|

|

市場調査レポート

商品コード

1728608

ポリエーテルエーテルケトン(PEEK)の世界市場:強化タイプ別、エンドユーザー別、加工方法別、地域別 - 2030年までの予測PEEK Market by Reinforcement Type (Glass Filled, Carbon Filled, Unfilled), Processing Method (Extrusion, Injection Molding), End User (Electrical & Electronics, Aerospace, Automotive, Oil & Gas, Medical), and Region - Global Forecast to 2030 |

||||||

カスタマイズ可能

|

|||||||

| ポリエーテルエーテルケトン(PEEK)の世界市場:強化タイプ別、エンドユーザー別、加工方法別、地域別 - 2030年までの予測 |

|

出版日: 2025年05月08日

発行: MarketsandMarkets

ページ情報: 英文 232 Pages

納期: 即納可能

|

全表示

- 概要

- 図表

- 目次

世界のポリエーテルエーテルケトンの市場規模は、2025年の15億米ドルから2030年には21億4,000万米ドルに成長し、予測期間中のCAGRは7.5%と予測されています。

ポリエーテルエーテルケトン(PEEK)は、機械的強度、熱安定性、耐薬品性、生体適合性を兼ね備えた高性能の半結晶性熱可塑性ポリマーです。PEEKは、機械的強度、熱安定性、耐薬品性、生体適合性などの優れた特性を兼ね備えており、様々な産業分野で要求の厳しい用途に使用されています。PEEK市場は、主に航空宇宙や自動車分野での軽量、高強度材料への需要の増加、生体適合性による医療用インプラントでのPEEKの採用の増加、優れた電気絶縁特性によるエレクトロニクス業界でのPEEKの使用の拡大によって牽引されています。

| 調査範囲 | |

|---|---|

| 調査対象年 | 2021年~2030年 |

| 基準年 | 2024年 |

| 予測期間 | 2025年~2030年 |

| 検討単位 | 金額(100万米ドル)、数量(キロトン) |

| セグメント | 強化タイプ別、エンドユーザー別、加工方法別、地域別 |

| 対象地域 | 北米、アジア太平洋、欧州、中東・アフリカ、南米 |

カーボン充填PEEK(ポリエーテルエーテルケトン)は、強化された機械的特性と高性能能力のユニークな組み合わせにより、予測期間中、数量ベースで第2位のシェアを占めると予測されています。炭素充填PEEKは、優れた強度、剛性、耐摩耗性を備えており、高い応力や機械的負荷に耐える部品を必要とする用途に最適です。この強化素材は、航空宇宙、自動車、電子機器など、軽量で耐久性のある素材が性能と効率の向上に不可欠な産業において特に有益です。また、炭素繊維の添加により熱伝導性と寸法安定性が向上し、過酷な環境下での用途に不可欠です。さらに、炭素繊維入りPEEKは摩擦の低減と低熱膨張を示し、ベアリング、シール、構造部品などの部品に適しています。産業界が軽量化と効率向上を図りながら、より優れた性能を提供する先端材料に焦点を当て続けているため、カーボン充填PEEKの需要は大きく伸びると予想されます。このような需要の高まりは、様々なハイエンド用途におけるその汎用性と相まって、カーボン充填PEEKが予測期間中、市場で強い存在感と大きなシェアを維持することを位置づけています。

ポリエーテルエーテルケトン(PEEK)市場において、自動車分野が予測期間中、数量ベースで2番目に大きなシェアを占めると予測されています。これは主に、より厳しい環境規制を満たしつつ、車両性能を向上させることができる軽量で耐久性のある材料への需要が高まっているためです。高強度、耐熱性、寸法安定性といったPEEKの優れた特性は、過酷な条件下で高い性能を必要とする自動車部品にとって理想的な選択肢となっています。燃料システム部品、ベアリング、シール、コネクターなどの部品は、従来の自動車と電気自動車の両方で、PEEKの高温、高圧、腐食性の化学薬品に耐える能力の恩恵を受けています。自動車産業が燃費効率を優先し、排出ガスを削減し続ける中、より重い金属に代わるPEEKのような軽量材料のニーズが高まることが予想されます。さらに、電気自動車やハイブリッド車の採用が増加しており、最適なバッテリー効率と車両全体の性能のために高度な材料が要求されるため、自動車用途のPEEK市場はさらに強化されます。このセグメントは最大規模にはならないと予想されるが、高性能で軽量な部品に対する大きな需要があるため、市場において強い地位を維持し続け、PEEK産業全体の成長に貢献することが確実です。

ポリエーテルエーテルケトン(PEEK)市場は、航空宇宙、自動車、ヘルスケアを中心としたいくつかの主要産業において高性能材料への需要が高まっていることから、予測期間中、北米地域が数量ベースで第2位のシェアを占めると予測されています。この地域の強力な製造能力と技術の進歩により、優れた強度、耐熱性、化学的安定性を必要とする重要な用途でPEEKの採用が増加しています。航空宇宙分野では、PEEKの高温に耐える能力と軽量化ソリューションが、構造部品、ベアリング、シールなどの部品への需要を牽引しています。さらに、北米の自動車産業では、燃費を向上させ、厳しい排ガス規制を遵守する軽量部品の需要を満たすために、PEEKへの依存度が高まっています。特に米国のヘルスケア産業は、PEEKの生体適合性の高さから、手術用インプラント、医療機器、診断機器などに使用されており、これも市場に大きく貢献しています。さらに、北米は、確立されたPEEKサプライチェーンとハイテク製造を支援する有利な政府政策の恩恵を受けており、世界のPEEK市場における同地域の地位をさらに強固なものにしています。

当レポートでは、世界のポリエーテルエーテルケトン(PEEK)市場について調査し、強化タイプ別、エンドユーザー別、加工方法別、地域別動向、および市場に参入する企業のプロファイルなどをまとめています。

目次

第1章 イントロダクション

第2章 調査手法

第3章 エグゼクティブサマリー

第4章 重要考察

第5章 市場概要

- イントロダクション

- 市場力学

- 促進要因

- 抑制要因

- 機会

- 課題

第6章 業界動向

- マクロ経済見通し

- サプライチェーン分析

- エコシステム分析

- ポーターのファイブフォース分析

- 主要な利害関係者と購入基準

- 価格分析

- 関税と規制状況

- 2025年~2026年の主な会議とイベント

- 特許分析

- 技術分析

- ケーススタディ分析

- 貿易分析

- 顧客のビジネスに影響を与える動向と混乱

- 投資と資金調達のシナリオ

- 生成AIの影響

- 米国の2025年関税

第7章 PEEK市場(強化タイプ別)

- イントロダクション

- ガラス充填

- カーボン充填

- 未充填

- その他

第8章 PEEK市場(エンドユーザー別)

- イントロダクション

- 電気・電子工学

- 航空宇宙

- 自動車

- 石油・ガス

- 医療

- その他

第9章 PEEK市場(加工方法別)

- イントロダクション

- 押出

- 射出成形

- その他

第10章 PEEK市場(地域別)

- イントロダクション

- 北米

- 米国

- カナダ

- メキシコ

- アジア太平洋

- 中国

- 日本

- インド

- 韓国

- オーストラリアとニュージーランド

- その他

- 欧州

- ドイツ

- フランス

- 英国

- イタリア

- スペイン

- その他

- 中東・アフリカ

- GCC

- 南アフリカ

- その他

- 南米

- ブラジル

- チリ

- アルゼンチン

- その他

第11章 競合情勢

- イントロダクション

- 主要参入企業の戦略/強み、2020年~2024年

- 収益分析、2020年~2024年

- 市場シェア分析、2024年

- ブランド/製品比較

- 企業評価マトリックス:主要参入企業、2024年

- 企業評価マトリックス:スタートアップ/中小企業、2024年

- 企業評価と財務指標

- 競合シナリオ

第12章 企業プロファイル

- 主要参入企業

- VICTREX PLC.

- SYENSQO

- EVONIK INDUSTRIES AG

- JILIN JOINATURE POLYMER CO., LTD.

- JUNHUA

- MITSUBISHI CHEMICAL GROUP

- AVIENT CORPORATION

- SURLOINDIA

- J.K. OVERSEAS

- CALEDONIAN INDUSTRIES LIMITED

- RTP COMPANY

- WESTLAKE PLASTICS

- DRAKE PLASTICS

- AMERICHEM

- LATI INDUSTRIA TERMOPLASTICI S.P.A.

- LEHMANN&VOSS&CO.

- POLYMER INDUSTRIES

- TORAY PLASTICS PRECISION CO., LTD.

- TRIDENT PLASTICS INC.

- その他の企業

- BIEGLO GMBH

- ZIBO BAINAISI CHEMICAL CO., LTD

- PEEKCHINA

- ZHEJIANG PFLUON TECHNOLOGY CO., LTD.

- PERFECT POLYMERS

第13章 隣接市場と関連市場

第14章 付録

List of Tables

- TABLE 1 PEEK MARKET SNAPSHOT, 2025 VS. 2030

- TABLE 2 REAL GDP GROWTH (ANNUAL PERCENTAGE CHANGE), BY COUNTRY, 2021-2023 (%)

- TABLE 3 UNEMPLOYMENT RATE, BY COUNTRY, 2021-2023 (%)

- TABLE 4 INFLATION RATE AVERAGE CONSUMER PRICES, BY COUNTRY, 2021-2023 (%)

- TABLE 5 FOREIGN DIRECT INVESTMENT, BY REGION/COUNTRY, 2022-2023 (USD BILLION)

- TABLE 6 ROLE OF COMPANIES IN ECOSYSTEM

- TABLE 7 IMPACT OF PORTER'S FIVE FORCES ANALYSIS

- TABLE 8 INFLUENCE OF STAKEHOLDERS ON BUYING PROCESS TOP THREE END-USERS (%)

- TABLE 9 KEY BUYING CRITERIA FOR TOP THREE END-USERS

- TABLE 10 AVERAGE SELLING PRICE TREND OF PEEK, BY REGION, 2022-2024 (USD/TON)

- TABLE 11 AVERAGE SELLING PRICE OF UNFILLED PEEK OFFERED BY KEY PLAYERS, 2024 (USD/TON)

- TABLE 12 TARIFF ANALYSIS FOR HS CODE 290722-COMPLIANT PRODUCTS

- TABLE 13 NORTH AMERICA: REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 14 EUROPE: REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 15 ASIA PACIFIC: REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 16 KEY CONFERENCES AND EVENTS, 2025-2026

- TABLE 17 PATENT ANALYSIS

- TABLE 18 IMPORT DATA FOR HS CODE 290722-COMPLIANT PRODUCTS, BY COUNTRY, 2020-2024 (USD THOUSAND)

- TABLE 19 EXPORT DATA FOR HS CODE 290722-COMPLIANT PRODUCTS, BY COUNTRY, 2020-2024 (USD THOUSAND)

- TABLE 20 PEEK MARKET, BY REINFORCEMENT TYPE, 2021-2024 (KILOTON)

- TABLE 21 PEEK MARKET, BY REINFORCEMENT TYPE, 2025-2030 (KILOTON)

- TABLE 22 GLASS-FILLED: PEEK MARKET, BY REGION, 2021-2024 (KILOTON)

- TABLE 23 GLASS-FILLED: PEEK MARKET, BY REGION, 2025-2030 (KILOTON)

- TABLE 24 CARBON-FILLED: PEEK MARKET, BY REGION, 2021-2024 (KILOTON)

- TABLE 25 CARBON-FILLED: PEEK MARKET, BY REGION, 2025-2030 (KILOTON)

- TABLE 26 UNFILLED: PEEK MARKET, BY REGION, 2021-2024 (KILOTON)

- TABLE 27 UNFILLED: PEEK MARKET, BY REGION, 2025-2030 (KILOTON)

- TABLE 28 OTHER REINFORCEMENT TYPES: PEEK MARKET, BY REGION, 2021-2024 (KILOTON)

- TABLE 29 OTHER REINFORCEMENT TYPES: PEEK MARKET, BY REGION, 2025-2030 (KILOTON)

- TABLE 30 PEEK MARKET, BY END-USER, 2021-2024 (KILOTON)

- TABLE 31 PEEK MARKET, BY END-USER, 2025-2030 (KILOTON)

- TABLE 32 PEEK MARKET, BY END-USER, 2021-2024 (USD MILLION)

- TABLE 33 PEEK MARKET, BY END-USER, 2025-2030 (USD MILLION)

- TABLE 34 ELECTRICAL & ELECTRONICS: PEEK MARKET, BY REGION, 2021-2024 (KILOTON)

- TABLE 35 ELECTRICAL & ELECTRONICS: PEEK MARKET, BY REGION, 2025-2030 (KILOTON)

- TABLE 36 ELECTRICAL & ELECTRONICS: PEEK MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 37 ELECTRICAL & ELECTRONICS: PEEK MARKET, BY REGION, 2025-2030 (USD MILLION)

- TABLE 38 AEROSPACE: PEEK MARKET, BY REGION, 2021-2024 (KILOTON)

- TABLE 39 AEROSPACE: PEEK MARKET, BY REGION, 2025-2030 (KILOTON)

- TABLE 40 AEROSPACE: PEEK MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 41 AEROSPACE: PEEK MARKET, BY REGION, 2025-2030 (USD MILLION)

- TABLE 42 AUTOMOTIVE: PEEK MARKET, BY REGION, 2021-2024 (KILOTON)

- TABLE 43 AUTOMOTIVE: PEEK MARKET, BY REGION, 2025-2030 (KILOTON)

- TABLE 44 AUTOMOTIVE: PEEK MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 45 AUTOMOTIVE: PEEK MARKET, BY REGION, 2025-2030 (USD MILLION)

- TABLE 46 OIL & GAS: PEEK MARKET, BY REGION, 2021-2024 (KILOTON)

- TABLE 47 OIL & GAS: PEEK MARKET, BY REGION, 2025-2030 (KILOTON)

- TABLE 48 OIL & GAS: PEEK MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 49 OIL & GAS: PEEK MARKET, BY REGION, 2025-2030 (USD MILLION)

- TABLE 50 MEDICAL: PEEK MARKET, BY REGION, 2021-2024 (KILOTON)

- TABLE 51 MEDICAL: PEEK MARKET, BY REGION, 2025-2030 (KILOTON)

- TABLE 52 MEDICAL: PEEK MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 53 MEDICAL: PEEK MARKET, BY REGION, 2025-2030 (USD MILLION)

- TABLE 54 OTHER END-USERS: PEEK MARKET, BY REGION, 2021-2024 (KILOTON)

- TABLE 55 OTHER END-USERS: PEEK MARKET, BY REGION, 2025-2030 (KILOTON)

- TABLE 56 OTHER END-USERS: PEEK MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 57 OTHER END-USERS: PEEK MARKET, BY REGION, 2025-2030 (USD MILLION)

- TABLE 58 PEEK MARKET, BY REGION, 2021-2024 (KILOTON)

- TABLE 59 PEEK MARKET, BY REGION, 2025-2030 (KILOTON)

- TABLE 60 PEEK MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 61 PEEK MARKET, BY REGION, 2025-2030 (USD MILLION)

- TABLE 62 NORTH AMERICA: PEEK MARKET, BY COUNTRY, 2021-2024 (KILOTON)

- TABLE 63 NORTH AMERICA: PEEK MARKET, BY COUNTRY, 2025-2030 (KILOTON)

- TABLE 64 NORTH AMERICA: PEEK MARKET, BY COUNTRY, 2021-2024 (USD MILLION)

- TABLE 65 NORTH AMERICA: PEEK MARKET, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 66 NORTH AMERICA: PEEK MARKET, BY END-USER, 2021-2024 (KILOTON)

- TABLE 67 NORTH AMERICA: PEEK MARKET, BY END-USER, 2025-2030 (KILOTON)

- TABLE 68 NORTH AMERICA: PEEK MARKET, BY END-USER, 2021-2024 (USD MILLION)

- TABLE 69 NORTH AMERICA: PEEK MARKET, BY END-USER, 2025-2030 (USD MILLION)

- TABLE 70 NORTH AMERICA: PEEK MARKET, BY REINFORCEMENT TYPE, 2021-2024 (KILOTON)

- TABLE 71 NORTH AMERICA: PEEK MARKET, BY REINFORCEMENT TYPE, 2025-2030 (KILOTON)

- TABLE 72 US: PEEK MARKET, BY END-USER, 2021-2024 (KILOTON)

- TABLE 73 US: PEEK MARKET, BY END-USER, 2025-2030 (KILOTON)

- TABLE 74 US: PEEK MARKET, BY END-USER, 2021-2024 (USD MILLION)

- TABLE 75 US: PEEK MARKET, BY END-USER, 2025-2030 (USD MILLION)

- TABLE 76 CANADA: PEEK MARKET, BY END-USER, 2021-2024 (KILOTON)

- TABLE 77 CANADA: PEEK MARKET, BY END-USER, 2025-2030 (KILOTON)

- TABLE 78 CANADA: PEEK MARKET, BY END-USER, 2021-2024 (USD MILLION)

- TABLE 79 CANADA: PEEK MARKET, BY END-USER, 2025-2030 (USD MILLION)

- TABLE 80 MEXICO: PEEK MARKET, BY END-USER, 2021-2024 (KILOTON)

- TABLE 81 MEXICO: PEEK MARKET, BY END-USER, 2025-2030 (KILOTON)

- TABLE 82 MEXICO: PEEK MARKET, BY END-USER, 2021-2024 (USD MILLION)

- TABLE 83 MEXICO: PEEK MARKET, BY END-USER, 2025-2030 (USD MILLION)

- TABLE 84 ASIA PACIFIC: PEEK MARKET, BY COUNTRY, 2021-2024 (KILOTON)

- TABLE 85 ASIA PACIFIC: PEEK MARKET, BY COUNTRY, 2025-2030 (KILOTON)

- TABLE 86 ASIA PACIFIC: PEEK MARKET, BY COUNTRY, 2021-2024 (USD MILLION)

- TABLE 87 ASIA PACIFIC: PEEK MARKET, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 88 ASIA PACIFIC: PEEK MARKET, BY END-USER, 2021-2024 (KILOTON)

- TABLE 89 ASIA PACIFIC: PEEK MARKET, BY END-USER, 2025-2030 (KILOTON)

- TABLE 90 ASIA PACIFIC: PEEK MARKET, BY END-USER, 2021-2024 (USD MILLION)

- TABLE 91 ASIA PACIFIC: PEEK MARKET, BY END-USER, 2025-2030 (USD MILLION)

- TABLE 92 ASIA PACIFIC: PEEK MARKET, BY REINFORCEMENT TYPE, 2021-2024 (KILOTON)

- TABLE 93 ASIA PACIFIC: PEEK MARKET, BY REINFORCEMENT TYPE, 2025-2030 (KILOTON)

- TABLE 94 CHINA: PEEK MARKET, BY END-USER, 2021-2024 (KILOTON)

- TABLE 95 CHINA: PEEK MARKET, BY END-USER, 2025-2030 (KILOTON)

- TABLE 96 CHINA: PEEK MARKET, BY END-USER, 2021-2024 (USD MILLION)

- TABLE 97 CHINA: PEEK MARKET, BY END-USER, 2025-2030 (USD MILLION)

- TABLE 98 JAPAN: PEEK MARKET, BY END-USER, 2021-2024 (KILOTON)

- TABLE 99 JAPAN: PEEK MARKET, BY END-USER, 2025-2030 (KILOTON)

- TABLE 100 JAPAN: PEEK MARKET, BY END-USER, 2021-2024 (USD MILLION)

- TABLE 101 JAPAN: PEEK MARKET, BY END-USER, 2025-2030 (USD MILLION)

- TABLE 102 INDIA: PEEK MARKET, BY END-USER, 2021-2024 (KILOTON)

- TABLE 103 INDIA: PEEK MARKET, BY END-USER, 2025-2030 (KILOTON)

- TABLE 104 INDIA: PEEK MARKET, BY END-USER, 2021-2024 (USD MILLION)

- TABLE 105 INDIA: PEEK MARKET, BY END-USER, 2025-2030 (USD MILLION)

- TABLE 106 SOUTH KOREA: PEEK MARKET, BY END-USER, 2021-2024 (KILOTON)

- TABLE 107 SOUTH KOREA: PEEK MARKET, BY END-USER, 2025-2030 (KILOTON)

- TABLE 108 SOUTH KOREA: PEEK MARKET, BY END-USER, 2021-2024 (USD MILLION)

- TABLE 109 SOUTH KOREA: PEEK MARKET, BY END-USER, 2025-2030 (USD MILLION)

- TABLE 110 AUSTRALIA & NEW ZEALAND: PEEK MARKET, BY END-USER, 2021-2024 (KILOTON)

- TABLE 111 AUSTRALIA & NEW ZEALAND: PEEK MARKET, BY END-USER, 2025-2030 (KILOTON)

- TABLE 112 AUSTRALIA & NEW ZEALAND: PEEK MARKET, BY END-USER, 2021-2024 (USD MILLION)

- TABLE 113 AUSTRALIA & NEW ZEALAND: PEEK MARKET, BY END-USER, 2025-2030 (USD MILLION)

- TABLE 114 REST OF ASIA PACIFIC: PEEK MARKET, BY END-USER, 2021-2024 (KILOTON)

- TABLE 115 REST OF ASIA PACIFIC: PEEK MARKET, BY END-USER, 2025-2030 (KILOTON)

- TABLE 116 REST OF ASIA PACIFIC: PEEK MARKET, BY END-USER, 2021-2024 (USD MILLION)

- TABLE 117 REST OF ASIA PACIFIC: PEEK MARKET, BY END-USER, 2025-2030 (USD MILLION)

- TABLE 118 EUROPE: PEEK MARKET, BY COUNTRY, 2021-2024 (KILOTON)

- TABLE 119 EUROPE: PEEK MARKET, BY COUNTRY, 2025-2030 (KILOTON)

- TABLE 120 EUROPE: PEEK MARKET, BY COUNTRY, 2021-2024 (USD MILLION)

- TABLE 121 EUROPE: PEEK MARKET, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 122 EUROPE: PEEK MARKET, BY END-USER, 2021-2024 (KILOTON)

- TABLE 123 EUROPE: PEEK MARKET, BY END-USER, 2025-2030 (KILOTON)

- TABLE 124 EUROPE: PEEK MARKET, BY END-USER, 2021-2024 (USD MILLION)

- TABLE 125 EUROPE: PEEK MARKET, BY END-USER, 2025-2030 (USD MILLION)

- TABLE 126 EUROPE: PEEK MARKET, BY REINFORCEMENT TYPE, 2021-2024 (KILOTON)

- TABLE 127 EUROPE: PEEK MARKET, BY REINFORCEMENT TYPE, 2025-2030 (KILOTON)

- TABLE 128 GERMANY: PEEK MARKET, BY END-USER, 2021-2024 (KILOTON)

- TABLE 129 GERMANY: PEEK MARKET, BY END-USER, 2025-2030 (KILOTON)

- TABLE 130 GERMANY: PEEK MARKET, BY END-USER, 2021-2024 (USD MILLION)

- TABLE 131 GERMANY: PEEK MARKET, BY END-USER, 2025-2030 (USD MILLION)

- TABLE 132 FRANCE: PEEK MARKET, BY END-USER, 2021-2024 (KILOTON)

- TABLE 133 FRANCE: PEEK MARKET, BY END-USER, 2025-2030 (KILOTON)

- TABLE 134 FRANCE: PEEK MARKET, BY END-USER, 2021-2024 (USD MILLION)

- TABLE 135 FRANCE: PEEK MARKET, BY END-USER, 2025-2030 (USD MILLION)

- TABLE 136 UK: PEEK MARKET, BY END-USER, 2021-2024 (KILOTON)

- TABLE 137 UK: PEEK MARKET, BY END-USER, 2025-2030 (KILOTON)

- TABLE 138 UK: PEEK MARKET, BY END-USER, 2021-2024 (USD MILLION)

- TABLE 139 UK: PEEK MARKET, BY END-USER, 2025-2030 (USD MILLION)

- TABLE 140 ITALY: PEEK MARKET, BY END-USER, 2021-2024 (KILOTON)

- TABLE 141 ITALY: PEEK MARKET, BY END-USER, 2025-2030 (KILOTON)

- TABLE 142 ITALY: PEEK MARKET, BY END-USER, 2021-2024 (USD MILLION)

- TABLE 143 ITALY: PEEK MARKET, BY END-USER, 2025-2030 (USD MILLION)

- TABLE 144 SPAIN: PEEK MARKET, BY END-USER, 2021-2024 (KILOTON)

- TABLE 145 SPAIN: PEEK MARKET, BY END-USER, 2025-2030 (KILOTON)

- TABLE 146 SPAIN: PEEK MARKET, BY END-USER, 2021-2024 (USD MILLION)

- TABLE 147 SPAIN: PEEK MARKET, BY END-USER, 2025-2030 (USD MILLION)

- TABLE 148 REST OF EUROPE: PEEK MARKET, BY END-USER, 2021-2024 (KILOTON)

- TABLE 149 REST OF EUROPE: PEEK MARKET, BY END-USER, 2025-2030 (KILOTON)

- TABLE 150 REST OF EUROPE: PEEK MARKET, BY END-USER, 2021-2024 (USD MILLION)

- TABLE 151 REST OF EUROPE: PEEK MARKET, BY END-USER, 2025-2030 (USD MILLION)

- TABLE 152 MIDDLE EAST & AFRICA: PEEK MARKET, BY COUNTRY, 2021-2024 (KILOTON)

- TABLE 153 MIDDLE EAST & AFRICA: PEEK MARKET, BY COUNTRY, 2025-2030 (KILOTON)

- TABLE 154 MIDDLE EAST & AFRICA: PEEK MARKET, BY COUNTRY, 2021-2024 (USD MILLION)

- TABLE 155 MIDDLE EAST & AFRICA: PEEK MARKET, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 156 MIDDLE EAST & AFRICA: PEEK MARKET, BY END-USER, 2021-2024 (KILOTON)

- TABLE 157 MIDDLE EAST & AFRICA: PEEK MARKET, BY END-USER, 2025-2030 (KILOTON)

- TABLE 158 MIDDLE EAST & AFRICA: PEEK MARKET, BY END-USER, 2021-2024 (USD MILLION)

- TABLE 159 MIDDLE EAST & AFRICA: PEEK MARKET, BY END-USER, 2025-2030 (USD MILLION)

- TABLE 160 MIDDLE EAST & AFRICA: PEEK MARKET, BY REINFORCEMENT TYPE, 2021-2024 (KILOTON)

- TABLE 161 MIDDLE EAST & AFRICA: PEEK MARKET, BY REINFORCEMENT TYPE, 2025-2030 (KILOTON)

- TABLE 162 SAUDI ARABIA: PEEK MARKET, BY END-USER, 2021-2024 (KILOTON)

- TABLE 163 SAUDI ARABIA: PEEK MARKET, BY END-USER, 2025-2030 (KILOTON)

- TABLE 164 SAUDI ARABIA: PEEK MARKET, BY END-USER, 2021-2024 (USD MILLION)

- TABLE 165 SAUDI ARABIA: PEEK MARKET, BY END-USER, 2025-2030 (USD MILLION)

- TABLE 166 UAE: PEEK MARKET, BY END-USER, 2021-2024 (KILOTON)

- TABLE 167 UAE: PEEK MARKET, BY END-USER, 2025-2030 (KILOTON)

- TABLE 168 UAE: PEEK MARKET, BY END-USER, 2021-2024 (USD MILLION)

- TABLE 169 UAE: PEEK MARKET, BY END-USER, 2025-2030 (USD MILLION)

- TABLE 170 REST OF GCC: PEEK MARKET, BY END-USER, 2021-2024 (KILOTON)

- TABLE 171 REST OF GCC: PEEK MARKET, BY END-USER, 2025-2030 (KILOTON)

- TABLE 172 REST OF GCC: PEEK MARKET, BY END-USER, 2021-2024 (USD MILLION)

- TABLE 173 REST OF GCC: PEEK MARKET, BY END-USER, 2025-2030 (USD MILLION)

- TABLE 174 SOUTH AFRICA: PEEK MARKET, BY END-USER, 2021-2024 (KILOTON)

- TABLE 175 SOUTH AFRICA: PEEK MARKET, BY END-USER, 2025-2030 (KILOTON)

- TABLE 176 SOUTH AFRICA: PEEK MARKET, BY END-USER, 2021-2024 (USD MILLION)

- TABLE 177 SOUTH AFRICA: PEEK MARKET, BY END-USER, 2025-2030 (USD MILLION)

- TABLE 178 REST OF MIDDLE EAST & AFRICA: PEEK MARKET, BY END-USER, 2021-2024 (KILOTON)

- TABLE 179 REST OF MIDDLE EAST & AFRICA: PEEK MARKET, BY END-USER, 2025-2030 (KILOTON)

- TABLE 180 REST OF MIDDLE EAST & AFRICA: PEEK MARKET, BY END-USER, 2021-2024 (USD MILLION)

- TABLE 181 REST OF MIDDLE EAST & AFRICA: PEEK MARKET, BY END-USER, 2025-2030 (USD MILLION)

- TABLE 182 SOUTH AMERICA: PEEK MARKET, BY COUNTRY, 2021-2024 (KILOTON)

- TABLE 183 SOUTH AMERICA: PEEK MARKET, BY COUNTRY, 2025-2030 (KILOTON)

- TABLE 184 SOUTH AMERICA: PEEK MARKET, BY COUNTRY, 2021-2024 (USD MILLION)

- TABLE 185 SOUTH AMERICA: PEEK MARKET, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 186 SOUTH AMERICA: PEEK MARKET, BY END-USER, 2021-2024 (KILOTON)

- TABLE 187 SOUTH AMERICA: PEEK MARKET, BY END-USER, 2025-2030 (KILOTON)

- TABLE 188 SOUTH AMERICA: PEEK MARKET, BY END-USER, 2021-2024 (USD MILLION)

- TABLE 189 SOUTH AMERICA: PEEK MARKET, BY END-USER, 2025-2030 (USD MILLION)

- TABLE 190 SOUTH AMERICA: PEEK MARKET, BY REINFORCEMENT TYPE, 2021-2024 (KILOTON)

- TABLE 191 SOUTH AMERICA: PEEK MARKET, BY REINFORCEMENT TYPE, 2025-2030 (KILOTON)

- TABLE 192 BRAZIL: PEEK MARKET, BY END-USER, 2021-2024 (KILOTON)

- TABLE 193 BRAZIL: PEEK MARKET, BY END-USER, 2025-2030 (KILOTON)

- TABLE 194 BRAZIL: PEEK MARKET, BY END-USER, 2021-2024 (USD MILLION)

- TABLE 195 BRAZIL: PEEK MARKET, BY END-USER, 2025-2030 (USD MILLION)

- TABLE 196 CHILE: PEEK MARKET, BY END-USER, 2021-2024 (KILOTON)

- TABLE 197 CHILE: PEEK MARKET, BY END-USER, 2025-2030 (KILOTON)

- TABLE 198 CHILE: PEEK MARKET, BY END-USER, 2021-2024 (USD MILLION)

- TABLE 199 CHILE: PEEK MARKET, BY END-USER, 2025-2030 (USD MILLION)

- TABLE 200 ARGENTINA: PEEK MARKET, BY END-USER, 2021-2024 (KILOTON)

- TABLE 201 ARGENTINA: PEEK MARKET, BY END-USER, 2025-2030 (KILOTON)

- TABLE 202 ARGENTINA: PEEK MARKET, BY END-USER, 2021-2024 (USD MILLION)

- TABLE 203 ARGENTINA: PEEK MARKET, BY END-USER, 2025-2030 (USD MILLION)

- TABLE 204 REST OF SOUTH AMERICA: PEEK MARKET, BY END-USER, 2021-2024 (KILOTON)

- TABLE 205 REST OF SOUTH AMERICA: PEEK MARKET, BY END-USER, 2025-2030 (KILOTON)

- TABLE 206 REST OF SOUTH AMERICA: PEEK MARKET, BY END-USER, 2021-2024 (USD MILLION)

- TABLE 207 REST OF SOUTH AMERICA: PEEK MARKET, BY END-USER, 2025-2030 (USD MILLION)

- TABLE 208 KEY PLAYER STRATEGIES/RIGHT TO WIN, 2020-2024

- TABLE 209 MARKET SHARE ANALYSIS OF KEY PLAYERS, 2024

- TABLE 210 PRODUCTION CAPACITY OF MAJOR PLAYERS, 2024 (TONS)

- TABLE 211 REGION FOOTPRINT

- TABLE 212 REINFORCEMENT TYPE FOOTPRINT

- TABLE 213 END-USER FOOTPRINT

- TABLE 214 PROCESSING METHOD FOOTPRINT

- TABLE 215 POLYETHER ETHER KETONE MARKET: LIST OF START-UPS/SMES

- TABLE 216 COMPETITIVE BENCHMARKING OF START-UPS/SMES

- TABLE 217 PEEK MARKET: PRODUCT LAUNCHES, 2020-2025

- TABLE 218 PEEK MARKET: DEALS, 2020-2025

- TABLE 219 VICTREX PLC.: COMPANY OVERVIEW

- TABLE 220 VICTREX PLC.: PRODUCTS OFFERED

- TABLE 221 VICTREX PLC.: PRODUCT LAUNCHES

- TABLE 222 VICTREX PLC.: DEALS

- TABLE 223 SYENSQO: COMPANY OVERVIEW

- TABLE 224 SYENSQO: PRODUCTS OFFERED

- TABLE 225 SYENSQO: DEALS

- TABLE 226 EVONIK INDUSTRIES AG: COMPANY OVERVIEW

- TABLE 227 EVONIK INDUSTRIES AG: PRODUCTS OFFERED

- TABLE 228 EVONIK INDUSTRIES AG: PRODUCT LAUNCHES

- TABLE 229 EVONIK INDUSTRIES AG: DEALS

- TABLE 230 JILIN JOINATURE POLYMER CO., LTD.: COMPANY OVERVIEW

- TABLE 231 JILIN JOINATURE POLYMER CO., LTD.: PRODUCTS OFFERED

- TABLE 232 JUNHUA: COMPANY OVERVIEW

- TABLE 233 JUNHUA: PRODUCTS OFFERED

- TABLE 234 MITSUBISHI CHEMICAL GROUP: COMPANY OVERVIEW

- TABLE 235 MITSUBISHI CHEMICAL GROUP: PRODUCTS OFFERED

- TABLE 236 AVIENT CORPORATION: COMPANY OVERVIEW

- TABLE 237 AVIENT CORPORATION: PRODUCTS OFFERED

- TABLE 238 SURLOINDIA: COMPANY OVERVIEW

- TABLE 239 SURLOINDIA: PRODUCTS OFFERED

- TABLE 240 J.K. OVERSEAS: COMPANY OVERVIEW

- TABLE 241 J.K. OVERSEAS: PRODUCTS OFFERED

- TABLE 242 CALEDONIAN INDUSTRIES LIMITED: COMPANY OVERVIEW

- TABLE 243 CALEDONIAN INDUSTRIES LIMITED: PRODUCTS OFFERED

- TABLE 244 RTP COMPANY: COMPANY OVERVIEW

- TABLE 245 RTP COMPANY: PRODUCTS OFFERED

- TABLE 246 WESTLAKE PLASTICS: COMPANY OVERVIEW

- TABLE 247 WESTLAKE PLASTICS: PRODUCTS OFFERED

- TABLE 248 DRAKE PLASTICS: COMPANY OVERVIEW

- TABLE 249 DRAKE PLASTICS: PRODUCTS OFFERED

- TABLE 250 DRAKE PLASTICS: DEALS

- TABLE 251 AMERICHEM: COMPANY OVERVIEW

- TABLE 252 AMERICHEM: PRODUCTS OFFERED

- TABLE 253 LATI INDUSTRIA TERMOPLASTICI S.P.A.: COMPANY OVERVIEW

- TABLE 254 LATI INDUSTRIA TERMOPLASTICI S.P.A.: PRODUCTS OFFERED

- TABLE 255 LEHMANN&VOSS&CO.: COMPANY OVERVIEW

- TABLE 256 LEHMANN&VOSS&CO.: PRODUCTS OFFERED

- TABLE 257 POLYMER INDUSTRIES: COMPANY OVERVIEW

- TABLE 258 POLYMER INDUSTRIES: PRODUCTS OFFERED

- TABLE 259 TORAY PLASTICS PRECISION CO., LTD.: COMPANY OVERVIEW

- TABLE 260 TORAY PLASTICS PRECISION CO., LTD.: PRODUCTS OFFERED

- TABLE 261 TRIDENT PLASTICS INC.: COMPANY OVERVIEW

- TABLE 262 TRIDENT PLASTICS INC.: PRODUCTS OFFERED

- TABLE 263 BIEGLO GMBH: COMPANY OVERVIEW

- TABLE 264 ZIBO BAINAISI CHEMICAL CO., LTD: COMPANY OVERVIEW

- TABLE 265 PEEKCHINA: COMPANY OVERVIEW

- TABLE 266 ZHEJIANG PFLUON TECHNOLOGY CO., LTD.: COMPANY OVERVIEW

- TABLE 267 PERFECT POLYMERS: COMPANY OVERVIEW

- TABLE 268 PAEK MARKET, BY TYPE, 2019-2021 (TON)

- TABLE 269 PAEK MARKET, BY TYPE, 2022-2027 (TON)

- TABLE 270 PAEK MARKET, BY TYPE, 2019-2021 (USD MILLION)

- TABLE 271 PAEK MARKET, BY TYPE, 2022-2027 (USD MILLION)

- TABLE 272 PEEK MARKET, BY REGION, 2019-2021 (TON)

- TABLE 273 PEEK MARKET, BY REGION, 2022-2027 (TON)

- TABLE 274 PEEK MARKET, BY REGION, 2019-2021 (USD MILLION)

- TABLE 275 PEEK MARKET, BY REGION, 2022-2027 (USD MILLION)

- TABLE 276 PEK MARKET, BY REGION, 2019-2021 (TON)

- TABLE 277 PEK MARKET, BY REGION, 2022-2027 (TON)

- TABLE 278 PEK MARKET, BY REGION, 2019-2021 (USD MILLION)

- TABLE 279 PEK MARKET, BY REGION, 2022-2027 (USD MILLION)

- TABLE 280 PEKK MARKET, BY REGION, 2019-2021 (TON)

- TABLE 281 PEKK MARKET, BY REGION, 2022-2027 (TON)

- TABLE 282 PEKK MARKET, BY REGION, 2019-2021 (USD MILLION)

- TABLE 283 PEKK MARKET, BY REGION, 2022-2027 (USD MILLION)

List of Figures

- FIGURE 1 PEEK MARKET SEGMENTATION

- FIGURE 2 RESEARCH DESIGN

- FIGURE 3 BOTTOM-UP APPROACH

- FIGURE 4 TOP-DOWN APPROACH

- FIGURE 5 METHODOLOGY FOR SUPPLY-SIDE SIZING OF PEEK MARKET (1/2)

- FIGURE 6 METHODOLOGY FOR SUPPLY-SIDE SIZING OF PEEK MARKET (2/2)

- FIGURE 7 DATA TRIANGULATION

- FIGURE 8 ELECTRICAL & ELECTRONICS TO BE LARGEST SEGMENT DURING FORECAST PERIOD

- FIGURE 9 ASIA PACIFIC TO BE FASTEST-GROWING MARKET FOR PEEK DURING FORECAST PERIOD

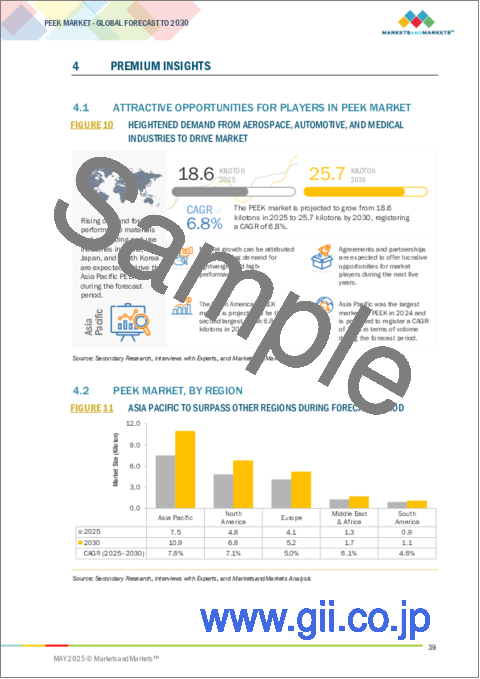

- FIGURE 10 HEIGHTENED DEMAND FROM AEROSPACE, AUTOMOTIVE, AND MEDICAL INDUSTRIES TO DRIVE MARKET

- FIGURE 11 ASIA PACIFIC TO SURPASS OTHER REGIONS DURING FORECAST PERIOD

- FIGURE 12 GLASS-FILLED SEGMENT TO EXHIBIT FASTEST GROWTH DURING FORECAST PERIOD

- FIGURE 13 ELECTRICAL & ELECTRONICS SEGMENT TO SECURE LEADING POSITION DURING FORECAST PERIOD

- FIGURE 14 CHINA TO REGISTER HIGHEST CAGR DURING FORECAST PERIOD

- FIGURE 15 PEEK MARKET DYNAMICS

- FIGURE 16 CARS MANUFACTURED, 2022 VS. 2024

- FIGURE 17 GLOBAL BATTERY ELECTRIC VEHICLE SALES, 2021 VS. 2023

- FIGURE 18 SUPPLY CHAIN ANALYSIS

- FIGURE 19 ECOSYSTEM ANALYSIS

- FIGURE 20 PORTER'S FIVE FORCES ANALYSIS

- FIGURE 21 INFLUENCE OF STAKEHOLDERS ON BUYING PROCESS FOR TOP THREE END-USERS

- FIGURE 22 KEY BUYING CRITERIA FOR TOP THREE END-USERS

- FIGURE 23 AVERAGE SELLING PRICE TREND OF PEEK, BY REGION, 2022-2024 (USD/TON)

- FIGURE 24 PATENT ANALYSIS

- FIGURE 25 IMPORT DATA FOR HS CODE 290722-COMPLIANT PRODUCTS, BY COUNTRY, 2020-2024 (USD THOUSAND)

- FIGURE 26 EXPORT DATA FOR HS CODE 290722-COMPLIANT PRODUCTS, BY COUNTRY, 2020-2024 (USD THOUSAND)

- FIGURE 27 TRENDS AND DISRUPTIONS IMPACTING CUSTOMER BUSINESS

- FIGURE 28 INVESTMENT AND FUNDING SCENARIO, 2020-2024

- FIGURE 29 PEEK MARKET, BY REINFORCEMENT TYPE, 2025-2030 (KILOTON)

- FIGURE 30 PEEK MARKET, BY END-USER, 2025-2030 (USD MILLION)

- FIGURE 31 PEEK MARKET, BY REGION, 2025-2030 (USD MILLION)

- FIGURE 32 NORTH AMERICA: PEEK MARKET SNAPSHOT

- FIGURE 33 ASIA PACIFIC: PEEK MARKET SNAPSHOT

- FIGURE 34 EUROPE: PEEK MARKET SNAPSHOT

- FIGURE 35 REVENUE ANALYSIS OF TOP FOUR PLAYERS, 2020-2024

- FIGURE 36 MARKET SHARE ANALYSIS OF KEY PLAYERS, 2024

- FIGURE 37 BRAND/PRODUCT COMPARISON

- FIGURE 38 COMPANY EVALUATION MATRIX (KEY PLAYERS), 2024

- FIGURE 39 COMPANY FOOTPRINT

- FIGURE 40 COMPANY EVALUATION MATRIX (START-UPS/SMES), 2024

- FIGURE 41 EV/EBITDA OF PEEK MANUFACTURERS

- FIGURE 42 VALUATION OF PEEK MANUFACTURERS (USD BILLION)

- FIGURE 43 YEAR-TO-DATE (YTD) PRICE TOTAL RETURN AND FIVE-YEAR STOCK BETA OF PEEK MANUFACTURERS

- FIGURE 44 VICTREX PLC.: COMPANY SNAPSHOT

- FIGURE 45 SYENSQO: COMPANY SNAPSHOT

- FIGURE 46 EVONIK INDUSTRIES AG: COMPANY SNAPSHOT

- FIGURE 47 JILIN JOINATURE POLYMER CO., LTD.: COMPANY SNAPSHOT

- FIGURE 48 MITSUBISHI CHEMICAL GROUP: COMPANY SNAPSHOT

- FIGURE 49 AVIENT CORPORATION: COMPANY SNAPSHOT

The global polyether ether ketone market is projected to grow from USD 1.50 billion in 2025 to USD 2.14 billion by 2030, at a CAGR of 7.5% during the forecast period. Polyether ether ketone (PEEK) is a high-performance, semi-crystalline thermoplastic polymer renowned for its exceptional combination of mechanical strength, thermal stability, chemical resistance, and biocompatibility. These properties make it a sought-after material in demanding applications across diverse industries. The PEEK market is primarily driven by the increasing demand for lightweight, high-strength materials in the aerospace and automotive sectors, the rising adoption of PEEK in medical implants due to its biocompatibility, and the expanding use of PEEK in the electronics industry for its excellent electrical insulation properties.

| Scope of the Report | |

|---|---|

| Years Considered for the Study | 2021-2030 |

| Base Year | 2024 |

| Forecast Period | 2025-2030 |

| Units Considered | Value (USD Million), Volume (Kilotons) |

| Segments | Reinforcement Type and End-use Industry |

| Regions covered | North America, Asia Pacific, Europe, Middle East & Africa, and South America |

"The carbon-filled PEEK segment, by reinforcement type, is estimated to account for the second- largest share during the forecast period."

Carbon-filled PEEK (Polyether Ether Ketone) is expected to account for the second-largest share of the market in terms of volume during the forecast period due to its unique combination of enhanced mechanical properties and high-performance capabilities. Carbon-filled PEEK offers superior strength, stiffness, and wear resistance, making it ideal for applications that require components to withstand high stress and mechanical loads. This reinforced material is particularly beneficial in industries such as aerospace, automotive, and electronics, where lightweight and durable materials are essential for improving performance and efficiency. The addition of carbon fibers also enhances its thermal conductivity and dimensional stability, which are critical for applications in harsh environments. Moreover, carbon-filled PEEK exhibits reduced friction and lower thermal expansion, making it suitable for components such as bearings, seals, and structural parts. As industries continue to focus on advanced materials that offer better performance while reducing weight and improving efficiency, the demand for carbon-filled PEEK is expected to grow significantly. This growing demand, combined with its versatility across various high-end applications, positions carbon-filled PEEK to maintain a strong market presence and a substantial share during the forecast period.

"By end user, the automotive segment accounted for the second-largest share during the forecast period."

The automotive segment is expected to account for the second-largest share of the polyether ether ketone (PEEK) market in terms of volume during the forecast period, primarily due to its growing demand for lightweight, durable materials that can enhance vehicle performance while meeting stricter environmental regulations. PEEK's remarkable properties, such as high strength, heat resistance, and dimensional stability, make it an ideal choice for automotive components that require high performance under extreme conditions. Components such as fuel system parts, bearings, seals, and connectors in both conventional and electric vehicles benefit from PEEK's ability to withstand high temperatures, pressures, and aggressive chemicals. As the automotive industry continues to prioritize fuel efficiency and reduce emissions, the need for lightweight materials like PEEK to replace heavier metals is expected to rise. Moreover, the increasing adoption of electric and hybrid vehicles, which demand advanced materials for optimal battery efficiency and overall vehicle performance, further strengthens the market for PEEK in automotive applications. While the segment is not expected to be the largest, its significant demand for high-performance, lightweight components ensures that it will continue to hold a strong position in the market, contributing to overall growth in the PEEK industry.

"North America region is estimated to account for the second largest share during the forecast period."

The North American region is expected to account for the second-largest share of the polyether ether ketone (PEEK) market in terms of volume during the forecast period, driven by the growing demand for high-performance materials across several key industries, particularly aerospace, automotive, and healthcare. The region's strong manufacturing capabilities and technological advancements have led to an increased adoption of PEEK in critical applications that require superior strength, heat resistance, and chemical stability. In the aerospace sector, PEEK's ability to withstand high temperatures and provide lightweight solutions is driving its demand for components such as structural parts, bearings, and seals. Additionally, the automotive industry in North America is increasingly relying on PEEK to meet the demand for lightweight components that improve fuel efficiency and comply with stringent emission regulations. The healthcare industry, particularly in the U.S., is another significant contributor to the market, with PEEK being used in surgical implants, medical devices, and diagnostic equipment due to its biocompatibility. Furthermore, North America benefits from a well-established PEEK supply chain and favorable government policies supporting high-tech manufacturing, further solidifying the region's position in the global PEEK market.

Profile break-up of primary participants for the report:

- By Company Type: Tier 1 - 65%, Tier 2 - 20%, and Tier 3 - 15%

- By Designation: Directors- 25%, Managers- 30%, and Others - 45%

- By Region: North America - 30%, Asia Pacific - 40%, Europe - 20%, Middle East & Africa - 7%, and South America - 3%

Victrex Plc. (UK), Syensqo (Belgium), Evonik Industries AG (Germany), Jilin Joinature Polymer Co., Ltd. (China), and Junhua (China) are some of the major players operating in the polyether ether ketone market. These players have adopted partnerships, agreements, and product launches to increase their market share business revenue.

Research Coverage:

The report defines, segments, and projects the polyether ether ketone market based on reinforcement type, end user, processing method, and region. It provides detailed information regarding the major factors influencing the market's growth, such as drivers, restraints, opportunities, and challenges. It strategically profiles polyether ether ketone manufacturers, comprehensively analyzing their market shares and core competencies, and tracks and analyzes competitive developments, such as partnerships, , agreements, product launches, and joint ventures.

Reasons to Buy the Report:

The report is expected to help the market leaders/new entrants by providing them with the closest approximations of revenue numbers of the polyether ether ketone market and its segments. This report is also expected to help stakeholders obtain an improved understanding of the market's competitive landscape, gain insights to improve the position of their businesses and make suitable go-to-market strategies. It also enables stakeholders to understand the market's pulse and provides information on key market drivers, restraints, challenges, and opportunities.

The report provides insights on the following pointers:

- Analysis of critical drivers (growing demand for lightweight and high-performance materials, and rising demand across various end-use industries), restraints (availability of substitute polymers), opportunities (expanding applications in healthcare industry, and the ability of peek to act as a substitute to metal), and challenges (manufacturing and processing complexities) influencing the growth of the polyether ether ketone market.

- Product Development/Innovation: Detailed insights on upcoming technologies, research & development activities in the polyether ether ketone market.

- Market Development: Comprehensive information about lucrative markets - the report analyses the polyether ether ketone market across varied regions.

- Market Diversification: Exhaustive information about new products, various types, untapped geographies, recent developments, and investments in the polyether ether ketone market.

- Competitive Assessment: In-depth assessment of market shares, growth strategies, and product offerings of leading players such as Victrex Plc. (UK), Syensqo (Belgium), Evonik Industries AG (Germany), Jilin Joinature Polymer Co., Ltd. (China), and Junhua (China), and others in the polyether ether ketone market.

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 STUDY OBJECTIVES

- 1.2 MARKET DEFINITION

- 1.3 STUDY SCOPE

- 1.3.1 MARKETS COVERED AND REGIONAL SCOPE

- 1.3.2 INCLUSIONS AND EXCLUSIONS

- 1.3.3 YEARS CONSIDERED

- 1.4 CURRENCY CONSIDERED

- 1.5 UNIT CONSIDERED

- 1.6 STAKEHOLDERS

- 1.7 SUMMARY OF CHANGES

2 RESEARCH METHODOLOGY

- 2.1 RESEARCH DATA

- 2.1.1 SECONDARY DATA

- 2.1.1.1 Key data from secondary sources

- 2.1.2 PRIMARY DATA

- 2.1.2.1 Primary insights

- 2.1.2.2 Breakdown of primary interviews

- 2.1.1 SECONDARY DATA

- 2.2 MATRIX FOR DEMAND-SIDE ANALYSIS

- 2.3 MARKET SIZE ESTIMATION

- 2.3.1 BOTTOM-UP APPROACH

- 2.3.2 TOP-DOWN APPROACH

- 2.3.2.1 Calculations for supply-side analysis

- 2.4 GROWTH FORECAST

- 2.5 DATA TRIANGULATION

- 2.6 RESEARCH ASSUMPTIONS

- 2.7 RESEARCH LIMITATIONS

- 2.8 RISK ASSESSMENT

3 EXECUTIVE SUMMARY

4 PREMIUM INSIGHTS

- 4.1 ATTRACTIVE OPPORTUNITIES FOR PLAYERS IN PEEK MARKET

- 4.2 PEEK MARKET, BY REGION

- 4.3 PEEK MARKET, BY REINFORCEMENT TYPE

- 4.4 PEEK MARKET, BY END-USER

- 4.5 PEEK MARKET, BY COUNTRY

5 MARKET OVERVIEW

- 5.1 INTRODUCTION

- 5.2 MARKET DYNAMICS

- 5.2.1 DRIVERS

- 5.2.1.1 Elevated demand from diverse end-use industries

- 5.2.2 RESTRAINTS

- 5.2.2.1 Availability of substitute polymers

- 5.2.3 OPPORTUNITIES

- 5.2.3.1 Expanding applications in healthcare

- 5.2.3.2 Potential substitute for metals

- 5.2.4 CHALLENGES

- 5.2.4.1 Manufacturing and processing complexities

- 5.2.1 DRIVERS

6 INDUSTRY TRENDS

- 6.1 MACROECONOMIC OUTLOOK

- 6.1.1 GDP

- 6.1.2 R&D EXPENDITURE

- 6.2 SUPPLY CHAIN ANALYSIS

- 6.3 ECOSYSTEM ANALYSIS

- 6.4 PORTER'S FIVE FORCES ANALYSIS

- 6.4.1 BARGAINING POWER OF SUPPLIERS

- 6.4.2 BARGAINING POWER OF BUYERS

- 6.4.3 THREAT OF NEW ENTRANTS

- 6.4.4 THREAT OF SUBSTITUTES

- 6.4.5 INTENSITY OF COMPETITIVE RIVALRY

- 6.5 KEY STAKEHOLDERS AND BUYING CRITERIA

- 6.5.1 KEY STAKEHOLDERS IN BUYING PROCESS

- 6.5.2 BUYING CRITERIA

- 6.6 PRICING ANALYSIS

- 6.6.1 AVERAGE SELLING PRICE TREND, BY REGION

- 6.6.2 AVERAGE SELLING PRICE OF UNFILLED PEEK OFFERED BY KEY PLAYERS

- 6.7 TARIFF AND REGULATORY LANDSCAPE

- 6.7.1 TARIFF ANALYSIS

- 6.7.2 REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- 6.8 KEY CONFERENCES AND EVENTS, 2025-2026

- 6.9 PATENT ANALYSIS

- 6.10 TECHNOLOGY ANALYSIS

- 6.10.1 KEY TECHNOLOGIES

- 6.10.1.1 Biocompatible PEEK

- 6.10.2 ADJACENT TECHNOLOGIES

- 6.10.2.1 Polyetherketoneketone (PEKK)

- 6.10.1 KEY TECHNOLOGIES

- 6.11 CASE STUDY ANALYSIS

- 6.11.1 REDUCING COSTS AND ENHANCING EFFICIENCY WITH VICTREX PEEK IN AEROSPACE COMPONENTS

- 6.11.2 INNOVATING PACKING TECHNOLOGY WITH NEXRING MADE FROM VICTREX PEEK

- 6.12 TRADE ANALYSIS

- 6.12.1 IMPORT SCENARIO (HS CODE 290722)

- 6.12.2 EXPORT SCENARIO (HS CODE 290722)

- 6.13 TRENDS AND DISRUPTIONS IMPACTING CUSTOMER BUSINESS

- 6.14 INVESTMENT AND FUNDING SCENARIO

- 6.15 IMPACT OF GENERATIVE AI

- 6.15.1 INTRODUCTION

- 6.15.2 MATERIAL INNOVATION AND CUSTOMIZATION

- 6.15.3 PROCESS OPTIMIZATION

- 6.15.4 DEMAND FORECASTING

- 6.16 US 2025 TARIFF

- 6.16.1 KEY TARIFF RATES

- 6.16.2 PRICE IMPACT ANALYSIS

- 6.16.3 IMPACT ON VARIOUS REGIONS

- 6.16.3.1 US

- 6.16.3.2 Europe

- 6.16.3.3 Asia Pacific

- 6.16.4 IMPACT ON END-USE INDUSTRIES

- 6.16.4.1 Electrical & Electronics

- 6.16.4.2 Aerospace

- 6.16.4.3 Automotive

- 6.16.4.4 Medical

- 6.16.4.5 Oil & Gas

7 PEEK MARKET, BY REINFORCEMENT TYPE

- 7.1 INTRODUCTION

- 7.2 GLASS-FILLED

- 7.2.1 EXTENSIVE USE IN AEROSPACE, AUTOMOTIVE, AND ELECTRICAL INDUSTRIES DUE TO HIGH STRENGTH AND THERMAL STABILITY

- 7.3 CARBON-FILLED

- 7.3.1 FLEXURAL AND TENSILE STRENGTH SPUR ADOPTION IN HIGH-PERFORMANCE APPLICATIONS

- 7.4 UNFILLED

- 7.4.1 OPTIMAL MECHANICAL, THERMAL, AND CHEMICAL PROPERTIES BOOST USAGE

- 7.5 OTHER REINFORCEMENT TYPES

8 PEEK MARKET, BY END-USER

- 8.1 INTRODUCTION

- 8.2 ELECTRICAL & ELECTRONICS

- 8.2.1 SURGE IN DEMAND FOR MINIATURIZED, HIGH-EFFICIENCY, AND HIGH-RELIABILITY ELECTRIC COMPONENTS

- 8.3 AEROSPACE

- 8.3.1 NEED TO COMPLY WITH STRINGENT FLAMMABILITY STANDARDS IN AVIATION

- 8.4 AUTOMOTIVE

- 8.4.1 TREND OF SUSTAINABILITY AND ADVANCED MOBILITY

- 8.5 OIL & GAS

- 8.5.1 INCREASED PREFERENCE DUE TO NON-CORROSIVE NATURE, LIGHT WEIGHT, AND LONG SERVICE LIFE

- 8.6 MEDICAL

- 8.6.1 HIGH DEMAND FOR BIOCOMPATIBLE, DURABLE, AND STERILIZABLE MATERIALS

- 8.7 OTHER END-USERS

9 PEEK MARKET, BY PROCESSING METHOD

- 9.1 INTRODUCTION

- 9.2 EXTRUSION

- 9.3 INJECTION MOLDING

- 9.4 OTHER PROCESSING METHODS

10 PEEK MARKET, BY REGION

- 10.1 INTRODUCTION

- 10.2 NORTH AMERICA

- 10.2.1 US

- 10.2.1.1 Strong demand from multiple industries to drive market

- 10.2.2 CANADA

- 10.2.2.1 Robust automotive and aerospace industries to drive market

- 10.2.3 MEXICO

- 10.2.3.1 Concentration of OEMs and auto parts suppliers to drive market

- 10.2.1 US

- 10.3 ASIA PACIFIC

- 10.3.1 CHINA

- 10.3.1.1 Growing automotive industry to drive market

- 10.3.2 JAPAN

- 10.3.2.1 Advanced manufacturing capabilities and robust industrial base to drive market

- 10.3.3 INDIA

- 10.3.3.1 Favorable government policies to drive market

- 10.3.4 SOUTH KOREA

- 10.3.4.1 Surplus demand across high-growth industries to drive market

- 10.3.5 AUSTRALIA & NEW ZEALAND

- 10.3.5.1 Focus on sustainable manufacturing practices to drive market

- 10.3.6 REST OF ASIA PACIFIC

- 10.3.1 CHINA

- 10.4 EUROPE

- 10.4.1 GERMANY

- 10.4.1.1 Strong automotive manufacturing and assembly capabilities to drive market

- 10.4.2 FRANCE

- 10.4.2.1 Substantial investments in healthcare innovation to drive market

- 10.4.3 UK

- 10.4.3.1 Heightened vehicle production to drive market

- 10.4.4 ITALY

- 10.4.4.1 Need for high-performance materials in oil & gas industry to drive market

- 10.4.5 SPAIN

- 10.4.5.1 Rise in defense modernization and oil exports to drive market

- 10.4.6 REST OF EUROPE

- 10.4.1 GERMANY

- 10.5 MIDDLE EAST & AFRICA

- 10.5.1 GCC

- 10.5.1.1 Saudi Arabia

- 10.5.1.1.1 Emerging mobility platforms to drive market

- 10.5.1.2 UAE

- 10.5.1.2.1 Expansion of oil production infrastructure to drive market

- 10.5.1.3 Rest of GCC

- 10.5.1.1 Saudi Arabia

- 10.5.2 SOUTH AFRICA

- 10.5.2.1 Advancements in automotive, aerospace, and defense industries to drive market

- 10.5.3 REST OF MIDDLE EAST & AFRICA

- 10.5.1 GCC

- 10.6 SOUTH AMERICA

- 10.6.1 BRAZIL

- 10.6.1.1 Booming automotive industry to drive market

- 10.6.2 CHILE

- 10.6.2.1 Shift toward electric vehicles to drive market

- 10.6.3 ARGENTINA

- 10.6.3.1 Government's push for innovation and technology transfer to drive market

- 10.6.4 REST OF SOUTH AMERICA

- 10.6.1 BRAZIL

11 COMPETITIVE LANDSCAPE

- 11.1 INTRODUCTION

- 11.2 KEY PLAYER STRATEGIES/RIGHT TO WIN, 2020-2024

- 11.3 REVENUE ANALYSIS, 2020-2024

- 11.4 MARKET SHARE ANALYSIS, 2024

- 11.5 BRAND/PRODUCT COMPARISON

- 11.6 COMPANY EVALUATION MATRIX: KEY PLAYERS, 2024

- 11.6.1 STARS

- 11.6.2 EMERGING LEADERS

- 11.6.3 PERVASIVE PLAYERS

- 11.6.4 PARTICIPANTS

- 11.6.4.1 Company footprint

- 11.6.4.2 Region footprint

- 11.6.4.3 Reinforcement type footprint

- 11.6.4.4 End-user footprint

- 11.6.4.5 Processing method footprint

- 11.7 COMPANY EVALUATION MATRIX: START-UPS/SMES, 2024

- 11.7.1 PROGRESSIVE COMPANIES

- 11.7.2 RESPONSIVE COMPANIES

- 11.7.3 DYNAMIC COMPANIES

- 11.7.4 STARTING BLOCKS

- 11.7.5 COMPETITIVE BENCHMARKING

- 11.7.5.1 List of start-ups/SMEs

- 11.7.5.2 Competitive benchmarking of start-ups/SMEs

- 11.8 COMPANY VALUATION AND FINANCIAL METRICS

- 11.9 COMPETITIVE SCENARIO

- 11.9.1 PRODUCT LAUNCHES

- 11.9.2 DEALS

12 COMPANY PROFILES

- 12.1 KEY PLAYERS

- 12.1.1 VICTREX PLC.

- 12.1.1.1 Business overview

- 12.1.1.2 Products offered

- 12.1.1.3 Recent developments

- 12.1.1.3.1 Product launches

- 12.1.1.3.2 Deals

- 12.1.1.4 MnM view

- 12.1.1.4.1 Right to win

- 12.1.1.4.2 Strategic choices

- 12.1.1.4.3 Weaknesses and competitive threats

- 12.1.2 SYENSQO

- 12.1.2.1 Business overview

- 12.1.2.2 Products offered

- 12.1.2.3 Recent developments

- 12.1.2.3.1 Deals

- 12.1.2.4 MnM view

- 12.1.2.4.1 Right to win

- 12.1.2.4.2 Strategic choices

- 12.1.2.4.3 Weaknesses and competitive threats

- 12.1.3 EVONIK INDUSTRIES AG

- 12.1.3.1 Business overview

- 12.1.3.2 Products offered

- 12.1.3.3 Recent developments

- 12.1.3.3.1 Product launches

- 12.1.3.3.2 Deals

- 12.1.3.4 MnM view

- 12.1.3.4.1 Right to win

- 12.1.3.4.2 Strategic choices

- 12.1.3.4.3 Weaknesses and competitive threats

- 12.1.4 JILIN JOINATURE POLYMER CO., LTD.

- 12.1.4.1 Business overview

- 12.1.4.2 Products offered

- 12.1.4.3 MnM view

- 12.1.4.3.1 Right to win

- 12.1.4.3.2 Strategic choices

- 12.1.4.3.3 Weaknesses and competitive threats

- 12.1.5 JUNHUA

- 12.1.5.1 Business overview

- 12.1.5.2 Products offered

- 12.1.5.3 MnM view

- 12.1.5.3.1 Right to win

- 12.1.5.3.2 Strategic choices

- 12.1.5.3.3 Weaknesses and competitive threats

- 12.1.6 MITSUBISHI CHEMICAL GROUP

- 12.1.6.1 Business overview

- 12.1.6.2 Products offered

- 12.1.7 AVIENT CORPORATION

- 12.1.7.1 Business overview

- 12.1.7.2 Products offered

- 12.1.8 SURLOINDIA

- 12.1.8.1 Business overview

- 12.1.8.2 Products offered

- 12.1.9 J.K. OVERSEAS

- 12.1.9.1 Business overview

- 12.1.9.2 Products offered

- 12.1.10 CALEDONIAN INDUSTRIES LIMITED

- 12.1.10.1 Business overview

- 12.1.10.2 Products offered

- 12.1.11 RTP COMPANY

- 12.1.11.1 Business overview

- 12.1.11.2 Products offered

- 12.1.12 WESTLAKE PLASTICS

- 12.1.12.1 Business overview

- 12.1.12.2 Products offered

- 12.1.13 DRAKE PLASTICS

- 12.1.13.1 Business overview

- 12.1.13.2 Products offered

- 12.1.13.3 Recent developments

- 12.1.13.3.1 Deals

- 12.1.14 AMERICHEM

- 12.1.14.1 Business overview

- 12.1.14.2 Products offered

- 12.1.15 LATI INDUSTRIA TERMOPLASTICI S.P.A.

- 12.1.15.1 Business overview

- 12.1.15.2 Products offered

- 12.1.16 LEHMANN&VOSS&CO.

- 12.1.16.1 Business overview

- 12.1.16.2 Products offered

- 12.1.17 POLYMER INDUSTRIES

- 12.1.17.1 Business overview

- 12.1.17.2 Products offered

- 12.1.18 TORAY PLASTICS PRECISION CO., LTD.

- 12.1.18.1 Business overview

- 12.1.18.2 Products offered

- 12.1.19 TRIDENT PLASTICS INC.

- 12.1.19.1 Business overview

- 12.1.19.2 Products offered

- 12.1.1 VICTREX PLC.

- 12.2 OTHER PLAYERS

- 12.2.1 BIEGLO GMBH

- 12.2.2 ZIBO BAINAISI CHEMICAL CO., LTD

- 12.2.3 PEEKCHINA

- 12.2.4 ZHEJIANG PFLUON TECHNOLOGY CO., LTD.

- 12.2.5 PERFECT POLYMERS

13 ADJACENT AND RELATED MARKETS

- 13.1 INTRODUCTION

- 13.2 LIMITATIONS

- 13.3 INTERCONNECTED MARKETS

- 13.4 POLYARYLETHERKETONE (PAEK) MARKET

- 13.4.1 MARKET DEFINITION

- 13.4.2 MARKET OVERVIEW

- 13.4.3 POLYARYLETHERKETONE (PAEK) MARKET, BY TYPE

14 APPENDIX

- 14.1 DISCUSSION GUIDE

- 14.2 KNOWLEDGESTORE: MARKETSANDMARKETS' SUBSCRIPTION PORTAL

- 14.3 CUSTOMIZATION OPTIONS

- 14.4 RELATED REPORTS

- 14.5 AUTHOR DETAILS