 (USD MILLION)

- TABLE 46 POLAR: 3D PRINTING ROBOT MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 47 POLAR: 3D PRINTING ROBOT MARKET, BY REGION, 2025-2030 (USD MILLION)

- TABLE 48 DELTA: 3D PRINTING ROBOT MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 49 DELTA: 3D PRINTING ROBOT MARKET, BY REGION, 2025-2030 (USD MILLION)

- TABLE 50 OTHER ROBOT TYPES: 3D PRINTING ROBOT MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 51 OTHER ROBOT TYPES: 3D PRINTING ROBOT MARKET, BY REGION, 2025-2030 (USD MILLION)

- TABLE 52 3D PRINTING ROBOT MARKET, BY APPLICATION, 2021-2024 (USD MILLION)

- TABLE 53 3D PRINTING ROBOT MARKET, BY APPLICATION, 2025-2030 (USD MILLION)

- TABLE 54 PROTOTYPING: 3D PRINTING ROBOT MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 55 PROTOTYPING: 3D PRINTING ROBOT MARKET, BY REGION, 2025-2030 (USD MILLION)

- TABLE 56 TOOLING: 3D PRINTING ROBOT MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 57 TOOLING:3D PRINTING ROBOT MARKET, BY REGION, 2025-2030 (USD MILLION)

- TABLE 58 FUNCTIONAL PART MANUFACTURING: 3D PRINTING ROBOT MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 59 FUNCTIONAL PART MANUFACTURING: 3D PRINTING ROBOT MARKET, BY REGION, 2025-2030 (USD MILLION)

- TABLE 60 3D PRINTING ROBOT MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 61 3D PRINTING ROBOT MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 62 AUTOMOTIVE: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2021-2024 (USD MILLION)

- TABLE 63 AUTOMOTIVE: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2025-2030 (USD MILLION)

- TABLE 64 AUTOMOTIVE: 3D PRINTING ROBOT MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 65 AUTOMOTIVE: 3D PRINTING ROBOT MARKET, BY REGION, 2025-2030 (USD MILLION)

- TABLE 66 AUTOMOTIVE: 3D PRINTING ROBOT MARKET FOR ROBOT ARMS, BY REGION, 2021-2024 (USD MILLION)

- TABLE 67 AUTOMOTIVE: 3D PRINTING ROBOT MARKET FOR ROBOT ARMS, BY REGION, 2025-2030 (USD MILLION)

- TABLE 68 AUTOMOTIVE: 3D PRINTING ROBOT MARKET FOR 3D PRINTING HEADS, BY REGION, 2021-2024 (USD MILLION)

- TABLE 69 AUTOMOTIVE: 3D PRINTING ROBOT MARKET FOR 3D PRINTING HEADS, BY REGION, 2025-2030 (USD MILLION)

- TABLE 70 AUTOMOTIVE: 3D PRINTING ROBOT MARKET FOR SOFTWARE, BY REGION, 2021-2024 (USD THOUSAND)

- TABLE 71 AUTOMOTIVE: 3D PRINTING ROBOT MARKET FOR SOFTWARE, BY REGION, 2025-2030 (USD THOUSAND)

- TABLE 72 FMCG: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2021-2024 (USD MILLION)

- TABLE 73 FMCG: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2025-2030 (USD MILLION)

- TABLE 74 FMCG: 3D PRINTING ROBOT MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 75 FMCG: 3D PRINTING ROBOT MARKET, BY REGION, 2025-2030 (USD MILLION)

- TABLE 76 FMCG: 3D PRINTING ROBOT MARKET FOR ROBOT ARMS, BY REGION, 2021-2024 (USD MILLION)

- TABLE 77 FMCG: 3D PRINTING ROBOT MARKET FOR ROBOT ARMS, BY REGION, 2025-2030 (USD MILLION)

- TABLE 78 FMCG: 3D PRINTING ROBOT MARKET FOR 3D PRINTING HEADS, BY REGION, 2021-2024 (USD THOUSAND)

- TABLE 79 FMCG: 3D PRINTING ROBOT MARKET 3D PRINTING HEADS, BY REGION, 2025-2030 (USD THOUSAND)

- TABLE 80 FMCG: 3D PRINTING ROBOT MARKET FOR SOFTWARE, BY REGION, 2021-2024 (USD THOUSAND)

- TABLE 81 FMCG: 3D PRINTING ROBOT MARKET FOR SOFTWARE, BY REGION, 2025-2030 (USD THOUSAND)

- TABLE 82 AEROSPACE & DEFENSE: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2021-2024 (USD MILLION)

- TABLE 83 AEROSPACE & DEFENSE: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2025-2030 (USD MILLION)

- TABLE 84 AEROSPACE & DEFENSE: 3D PRINTING ROBOT MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 85 AEROSPACE & DEFENSE: 3D PRINTING ROBOT MARKET, BY REGION, 2025-2030 (USD MILLION)

- TABLE 86 AEROSPACE & DEFENSE: 3D PRINTING ROBOT MARKET FOR ROBOT ARMS, BY REGION, 2021-2024 (USD MILLION)

- TABLE 87 AEROSPACE & DEFENSE: 3D PRINTING ROBOT MARKET FOR ROBOT ARMS, BY REGION, 2025-2030 (USD MILLION)

- TABLE 88 AEROSPACE & DEFENSE: 3D PRINTING ROBOT MARKET FOR 3D PRINTING HEADS, BY REGION, 2021-2024 (USD MILLION)

- TABLE 89 AEROSPACE & DEFENSE: 3D PRINTING ROBOT MARKET FOR 3D PRINTING HEADS, BY REGION, 2025-2030 (USD MILLION)

- TABLE 90 AEROSPACE & DEFENSE: 3D PRINTING ROBOT MARKET FOR SOFTWARE, BY REGION, 2021-2024 (USD THOUSAND)

- TABLE 91 AEROSPACE & DEFENSE: 3D PRINTING ROBOT MARKET FOR SOFTWARE, BY REGION, 2025-2030 (USD THOUSAND)

- TABLE 92 CONSTRUCTION: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2021-2024 (USD MILLION)

- TABLE 93 CONSTRUCTION: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2025-2030 (USD MILLION)

- TABLE 94 CONSTRUCTION: 3D PRINTING ROBOT MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 95 CONSTRUCTION: 3D PRINTING ROBOT MARKET, BY REGION, 2025-2030 (USD MILLION)

- TABLE 96 CONSTRUCTION: 3D PRINTING ROBOT MARKET FOR ROBOT ARMS, BY REGION, 2021-2024 (USD MILLION)

- TABLE 97 CONSTRUCTION: 3D PRINTING ROBOT MARKET FOR ROBOT ARMS, BY REGION, 2025-2030 (USD MILLION)

- TABLE 98 CONSTRUCTION: 3D PRINTING ROBOT MARKET FOR 3D PRINTING HEADS, BY REGION, 2021-2024 (USD THOUSAND)

- TABLE 99 CONSTRUCTION: 3D PRINTING ROBOT MARKET FOR 3D PRINTING HEADS, BY REGION, 2025-2030 (USD THOUSAND)

- TABLE 100 CONSTRUCTION: 3D PRINTING ROBOT MARKET FOR SOFTWARE, BY REGION, 2021-2024 (USD THOUSAND)

- TABLE 101 CONSTRUCTION: 3D PRINTING ROBOT MARKET FOR SOFTWARE, BY REGION, 2025-2030 (USD THOUSAND)

- TABLE 102 CULINARY: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2021-2024 (USD MILLION)

- TABLE 103 CULINARY: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2025-2030 (USD MILLION)

- TABLE 104 CULINARY: 3D PRINTING ROBOT MARKET, BY REGION, 2021-2024 (USD THOUSAND)

- TABLE 105 CULINARY: 3D PRINTING ROBOT MARKET, BY REGION, 2025-2030 (USD THOUSAND)

- TABLE 106 CULINARY: 3D PRINTING ROBOT MARKET FOR ROBOT ARMS, BY REGION, 2021-2024 (USD THOUSAND)

- TABLE 107 CULINARY: 3D PRINTING ROBOT MARKET FOR ROBOT ARMS, BY REGION, 2025-2030 (USD THOUSAND)

- TABLE 108 CULINARY: 3D PRINTING ROBOT MARKET FOR 3D PRINTING HEADS, BY REGION, 2021-2024 (USD THOUSAND)

- TABLE 109 CULINARY: 3D PRINTING ROBOT MARKET FOR 3D PRINTING HEADS, BY REGION, 2025-2030 (USD THOUSAND)

- TABLE 110 CULINARY: 3D PRINTING ROBOT MARKET FOR SOFTWARE, BY REGION, 2021-2024 (USD THOUSAND)

- TABLE 111 CULINARY: 3D PRINTING ROBOT MARKET FOR SOFTWARE, BY REGION, 2025-2030 (USD THOUSAND)

- TABLE 112 OTHER END-USE INDUSTRIES: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2021-2024 (USD MILLION)

- TABLE 113 OTHER END-USE INDUSTRIES: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2025-2030 (USD MILLION)

- TABLE 114 OTHER END-USE INDUSTRIES: 3D PRINTING ROBOT MARKET, BY REGION, 2021-2024 (USD THOUSAND)

- TABLE 115 OTHER END-USE INDUSTRIES: 3D PRINTING ROBOT MARKET, BY REGION, 2025-2030 (USD THOUSAND)

- TABLE 116 OTHER END-USE INDUSTRIES: 3D PRINTING ROBOT MARKET FOR ROBOT ARMS, BY REGION, 2021-2024 (USD THOUSAND)

- TABLE 117 OTHER END-USE INDUSTRIES: 3D PRINTING ROBOT MARKET FOR ROBOT ARMS, BY REGION, 2025-2030 (USD THOUSAND)

- TABLE 118 OTHER END-USE INDUSTRIES: 3D PRINTING ROBOT MARKET FOR 3D PRINTING HEADS, BY REGION, 2021-2024 (USD THOUSAND)

- TABLE 119 OTHER END-USE INDUSTRIES: 3D PRINTING ROBOT MARKET FOR 3D PRINTING HEADS, BY REGION, 2025-2030 (USD THOUSAND)

- TABLE 120 OTHER END-USE INDUSTRIES: 3D PRINTING ROBOT MARKET FOR SOFTWARE, BY REGION, 2021-2024 (USD THOUSAND)

- TABLE 121 OTHER END-USE INDUSTRIES: 3D PRINTING ROBOT MARKET FOR SOFTWARE, BY REGION, 2025-2030 (USD THOUSAND)

- TABLE 122 3D PRINTING ROBOT MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 123 3D PRINTING ROBOT MARKET, BY REGION, 2025-2030 (USD MILLION)

- TABLE 124 NORTH AMERICA: 3D PRINTING ROBOT MARKET, BY COUNTRY, 2021-2024 (USD MILLION)

- TABLE 125 NORTH AMERICA: 3D PRINTING ROBOT MARKET, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 126 NORTH AMERICA: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2021-2024 (USD MILLION)

- TABLE 127 NORTH AMERICA: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2025-2030 (USD MILLION)

- TABLE 128 NORTH AMERICA: 3D PRINTING ROBOT MARKET, BY ROBOT TYPE, 2021-2024 (USD MILLION)

- TABLE 129 NORTH AMERICA: 3D PRINTING ROBOT MARKET, BY ROBOT TYPE, 2025-2030 (USD MILLION)

- TABLE 130 NORTH AMERICA: 3D PRINTING ROBOT MARKET, BY APPLICATION, 2021-2024 (USD MILLION)

- TABLE 131 NORTH AMERICA: 3D PRINTING ROBOT MARKET, BY APPLICATION, 2025-2030 (USD MILLION)

- TABLE 132 NORTH AMERICA: 3D PRINTING ROBOT MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 133 NORTH AMERICA: 3D PRINTING ROBOT MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 134 NORTH AMERICA: 3D PRINTING ROBOT MARKET FOR ROBOT ARMS, BY COUNTRY, 2021-2024 (USD MILLION)

- TABLE 135 NORTH AMERICA: 3D PRINTING ROBOT MARKET FOR ROBOT ARMS, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 136 NORTH AMERICA: 3D PRINTING ROBOT MARKET FOR 3D PRINTING HEADS, BY COUNTRY, 2021-2024 (USD MILLION)

- TABLE 137 NORTH AMERICA: 3D PRINTING ROBOT MARKET FOR 3D PRINTING HEADS, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 138 NORTH AMERICA: 3D PRINTING ROBOT MARKET FOR SOFTWARE, BY COUNTRY, 2021-2024 (USD MILLION)

- TABLE 139 NORTH AMERICA: 3D PRINTING ROBOT MARKET FOR SOFTWARE, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 140 US: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2021-2024 (USD MILLION)

- TABLE 141 US: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2025-2030 (USD MILLION)

- TABLE 142 CANADA: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2021-2024 (USD MILLION)

- TABLE 143 CANADA: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2025-2030 (USD MILLION)

- TABLE 144 MEXICO: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2021-2024 (USD MILLION)

- TABLE 145 MEXICO: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2025-2030 (USD MILLION)

- TABLE 146 EUROPE: 3D PRINTING ROBOT MARKET, BY COUNTRY, 2021-2024 (USD MILLION)

- TABLE 147 EUROPE: 3D PRINTING ROBOT MARKET, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 148 EUROPE: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2021-2024 (USD MILLION)

- TABLE 149 EUROPE: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2025-2030 (USD MILLION)

- TABLE 150 EUROPE: 3D PRINTING ROBOT MARKET, BY ROBOT TYPE, 2021-2024 (USD MILLION)

- TABLE 151 EUROPE: 3D PRINTING ROBOT MARKET, BY ROBOT TYPE, 2025-2030 (USD MILLION)

- TABLE 152 EUROPE: 3D PRINTING ROBOT MARKET, BY APPLICATION, 2021-2024 (USD MILLION)

- TABLE 153 EUROPE: 3D PRINTING ROBOT MARKET, BY APPLICATION, 2025-2030 (USD MILLION)

- TABLE 154 EUROPE: 3D PRINTING ROBOT MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 155 EUROPE: 3D PRINTING ROBOT MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 156 EUROPE: 3D PRINTING ROBOT MARKET FOR ROBOT ARMS, BY COUNTRY, 2021-2024 (USD MILLION)

- TABLE 157 EUROPE: 3D PRINTING ROBOT MARKET FOR ROBOT ARMS, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 158 EUROPE: 3D PRINTING ROBOT MARKET FOR 3D PRINTING HEADS, BY COUNTRY, 2021-2024 (USD THOUSAND)

- TABLE 159 EUROPE: 3D PRINTING ROBOT MARKET FOR 3D PRINTING HEADS, BY COUNTRY, 2025-2030 (USD THOUSAND)

- TABLE 160 3D PRINTING ROBOT MARKET FOR SOFTWARE, BY COUNTRY, 2021-2024 (USD THOUSAND)

- TABLE 161 3D PRINTING ROBOT MARKET FOR SOFTWARE, BY COUNTRY, 2025-2030 (USD THOUSAND)

- TABLE 162 UK: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2021-2024 (USD MILLION)

- TABLE 163 UK: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2025-2030 (USD MILLION)

- TABLE 164 GERMANY: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2021-2024 (USD MILLION)

- TABLE 165 GERMANY: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2025-2030 (USD MILLION)

- TABLE 166 FRANCE: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2021-2024 (USD MILLION)

- TABLE 167 FRANCE: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2025-2030 (USD MILLION)

- TABLE 168 ITALY: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2021-2024 (USD THOUSAND)

- TABLE 169 ITALY: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2025-2030 (USD THOUSAND)

- TABLE 170 SPAIN: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2021-2024 (USD THOUSAND)

- TABLE 171 SPAIN: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2025-2030 (USD THOUSAND)

- TABLE 172 POLAND: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2021-2024 (USD THOUSAND)

- TABLE 173 POLAND: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2025-2030 (USD THOUSAND)

- TABLE 174 NORDICS: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2021-2024 (USD THOUSAND)

- TABLE 175 NORDICS: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2025-2030 (USD THOUSAND)

- TABLE 176 REST OF EUROPE: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2021-2024 (USD THOUSAND)

- TABLE 177 REST OF EUROPE: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2025-2030 (USD THOUSAND)

- TABLE 178 ASIA PACIFIC: 3D PRINTING ROBOT MARKET, BY COUNTRY, 2021-2024 (USD MILLION)

- TABLE 179 ASIA PACIFIC: 3D PRINTING ROBOT MARKET, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 180 ASIA PACIFIC: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2021-2024 (USD MILLION)

- TABLE 181 ASIA PACIFIC: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2025-2030 (USD MILLION)

- TABLE 182 ASIA PACIFIC: 3D PRINTING ROBOT MARKET, BY ROBOT TYPE, 2021-2024 (USD MILLION)

- TABLE 183 ASIA PACIFIC: 3D PRINTING ROBOT MARKET, BY ROBOT TYPE, 2025-2030 (USD MILLION)

- TABLE 184 ASIA PACIFIC: 3D PRINTING ROBOT MARKET, BY APPLICATION, 2021-2024 (USD MILLION)

- TABLE 185 ASIA PACIFIC: 3D PRINTING ROBOT MARKET, BY APPLICATION, 2025-2030 (USD MILLION)

- TABLE 186 ASIA PACIFIC: 3D PRINTING ROBOT MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 187 ASIA PACIFIC: 3D PRINTING ROBOT MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 188 ASIA PACIFIC: 3D PRINTING ROBOT MARKET FOR ROBOT ARMS, BY COUNTRY, 2021-2024 (USD MILLION)

- TABLE 189 ASIA PACIFIC: 3D PRINTING ROBOT MARKET FOR ROBOT ARMS, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 190 ASIA PACIFIC: 3D PRINTING ROBOT MARKET FOR 3D PRINTING HEADS, BY COUNTRY, 2021-2024 (USD MILLION)

- TABLE 191 ASIA PACIFIC: 3D PRINTING ROBOT MARKET FOR 3D PRINTING HEADS, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 192 ASIA PACIFIC: 3D PRINTING ROBOT MARKET FOR SOFTWARE, BY COUNTRY, 2021-2024 (USD MILLION)

- TABLE 193 ASIA PACIFIC: 3D PRINTING ROBOT MARKET FOR SOFTWARE, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 194 CHINA: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2021-2024 (USD MILLION)

- TABLE 195 CHINA: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2025-2030 (USD MILLION)

- TABLE 196 JAPAN: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2021-2024 (USD MILLION)

- TABLE 197 JAPAN: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2025-2030 (USD MILLION)

- TABLE 198 SOUTH KOREA: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2021-2024 (USD MILLION)

- TABLE 199 SOUTH KOREA: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2025-2030 (USD MILLION)

- TABLE 200 INDIA: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2021-2024 (USD MILLION)

- TABLE 201 INDIA: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2025-2030 (USD MILLION)

- TABLE 202 AUSTRALIA: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2021-2024 (USD MILLION)

- TABLE 203 AUSTRALIA: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2025-2030 (USD MILLION)

- TABLE 204 INDONESIA: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2021-2024 (USD MILLION)

- TABLE 205 INDONESIA: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2025-2030 (USD MILLION)

- TABLE 206 MALAYSIA: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2021-2024 (USD MILLION)

- TABLE 207 MALAYSIA: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2025-2030 (USD MILLION)

- TABLE 208 THAILAND: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2021-2024 (USD MILLION)

- TABLE 209 THAILAND: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2025-2030 (USD MILLION)

- TABLE 210 VIETNAM: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2021-2024 (USD MILLION)

- TABLE 211 VIETNAM: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2025-2030 (USD MILLION)

- TABLE 212 REST OF ASIA PACIFIC: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2021-2024 (USD MILLION)

- TABLE 213 REST OF ASIA PACIFIC: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2025-2030 (USD MILLION)

- TABLE 214 ROW: 3D PRINTING ROBOT MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 215 ROW: 3D PRINTING ROBOT MARKET, BY REGION, 2025-2030 (USD MILLION)

- TABLE 216 ROW: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2021-2024 (USD MILLION)

- TABLE 217 ROW: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2025-2030 (USD MILLION)

- TABLE 218 ROW: 3D PRINTING ROBOT MARKET, BY ROBOT TYPE, 2021-2024 (USD MILLION)

- TABLE 219 ROW: 3D PRINTING ROBOT MARKET, BY ROBOT TYPE, 2025-2030 (USD MILLION)

- TABLE 220 ROW: 3D PRINTING ROBOT MARKET, BY APPLICATION, 2021-2024 (USD MILLION)

- TABLE 221 ROW: 3D PRINTING ROBOT MARKET, BY APPLICATION, 2025-2030 (USD MILLION)

- TABLE 222 ROW: 3D PRINTING ROBOT MARKET, BY END-USE INDUSTRY, 2021-2024 (USD THOUSAND)

- TABLE 223 ROW: 3D PRINTING ROBOT MARKET, BY END-USE INDUSTRY, 2025-2030 (USD THOUSAND)

- TABLE 224 ROW: 3D PRINTING ROBOT MARKET FOR ROBOT ARMS, BY REGION, 2021-2024 (USD MILLION)

- TABLE 225 ROW: 3D PRINTING ROBOT MARKET FOR ROBOT ARMS, BY REGION, 2025-2030 (USD MILLION)

- TABLE 226 ROW: 3D PRINTING ROBOT MARKET FOR 3D PRINTING HEADS, BY REGION, 2021-2024 (USD MILLION)

- TABLE 227 ROW: 3D PRINTING ROBOT MARKET FOR 3D PRINTING HEADS, BY REGION, 2025-2030 (USD MILLION)

- TABLE 228 ROW: 3D PRINTING ROBOT MARKET FOR SOFTWARE, BY REGION, 2021-2024 (USD MILLION)

- TABLE 229 ROW: 3D PRINTING ROBOT MARKET FOR SOFTWARE, BY REGION, 2025-2030 (USD MILLION)

- TABLE 230 MIDDLE EAST: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2021-2024 (USD MILLION)

- TABLE 231 MIDDLE EAST: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2025-2030 (USD MILLION)

- TABLE 232 AFRICA: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2021-2024 (USD MILLION)

- TABLE 233 AFRICA: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2025-2030 (USD MILLION)

- TABLE 234 SOUTH AMERICA: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2021-2024 (USD MILLION)

- TABLE 235 SOUTH AMERICA: 3D PRINTING ROBOT MARKET, BY COMPONENT, 2025-2030 (USD MILLION)

- TABLE 236 MIDDLE EAST: 3D PRINTING ROBOT MARKET, BY COUNTRY, 2021-2024 (USD MILLION)

- TABLE 237 MIDDLE EAST: 3D PRINTING ROBOT MARKET, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 238 AFRICA: 3D PRINTING ROBOT MARKET, BY COUNTRY, 2021-2024 (USD MILLION)

- TABLE 239 AFRICA: 3D PRINTING ROBOT MARKET, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 240 AFRICA: 3D PRINTING ROBOT MARKET, BY COUNTRY, 2021-2024 (USD MILLION)

- TABLE 241 AFRICA: 3D PRINTING ROBOT MARKET, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 242 MIDDLE EAST: 3D PRINTING ROBOT MARKET, BY COUNTRY, 2021-2024 (USD MILLION)

- TABLE 243 MIDDLE EAST: 3D PRINTING ROBOT MARKET, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 244 OVERVIEW OF STRATEGIES ADOPTED BY 3D PRINTING ROBOT VENDORS, 2021-2025

- TABLE 245 3D PRINTING ROBOT MARKET SHARE ANALYSIS, 2024

- TABLE 246 3D PRINTING ROBOT MARKET: REGION FOOTPRINT

- TABLE 247 3D PRINTING ROBOT MARKET: COMPONENT FOOTPRINT

- TABLE 248 3D PRINTING ROBOT MARKET: ROBOT TYPE FOOTPRINT

- TABLE 249 3D PRINTING ROBOT MARKET: END-USE INDUSTRY FOOTPRINT

- TABLE 250 3D PRINTING ROBOT MARKET: LIST OF KEYS STARTUPS/SMES

- TABLE 251 3D PRINTING ROBOT MARKET: COMPETITIVE BENCHMARKING OF KEY STARTUPS/SMES

- TABLE 252 3D PRINTING ROBOT MARKET: PRODUCT LAUNCHES, JANUARY 2021-MAY 2025

- TABLE 253 3D PRINTING ROBOT MARKET: DEALS, JANUARY 2021-MAY 2025

- TABLE 254 KUKA AG: COMPANY OVERVIEW

- TABLE 255 KUKA AG: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 256 KUKA AG: DEALS

- TABLE 257 ABB: COMPANY OVERVIEW

- TABLE 258 ABB: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 259 ABB: PRODUCT LAUNCHES

- TABLE 260 ABB: DEALS

- TABLE 261 YASKAWA ELECTRIC CORPORATION: COMPANY OVERVIEW

- TABLE 262 YASKAWA ELECTRIC CORPORATION: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 263 YASKAWA ELECTRIC CORPORATION: DEALS

- TABLE 264 FANUC CORPORATION: COMPANY OVERVIEW

- TABLE 265 FANUC CORPORATION: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 266 FANUC CORPORATION: DEALS

- TABLE 267 UNIVERSAL ROBOTS A/S: COMPANY OVERVIEW

- TABLE 268 UNIVERSAL ROBOTS A/S: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 269 UNIVERSAL ROBOTS A/S: PRODUCT LAUNCHES

- TABLE 270 UNIVERSAL ROBOTS A/S: DEALS

- TABLE 271 MASSIVE DIMENSION: COMPANY OVERVIEW

- TABLE 272 MASSIVE DIMENSION: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 273 MASSIVE DIMENSION: PRODUCT LAUNCHES

- TABLE 274 MASSIVE DIMENSION: DEALS

- TABLE 275 CEAD B.V.: COMPANY OVERVIEW

- TABLE 276 CEAD B.V.: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 277 CEAD B.V.: PRODUCT LAUNCHES

- TABLE 278 CEAD B.V.: DEALS

- TABLE 279 CARACOL: COMPANY OVERVIEW

- TABLE 280 CARACOL: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 281 CARACOL: PRODUCT LAUNCHES

- TABLE 282 CARACOL: DEALS

- TABLE 283 WEBER MASCHINENFABRIK: COMPANY OVERVIEW

- TABLE 284 WEBER MASCHINENFABRIK: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 285 WEBER MASCHINENFABRIK: PRODUCT LAUNCHES

- TABLE 286 WEBER MASCHINENFABRIK: DEALS

- TABLE 287 MELTIO3D: COMPANY OVERVIEW

- TABLE 288 MELTIO3D: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 289 MELTIO3D: PRODUCT LAUNCHES

- TABLE 290 MELTIO3D: DEALS

- TABLE 291 COMAU: COMPANY OVERVIEW

- TABLE 292 COMAU: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 293 COMAU: DEALS

- TABLE 294 BAUBOT GMBH: COMPANY OVERVIEW

- TABLE 295 MX3D: COMPANY OVERVIEW

- TABLE 296 TWENTE ADDITIVE MANUFACTURING: COMPANY OVERVIEW

- TABLE 297 DOBOT: COMPANY OVERVIEW

- TABLE 298 DYZE DESIGN: COMPANY OVERVIEW

- TABLE 299 REV3RD S.R.L.: COMPANY OVERVIEW

- TABLE 300 ADAXIS SAS: COMPANY OVERVIEW

- TABLE 301 ORBITAL COMPOSITES INC.: COMPANY OVERVIEW

- TABLE 302 AI BUILD LIMITED: COMPANY OVERVIEW

- TABLE 303 INDUSUITE: COMPANY OVERVIEW

- TABLE 304 HYPERION ROBOTICS: COMPANY OVERVIEW

- TABLE 305 HYPERTHERM, INC.: COMPANY OVERVIEW

- TABLE 306 INGERSOLL MACHINE TOOLS, INC.: COMPANY OVERVIEW

- TABLE 307 3D MINERALS: COMPANY OVERVIEW

List of Figures

- FIGURE 1 3D PRINTING ROBOT MARKET SEGMENTATION AND REGIONAL SCOPE

- FIGURE 2 3D PRINTING ROBOT MARKET: RESEARCH DESIGN

- FIGURE 3 3D PRINTING ROBOT MARKET: RESEARCH FLOW OF MARKET SIZE ESTIMATION

- FIGURE 4 3D PRINTING ROBOT MARKET: SUPPLY-SIDE ANALYSIS

- FIGURE 5 3D PRINTING ROBOT MARKET: BOTTOM-UP APPROACH

- FIGURE 6 3D PRINTING ROBOT MARKET: TOP-DOWN APPROACH

- FIGURE 7 3D PRINTING ROBOT MARKET: DATA TRIANGULATION

- FIGURE 8 ROBOT ARMS TO ACCOUNT FOR LARGEST MARKET SHARE IN 2025

- FIGURE 9 ARTICULATED ROBOTS TO SECURE LARGEST MARKET SHARE IN 2025

- FIGURE 10 FUNCTIONAL PART MANUFACTURING APPLICATIONS TO MAINTAIN TOP POSITION IN 2025

- FIGURE 11 AEROSPACE & DEFENSE INDUSTRY TO DOMINATE MARKET IN 2025

- FIGURE 12 ASIA PACIFIC TO BE RAPIDLY EXPANDING MARKET DURING FORECAST PERIOD

- FIGURE 13 NORTH AMERICA TO HOLD LARGEST MARKET SHARE IN 2025

- FIGURE 14 GROWING FOCUS ON AUTOMATION AND PERSONALIZED MANUFACTURING, DRIVEN BY ADVANCEMENTS IN ROBOTIC ARMS, TO PROPEL MARKET

- FIGURE 15 AUTOMOTIVE INDUSTRY TO RECORD HIGHEST CAGR DURING FORECAST PERIOD

- FIGURE 16 SCARA ROBOTS TO REGISTER HIGHEST CAGR DURING FORECAST PERIOD

- FIGURE 17 FUNCTIONAL PART MANUFACTURING APPLICATIONS TO EXHIBIT HIGHEST CAGR FROM 2025 TO 2030

- FIGURE 18 ASIA PACIFIC TO WITNESS HIGHEST CAGR BETWEEN 2025 AND 2030

- FIGURE 19 CHINA TO EXHIBIT HIGHEST CAGR IN GLOBAL 3D PRINTING ROBOT MARKET DURING FORECAST PERIOD

- FIGURE 20 3D PRINTING ROBOT MARKET: DRIVERS, RESTRAINTS, OPPORTUNITIES, AND CHALLENGES

- FIGURE 21 IMPACT ANALYSIS: DRIVERS

- FIGURE 22 IMPACT ANALYSIS: RESTRAINTS

- FIGURE 23 IMPACT ANALYSIS: OPPORTUNITIES

- FIGURE 24 IMPACT ANALYSIS: CHALLENGES

- FIGURE 25 3D PRINTING ROBOT MARKET: PORTER'S FIVE FORCES ANALYSIS

- FIGURE 26 3D PRINTING ROBOT: ECOSYSTEM ANALYSIS

- FIGURE 27 3D PRINTING ROBOT MARKET: VALUE CHAIN ANALYSIS

- FIGURE 28 IMPORT SCENARIO FOR HS CODE 844311-COMPLIANT PRODUCTS IN TOP 5 COUNTRIES, 2020-2024

- FIGURE 29 EXPORT SCENARIO FOR HS CODE 844311-COMPLIANT PRODUCTS IN TOP 5 COUNTRIES, 2020-2024

- FIGURE 30 AVERAGE SELLING PRICE TREND OF ROBOT ARMS, BY REGION, 2021-2024

- FIGURE 31 AVERAGE SELLING PRICE TREND OF 3D PRINTING HEADS, BY REGION, 2021-2024

- FIGURE 32 3D PRINTING ROBOT MARKET: PATENT ANALYSIS, 2014-2024

- FIGURE 33 INFLUENCE OF STAKEHOLDERS ON BUYING PROCESS FOR TOP 3 END-USE INDUSTRIES

- FIGURE 34 KEY BUYING CRITERIA FOR TOP 3 END-USE INDUSTRIES

- FIGURE 35 INVESTMENT AND FUNDING SCENARIO, 2013-2024

- FIGURE 36 TRENDS/DISRUPTIONS INFLUENCING CUSTOMER BUSINESS

- FIGURE 37 ROBOT ARMS SEGMENT TO ACCOUNT FOR PROMINENT SHARE OF 3D PRINTING ROBOT MARKET IN 2025

- FIGURE 38 SCARA 3D PRINTING ROBOTS TO EXHIBIT HIGHEST CAGR FROM 2025 TO 2030

- FIGURE 39 FUNCTIONAL PART MANUFACTURING SEGMENT TO ACCOUNT FOR LARGEST MARKET SHARE IN 2030

- FIGURE 40 AUTOMOTIVE SEGMENT TO HOLD MAJORITY OF 3D PRINTING ROBOT MARKET SHARE IN 2030

- FIGURE 41 ASIA PACIFIC TO BE FASTEST-GROWING MARKET DURING FORECAST PERIOD

- FIGURE 42 NORTH AMERICA: 3D PRINTING ROBOT MARKET SNAPSHOT

- FIGURE 43 US TO DOMINATE NORTH AMERICAN MARKET THROUGHOUT FORECAST PERIOD

- FIGURE 44 EUROPE: 3D PRINTING ROBOT MARKET SNAPSHOT

- FIGURE 45 GERMANY TO BE FASTEST-GROWING MARKET IN EUROPE DURING FORECAST PERIOD

- FIGURE 46 ASIA PACIFIC: 3D PRINTING ROBOT MARKET SNAPSHOT

- FIGURE 47 CHINA TO LEAD 3D PRINTING ROBOT MARKET IN ASIA PACIFIC THROUGHOUT FORECAST PERIOD

- FIGURE 48 ROW: 3D PRINTING ROBOT MARKET SNAPSHOT

- FIGURE 49 SOUTH AMERICA TO CAPTURE LARGEST SHARE OF 3D PRINTING ROBOT MARKET IN ROW IN 2030

- FIGURE 50 REVENUE ANALYSIS OF KEY FIVE PLAYERS IN 3D PRINTING ROBOT MARKET, 2021-2024

- FIGURE 51 3D PRINTING ROBOT MARKET: SHARE OF KEY PLAYERS, 2024

- FIGURE 52 COMPANY VALUATION, 2025

- FIGURE 53 FINANCIAL METRICS (EV/EBITDA), 2025

- FIGURE 54 BRAND/PRODUCT COMPARISON

- FIGURE 55 3D PRINTING ROBOT MARKET: COMPETITIVE EVALUATION MATRIX (KEY PLAYERS), 2024

- FIGURE 56 3D PRINTING ROBOT MARKET: COMPANY FOOTPRINT

- FIGURE 57 3D PRINTING ROBOT MARKET: EVALUATION MATRIX (STARTUPS/SMES), 2024

- FIGURE 58 KUKA AG: COMPANY SNAPSHOT

- FIGURE 59 ABB: COMPANY SNAPSHOT

- FIGURE 60 YASKAWA ELECTRIC CORPORATION: COMPANY SNAPSHOT

- FIGURE 61 FANUC CORPORATION: COMPANY SNAPSHOT

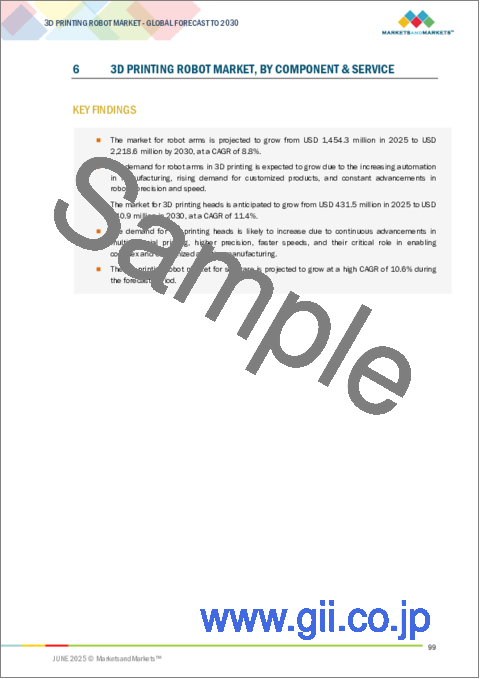

The global 3D printing robot market is anticipated to grow from USD 2.00 billion in 2025 to USD 3.14 billion by 2030, registering a CAGR of 9.5%.

| Scope of the Report | |

|---|---|

| Years Considered for the Study | 2020-2030 |

| Base Year | 2024 |

| Forecast Period | 2025-2030 |

| Units Considered | Value (USD Billion) |

| Segments | By Component & Service, Robot Type, Application and Region |

| Regions covered | North America, Europe, APAC, RoW |

The 3D printing robot market is expected to grow at a fast rate with the increasing adoption of automation and the escalating demand for customized, cost-optimized manufacturing solutions by various industries. Organizations are increasingly adopting robotic 3D printing systems to obtain complex shapes, reduce material waste, and optimize production cycles. The convergence of next-generation robots and additive manufacturing technology makes it possible to produce large-scale, high-precision, demand-based parts. Manufacturers of functional parts and providers of tooling and prototype services are transforming their operations by dramatically reducing lead times, enabling them to respond swiftly to market demands and deliver exceptional value to their clients. Additionally, the revolution in Industry 4.0 project design and the evolution of smart factories boost the adoption of robotic 3D printing technology, mainly in the aerospace, automotive, and construction industries. The market is subject to limitations, such as high upfront capital expenditures on robotic systems and additive manufacturing, which may discourage small and medium-sized businesses from adopting 3D printing robots. In addition, the absence of a skilled workforce to run and maintain complex robotic 3D printing equipment presents a major hurdle to mass adoption.

"Tooling segment, by application, is projected to record second-highest CAGR during forecast period"

Tooling applications are expected to exhibit the second-highest CAGR in the 3D printing robot market during the forecast period due to the growing need for rapid, cost-effective, and customized tool production across various industries, such as automotive, aerospace & defense, and construction. Traditional tooling methods are time-consuming and expensive, particularly for low-volume or complex parts. Robotic 3D printing significantly reduces lead times and minimizes waste, while enabling the production of complex geometries that are difficult to achieve through traditional methods. This technology is primarily used by the automotive, aerospace, and industrial equipment sectors for manufacturing jigs, fixtures, molds, and machining aids, providing greater flexibility and responsiveness in the manufacturing environment.

The ability of robotic arms to automate and optimize the manufacturing of tooling parts has increased their demand, especially in environments focused on mass customization and lean production. Additionally, advancements in high-performance materials and multi-axis robotic systems have expanded the range of tooling applications that can be achieved using 3D printing robots. As companies seek to reduce costs while improving productivity, the need for robotic 3D printing in tooling is expected to grow, making it one of the fastest-growing applications in the industry.

"Aerospace & defense segment to record second-largest market share in 2030"

The aerospace & defense sector is expected to hold the second-largest share of the 3D printing robot market, by end user, during the forecast period, due to its heavy focus on high-performance, lightweight, and complex pieces. The aerospace & defense industry is marked by high material expectations and low production levels, rendering traditional manufacturing less feasible. Additive manufacturing using robots easily addresses these challenges by providing scalability, customization, and consistent quality. Also, government investments in aerospace technology and defense weapon modernization in the US and Europe are driving the adoption of advanced manufacturing. As commercial and defense aerospace firms seek to reduce costs and lead times without compromising performance, robotic 3D printing emerges as a strategic solution, reinforcing the sector's growing market share.

"Cartesian robots are likely to account for significant market share in 2030"

Cartesian robots are likely to capture the second-largest share of the 3D printing robot market, by robot type, in 2030 due to their large number of industrial applications, accuracy, and design simplicity. These robots operate on three linear axes (X, Y, and Z), perfect for compliant, high-precision additive manufacturing processes. Additionally, they are suitable for producing large parts with reduced setup complexity. With the increasing demand for customizable and robust 3D printing systems in automotive, aerospace, and architecture sectors, Cartesian robots have emerged as a highly effective solution, delivering substantial output with exceptional precision. Their adaptability to integrate diverse 3D printing heads and materials enhances their appeal, positioning this segment for sustained high growth and significant market share throughout the forecasting period. The versatility and reliability of Cartesian robots align well with the evolving requirements of advanced manufacturing processes.

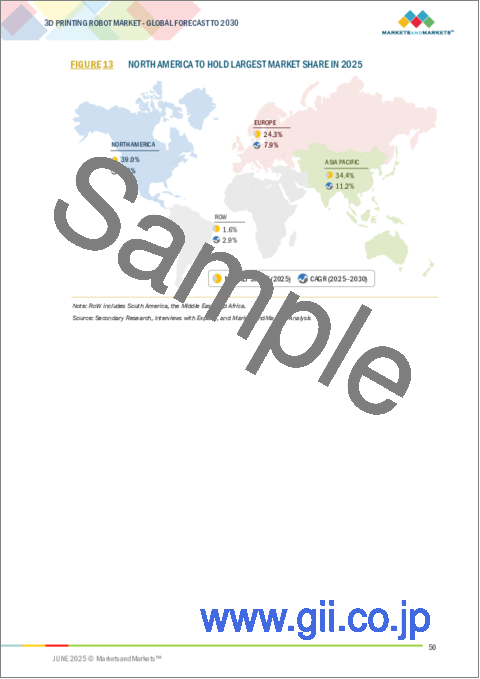

"North America to register highest CAGR in 3D printing robot market during forecast period"

North America is expected to witness a high compound annual growth rate (CAGR) in the 3D printing robot market during the forecast period due to its strong base in advanced manufacturing technologies, heavy investments in research and development, and early adoption of automation across various industries. Top players in the aerospace, automotive, healthcare, and construction sectors control the market, which is increasingly buying robotic 3D printing equipment to automate manufacturing, improve accuracy, and reduce material losses. The United States has a highly developed ecosystem of robotics suppliers, software companies committed to creating automation tools, and additive manufacturing startups, all of which together constitute an aggressive ecosystem that fosters innovation. In addition, supportive government policies, including those for smart manufacturing and defense modernization appropriations, further drive market growth. Lastly, North American university research centers and institutions actively engage in next-generation robotic 3D printing technology innovation, such as mobile and large-scale systems. The emphasis on sustainability and tailored solutions in manufacturing, particularly within the healthcare and construction industries, creates significant opportunities for on-site and mobile 3D printing robotics. With a favorable regulatory framework and increasing demand for high-performance components, North America is poised for substantial growth, leading to a robust CAGR during the forecast period.

Extensive primary interviews were conducted with key industry experts in the 3D printing robot market space to determine and verify the market size for various segments and subsegments gathered through secondary research. The breakdown of primary participants for the report is shown below.

The study contains insights from various industry experts, from component suppliers to Tier 1 companies and OEMs. The break-up of the primaries is as follows:

- By Company Type - Tier 1 - 60%, Tier 2 - 10%, and Tier 3 - 30%

- By Designation - C-level Executives - 10%, Directors - 30%, and Others - 60%

- By Region - Asia Pacific - 5%, Europe - 20%, North America - 70%, and RoW - 5%

Note: Other designations include technology heads, media analysts, sales managers, marketing managers, and product managers.

The three tiers of companies are based on their total revenues as of 2024: Tier 1 : >USD 1 billion, Tier 2: USD 500 million to 1 billion, and Tier 3: <USD 500 million.

- The 3D printing robot is dominated by a few globally established players, such ABB (Switzerland), KUKA AG (Germany), Yaskawa Electric Corporation (Japan), FANUC (Japan), Universal Robots A/S (Denmark), Massive Dimension (US), CEAD B.V. (Netherlands), Caracol (Italy), WEBER Maschinenfabrik (Germany), Meltio3D (Spain), Comau (Italy), Baubot (Austria), MX3D (US), Twente Additive Manufacturing (Netherlands), Dobot (China), Dyze Design (Canada), REV3RD (Italy), ADAXIS SAS (France), Orbital Composites Inc. (US), AI Build Limited (US), Octopuz (Canada), Hyperion Robotics (US), Hypertherm, Inc. (US), Ingersoll Machine Tools Inc. (US), 3D Minerals (France).

The study includes an in-depth competitive analysis of these key players in the 3D printing robot market, with their company profiles, recent developments, and key market strategies.

Research Coverage:

The report segments the 3D printing robot market. It forecasts its size by component & service (robot arms, 3D printing heads, software, service), robot type (articulated, Cartesian, SCARA, delta, polar, and other robot types that include collaborative, desktop printing, and cylindrical robots), application (prototyping, tooling, functional part manufacturing), and end user (automotive, FMCG, aerospace & defense, construction, culinary and other end users such as custom tooling, printed electronics, jewelery, energy, education, and shipbuilding). It also discusses the market's drivers, restraints, opportunities, and challenges. It gives a detailed view of the market across four main regions (North America, Europe, Asia Pacific, and RoW). The report includes an ecosystem analysis of key players.

Key Benefits of Buying the Report:

- Analysis of key drivers (increasing inclination toward automation and personalized manufacturing, advancements in robotic arms and additive manufacturing, elevating demand from aerospace & defense sector, restraints (high initial investment costs, .lack of skilled workforce), opportunities (expanding landscape of sustainable construction, emergence of mobile 3D printing robotics, growing trend toward adopting tailored solutions in healthcare to meet patient needs), challenges (complexities associated with system integration, durability and structural integrity concerns)

- Service Development/Innovation: Detailed insights on upcoming technologies, research and development activities, and new product launches in the 3D printing robot market

- Market Development: Comprehensive information about lucrative markets through the analysis of the 3D printing robot market across varied regions

- Market Diversification: Exhaustive information about new products and services, untapped geographies, recent developments, and investments in the 3D printing robot market

- Competitive Assessment: In-depth assessment of market shares, growth strategies, and service offerings of leading players, such as KUKA AG (Germany), ABB (Switzerland), Yaskawa Electric Corporation (Japan), FANUC Corporation (Japan), Universal Robots A/S (Denmark), Massive Dimension (US), CEAD B.V. (Netherlands), Caracol (Italy), WEBER Maschinenfabrik (Germany), Meltio3D (Spain), Comau (Italy), Baubot (Austria), MX3D (US), Twente Additive Manufacturing (TAM) (Netherlands), Dobot (China), among others.

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 STUDY OBJECTIVES

- 1.2 MARKET DEFINITION

- 1.3 STUDY SCOPE

- 1.3.1 MARKETS COVERED

- 1.3.2 INCLUSIONS AND EXCLUSIONS

- 1.3.3 YEARS CONSIDERED

- 1.4 CURRENCY CONSIDERED

- 1.5 UNIT CONSIDERED

- 1.6 LIMITATIONS

- 1.7 STAKEHOLDERS

- 1.8 SUMMARY OF CHANGES

2 RESEARCH METHODOLOGY

- 2.1 RESEARCH DATA

- 2.1.1 SECONDARY DATA

- 2.1.1.1 List of major secondary sources

- 2.1.1.2 Key data from secondary sources

- 2.1.2 PRIMARY DATA

- 2.1.2.1 List of primary interview participants

- 2.1.2.2 Breakdown of primaries

- 2.1.2.3 Key data from primary sources

- 2.1.2.4 Key industry insights

- 2.1.3 SECONDARY AND PRIMARY RESEARCH

- 2.1.1 SECONDARY DATA

- 2.2 MARKET SIZE ESTIMATION

- 2.2.1 BOTTOM-UP APPROACH

- 2.2.1.1 Approach to estimate market size using bottom-up analysis (demand side)

- 2.2.2 TOP-DOWN APPROACH

- 2.2.2.1 Approach to estimate market size using top-down analysis (supply side)

- 2.2.1 BOTTOM-UP APPROACH

- 2.3 MARKET BREAKDOWN AND DATA TRIANGULATION

- 2.4 RESEARCH ASSUMPTIONS

- 2.5 RESEARCH LIMITATIONS

- 2.6 RISK ASSESSMENT

3 EXECUTIVE SUMMARY

4 PREMIUM INSIGHTS

- 4.1 ATTRACTIVE OPPORTUNITIES FOR PLAYERS IN 3D PRINTING ROBOT MARKET

- 4.2 3D PRINTING ROBOT MARKET, BY END-USE INDUSTRY

- 4.3 3D PRINTING ROBOT MARKET, BY ROBOT TYPE

- 4.4 3D PRINTING ROBOT MARKET, BY APPLICATION

- 4.5 3D PRINTING ROBOT MARKET, BY REGION

- 4.6 3D PRINTING ROBOT MARKET, BY COUNTRY

5 MARKET OVERVIEW

- 5.1 INTRODUCTION

- 5.2 MARKET DYNAMICS

- 5.2.1 DRIVERS

- 5.2.1.1 Shift toward automation and personalized manufacturing

- 5.2.1.2 Advancements in robotic arms and additive manufacturing

- 5.2.1.3 High demand from aerospace & defense sector

- 5.2.2 RESTRAINTS

- 5.2.2.1 High initial investment costs

- 5.2.2.2 Lack of skilled workforce

- 5.2.3 OPPORTUNITIES

- 5.2.3.1 Focus of construction industry on sustainability

- 5.2.3.2 Emergence of mobile 3D printing robotic solutions

- 5.2.3.3 Need for customized healthcare products

- 5.2.4 CHALLENGES

- 5.2.4.1 Complexities associated with system integration

- 5.2.4.2 Concerns regarding durability and structural integrity

- 5.2.1 DRIVERS

- 5.3 PORTER'S FIVE FORCES ANALYSIS

- 5.4 ECOSYSTEM ANALYSIS

- 5.5 VALUE CHAIN ANALYSIS

- 5.6 REGULATORY LANDSCAPE

- 5.6.1 REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- 5.6.2 STANDARDS

- 5.6.2.1 North America

- 5.6.2.1.1 US-FDA 21 CFR Part 812

- 5.6.2.1.2 ANSI/RIA R15.06 - 2012

- 5.6.2.1.3 NFPA 70E

- 5.6.2.1.4 OSHA 29 CFR 1910.1030

- 5.6.2.1.5 OSHA 29 CFR 1910.147

- 5.6.2.2 Europe

- 5.6.2.2.1 Europe-CE (Conformity European)

- 5.6.2.2.2 EN ISO 10218-2:2011

- 5.6.2.2.3 IEC 61508

- 5.6.2.2.4 Low Voltage Directive 2014/35/EU

- 5.6.2.2.5 Electromagnetic Compatibility (EMC) Directive 2014/30/EU

- 5.6.2.3 Asia Pacific

- 5.6.2.3.1 China-MIIT (Ministry of Industry and Information Technology)

- 5.6.2.3.2 Japan-PMDA (Pharmaceuticals and Medical Devices Agency)

- 5.6.2.3.3 India-DGFT (Directorate General of Foreign Trade)

- 5.6.2.3.4 ISO 10218-2:2011

- 5.6.2.3.5 Chinese National Standard (CNS) 12706-1:2011

- 5.6.2.3.6 Japanese Industrial Standard (JIS) B8914

- 5.6.2.3.7 Chinese National Standard (CNS) 12706-1:2011

- 5.6.2.4 RoW

- 5.6.2.4.1 IEC 61508

- 5.6.2.1 North America

- 5.7 TRADE ANALYSIS

- 5.7.1 IMPORT DATA (HS CODE 844311)

- 5.7.2 EXPORT SCENARIO (HS CODE 844311)

- 5.8 PRICING ANALYSIS

- 5.8.1 AVERAGE SELLING PRICE OF 3D PRINTING ROBOT COMPONENTS, BY KEY PLAYER, 2024

- 5.8.1.1 Average selling price of robotic arms, by key player, 2024

- 5.8.1.2 Average selling price of 3D printing heads, by key player, 2024

- 5.8.2 PRICING RANGE OF 3D PRINTING ROBOTS, BY KEY PLAYER, 2024

- 5.8.3 AVERAGE SELLING PRICE TREND OF 3D PRINTING ROBOT COMPONENTS, BY REGION, 2021-2024

- 5.8.3.1 Average selling price trend of robot arms, by region, 2021-2024

- 5.8.3.2 Average selling price trend of 3D printing heads, by region, 2021-2024

- 5.8.1 AVERAGE SELLING PRICE OF 3D PRINTING ROBOT COMPONENTS, BY KEY PLAYER, 2024

- 5.9 TECHNOLOGY ANALYSIS

- 5.9.1 KEY TECHNOLOGIES

- 5.9.1.1 Selective lazer melting (SLM)

- 5.9.1.2 Fused deposition modelling (FDM)

- 5.9.1.3 Binder jetting

- 5.9.2 ADJACENT TECHNOLOGIES

- 5.9.2.1 Post-processing robotics

- 5.9.3 COMPLEMENTARY TECHNOLOGIES

- 5.9.3.1 AI for defect detection

- 5.9.3.2 Cloud integration

- 5.9.1 KEY TECHNOLOGIES

- 5.10 PATENT ANALYSIS

- 5.11 CASE STUDY ANALYSIS

- 5.11.1 ABB AND DRK COLLABORATE ON GERMANY'S FIRST 3D-PRINTED NON-RESIDENTIAL BUILDING

- 5.11.2 EPLUS3D DELIVERS BIOCOMPATIBLE PROSTHETICS THROUGH ADVANCED METAL 3D PRINTING

- 5.11.3 PROTOLABS ENHANCES DURABILITY AND FLEXIBILITY IN FARMING ROBOTS

- 5.11.4 YASKAWA EUROPE TRANSFORMS RTM INJECTION WITH ROBOTIC AUTOMATION

- 5.12 KEY STAKEHOLDERS AND BUYING CRITERIA

- 5.12.1 KEY STAKEHOLDERS IN BUYING PROCESS

- 5.12.2 BUYING CRITERIA

- 5.13 KEY CONFERENCES AND EVENTS, 2025-2026

- 5.14 INVESTMENT AND FUNDING SCENARIO, 2013-2024

- 5.15 TRENDS/DISRUPTIONS IMPACTING CUSTOMER BUSINESS

- 5.16 2025 US TARIFF IMPACT ANALYSIS

- 5.16.1 INTRODUCTION

- 5.16.2 KEY TARIFF RATES

- 5.16.3 IMPACT ON COUNTRY/REGION

- 5.16.3.1 US

- 5.16.3.2 Europe

- 5.16.3.3 Asia Pacific

- 5.16.4 IMPACT ON END-USE INDUSTRIES

- 5.16.4.1 Automotive

- 5.16.4.2 FMCG (Fast-Moving Consumer Goods)

- 5.16.4.3 Aerospace & defense

- 5.16.4.4 Construction

- 5.16.4.5 Culinary

- 5.17 IMPACT OF AI ON 3D PRINTING MARKET

6 3D PRINTING ROBOT MARKET, BY COMPONENT & SERVICE

- 6.1 INTRODUCTION

- 6.2 ROBOT ARMS

- 6.2.1 RISING USE OF ROBOT ARMS IN COMPLEX AND LARGE-SCALE 3D-PRINTED MODELS TO ACCELERATE MARKET GROWTH

- 6.3 3D PRINTING HEADS

- 6.3.1 INCREASING RELIANCE ON EFFICIENT 3D PRINTING HEADS FOR HIGH-THROUGHPUT OPERATIONS TO DRIVE MARKET

- 6.4 SOFTWARE

- 6.4.1 SURGING NEED FOR HIGHLY PRECISE, FLEXIBLE, AND EASY-TO-INTEGRATE ROBOTIC SOLUTIONS TO FUEL DEMAND

- 6.5 SERVICES

- 6.5.1 INTRODUCTION OF ROBOTICS-AS-A-SERVICE MODEL TO BOOST DEMAND

7 3D PRINTING ROBOT MARKET, BY ROBOT TYPE

- 7.1 INTRODUCTION

- 7.2 ARTICULATED

- 7.2.1 ABILITY TO PERFORM COMPLEX 3D PRINTING TASKS WITH PRECISION TO SPIKE DEMAND

- 7.3 CARTESIAN

- 7.3.1 HIGH SPEED, PRECISION, AND ADAPTABILITY FEATURES TO SPUR DEMAND

- 7.4 SCARA

- 7.4.1 COMPACT FOOTPRINT, EASE OF INTEGRATION, AND RAPID CYCLE TIMES TO SUPPORT MARKET GROWTH

- 7.5 POLAR

- 7.5.1 PROFICIENCY IN FABRICATING LARGE, COMPLEX GEOMETRIES TO DRIVE MARKET

- 7.6 DELTA

- 7.6.1 LOW MAINTENANCE, COST EFFICIENCY, AND COMPATIBILITY WITH VARIOUS MATERIALS TO FUEL SEGMENTAL GROWTH

- 7.7 OTHER ROBOT TYPES

8 3D PRINTING ROBOT MARKET, BY APPLICATION

- 8.1 INTRODUCTION

- 8.2 PROTOTYPING

- 8.2.1 RISING ADOPTION OF 3D PRINTING ROBOTS IN AUTOMOBILE AND AIRCRAFT PART PROTOTYPING TO ACCELERATE SEGMENTAL GROWTH

- 8.3 TOOLING

- 8.3.1 ADOPTION OF 3D PRINTING ROBOTS IN MANUFACTURING COMPLEX COMPONENTS AND TOOLS TO DRIVE MARKET

- 8.4 FUNCTIONAL PART MANUFACTURING

- 8.4.1 RELIANCE ON 3D PRINTING ROBOTS TO CREATE COMPLEX GEOMETRIES AND LOAD-BEARING PARTS TO PROPEL MARKET

9 3D PRINTING ROBOT MARKET, BY END-USE INDUSTRY

- 9.1 INTRODUCTION

- 9.2 AUTOMOTIVE

- 9.2.1 RISING FOCUS OF AUTOMOBILE COMPANIES ON INCREASING MANUFACTURING EFFICIENCY TO BOOST SEGMENTAL GROWTH

- 9.3 FMCG

- 9.3.1 FOCUS ON PROMOTING ENVIRONMENTAL SUSTAINABILITY TO BOOST DEMAND

- 9.4 AEROSPACE & DEFENSE

- 9.4.1 URGENT NEED TO REDUCE PRODUCTION TIME AND MINIMIZE MATERIAL WASTE TO FUEL MARKET GROWTH

- 9.5 CONSTRUCTION

- 9.5.1 GROWING INCLINATION TOWARD SUSTAINABLE CONSTRUCTION PRACTICES TO PROPEL MARKET

- 9.6 CULINARY

- 9.6.1 ELEVATING ADOPTION TO CRAFT INTRICATE DESSERTS AND PERSONALIZED CONFECTIONERY TO SUPPORT SEGMENTAL GROWTH

- 9.7 OTHER END-USE INDUSTRIES

10 3D PRINTING ROBOT MARKET, BY REGION

- 10.1 INTRODUCTION

- 10.2 NORTH AMERICA

- 10.2.1 MACROECONOMIC OUTLOOK FOR NORTH AMERICA

- 10.2.2 US

- 10.2.2.1 Rising focus on additive manufacturing projects to revolutionize industrial processes to foster market growth

- 10.2.3 CANADA

- 10.2.3.1 Surging adoption of 3D printing robots to develop lightweight, complex, and durable automobile parts to propel market

- 10.2.4 MEXICO

- 10.2.4.1 Government support for businesses leveraging 3D printing technology to drive market

- 10.3 EUROPE

- 10.3.1 MACROECONOMIC OUTLOOK FOR EUROPE

- 10.3.2 GERMANY

- 10.3.2.1 Increased adoption by automobile manufacturers to develop prototypes to drive market

- 10.3.3 UK

- 10.3.3.1 Substantial investments in advanced manufacturing technologies to support market growth

- 10.3.4 FRANCE

- 10.3.4.1 High construction costs and shortage of skilled labor to boost demand

- 10.3.5 ITALY

- 10.3.5.1 High intricacy of aerospace and defense systems to fuel demand

- 10.3.6 SPAIN

- 10.3.6.1 Surging demand for lightweight and complex automotive components by car manufacturers to foster market growth

- 10.3.7 POLAND

- 10.3.7.1 Labor shortage issue and significant focus on industrial innovation to create opportunities

- 10.3.8 NORDICS

- 10.3.8.1 Increasing defense budget to deploy additive manufacturing technologies to support market growth

- 10.3.9 REST OF EUROPE

- 10.4 ASIA PACIFIC

- 10.4.1 MACROECONOMIC OUTLOOK FOR ASIA PACIFIC

- 10.4.2 CHINA

- 10.4.2.1 Implementation of subsidies and tax breaks for R&D of 3D printing technologies to fuel market growth

- 10.4.3 SOUTH KOREA

- 10.4.3.1 Smart construction and manufacturing automation initiatives to spike demand

- 10.4.4 JAPAN

- 10.4.4.1 Substantial investments in additive manufacturing research and infrastructure to create growth opportunities

- 10.4.5 INDIA

- 10.4.5.1 Push toward Industry 4.0 and smart factory adoption to support market growth

- 10.4.6 AUSTRALIA

- 10.4.6.1 Rising adoption of digital technologies and additive manufacturing to contribute to market growth

- 10.4.7 INDONESIA

- 10.4.7.1 Thriving automotive, electronics, and construction sectors to favor market growth

- 10.4.8 MALAYSIA

- 10.4.8.1 Commitment to advancing aerospace manufacturing capabilities through digital transformation to propel market

- 10.4.9 THAILAND

- 10.4.9.1 Launch of Thailand 4.0 initiative and Eastern Economic Corridor (EEC) development project to support market growth

- 10.4.10 VIETNAM

- 10.4.10.1 Rising use of advanced manufacturing technologies due to rapid industrialization to fuel market growth

- 10.4.11 REST OF ASIA PACIFIC

- 10.5 ROW

- 10.5.1 MACROECONOMIC OUTLOOK FOR ROW

- 10.5.2 SOUTH AMERICA

- 10.5.2.1 Rising adoption of additive manufacturing in construction and industrial sectors to drive market

- 10.5.3 AFRICA

- 10.5.3.1 South Africa

- 10.5.3.1.1 Ongoing aerospace-related robotic additive manufacturing projects to spur demand

- 10.5.3.2 Other African countries

- 10.5.3.1 South Africa

- 10.5.4 MIDDLE EAST

- 10.5.4.1 Bahrain

- 10.5.4.1.1 Rising focus of construction companies on improving quality and reducing costs, time, and material waste to drive demand

- 10.5.4.2 Kuwait

- 10.5.4.2.1 Development of educational platform for robotics and embedded systems to support market growth

- 10.5.4.3 Oman

- 10.5.4.3.1 Launch of Oman AWTAD 3D Printing Educational Program to create opportunities for market players

- 10.5.4.4 Qatar

- 10.5.4.4.1 Emerging artistic applications of additive manufacturing to support market growth

- 10.5.4.5 Saudi Arabia

- 10.5.4.5.1 Necessity for efficient and cost-effective housing solutions in remote areas to boost adoption

- 10.5.4.6 UAE

- 10.5.4.6.1 Active promotion of 3D printing robotics among youth to expedite market growth

- 10.5.4.7 Rest of Middle East

- 10.5.4.1 Bahrain

11 COMPETITIVE LANDSCAPE

- 11.1 OVERVIEW

- 11.2 KEY PLAYER STRATEGIES/RIGHT TO WIN, 2021-2025

- 11.3 REVENUE ANALYSIS, 2021-2024

- 11.4 MARKET SHARE ANALYSIS, 2024

- 11.5 COMPANY VALUATION AND FINANCIAL METRICS, 2025

- 11.6 BRAND/PRODUCT COMPARISON

- 11.7 COMPANY EVALUATION MATRIX: KEY PLAYERS, 2024

- 11.7.1 STARS

- 11.7.2 EMERGING LEADERS

- 11.7.3 PERVASIVE PLAYERS

- 11.7.4 PARTICIPANTS

- 11.7.5 COMPANY FOOTPRINT: KEY PLAYERS, 2024

- 11.7.5.1 Company footprint

- 11.7.5.2 Region footprint

- 11.7.5.3 Component footprint

- 11.7.5.4 Robot type footprint

- 11.7.5.5 End-use industry footprint

- 11.8 COMPANY EVALUATION MATRIX: STARTUPS/SMES, 2024

- 11.8.1 PROGRESSIVE COMPANIES

- 11.8.2 RESPONSIVE COMPANIES

- 11.8.3 DYNAMIC COMPANIES

- 11.8.4 STARTING BLOCKS

- 11.8.5 COMPETITIVE BENCHMARKING: STARTUPS/SMES, 2024

- 11.8.5.1 Detailed list of key startups/SMEs

- 11.8.5.2 Competitive benchmarking of key startups/SMES

- 11.9 COMPETITIVE SCENARIO

- 11.9.1 PRODUCT LAUNCHES

- 11.9.2 DEALS

12 COMPANY PROFILES

- 12.1 KEY PLAYERS

- 12.1.1 KUKA AG

- 12.1.1.1 Business overview

- 12.1.1.2 Products/Solutions/Services offered

- 12.1.1.3 Recent developments

- 12.1.1.3.1 Deals

- 12.1.1.4 MnM view

- 12.1.1.4.1 Key strengths

- 12.1.1.4.2 Strategic choices

- 12.1.1.4.3 Weaknesses and competitive threats

- 12.1.2 ABB

- 12.1.2.1 Business overview

- 12.1.2.2 Products/Solutions/Services offered

- 12.1.2.3 Recent developments

- 12.1.2.3.1 Product launches

- 12.1.2.3.2 Deals

- 12.1.2.4 MnM view

- 12.1.2.4.1 Key strengths

- 12.1.2.4.2 Strategic choices

- 12.1.2.4.3 Weaknesses and competitive threats

- 12.1.3 YASKAWA ELECTRIC CORPORATION

- 12.1.3.1 Business overview

- 12.1.3.2 Products/Solutions/Services offered

- 12.1.3.3 Recent developments

- 12.1.3.3.1 Deals

- 12.1.3.4 MnM view

- 12.1.3.4.1 Key strengths

- 12.1.3.4.2 Strategic choices

- 12.1.3.4.3 Weaknesses and competitive threats

- 12.1.4 FANUC CORPORATION

- 12.1.4.1 Business overview

- 12.1.4.2 Products/Solutions/Services offered

- 12.1.4.3 Recent developments

- 12.1.4.3.1 Deals

- 12.1.4.4 MnM view

- 12.1.4.4.1 Key strengths

- 12.1.4.4.2 Strategic choices

- 12.1.4.4.3 Weaknesses and competitive threats

- 12.1.5 UNIVERSAL ROBOTS A/S

- 12.1.5.1 Business overview

- 12.1.5.2 Products/Solutions/Services offered

- 12.1.5.3 Recent developments

- 12.1.5.3.1 Product launches

- 12.1.5.3.2 Deals

- 12.1.5.4 MnM view

- 12.1.5.4.1 Key strengths

- 12.1.5.4.2 Strategic choices

- 12.1.5.4.3 Weaknesses and competitive threats

- 12.1.6 MASSIVE DIMENSION

- 12.1.6.1 Business overview

- 12.1.6.2 Products/Solutions/Services offered

- 12.1.6.3 Recent developments

- 12.1.7 CEAD B.V.

- 12.1.7.1 Business overview

- 12.1.7.2 Products/Solutions/Services offered

- 12.1.7.3 Recent developments

- 12.1.7.3.1 Product launches

- 12.1.7.3.2 Deals

- 12.1.8 CARACOL

- 12.1.8.1 Business overview

- 12.1.8.2 Products/Solutions/Services offered

- 12.1.8.3 Recent developments

- 12.1.8.3.1 Product launches

- 12.1.8.3.2 Deals

- 12.1.9 WEBER MASCHINENFABRIK

- 12.1.9.1 Business overview

- 12.1.9.2 Products/Solutions/Services offered

- 12.1.9.3 Recent developments

- 12.1.9.3.1 Product launches

- 12.1.9.3.2 Deals

- 12.1.10 MELTIO3D

- 12.1.10.1 Business overview

- 12.1.10.2 Products/Solutions/Services offered

- 12.1.10.3 Recent developments

- 12.1.10.3.1 Product launches

- 12.1.10.3.2 Deals

- 12.1.11 COMAU

- 12.1.11.1 Business overview

- 12.1.11.2 Products/Solutions/Services offered

- 12.1.11.3 Recent developments

- 12.1.11.3.1 Deals

- 12.1.1 KUKA AG

- 12.2 OTHER PLAYERS

- 12.2.1 BAUBOT GMBH

- 12.2.2 MX3D

- 12.2.3 TWENTE ADDITIVE MANUFACTURING

- 12.2.4 DOBOT

- 12.2.5 DYZE DESIGN

- 12.2.6 REV3RD S.R.L.

- 12.2.7 ADAXIS SAS

- 12.2.8 ORBITAL COMPOSITES INC.

- 12.2.9 AI BUILD LIMITED

- 12.2.10 OCTOPUZ INDUSUITE

- 12.2.11 HYPERION ROBOTICS

- 12.2.12 HYPERTHERM, INC.

- 12.2.13 INGERSOLL MACHINE TOOLS, INC.

- 12.2.14 3D MINERALS

13 APPENDIX

- 13.1 INSIGHTS FROM INDUSTRY EXPERTS

- 13.2 DISCUSSION GUIDE

- 13.3 KNOWLEDGESTORE: MARKETSANDMARKETS' SUBSCRIPTION PORTAL

- 13.4 CUSTOMIZATION OPTIONS

- 13.5 RELATED REPORTS

- 13.6 AUTHOR DETAILS