|

|

市場調査レポート

商品コード

1803651

真空部品市場:製品タイプ、材料タイプ、用途、エンドユーザー産業、流通チャネル別-2025-2030年世界予測Vacuum Components Market by Product Type, Material Type, Application, End-User Industry, Distribution Channel - Global Forecast 2025-2030 |

||||||

カスタマイズ可能

適宜更新あり

|

|||||||

| 真空部品市場:製品タイプ、材料タイプ、用途、エンドユーザー産業、流通チャネル別-2025-2030年世界予測 |

|

出版日: 2025年08月28日

発行: 360iResearch

ページ情報: 英文 181 Pages

納期: 即日から翌営業日

|

全表示

- 概要

- 図表

- 目次

真空部品市場は、2024年には168億8,000万米ドルとなり、2025年には180億2,000万米ドル、CAGR6.93%で成長し、2030年には252億4,000万米ドルに達すると予測されています。

| 主な市場の統計 | |

|---|---|

| 基準年2024 | 168億8,000万米ドル |

| 推定年2025 | 180億2,000万米ドル |

| 予測年2030 | 252億4,000万米ドル |

| CAGR(%) | 6.93% |

重要な市場促進要因、破壊的イノベーション、戦略的インパータンスを捉えた真空部品市場の権威あるイントロダクション

真空コンポーネントは、さまざまな産業および研究用途において、制御された低圧環境を実現するために不可欠な設計要素です。これらの精密機器は、高度な半導体製造から分析機器に至るプロセスをサポートし、厳しい条件下で信頼できる性能と一貫した成果を保証します。過去10年間、絶え間ない材料革新と小型化の動向は、性能の閾値を高め、実験精度を向上させる一方で、操作面積を縮小してきました。

業界の軌道を形成する真空コンポーネント技術のサプライチェーンと競争ダイナミクスの変容を探る

近年、真空コンポーネント技術と市場力学のパラダイムシフトが起こり、企業は従来の設計と調達の枠組みを再評価する必要に迫られています。高性能ポリマーや特殊合金などの先端材料の普及は、より軽量で耐久性の高いチャンバーアセンブリを可能にし、積層造形技術はプロトタイピングサイクルを加速し、リードタイムを短縮しています。その結果、最終用途産業は設計をより迅速に反復し、資本支出を抑えながら優れた真空性能を達成することができます。

米国の新関税が2025年の真空コンポーネントサプライチェーンの調達コストと競争力に与える総合的な影響の評価

2025年、重要な真空部品の輸入に対する米国の関税強化の導入は、業界の利害関係者に多面的な圧力を及ぼしています。高精度ゲージや特殊ポンプアセンブリのコスト構造は上方修正され、メーカーはサプライヤーのポートフォリオを見直し、ニアショアリングの選択肢を検討せざるを得なくなりました。輸入関税が陸揚げコストを上昇させたため、半導体や研究部門の川下企業は、場合によってはスケジュールの延長やコスト・パススルー戦略を余儀なくされるような業務支出の増加の連鎖に直面しました。

製品タイプ、材料、用途、業界、流通チャネルにまたがる重要な洞察を明らかにする詳細なセグメンテーション分析

徹底的なセグメンテーション分析により、製品タイプ、材料カテゴリー、アプリケーション領域、エンドユーザー業界、流通チャネルにまたがる明確な成長軌道と競合情勢が明らかになりました。製品面では、チャンバーが制御環境システムの基本であることに変わりはなく、カップリング、フランジ、シールから成る継手分野は、モジュラーシステム統合に対する需要の高まりから恩恵を受けています。キャパシタンス、イオナイゼーション、ピラニなど、強化されたゲージ技術は、圧力差に関する重要な洞察を提供し、精密なモニタリング・ソリューションへの投資を促進しています。ダイアフラム、ドライ、ロータリーベーン、スクロール、ターボ分子設計を含むポンプセグメントは、高スループットアプリケーションがオイルフリーやハイブリッドポンプメカニズムを選択するようになっているため、差別化された採用率を経験しています。ボール、バタフライ、ゲートなどのバルブアーキテクチャも同様に、自動化されたプロセスシーケンスと高速サイクルタイムをサポートするために進化しています。

南北アメリカ、中東アフリカ、アジア太平洋地域の市場力学と成長パターンを発表

地域別分析では、南北アメリカ、中東・アフリカ、アジア太平洋地域で、成長の原動力と戦略的要請が異なることが明らかになりました。南北アメリカは引き続き強い内需と成熟した産業基盤、特に半導体製造拠点と研究機関を活用しています。北米のプレーヤーは確立されたサプライチェーンの恩恵を受けているが、地域の低コスト生産者との競争激化に直面しており、リーダーシップを維持するためには自動化と先端材料への継続的な投資が必要です。

世界的な競争優位と戦略的パートナーシップを推進する主要真空部品メーカーと新規参入企業のプロファイリング

真空部品分野の主要企業は、技術リーダーシップ、戦略的パートナーシップ、対象地域の拡大を通じて差別化を図っています。いくつかの既存企業は研究開発への投資を強化し、次世代メンブレン素材や予測診断用センサーの統合に注力しています。学術機関や研究コンソーシアムとの協力関係は、新奇な材料科学のブレークスルーを商業グレードのコンポーネントに変換することを加速しています。

行動可能な戦略的提言新興技術と進化する市場機会を活用するために業界リーダーを強化します

業界リーダーは、デジタルツインと予測分析を真空コンポーネントの設計とメンテナンスのワークフローに統合し、優れた稼働時間と性能を達成することを優先すべきです。リアルタイムモニタリングの枠組みを確立することで、組織は先手を打って異常を検出し、メンテナンススケジュールを最適化することができます。

定性的インタビュー量的データ分析と競合ベンチマーキングを組み合わせた包括的な多段階調査手法

本分析を支える調査手法は、専門家による定性的インタビュー、包括的な2次データレビュー、定量的データ分析を組み合わせた多段階アプローチを採用しました。最初に、メーカー、システムインテグレーター、エンドユーザー企業の上級幹部と技術スペシャリストを対象に構造化インタビューを実施し、一般的な課題、イノベーションのロードマップ、戦略的優先事項に関する洞察を収集しました。

世界の真空部品市場における戦略的意思決定を促進するための重要な知見をまとめた結論的洞察

このエグゼクティブサマリーでは、ダイナミックな真空部品市場に関する重要な洞察を総合し、新たな技術動向、貿易政策シフトの影響、セグメンテーションに基づく成長機会、地域市場のニュアンスに焦点を当てています。先端材料、デジタル化、モジュラーアーキテクチャーの相互作用は、真空システムの設計、製造、導入方法における根本的な変革を浮き彫りにしています。累積的な関税圧力はサプライチェーンの再編成を促し、セグメンテーションの幅は多様な産業における製品イノベーションと市場参入のための的を絞った道を提供します。

目次

第1章 序文

第2章 調査手法

第3章 エグゼクティブサマリー

第4章 市場の概要

第5章 市場力学

- リアルタイムのパフォーマンス監視のために真空部品にIoTセンサーを統合

- 複雑な真空部品形状を製造するための積層造形技術の採用

- 環境への影響が少ない環境に優しい真空ポンプ材料の需要増加

- 真空システムのダウンタイムを削減するための予測メンテナンスアルゴリズムの実装

- 500℃以上で動作する真空システム用耐高温シールの開発

- 不足の中で重要な真空部品のためのグローバルサプライチェーンの統合の傾向

第6章 市場洞察

- ポーターのファイブフォース分析

- PESTEL分析

第7章 米国の関税の累積的な影響2025

第8章 真空部品市場:製品タイプ別

- チェンバース

- 継手

- カップリング

- フランジ

- シール

- ゲージ

- 静電容量計

- イオン化計

- ピラニゲージ

- パンプス

- ダイヤフラムポンプ

- ドライポンプ

- ロータリーベーンポンプ

- スクロールポンプ

- ターボ分子ポンプ

- バルブ

- ボールバルブ

- バタフライバルブ

- ゲートバルブ

第9章 真空部品市場:素材タイプ別

- アルミニウム

- 銅

- プラスチック

- ステンレス鋼

第10章 真空部品市場:用途別

- 食品包装

- 工業処理

- 医療機器

- 研究開発

- 半導体製造

第11章 真空部品市場:エンドユーザー業界別

- 自動車

- 化学薬品

- エレクトロニクス

- 飲食品

- ヘルスケア

- パッケージ

第12章 真空部品市場:流通チャネル別

- 直接販売

- 販売代理店販売

- オンライン販売

第13章 南北アメリカの真空部品市場

- 米国

- カナダ

- メキシコ

- ブラジル

- アルゼンチン

第14章 欧州・中東・アフリカの真空部品市場

- 英国

- ドイツ

- フランス

- ロシア

- イタリア

- スペイン

- アラブ首長国連邦

- サウジアラビア

- 南アフリカ

- デンマーク

- オランダ

- カタール

- フィンランド

- スウェーデン

- ナイジェリア

- エジプト

- トルコ

- イスラエル

- ノルウェー

- ポーランド

- スイス

第15章 アジア太平洋地域の真空部品市場

- 中国

- インド

- 日本

- オーストラリア

- 韓国

- インドネシア

- タイ

- フィリピン

- マレーシア

- シンガポール

- ベトナム

- 台湾

第16章 競合情勢

- 市場シェア分析, 2024

- FPNVポジショニングマトリックス, 2024

- 競合分析

- Atlas Copco AB

- ULVAC, Inc.

- Pfeiffer Vacuum Technology AG

- Oerlikon Leybold Vacuum GmbH

- MKS Instruments, Inc.

- VAT Group AG

- AMETEK, Inc.

- Agilent Technologies, Inc.

- Ebara Corporation

- Shimadzu Corporation

- Ingersoll Rand Inc.

- Thermo Fisher Scientific Inc.

- Oxford Instruments plc

- Nikkiso Co., Ltd.

- Piab AB

- Shin Nippon Machinery Co., Ltd.

第17章 リサーチAI

第18章 リサーチ統計

第19章 リサーチコンタクト

第20章 リサーチ記事

第21章 付録

LIST OF FIGURES

- FIGURE 1. VACUUM COMPONENTS MARKET RESEARCH PROCESS

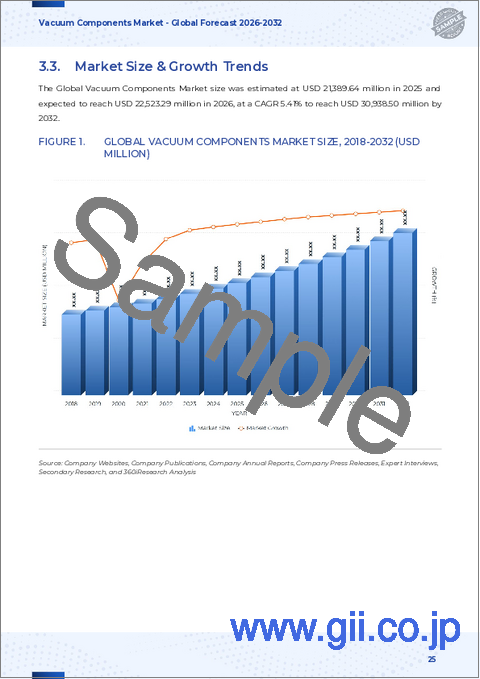

- FIGURE 2. GLOBAL VACUUM COMPONENTS MARKET SIZE, 2018-2030 (USD MILLION)

- FIGURE 3. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY REGION, 2024 VS 2025 VS 2030 (USD MILLION)

- FIGURE 4. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY COUNTRY, 2024 VS 2025 VS 2030 (USD MILLION)

- FIGURE 5. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY PRODUCT TYPE, 2024 VS 2030 (%)

- FIGURE 6. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY PRODUCT TYPE, 2024 VS 2025 VS 2030 (USD MILLION)

- FIGURE 7. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY MATERIAL TYPE, 2024 VS 2030 (%)

- FIGURE 8. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY MATERIAL TYPE, 2024 VS 2025 VS 2030 (USD MILLION)

- FIGURE 9. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY APPLICATION, 2024 VS 2030 (%)

- FIGURE 10. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY APPLICATION, 2024 VS 2025 VS 2030 (USD MILLION)

- FIGURE 11. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY END-USER INDUSTRY, 2024 VS 2030 (%)

- FIGURE 12. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY END-USER INDUSTRY, 2024 VS 2025 VS 2030 (USD MILLION)

- FIGURE 13. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY DISTRIBUTION CHANNEL, 2024 VS 2030 (%)

- FIGURE 14. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY DISTRIBUTION CHANNEL, 2024 VS 2025 VS 2030 (USD MILLION)

- FIGURE 15. AMERICAS VACUUM COMPONENTS MARKET SIZE, BY COUNTRY, 2024 VS 2030 (%)

- FIGURE 16. AMERICAS VACUUM COMPONENTS MARKET SIZE, BY COUNTRY, 2024 VS 2025 VS 2030 (USD MILLION)

- FIGURE 17. UNITED STATES VACUUM COMPONENTS MARKET SIZE, BY STATE, 2024 VS 2030 (%)

- FIGURE 18. UNITED STATES VACUUM COMPONENTS MARKET SIZE, BY STATE, 2024 VS 2025 VS 2030 (USD MILLION)

- FIGURE 19. EUROPE, MIDDLE EAST & AFRICA VACUUM COMPONENTS MARKET SIZE, BY COUNTRY, 2024 VS 2030 (%)

- FIGURE 20. EUROPE, MIDDLE EAST & AFRICA VACUUM COMPONENTS MARKET SIZE, BY COUNTRY, 2024 VS 2025 VS 2030 (USD MILLION)

- FIGURE 21. ASIA-PACIFIC VACUUM COMPONENTS MARKET SIZE, BY COUNTRY, 2024 VS 2030 (%)

- FIGURE 22. ASIA-PACIFIC VACUUM COMPONENTS MARKET SIZE, BY COUNTRY, 2024 VS 2025 VS 2030 (USD MILLION)

- FIGURE 23. VACUUM COMPONENTS MARKET SHARE, BY KEY PLAYER, 2024

- FIGURE 24. VACUUM COMPONENTS MARKET, FPNV POSITIONING MATRIX, 2024

- FIGURE 25. VACUUM COMPONENTS MARKET: RESEARCHAI

- FIGURE 26. VACUUM COMPONENTS MARKET: RESEARCHSTATISTICS

- FIGURE 27. VACUUM COMPONENTS MARKET: RESEARCHCONTACTS

- FIGURE 28. VACUUM COMPONENTS MARKET: RESEARCHARTICLES

LIST OF TABLES

- TABLE 1. VACUUM COMPONENTS MARKET SEGMENTATION & COVERAGE

- TABLE 2. UNITED STATES DOLLAR EXCHANGE RATE, 2018-2024

- TABLE 3. GLOBAL VACUUM COMPONENTS MARKET SIZE, 2018-2024 (USD MILLION)

- TABLE 4. GLOBAL VACUUM COMPONENTS MARKET SIZE, 2025-2030 (USD MILLION)

- TABLE 5. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY REGION, 2018-2024 (USD MILLION)

- TABLE 6. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY REGION, 2025-2030 (USD MILLION)

- TABLE 7. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY COUNTRY, 2018-2024 (USD MILLION)

- TABLE 8. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 9. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY PRODUCT TYPE, 2018-2024 (USD MILLION)

- TABLE 10. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY PRODUCT TYPE, 2025-2030 (USD MILLION)

- TABLE 11. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY CHAMBERS, BY REGION, 2018-2024 (USD MILLION)

- TABLE 12. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY CHAMBERS, BY REGION, 2025-2030 (USD MILLION)

- TABLE 13. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY FITTINGS, BY REGION, 2018-2024 (USD MILLION)

- TABLE 14. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY FITTINGS, BY REGION, 2025-2030 (USD MILLION)

- TABLE 15. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY COUPLINGS, BY REGION, 2018-2024 (USD MILLION)

- TABLE 16. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY COUPLINGS, BY REGION, 2025-2030 (USD MILLION)

- TABLE 17. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY FLANGES, BY REGION, 2018-2024 (USD MILLION)

- TABLE 18. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY FLANGES, BY REGION, 2025-2030 (USD MILLION)

- TABLE 19. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY SEALS, BY REGION, 2018-2024 (USD MILLION)

- TABLE 20. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY SEALS, BY REGION, 2025-2030 (USD MILLION)

- TABLE 21. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY FITTINGS, 2018-2024 (USD MILLION)

- TABLE 22. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY FITTINGS, 2025-2030 (USD MILLION)

- TABLE 23. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY GAUGES, BY REGION, 2018-2024 (USD MILLION)

- TABLE 24. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY GAUGES, BY REGION, 2025-2030 (USD MILLION)

- TABLE 25. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY CAPACITANCE GAUGE, BY REGION, 2018-2024 (USD MILLION)

- TABLE 26. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY CAPACITANCE GAUGE, BY REGION, 2025-2030 (USD MILLION)

- TABLE 27. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY IONIZATION GAUGE, BY REGION, 2018-2024 (USD MILLION)

- TABLE 28. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY IONIZATION GAUGE, BY REGION, 2025-2030 (USD MILLION)

- TABLE 29. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY PIRANI GAUGE, BY REGION, 2018-2024 (USD MILLION)

- TABLE 30. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY PIRANI GAUGE, BY REGION, 2025-2030 (USD MILLION)

- TABLE 31. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY GAUGES, 2018-2024 (USD MILLION)

- TABLE 32. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY GAUGES, 2025-2030 (USD MILLION)

- TABLE 33. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY PUMPS, BY REGION, 2018-2024 (USD MILLION)

- TABLE 34. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY PUMPS, BY REGION, 2025-2030 (USD MILLION)

- TABLE 35. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY DIAPHRAGM PUMPS, BY REGION, 2018-2024 (USD MILLION)

- TABLE 36. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY DIAPHRAGM PUMPS, BY REGION, 2025-2030 (USD MILLION)

- TABLE 37. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY DRY PUMPS, BY REGION, 2018-2024 (USD MILLION)

- TABLE 38. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY DRY PUMPS, BY REGION, 2025-2030 (USD MILLION)

- TABLE 39. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY ROTARY VANE PUMPS, BY REGION, 2018-2024 (USD MILLION)

- TABLE 40. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY ROTARY VANE PUMPS, BY REGION, 2025-2030 (USD MILLION)

- TABLE 41. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY SCROLL PUMPS, BY REGION, 2018-2024 (USD MILLION)

- TABLE 42. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY SCROLL PUMPS, BY REGION, 2025-2030 (USD MILLION)

- TABLE 43. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY TURBOMOLECULAR PUMPS, BY REGION, 2018-2024 (USD MILLION)

- TABLE 44. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY TURBOMOLECULAR PUMPS, BY REGION, 2025-2030 (USD MILLION)

- TABLE 45. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY PUMPS, 2018-2024 (USD MILLION)

- TABLE 46. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY PUMPS, 2025-2030 (USD MILLION)

- TABLE 47. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY VALVES, BY REGION, 2018-2024 (USD MILLION)

- TABLE 48. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY VALVES, BY REGION, 2025-2030 (USD MILLION)

- TABLE 49. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY BALL VALVES, BY REGION, 2018-2024 (USD MILLION)

- TABLE 50. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY BALL VALVES, BY REGION, 2025-2030 (USD MILLION)

- TABLE 51. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY BUTTERFLY VALVES, BY REGION, 2018-2024 (USD MILLION)

- TABLE 52. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY BUTTERFLY VALVES, BY REGION, 2025-2030 (USD MILLION)

- TABLE 53. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY GATE VALVES, BY REGION, 2018-2024 (USD MILLION)

- TABLE 54. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY GATE VALVES, BY REGION, 2025-2030 (USD MILLION)

- TABLE 55. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY VALVES, 2018-2024 (USD MILLION)

- TABLE 56. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY VALVES, 2025-2030 (USD MILLION)

- TABLE 57. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY MATERIAL TYPE, 2018-2024 (USD MILLION)

- TABLE 58. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY MATERIAL TYPE, 2025-2030 (USD MILLION)

- TABLE 59. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY ALUMINUM, BY REGION, 2018-2024 (USD MILLION)

- TABLE 60. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY ALUMINUM, BY REGION, 2025-2030 (USD MILLION)

- TABLE 61. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY COPPER, BY REGION, 2018-2024 (USD MILLION)

- TABLE 62. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY COPPER, BY REGION, 2025-2030 (USD MILLION)

- TABLE 63. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY PLASTIC, BY REGION, 2018-2024 (USD MILLION)

- TABLE 64. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY PLASTIC, BY REGION, 2025-2030 (USD MILLION)

- TABLE 65. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY STAINLESS STEEL, BY REGION, 2018-2024 (USD MILLION)

- TABLE 66. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY STAINLESS STEEL, BY REGION, 2025-2030 (USD MILLION)

- TABLE 67. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY APPLICATION, 2018-2024 (USD MILLION)

- TABLE 68. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY APPLICATION, 2025-2030 (USD MILLION)

- TABLE 69. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY FOOD PACKAGING, BY REGION, 2018-2024 (USD MILLION)

- TABLE 70. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY FOOD PACKAGING, BY REGION, 2025-2030 (USD MILLION)

- TABLE 71. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY INDUSTRIAL PROCESSING, BY REGION, 2018-2024 (USD MILLION)

- TABLE 72. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY INDUSTRIAL PROCESSING, BY REGION, 2025-2030 (USD MILLION)

- TABLE 73. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY MEDICAL EQUIPMENT, BY REGION, 2018-2024 (USD MILLION)

- TABLE 74. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY MEDICAL EQUIPMENT, BY REGION, 2025-2030 (USD MILLION)

- TABLE 75. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY RESEARCH & DEVELOPMENT, BY REGION, 2018-2024 (USD MILLION)

- TABLE 76. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY RESEARCH & DEVELOPMENT, BY REGION, 2025-2030 (USD MILLION)

- TABLE 77. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY SEMICONDUCTOR MANUFACTURING, BY REGION, 2018-2024 (USD MILLION)

- TABLE 78. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY SEMICONDUCTOR MANUFACTURING, BY REGION, 2025-2030 (USD MILLION)

- TABLE 79. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY END-USER INDUSTRY, 2018-2024 (USD MILLION)

- TABLE 80. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY END-USER INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 81. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY AUTOMOTIVE, BY REGION, 2018-2024 (USD MILLION)

- TABLE 82. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY AUTOMOTIVE, BY REGION, 2025-2030 (USD MILLION)

- TABLE 83. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY CHEMICAL, BY REGION, 2018-2024 (USD MILLION)

- TABLE 84. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY CHEMICAL, BY REGION, 2025-2030 (USD MILLION)

- TABLE 85. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY ELECTRONICS, BY REGION, 2018-2024 (USD MILLION)

- TABLE 86. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY ELECTRONICS, BY REGION, 2025-2030 (USD MILLION)

- TABLE 87. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY FOOD & BEVERAGE, BY REGION, 2018-2024 (USD MILLION)

- TABLE 88. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY FOOD & BEVERAGE, BY REGION, 2025-2030 (USD MILLION)

- TABLE 89. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY HEALTHCARE, BY REGION, 2018-2024 (USD MILLION)

- TABLE 90. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY HEALTHCARE, BY REGION, 2025-2030 (USD MILLION)

- TABLE 91. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY PACKAGING, BY REGION, 2018-2024 (USD MILLION)

- TABLE 92. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY PACKAGING, BY REGION, 2025-2030 (USD MILLION)

- TABLE 93. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY DISTRIBUTION CHANNEL, 2018-2024 (USD MILLION)

- TABLE 94. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY DISTRIBUTION CHANNEL, 2025-2030 (USD MILLION)

- TABLE 95. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY DIRECT SALES, BY REGION, 2018-2024 (USD MILLION)

- TABLE 96. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY DIRECT SALES, BY REGION, 2025-2030 (USD MILLION)

- TABLE 97. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY DISTRIBUTOR SALES, BY REGION, 2018-2024 (USD MILLION)

- TABLE 98. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY DISTRIBUTOR SALES, BY REGION, 2025-2030 (USD MILLION)

- TABLE 99. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY ONLINE SALES, BY REGION, 2018-2024 (USD MILLION)

- TABLE 100. GLOBAL VACUUM COMPONENTS MARKET SIZE, BY ONLINE SALES, BY REGION, 2025-2030 (USD MILLION)

- TABLE 101. AMERICAS VACUUM COMPONENTS MARKET SIZE, BY PRODUCT TYPE, 2018-2024 (USD MILLION)

- TABLE 102. AMERICAS VACUUM COMPONENTS MARKET SIZE, BY PRODUCT TYPE, 2025-2030 (USD MILLION)

- TABLE 103. AMERICAS VACUUM COMPONENTS MARKET SIZE, BY FITTINGS, 2018-2024 (USD MILLION)

- TABLE 104. AMERICAS VACUUM COMPONENTS MARKET SIZE, BY FITTINGS, 2025-2030 (USD MILLION)

- TABLE 105. AMERICAS VACUUM COMPONENTS MARKET SIZE, BY GAUGES, 2018-2024 (USD MILLION)

- TABLE 106. AMERICAS VACUUM COMPONENTS MARKET SIZE, BY GAUGES, 2025-2030 (USD MILLION)

- TABLE 107. AMERICAS VACUUM COMPONENTS MARKET SIZE, BY PUMPS, 2018-2024 (USD MILLION)

- TABLE 108. AMERICAS VACUUM COMPONENTS MARKET SIZE, BY PUMPS, 2025-2030 (USD MILLION)

- TABLE 109. AMERICAS VACUUM COMPONENTS MARKET SIZE, BY VALVES, 2018-2024 (USD MILLION)

- TABLE 110. AMERICAS VACUUM COMPONENTS MARKET SIZE, BY VALVES, 2025-2030 (USD MILLION)

- TABLE 111. AMERICAS VACUUM COMPONENTS MARKET SIZE, BY MATERIAL TYPE, 2018-2024 (USD MILLION)

- TABLE 112. AMERICAS VACUUM COMPONENTS MARKET SIZE, BY MATERIAL TYPE, 2025-2030 (USD MILLION)

- TABLE 113. AMERICAS VACUUM COMPONENTS MARKET SIZE, BY APPLICATION, 2018-2024 (USD MILLION)

- TABLE 114. AMERICAS VACUUM COMPONENTS MARKET SIZE, BY APPLICATION, 2025-2030 (USD MILLION)

- TABLE 115. AMERICAS VACUUM COMPONENTS MARKET SIZE, BY END-USER INDUSTRY, 2018-2024 (USD MILLION)

- TABLE 116. AMERICAS VACUUM COMPONENTS MARKET SIZE, BY END-USER INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 117. AMERICAS VACUUM COMPONENTS MARKET SIZE, BY DISTRIBUTION CHANNEL, 2018-2024 (USD MILLION)

- TABLE 118. AMERICAS VACUUM COMPONENTS MARKET SIZE, BY DISTRIBUTION CHANNEL, 2025-2030 (USD MILLION)

- TABLE 119. AMERICAS VACUUM COMPONENTS MARKET SIZE, BY COUNTRY, 2018-2024 (USD MILLION)

- TABLE 120. AMERICAS VACUUM COMPONENTS MARKET SIZE, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 121. UNITED STATES VACUUM COMPONENTS MARKET SIZE, BY PRODUCT TYPE, 2018-2024 (USD MILLION)

- TABLE 122. UNITED STATES VACUUM COMPONENTS MARKET SIZE, BY PRODUCT TYPE, 2025-2030 (USD MILLION)

- TABLE 123. UNITED STATES VACUUM COMPONENTS MARKET SIZE, BY FITTINGS, 2018-2024 (USD MILLION)

- TABLE 124. UNITED STATES VACUUM COMPONENTS MARKET SIZE, BY FITTINGS, 2025-2030 (USD MILLION)

- TABLE 125. UNITED STATES VACUUM COMPONENTS MARKET SIZE, BY GAUGES, 2018-2024 (USD MILLION)

- TABLE 126. UNITED STATES VACUUM COMPONENTS MARKET SIZE, BY GAUGES, 2025-2030 (USD MILLION)

- TABLE 127. UNITED STATES VACUUM COMPONENTS MARKET SIZE, BY PUMPS, 2018-2024 (USD MILLION)

- TABLE 128. UNITED STATES VACUUM COMPONENTS MARKET SIZE, BY PUMPS, 2025-2030 (USD MILLION)

- TABLE 129. UNITED STATES VACUUM COMPONENTS MARKET SIZE, BY VALVES, 2018-2024 (USD MILLION)

- TABLE 130. UNITED STATES VACUUM COMPONENTS MARKET SIZE, BY VALVES, 2025-2030 (USD MILLION)

- TABLE 131. UNITED STATES VACUUM COMPONENTS MARKET SIZE, BY MATERIAL TYPE, 2018-2024 (USD MILLION)

- TABLE 132. UNITED STATES VACUUM COMPONENTS MARKET SIZE, BY MATERIAL TYPE, 2025-2030 (USD MILLION)

- TABLE 133. UNITED STATES VACUUM COMPONENTS MARKET SIZE, BY APPLICATION, 2018-2024 (USD MILLION)

- TABLE 134. UNITED STATES VACUUM COMPONENTS MARKET SIZE, BY APPLICATION, 2025-2030 (USD MILLION)

- TABLE 135. UNITED STATES VACUUM COMPONENTS MARKET SIZE, BY END-USER INDUSTRY, 2018-2024 (USD MILLION)

- TABLE 136. UNITED STATES VACUUM COMPONENTS MARKET SIZE, BY END-USER INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 137. UNITED STATES VACUUM COMPONENTS MARKET SIZE, BY DISTRIBUTION CHANNEL, 2018-2024 (USD MILLION)

- TABLE 138. UNITED STATES VACUUM COMPONENTS MARKET SIZE, BY DISTRIBUTION CHANNEL, 2025-2030 (USD MILLION)

- TABLE 139. UNITED STATES VACUUM COMPONENTS MARKET SIZE, BY STATE, 2018-2024 (USD MILLION)

- TABLE 140. UNITED STATES VACUUM COMPONENTS MARKET SIZE, BY STATE, 2025-2030 (USD MILLION)

- TABLE 141. CANADA VACUUM COMPONENTS MARKET SIZE, BY PRODUCT TYPE, 2018-2024 (USD MILLION)

- TABLE 142. CANADA VACUUM COMPONENTS MARKET SIZE, BY PRODUCT TYPE, 2025-2030 (USD MILLION)

- TABLE 143. CANADA VACUUM COMPONENTS MARKET SIZE, BY FITTINGS, 2018-2024 (USD MILLION)

- TABLE 144. CANADA VACUUM COMPONENTS MARKET SIZE, BY FITTINGS, 2025-2030 (USD MILLION)

- TABLE 145. CANADA VACUUM COMPONENTS MARKET SIZE, BY GAUGES, 2018-2024 (USD MILLION)

- TABLE 146. CANADA VACUUM COMPONENTS MARKET SIZE, BY GAUGES, 2025-2030 (USD MILLION)

- TABLE 147. CANADA VACUUM COMPONENTS MARKET SIZE, BY PUMPS, 2018-2024 (USD MILLION)

- TABLE 148. CANADA VACUUM COMPONENTS MARKET SIZE, BY PUMPS, 2025-2030 (USD MILLION)

- TABLE 149. CANADA VACUUM COMPONENTS MARKET SIZE, BY VALVES, 2018-2024 (USD MILLION)

- TABLE 150. CANADA VACUUM COMPONENTS MARKET SIZE, BY VALVES, 2025-2030 (USD MILLION)

- TABLE 151. CANADA VACUUM COMPONENTS MARKET SIZE, BY MATERIAL TYPE, 2018-2024 (USD MILLION)

- TABLE 152. CANADA VACUUM COMPONENTS MARKET SIZE, BY MATERIAL TYPE, 2025-2030 (USD MILLION)

- TABLE 153. CANADA VACUUM COMPONENTS MARKET SIZE, BY APPLICATION, 2018-2024 (USD MILLION)

- TABLE 154. CANADA VACUUM COMPONENTS MARKET SIZE, BY APPLICATION, 2025-2030 (USD MILLION)

- TABLE 155. CANADA VACUUM COMPONENTS MARKET SIZE, BY END-USER INDUSTRY, 2018-2024 (USD MILLION)

- TABLE 156. CANADA VACUUM COMPONENTS MARKET SIZE, BY END-USER INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 157. CANADA VACUUM COMPONENTS MARKET SIZE, BY DISTRIBUTION CHANNEL, 2018-2024 (USD MILLION)

- TABLE 158. CANADA VACUUM COMPONENTS MARKET SIZE, BY DISTRIBUTION CHANNEL, 2025-2030 (USD MILLION)

- TABLE 159. MEXICO VACUUM COMPONENTS MARKET SIZE, BY PRODUCT TYPE, 2018-2024 (USD MILLION)

- TABLE 160. MEXICO VACUUM COMPONENTS MARKET SIZE, BY PRODUCT TYPE, 2025-2030 (USD MILLION)

- TABLE 161. MEXICO VACUUM COMPONENTS MARKET SIZE, BY FITTINGS, 2018-2024 (USD MILLION)

- TABLE 162. MEXICO VACUUM COMPONENTS MARKET SIZE, BY FITTINGS, 2025-2030 (USD MILLION)

- TABLE 163. MEXICO VACUUM COMPONENTS MARKET SIZE, BY GAUGES, 2018-2024 (USD MILLION)

- TABLE 164. MEXICO VACUUM COMPONENTS MARKET SIZE, BY GAUGES, 2025-2030 (USD MILLION)

- TABLE 165. MEXICO VACUUM COMPONENTS MARKET SIZE, BY PUMPS, 2018-2024 (USD MILLION)

- TABLE 166. MEXICO VACUUM COMPONENTS MARKET SIZE, BY PUMPS, 2025-2030 (USD MILLION)

- TABLE 167. MEXICO VACUUM COMPONENTS MARKET SIZE, BY VALVES, 2018-2024 (USD MILLION)

- TABLE 168. MEXICO VACUUM COMPONENTS MARKET SIZE, BY VALVES, 2025-2030 (USD MILLION)

- TABLE 169. MEXICO VACUUM COMPONENTS MARKET SIZE, BY MATERIAL TYPE, 2018-2024 (USD MILLION)

- TABLE 170. MEXICO VACUUM COMPONENTS MARKET SIZE, BY MATERIAL TYPE, 2025-2030 (USD MILLION)

- TABLE 171. MEXICO VACUUM COMPONENTS MARKET SIZE, BY APPLICATION, 2018-2024 (USD MILLION)

- TABLE 172. MEXICO VACUUM COMPONENTS MARKET SIZE, BY APPLICATION, 2025-2030 (USD MILLION)

- TABLE 173. MEXICO VACUUM COMPONENTS MARKET SIZE, BY END-USER INDUSTRY, 2018-2024 (USD MILLION)

- TABLE 174. MEXICO VACUUM COMPONENTS MARKET SIZE, BY END-USER INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 175. MEXICO VACUUM COMPONENTS MARKET SIZE, BY DISTRIBUTION CHANNEL, 2018-2024 (USD MILLION)

- TABLE 176. MEXICO VACUUM COMPONENTS MARKET SIZE, BY DISTRIBUTION CHANNEL, 2025-2030 (USD MILLION)

- TABLE 177. BRAZIL VACUUM COMPONENTS MARKET SIZE, BY PRODUCT TYPE, 2018-2024 (USD MILLION)

- TABLE 178. BRAZIL VACUUM COMPONENTS MARKET SIZE, BY PRODUCT TYPE, 2025-2030 (USD MILLION)

- TABLE 179. BRAZIL VACUUM COMPONENTS MARKET SIZE, BY FITTINGS, 2018-2024 (USD MILLION)

- TABLE 180. BRAZIL VACUUM COMPONENTS MARKET SIZE, BY FITTINGS, 2025-2030 (USD MILLION)

- TABLE 181. BRAZIL VACUUM COMPONENTS MARKET SIZE, BY GAUGES, 2018-2024 (USD MILLION)

- TABLE 182. BRAZIL VACUUM COMPONENTS MARKET SIZE, BY GAUGES, 2025-2030 (USD MILLION)

- TABLE 183. BRAZIL VACUUM COMPONENTS MARKET SIZE, BY PUMPS, 2018-2024 (USD MILLION)

- TABLE 184. BRAZIL VACUUM COMPONENTS MARKET SIZE, BY PUMPS, 2025-2030 (USD MILLION)

- TABLE 185. BRAZIL VACUUM COMPONENTS MARKET SIZE, BY VALVES, 2018-2024 (USD MILLION)

- TABLE 186. BRAZIL VACUUM COMPONENTS MARKET SIZE, BY VALVES, 2025-2030 (USD MILLION)

- TABLE 187. BRAZIL VACUUM COMPONENTS MARKET SIZE, BY MATERIAL TYPE, 2018-2024 (USD MILLION)

- TABLE 188. BRAZIL VACUUM COMPONENTS MARKET SIZE, BY MATERIAL TYPE, 2025-2030 (USD MILLION)

- TABLE 189. BRAZIL VACUUM COMPONENTS MARKET SIZE, BY APPLICATION, 2018-2024 (USD MILLION)

- TABLE 190. BRAZIL VACUUM COMPONENTS MARKET SIZE, BY APPLICATION, 2025-2030 (USD MILLION)

- TABLE 191. BRAZIL VACUUM COMPONENTS MARKET SIZE, BY END-USER INDUSTRY, 2018-2024 (USD MILLION)

- TABLE 192. BRAZIL VACUUM COMPONENTS MARKET SIZE, BY END-USER INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 193. BRAZIL VACUUM COMPONENTS MARKET SIZE, BY DISTRIBUTION CHANNEL, 2018-2024 (USD MILLION)

- TABLE 194. BRAZIL VACUUM COMPONENTS MARKET SIZE, BY DISTRIBUTION CHANNEL, 2025-2030 (USD MILLION)

- TABLE 195. ARGENTINA VACUUM COMPONENTS MARKET SIZE, BY PRODUCT TYPE, 2018-2024 (USD MILLION)

- TABLE 196. ARGENTINA VACUUM COMPONENTS MARKET SIZE, BY PRODUCT TYPE, 2025-2030 (USD MILLION)

- TABLE 197. ARGENTINA VACUUM COMPONENTS MARKET SIZE, BY FITTINGS, 2018-2024 (USD MILLION)

- TABLE 198. ARGENTINA VACUUM COMPONENTS MARKET SIZE, BY FITTINGS, 2025-2030 (USD MILLION)

- TABLE 199. ARGENTINA VACUUM COMPONENTS MARKET SIZE, BY GAUGES, 2018-2024 (USD MILLION)

- TABLE 200. ARGENTINA VACUUM COMPONENTS MARKET SIZE, BY GAUGES, 2025-2030 (USD MILLION)

- TABLE 201. ARGENTINA VACUUM COMPONENTS MARKET SIZE, BY PUMPS, 2018-2024 (USD MILLION)

- TABLE 202. ARGENTINA VACUUM COMPONENTS MARKET SIZE, BY PUMPS, 2025-2030 (USD MILLION)

- TABLE 203. ARGENTINA VACUUM COMPONENTS MARKET SIZE, BY VALVES, 2018-2024 (USD MILLION)

- TABLE 204. ARGENTINA VACUUM COMPONENTS MARKET SIZE, BY VALVES, 2025-2030 (USD MILLION)

- TABLE 205. ARGENTINA VACUUM COMPONENTS MARKET SIZE, BY MATERIAL TYPE, 2018-2024 (USD MILLION)

- TABLE 206. ARGENTINA VACUUM COMPONENTS MARKET SIZE, BY MATERIAL TYPE, 2025-2030 (USD MILLION)

- TABLE 207. ARGENTINA VACUUM COMPONENTS MARKET SIZE, BY APPLICATION, 2018-2024 (USD MILLION)

- TABLE 208. ARGENTINA VACUUM COMPONENTS MARKET SIZE, BY APPLICATION, 2025-2030 (USD MILLION)

- TABLE 209. ARGENTINA VACUUM COMPONENTS MARKET SIZE, BY END-USER INDUSTRY, 2018-2024 (USD MILLION)

- TABLE 210. ARGENTINA VACUUM COMPONENTS MARKET SIZE, BY END-USER INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 211. ARGENTINA VACUUM COMPONENTS MARKET SIZE, BY DISTRIBUTION CHANNEL, 2018-2024 (USD MILLION)

- TABLE 212. ARGENTINA VACUUM COMPONENTS MARKET SIZE, BY DISTRIBUTION CHANNEL, 2025-2030 (USD MILLION)

- TABLE 213. EUROPE, MIDDLE EAST & AFRICA VACUUM COMPONENTS MARKET SIZE, BY PRODUCT TYPE, 2018-2024 (USD MILLION)

- TABLE 214. EUROPE, MIDDLE EAST & AFRICA VACUUM COMPONENTS MARKET SIZE, BY PRODUCT TYPE, 2025-2030 (USD MILLION)

- TABLE 215. EUROPE, MIDDLE EAST & AFRICA VACUUM COMPONENTS MARKET SIZE, BY FITTINGS, 2018-2024 (USD MILLION)

- TABLE 216. EUROPE, MIDDLE EAST & AFRICA VACUUM COMPONENTS MARKET SIZE, BY FITTINGS, 2025-2030 (USD MILLION)

- TABLE 217. EUROPE, MIDDLE EAST & AFRICA VACUUM COMPONENTS MARKET SIZE, BY GAUGES, 2018-2024 (USD MILLION)

- TABLE 218. EUROPE, MIDDLE EAST & AFRICA VACUUM COMPONENTS MARKET SIZE, BY GAUGES, 2025-2030 (USD MILLION)

- TABLE 219. EUROPE, MIDDLE EAST & AFRICA VACUUM COMPONENTS MARKET SIZE, BY PUMPS, 2018-2024 (USD MILLION)

- TABLE 220. EUROPE, MIDDLE EAST & AFRICA VACUUM COMPONENTS MARKET SIZE, BY PUMPS, 2025-2030 (USD MILLION)

- TABLE 221. EUROPE, MIDDLE EAST & AFRICA VACUUM COMPONENTS MARKET SIZE, BY VALVES, 2018-2024 (USD MILLION)

- TABLE 222. EUROPE, MIDDLE EAST & AFRICA VACUUM COMPONENTS MARKET SIZE, BY VALVES, 2025-2030 (USD MILLION)

- TABLE 223. EUROPE, MIDDLE EAST & AFRICA VACUUM COMPONENTS MARKET SIZE, BY MATERIAL TYPE, 2018-2024 (USD MILLION)

- TABLE 224. EUROPE, MIDDLE EAST & AFRICA VACUUM COMPONENTS MARKET SIZE, BY MATERIAL TYPE, 2025-2030 (USD MILLION)

- TABLE 225. EUROPE, MIDDLE EAST & AFRICA VACUUM COMPONENTS MARKET SIZE, BY APPLICATION, 2018-2024 (USD MILLION)

- TABLE 226. EUROPE, MIDDLE EAST & AFRICA VACUUM COMPONENTS MARKET SIZE, BY APPLICATION, 2025-2030 (USD MILLION)

- TABLE 227. EUROPE, MIDDLE EAST & AFRICA VACUUM COMPONENTS MARKET SIZE, BY END-USER INDUSTRY, 2018-2024 (USD MILLION)

- TABLE 228. EUROPE, MIDDLE EAST & AFRICA VACUUM COMPONENTS MARKET SIZE, BY END-USER INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 229. EUROPE, MIDDLE EAST & AFRICA VACUUM COMPONENTS MARKET SIZE, BY DISTRIBUTION CHANNEL, 2018-2024 (USD MILLION)

- TABLE 230. EUROPE, MIDDLE EAST & AFRICA VACUUM COMPONENTS MARKET SIZE, BY DISTRIBUTION CHANNEL, 2025-2030 (USD MILLION)

- TABLE 231. EUROPE, MIDDLE EAST & AFRICA VACUUM COMPONENTS MARKET SIZE, BY COUNTRY, 2018-2024 (USD MILLION)

- TABLE 232. EUROPE, MIDDLE EAST & AFRICA VACUUM COMPONENTS MARKET SIZE, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 233. UNITED KINGDOM VACUUM COMPONENTS MARKET SIZE, BY PRODUCT TYPE, 2018-2024 (USD MILLION)

- TABLE 234. UNITED KINGDOM VACUUM COMPONENTS MARKET SIZE, BY PRODUCT TYPE, 2025-2030 (USD MILLION)

- TABLE 235. UNITED KINGDOM VACUUM COMPONENTS MARKET SIZE, BY FITTINGS, 2018-2024 (USD MILLION)

- TABLE 236. UNITED KINGDOM VACUUM COMPONENTS MARKET SIZE, BY FITTINGS, 2025-2030 (USD MILLION)

- TABLE 237. UNITED KINGDOM VACUUM COMPONENTS MARKET SIZE, BY GAUGES, 2018-2024 (USD MILLION)

- TABLE 238. UNITED KINGDOM VACUUM COMPONENTS MARKET SIZE, BY GAUGES, 2025-2030 (USD MILLION)

- TABLE 239. UNITED KINGDOM VACUUM COMPONENTS MARKET SIZE, BY PUMPS, 2018-2024 (USD MILLION)

- TABLE 240. UNITED KINGDOM VACUUM COMPONENTS MARKET SIZE, BY PUMPS, 2025-2030 (USD MILLION)

- TABLE 241. UNITED KINGDOM VACUUM COMPONENTS MARKET SIZE, BY VALVES, 2018-2024 (USD MILLION)

- TABLE 242. UNITED KINGDOM VACUUM COMPONENTS MARKET SIZE, BY VALVES, 2025-2030 (USD MILLION)

- TABLE 243. UNITED KINGDOM VACUUM COMPONENTS MARKET SIZE, BY MATERIAL TYPE, 2018-2024 (USD MILLION)

- TABLE 244. UNITED KINGDOM VACUUM COMPONENTS MARKET SIZE, BY MATERIAL TYPE, 2025-2030 (USD MILLION)

- TABLE 245. UNITED KINGDOM VACUUM COMPONENTS MARKET SIZE, BY APPLICATION, 2018-2024 (USD MILLION)

- TABLE 246. UNITED KINGDOM VACUUM COMPONENTS MARKET SIZE, BY APPLICATION, 2025-2030 (USD MILLION)

- TABLE 247. UNITED KINGDOM VACUUM COMPONENTS MARKET SIZE, BY END-USER INDUSTRY, 2018-2024 (USD MILLION)

- TABLE 248. UNITED KINGDOM VACUUM COMPONENTS MARKET SIZE, BY END-USER INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 249. UNITED KINGDOM VACUUM COMPONENTS MARKET SIZE, BY DISTRIBUTION CHANNEL, 2018-2024 (USD MILLION)

- TABLE 250. UNITED KINGDOM VACUUM COMPONENTS MARKET SIZE, BY DISTRIBUTION CHANNEL, 2025-2030 (USD MILLION)

- TABLE 251. GERMANY VACUUM COMPONENTS MARKET SIZE, BY PRODUCT TYPE, 2018-2024 (USD MILLION)

- TABLE 252. GERMANY VACUUM COMPONENTS MARKET SIZE, BY PRODUCT TYPE, 2025-2030 (USD MILLION)

- TABLE 253. GERMANY VACUUM COMPONENTS MARKET SIZE, BY FITTINGS, 2018-2024 (USD MILLION)

- TABLE 254. GERMANY VACUUM COMPONENTS MARKET SIZE, BY FITTINGS, 2025-2030 (USD MILLION)

- TABLE 255. GERMANY VACUUM COMPONENTS MARKET SIZE, BY GAUGES, 2018-2024 (USD MILLION)

- TABLE 256. GERMANY VACUUM COMPONENTS MARKET SIZE, BY GAUGES, 2025-2030 (USD MILLION)

- TABLE 257. GERMANY VACUUM COMPONENTS MARKET SIZE, BY PUMPS, 2018-2024 (USD MILLION)

- TABLE 258. GERMANY VACUUM COMPONENTS MARKET SIZE, BY PUMPS, 2025-2030 (USD MILLION)

- TABLE 259. GERMANY VACUUM COMPONENTS MARKET SIZE, BY VALVES, 2018-2024 (USD MILLION)

- TABLE 260. GERMANY VACUUM COMPONENTS MARKET SIZE, BY VALVES, 2025-2030 (USD MILLION)

- TABLE 261. GERMANY VACUUM COMPONENTS MARKET SIZE, BY MATERIAL TYPE, 2018-2024 (USD MILLION)

- TABLE 262. GERMANY VACUUM COMPONENTS MARKET SIZE, BY MATERIAL TYPE, 2025-2030 (USD MILLION)

- TABLE 263. GERMANY VACUUM COMPONENTS MARKET SIZE, BY APPLICATION, 2018-2024 (USD MILLION)

- TABLE 264. GERMANY VACUUM COMPONENTS MARKET SIZE, BY APPLICATION, 2025-2030 (USD MILLION)

- TABLE 265. GERMANY VACUUM COMPONENTS MARKET SIZE, BY END-USER INDUSTRY, 2018-2024 (USD MILLION)

- TABLE 266. GERMANY VACUUM COMPONENTS MARKET SIZE, BY END-USER INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 267. GERMANY VACUUM COMPONENTS MARKET SIZE, BY DISTRIBUTION CHANNEL, 2018-2024 (USD MILLION)

- TABLE 268. GERMANY VACUUM COMPONENTS MARKET SIZE, BY DISTRIBUTION CHANNEL, 2025-2030 (USD MILLION)

- TABLE 269. FRANCE VACUUM COMPONENTS MARKET SIZE, BY PRODUCT TYPE, 2018-2024 (USD MILLION)

- TABLE 270. FRANCE VACUUM COMPONENTS MARKET SIZE, BY PRODUCT TYPE, 2025-2030 (USD MILLION)

- TABLE 271. FRANCE VACUUM COMPONENTS MARKET SIZE, BY FITTINGS, 2018-2024 (USD MILLION)

- TABLE 272. FRANCE VACUUM COMPONENTS MARKET SIZE, BY FITTINGS, 2025-2030 (USD MILLION)

- TABLE 273. FRANCE VACUUM COMPONENTS MARKET SIZE, BY GAUGES, 2018-2024 (USD MILLION)

- TABLE 274. FRANCE VACUUM COMPONENTS MARKET SIZE, BY GAUGES, 2025-2030 (USD MILLION)

- TABLE 275. FRANCE VACUUM COMPONENTS MARKET SIZE, BY PUMPS, 2018-2024 (USD MILLION)

- TABLE 276. FRANCE VACUUM COMPONENTS MARKET SIZE, BY PUMPS, 2025-2030 (USD MILLION)

- TABLE 277. FRANCE VACUUM COMPONENTS MARKET SIZE, BY VALVES, 2018-2024 (USD MILLION)

- TABLE 278. FRANCE VACUUM COMPONENTS MARKET SIZE, BY VALVES, 2025-2030 (USD MILLION)

- TABLE 279. FRANCE VACUUM COMPONENTS MARKET SIZE, BY MATERIAL TYPE, 2018-2024 (USD MILLION)

- TABLE 280. FRANCE VACUUM COMPONENTS MARKET SIZE, BY MATERIAL TYPE, 2025-2030 (USD MILLION)

- TABLE 281. FRANCE VACUUM COMPONENTS MARKET SIZE, BY APPLICATION, 2018-2024 (USD MILLION)

- TABLE 282. FRANCE VACUUM COMPONENTS MARKET SIZE, BY APPLICATION, 2025-2030 (USD MILLION)

- TABLE 283. FRANCE VACUUM COMPONENTS MARKET SIZE, BY END-USER INDUSTRY, 2018-2024 (USD MILLION)

- TABLE 284. FRANCE VACUUM COMPONENTS MARKET SIZE, BY END-USER INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 285. FRANCE VACUUM COMPONENTS MARKET SIZE, BY DISTRIBUTION CHANNEL, 2018-2024 (USD MILLION)

- TABLE 286. FRANCE VACUUM COMPONENTS MARKET SIZE, BY DISTRIBUTION CHANNEL, 2025-2030 (USD MILLION)

- TABLE 287. RUSSIA VACUUM COMPONENTS MARKET SIZE, BY PRODUCT TYPE, 2018-2024 (USD MILLION)

- TABLE 288. RUSSIA VACUUM COMPONENTS MARKET SIZE, BY PRODUCT TYPE, 2025-2030 (USD MILLION)

- TABLE 289. RUSSIA VACUUM COMPONENTS MARKET SIZE, BY FITTINGS, 2018-2024 (USD MILLION)

- TABLE 290. RUSSIA VACUUM COMPONENTS MARKET SIZE, BY FITTINGS, 2025-2030 (USD MILLION)

- TABLE 291. RUSSIA VACUUM COMPONENTS MARKET SIZE, BY GAUGES, 2018-2024 (USD MILLION)

- TABLE 292. RUSSIA VACUUM COMPONENTS MARKET SIZE, BY GAUGES, 2025-2030 (USD MILLION)

- TABLE 293. RUSSIA VACUUM COMPONENTS MARKET SIZE, BY PUMPS, 2018-2024 (USD MILLION)

- TABLE 294. RUSSIA VACUUM COMPONENTS MARKET SIZE, BY PUMPS, 2025-2030 (USD MILLION)

- TABLE 295. RUSSIA VACUUM COMPONENTS MARKET SIZE, BY VALVES, 2018-2024 (USD MILLION)

- TABLE 296. RUSSIA VACUUM COMPONENTS MARKET SIZE, BY VALVES, 2025-2030 (USD MILLION)

- TABLE 297. RUSSIA VACUUM COMPONENTS MARKET SIZE, BY MATERIAL TYPE, 2018-2024 (USD MILLION)

- TABLE 298. RUSSIA VACUUM COMPONENTS MARKET SIZE, BY MATERIAL TYPE, 2025-2030 (USD MILLION)

- TABLE 299. RUSSIA VACUUM COMPONENTS MARKET SIZE, BY APPLICATION, 2018-2024 (USD MILLION)

- TABLE 300. RUSSIA VACUUM COMPONENTS MARKET SIZE, BY APPLICATION, 2025-2030 (USD MILLION)

- TABLE 301. RUSSIA VACUUM COMPONENTS MARKET SIZE, BY END-USER INDUSTRY, 2018-2024 (USD MILLION)

- TABLE 302. RUSSIA VACUUM COMPONENTS MARKET SIZE, BY END-USER INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 303. RUSSIA VACUUM COMPONENTS MARKET SIZE, BY DISTRIBUTION CHANNEL, 2018-2024 (USD MILLION)

- TABLE 304. RUSSIA VACUUM COMPONENTS MARKET SIZE, BY DISTRIBUTION CHANNEL, 2025-2030 (USD MILLION)

- TABLE 305. ITALY VACUUM COMPONENTS MARKET SIZE, BY PRODUCT TYPE, 2018-2024 (USD MILLION)

- TABLE 306. ITALY VACUUM COMPONENTS MARKET SIZE, BY PRODUCT TYPE, 2025-2030 (USD MILLION)

- TABLE 307. ITALY VACUUM COMPONENTS MARKET SIZE, BY FITTINGS, 2018-2024 (USD MILLION)

- TABLE 308. ITALY VACUUM COMPONENTS MARKET SIZE, BY FITTINGS, 2025-2030 (USD MILLION)

- TABLE 309. ITALY VACUUM COMPONENTS MARKET SIZE, BY GAUGES, 2018-2024 (USD MILLION)

- TABLE 310. ITALY VACUUM COMPONENTS MARKET SIZE, BY GAUGES, 2025-2030 (USD MILLION)

- TABLE 311. ITALY VACUUM COMPONENTS MARKET SIZE, BY PUMPS, 2018-2024 (USD MILLION)

- TABLE 312. ITALY VACUUM COMPONENTS MARKET SIZE, BY PUMPS, 2025-2030 (USD MILLION)

- TABLE 313. ITALY VACUUM COMPONENTS MARKET SIZE, BY VALVES, 2018-2024 (USD MILLION)

- TABLE 314. ITALY VACUUM COMPONENTS MARKET SIZE, BY VALVES, 2025-2030 (USD MILLION)

- TABLE 315. ITALY VACUUM COMPONENTS MARKET SIZE, BY MATERIAL TYPE, 2018-2024 (USD MILLION)

- TABLE 316. ITALY VACUUM COMPONENTS MARKET SIZE, BY MATERIAL TYPE, 2025-2030 (USD MILLION)

- TABLE 317. ITALY VACUUM COMPONENTS MARKET SIZE, BY APPLICATION, 2018-2024 (USD MILLION)

- TABLE 318. ITALY VACUUM COMPONENTS MARKET SIZE, BY APPLICATION, 2025-2030 (USD MILLION)

- TABLE 319. ITALY VACUUM COMPONENTS MARKET SIZE, BY END-USER INDUSTRY, 2018-2024 (USD MILLION)

- TABLE 320. ITALY VACUUM COMPONENTS MARKET SIZE, BY END-USER INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 321. ITALY VACUUM COMPONENTS MARKET SIZE, BY DISTRIBUTION CHANNEL, 2018-2024 (USD MILLION)

- TABLE 322. ITALY VACUUM COMPONENTS MARKET SIZE, BY DISTRIBUTION CHANNEL, 2025-2030 (USD MILLION)

- TABLE 323. SPAIN VACUUM COMPONENTS MARKET SIZE, BY PRODUCT TYPE, 2018-2024 (USD MILLION)

- TABLE 324. SPAIN VACUUM COMPONENTS MARKET SIZE, BY PRODUCT TYPE, 2025-2030 (USD MILLION)

- TABLE 325. SPAIN VACUUM COMPONENTS MARKET SIZE, BY FITTINGS, 2018-2024 (USD MILLION)

- TABLE 326. SPAIN VACUUM COMPONENTS MARKET SIZE, BY FITTINGS, 2025-2030 (USD MILLION)

- TABLE 327. SPAIN VACUUM COMPONENTS MARKET SIZE, BY GAUGES, 2018-2024 (USD MILLION)

- TABLE 328. SPAIN VACUUM COMPONENTS MARKET SIZE, BY GAUGES, 2025-2030 (USD MILLION)

- TABLE 329. SPAIN VACUUM COMPONENTS MARKET SIZE, BY PUMPS, 2018-2024 (USD MILLION)

- TABLE 330. SPAIN VACUUM COMPONENTS MARKET SIZE, BY PUMPS, 2025-2030 (USD MILLION)

- TABLE 331. SPAIN VACUUM COMPONENTS MARKET SIZE, BY VALVES, 2018-2024 (USD MILLION)

- TABLE 332. SPAIN VACUUM COMPONENTS MARKET SIZE, BY VALVES, 2025-2030 (USD MILLION)

- TABLE 333. SPAIN VACUUM COMPONENTS MARKET SIZE, BY MATERIAL TYPE, 2018-2024 (USD MILLION)

- TABLE 334. SPAIN VACUUM COMPONENTS MARKET SIZE, BY MATERIAL TYPE, 2025-2030 (USD MILLION)

- TABLE 335. SPAIN VACUUM COMPONENTS MARKET SIZE, BY APPLICATION, 2018-2024 (USD MILLION)

- TABLE 336. SPAIN VACUUM COMPONENTS MARKET SIZE, BY APPLICATION, 2025-2030 (USD MILLION)

- TABLE 337. SPAIN VACUUM COMPONENTS MARKET SIZE, BY END-USER INDUSTRY, 2018-2024 (USD MILLION)

- TABLE 338. SPAIN VACUUM COMPONENTS MARKET SIZE, BY END-USER INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 339. SPAIN VACUUM COMPONENTS MARKET SIZE, BY DISTRIBUTION CHANNEL, 2018-2024 (USD MILLION)

- TABLE 340. SPAIN VACUUM COMPONENTS MARKET SIZE, BY DISTRIBUTION CHANNEL, 2025-2030 (USD MILLION)

- TABLE 341. UNITED ARAB EMIRATES VACUUM COMPONENTS MARKET SIZE, BY PRODUCT TYPE, 2018-2024 (USD MILLION)

- TABLE 342. UNITED ARAB EMIRATES VACUUM COMPONENTS MARKET SIZE, BY PRODUCT TYPE, 2025-2030 (USD MILLION)

- TABLE 343. UNITED ARAB EMIRATES VACUUM COMPONENTS MARKET SIZE, BY FITTINGS, 2018-2024 (USD MILLION)

- TABLE 344. UNITED ARAB EMIRATES VACUUM COMPONENTS MARKET SIZE, BY FITTINGS, 2025-2030 (USD MILLION)

- TABLE 345. UNITED ARAB EMIRATES VACUUM COMPONENTS MARKET SIZE, BY GAUGES, 2018-2024 (USD MILLION)

- TABLE 346. UNITED ARAB EMIRATES VACUUM COMPONENTS MARKET SIZE, BY GAUGES, 2025-2030 (USD MILLION)

- TABLE 347. UNITED ARAB EMIRATES VACUUM COMPONENTS MARKET SIZE, BY PUMPS, 2018-2024 (USD MILLION)

- TABLE 348. UNITED ARAB EMIRATES VACUUM COMPONENTS MARKET SIZE, BY PUMPS, 2025-2030 (USD MILLION)

- TABLE 349. UNITED ARAB EMIRATES VACUUM COMPONENTS MARKET SIZE, BY VALVES, 2018-2024 (USD MILLION)

- TABLE 350. UNITED ARAB EMIRATES VACUUM COMPONENTS MARKET SIZE, BY VALVES, 2025-2030 (USD MILLION)

- TABLE 351. UNITED ARAB EMIRATES VACUUM COMPONENTS MARKET SIZE, BY MATERIAL TYPE, 201

The Vacuum Components Market was valued at USD 16.88 billion in 2024 and is projected to grow to USD 18.02 billion in 2025, with a CAGR of 6.93%, reaching USD 25.24 billion by 2030.

| KEY MARKET STATISTICS | |

|---|---|

| Base Year [2024] | USD 16.88 billion |

| Estimated Year [2025] | USD 18.02 billion |

| Forecast Year [2030] | USD 25.24 billion |

| CAGR (%) | 6.93% |

An Authoritative Introduction to the Vacuum Components Market Capturing Critical Industry Drivers Disruptive Innovations and Strategic Imperatives

Vacuum components are essential engineered elements that enable controlled low-pressure environments across a wide array of industrial and research applications. These precision instruments support processes ranging from advanced semiconductor fabrication to analytical instrumentation, ensuring reliable performance and consistent outcomes under demanding conditions. Over the past decade, continuous material innovations and miniaturization trends have elevated performance thresholds, enabling increased experimental accuracy while reducing operational footprints.

In recent years, the industry has witnessed significant shifts driven by the convergence of digital automation, additive manufacturing, and advanced materials science. This intersection has accelerated the development of next-generation pumps that deliver higher throughput and gauges offering improved sensitivity at lower power profiles. As manufacturers adopt leaner supply chain methodologies, the role of modular fittings and adaptive valve architectures has become increasingly pivotal. Consequently, stakeholders are compelled to refine strategic roadmaps, leveraging these technological advances to maintain competitive positioning and unlock new application frontiers.

Moreover, supply chain resilience has come to the forefront, with sourcing strategies adapting to regional disruptions and raw material volatility. Therefore, strategic alliances and cross-industry collaborations are providing a blueprint for sustained innovation while mitigating risk. This introduction sets the stage for a deeper exploration of transformative shifts, tariff implications, segmentation nuances, and actionable insights that will guide decision-makers in navigating a dynamic vacuum components landscape.

Exploring Transformative Shifts in Vacuum Component Technologies Supply Chains and Competitive Dynamics Reshaping Industry Trajectory

Recent years have brought paradigm shifts across vacuum component technologies and market dynamics, compelling organizations to re-evaluate conventional design and procurement frameworks. The proliferation of advanced materials such as high-performance polymers and specialty alloys has enabled lighter, more durable chamber assemblies, while additive manufacturing techniques accelerate prototyping cycles and reduce lead times. As a result, end-use industries can iterate designs faster, achieving superior vacuum performance with reduced capital expenditure.

Simultaneously, digitalization and data-driven maintenance regimes have revolutionized supply chain and operational models. Predictive analytics integrated into pump and valve systems enable preemptive maintenance scheduling, reducing unplanned downtime and extending equipment lifecycles. Additionally, the decentralization of manufacturing sites across strategic geographies has boosted responsiveness to regional demand fluctuations, mitigating exposure to logistics setbacks and trade constraints. These shifts underline a movement from monolithic production paradigms toward agile, networked ecosystems that prioritize modular scalability and collaborative innovation. Such structural transformations are reshaping competitive dynamics, as nimble incumbents and new market entrants vie to deliver tailored solutions that balance performance, cost efficiency, and sustainability mandates.

Furthermore, emerging regulatory frameworks around environmental reporting and safety compliance are driving demand for components that meet stringent certification requirements. As a result, lifecycle management and end-of-life recycling considerations are increasingly integral to design strategies.

Assessing the Aggregate Impact of New United States Tariffs on Vacuum Component Supply Chains Procurement Costs and Competitive Positioning in 2025

In 2025, the introduction of heightened United States tariffs on critical vacuum component imports has exerted multifaceted pressure on industry stakeholders. Cost structures for high-precision gauges and specialized pump assemblies experienced upward adjustments, compelling manufacturers to revisit supplier portfolios and consider nearshoring options. As import duties elevated landed costs, downstream players in semiconductor and research sectors faced a cascade of increased operational expenditures that, in some cases, necessitated schedule elongations or cost pass-through strategies.

These tariff measures also triggered realignment in global supply chains. Many vendors accelerated plans to diversify production footprints by establishing regional manufacturing nodes, thereby circumventing punitive duties and fostering localized value creation. At the same time, small and medium enterprises encountered challenges in absorbing additional cost burdens, prompting collaborative procurement initiatives and consortium-based sourcing to distribute financial impact.

Additionally, some stakeholders are exploring hybrid trade agreements to soften cost impacts, while others are lobbying for exemptions on critical research instruments. These adaptive measures underscore the importance of continuous monitoring and strategic agility. Looking ahead, industry participants must continuously monitor evolving trade frameworks and engage policymakers to advocate streamlined duty regimes. Proactive scenario planning and investment in tariff-compliant material substitutions can serve as critical levers to preserve competitiveness in a landscape defined by fiscal policy shifts and international trade volatility.

In-Depth Segmentation Analysis Revealing Critical Insights Across Product Type Material Application Industry and Distribution Channel Dimensions

An exhaustive segmentation analysis reveals distinct growth trajectories and competitive landscapes across product types, material categories, application domains, end-user industries, and distribution channels. From a product standpoint, chambers remain fundamental to controlled environment systems, while the fittings segment-comprising couplings, flanges, and seals-has benefited from rising demand for modular system integration. Enhanced gauge technologies, spanning capacitance, ionization, and Pirani variants, deliver critical insights into pressure differentials, driving investments in precise monitoring solutions. Pump segments, including diaphragm, dry, rotary vane, scroll, and turbomolecular designs, have experienced differentiated adoption rates, as high-throughput applications increasingly opt for oil-free and hybrid pumping mechanisms. Valve architectures, with ball, butterfly, and gate configurations, are likewise evolving to support automated process sequences and rapid cycle times.

Material innovation further stratifies market potential, as aluminum components offer lightweight advantages, copper variants ensure thermal conductivity, and stainless steel delivers corrosion resistance. Plastic materials are also gaining traction where lower cost and chemical inertness intersect with noncritical performance requirements. Application segmentation highlights robust uptake in food packaging and industrial processing sectors, alongside critical usage in medical equipment sterilization, research and development laboratories, and semiconductor manufacturing fabs. End-user industries encompass automotive, chemical production, electronics fabrication, food and beverage processing, healthcare provisioning, and packaging operations. Finally, distribution channels range from direct sales models, empowering bespoke engineering collaborations, to distributor partnerships that extend market reach, as well as online platforms facilitating rapid procurement. Together, these segmentation dimensions offer a holistic view that can inform targeted growth strategies and resource allocation.

Regional Market Dynamics and Growth Patterns Unveiled for the Americas Europe Middle East Africa and Asia Pacific Territories

Regional analysis underscores divergent growth drivers and strategic imperatives across the Americas, Europe Middle East & Africa, and Asia-Pacific. The Americas continue to leverage strong domestic demand and a mature industrial base, particularly in semiconductor manufacturing hubs and research institutions. North American players benefit from established supply chains, yet they face increasing competition from regional low-cost producers, necessitating ongoing investment in automation and advanced materials to sustain leadership.

In Europe Middle East & Africa, regulatory emphasis on energy efficiency and sustainability is catalyzing demand for eco-optimized vacuum components. European firms are pioneering green manufacturing processes, reducing carbon footprints, and integrating circular economy principles. Gulf Cooperation Council markets are investing in petrochemical expansion projects, driving demand for corrosion-resistant fittings and specialized valves. Meanwhile, Africa's nascent research infrastructure presents an emerging frontier for modular and cost-effective solutions.

Asia-Pacific remains the most dynamic region, propelled by robust semiconductor fabrication, pharmaceutical production, and solar panel manufacturing. Major economies are amplifying domestic capacity expansions, thus fueling uptake of high-capacity pumps and precision gauges. China's strategic initiatives in advanced materials innovation and India's focus on industrial modernization further accelerate regional momentum.

Government initiatives such as research grants in North America, the European Green Deal, and Asia Pacific manufacturing subsidies are shaping investment flows. These policy incentives play a pivotal role in accelerating regional adoption of advanced vacuum technologies.

Profiling Leading Vacuum Component Manufacturers and Innovative Entrants Driving Competitive Advantage and Strategic Partnerships Globally

Leading companies in the vacuum components arena are differentiating through technology leadership, strategic partnerships, and targeted geographic expansion. Several incumbents have deepened investment in R&D, focusing on next-generation membrane materials and sensor integration for predictive diagnostics. Collaborative alliances with academic institutions and research consortia are accelerating the translation of novel materials science breakthroughs into commercial-grade components.

Moreover, select market entrants have captured share by prioritizing agility and customization, offering rapid prototyping services and modular system configurations that address niche applications with unique performance demands. Joint ventures between component specialists and system integrators are becoming more prevalent, enabling seamless integration of pumps, valves, and gauges into turnkey solutions. These partnerships also broaden installed-base support and aftermarket service capabilities, which are critical for long-term customer retention.

Regional players in emerging markets are leveraging cost advantages and localized manufacturing to challenge established brands, particularly in medium-duty pump and valve segments. To counteract this, global firms are expanding production footprints through greenfield facilities and contract manufacturing arrangements, ensuring compliance with regional content requirements and reducing lead times.

Investment in digital service platforms and remote diagnostics is enabling companies to shift from product-centric to service-oriented business models. This transition not only drives recurring revenue but also fosters long-term customer engagement through continuous value delivery. This dynamic landscape underscores the importance of strategic agility, collaborative innovation, and operational excellence as key capabilities for leading players to sustain and grow their market positions.

Actionable Strategic Recommendations Empowering Industry Leaders to Capitalize on Emerging Technologies and Evolving Market Opportunities

Industry leaders should prioritize integration of digital twins and predictive analytics into vacuum component design and maintenance workflows to achieve superior uptime and performance outcomes. By establishing real-time monitoring frameworks, organizations can preemptively detect anomalies and optimize maintenance schedules, thereby reducing operational disruptions and total cost of ownership.

Simultaneously, diversifying supply chains across multiple geographies will enhance resilience against trade barriers and raw material shortages. Engaging with contract manufacturers in strategic regions can shorten lead times and mitigate exposure to tariff fluctuations. Cross-functional collaboration between procurement, engineering, and sustainability teams will enable the identification of alternative materials and process enhancements that align with environmental regulations and corporate responsibility goals.

To capture emerging growth pockets, companies must adopt a customer-centric approach, deploying modular platforms that can be tailored to specific application requirements in sectors such as pharmaceuticals and renewable energy. Investing in training programs and knowledge-sharing initiatives will empower sales and technical teams to articulate value propositions effectively.

Leaders should also invest in sustainability certifications and lifecycle assessments to differentiate their offerings and meet evolving environmental and social governance criteria. Finally, establishing a robust ecosystem of academic partnerships and startup accelerators will facilitate access to disruptive innovations, ensuring that organizations remain at the forefront of vacuum component technological evolution.

Comprehensive Multi-Stage Research Methodology Combining Qualitative Interviews Quantitative Data Analysis and Competitive Benchmarking

The research methodology underpinning this analysis employed a multi-stage approach combining qualitative expert interviews, comprehensive secondary data review, and quantitative data analysis. Initially, structured interviews were conducted with senior executives and technical specialists across manufacturers, system integrators, and end-user organizations to gather insights into prevailing challenges, innovation roadmaps, and strategic priorities.

Concurrently, an extensive review of industry publications, patent filings, regulatory databases, and corporate disclosures provided a robust secondary foundation. This phase enabled cross-validation of emerging technology trends and material innovations. Subsequently, primary data from proprietary surveys conducted with procurement and engineering teams was synthesized to quantify adoption drivers and pain points across different segments.

Finally, a rigorous data triangulation process was applied to ensure findings accuracy and reliability. Statistical analyses identified correlation patterns between segmentation dimensions and performance metrics, while competitive benchmarking assessed leading players' strategic positioning and technological capabilities. The resulting framework offers a transparent and reproducible basis for decision-making, ensuring that insights are grounded in empirical evidence and reflect the current state of the vacuum components market.

Conclusive Insights Synthesizing Critical Findings to Drive Strategic Decision Making in the Global Vacuum Components Market

This executive summary has synthesized critical insights into the dynamic vacuum components market, highlighting emerging technology trends, susceptibility to trade policy shifts, segmentation-based growth opportunities, and regional market nuances. The interplay between advanced materials, digitalization, and modular architectures underscores a fundamental transformation in how vacuum systems are designed, manufactured, and deployed. Cumulative tariff pressures have prompted supply chain realignments, while segmentation breadth offers targeted avenues for product innovation and market entry across diverse industries.

Regional analysis reveals that established markets are focusing on sustainability and efficiency enhancements, whereas growth in the Asia-Pacific corridor is being driven by aggressive expansions in semiconductor fabrication and pharmaceuticals. Key players are differentiating through R&D collaboration, agile manufacturing models, and strategic partnerships, while actionable recommendations provide a roadmap for enhancing operational resilience and capturing emerging opportunities.

Ultimately, the convergence of technological innovation, strategic policy alignment, and customer-driven customization will define market leadership. Stakeholders who proactively integrate these dimensions will secure a sustainable competitive edge. By adhering to the outlined strategic imperatives-ranging from predictive analytics adoption to supply chain diversification-industry participants can navigate uncertainties and capitalize on evolving demand patterns. This conclusion sets the stage for deeper engagement with tailored market research insights and underscores the imperative for continuous innovation in a landscape marked by rapid technological advancement and shifting geopolitical dynamics.

Table of Contents

1. Preface

- 1.1. Objectives of the Study

- 1.2. Market Segmentation & Coverage

- 1.3. Years Considered for the Study

- 1.4. Currency & Pricing

- 1.5. Language

- 1.6. Stakeholders

2. Research Methodology

- 2.1. Define: Research Objective

- 2.2. Determine: Research Design

- 2.3. Prepare: Research Instrument

- 2.4. Collect: Data Source

- 2.5. Analyze: Data Interpretation

- 2.6. Formulate: Data Verification

- 2.7. Publish: Research Report

- 2.8. Repeat: Report Update

3. Executive Summary

4. Market Overview

- 4.1. Introduction

- 4.2. Market Sizing & Forecasting

5. Market Dynamics

- 5.1. Integration of IoT sensors in vacuum components for real-time performance monitoring

- 5.2. Adoption of additive manufacturing techniques to produce complex vacuum component geometries

- 5.3. Rising demand for eco-friendly vacuum pump materials with lower environmental impact

- 5.4. Implementation of predictive maintenance algorithms to reduce downtime in vacuum systems

- 5.5. Development of high-temperature resistant seals for vacuum systems operating above 500°C

- 5.6. Trend in consolidation of global supply chains for critical vacuum components amid shortages

6. Market Insights

- 6.1. Porter's Five Forces Analysis

- 6.2. PESTLE Analysis

7. Cumulative Impact of United States Tariffs 2025

8. Vacuum Components Market, by Product Type

- 8.1. Introduction

- 8.2. Chambers

- 8.3. Fittings

- 8.3.1. Couplings

- 8.3.2. Flanges

- 8.3.3. Seals

- 8.4. Gauges

- 8.4.1. Capacitance Gauge

- 8.4.2. Ionization Gauge

- 8.4.3. Pirani Gauge

- 8.5. Pumps

- 8.5.1. Diaphragm Pumps

- 8.5.2. Dry Pumps

- 8.5.3. Rotary Vane Pumps

- 8.5.4. Scroll Pumps

- 8.5.5. Turbomolecular Pumps

- 8.6. Valves

- 8.6.1. Ball Valves

- 8.6.2. Butterfly Valves

- 8.6.3. Gate Valves

9. Vacuum Components Market, by Material Type

- 9.1. Introduction

- 9.2. Aluminum

- 9.3. Copper

- 9.4. Plastic

- 9.5. Stainless Steel

10. Vacuum Components Market, by Application

- 10.1. Introduction

- 10.2. Food Packaging

- 10.3. Industrial Processing

- 10.4. Medical Equipment

- 10.5. Research & Development

- 10.6. Semiconductor Manufacturing

11. Vacuum Components Market, by End-User Industry

- 11.1. Introduction

- 11.2. Automotive

- 11.3. Chemical

- 11.4. Electronics

- 11.5. Food & Beverage

- 11.6. Healthcare

- 11.7. Packaging

12. Vacuum Components Market, by Distribution Channel

- 12.1. Introduction

- 12.2. Direct Sales

- 12.3. Distributor Sales

- 12.4. Online Sales

13. Americas Vacuum Components Market

- 13.1. Introduction

- 13.2. United States

- 13.3. Canada

- 13.4. Mexico

- 13.5. Brazil

- 13.6. Argentina

14. Europe, Middle East & Africa Vacuum Components Market

- 14.1. Introduction

- 14.2. United Kingdom

- 14.3. Germany

- 14.4. France

- 14.5. Russia

- 14.6. Italy

- 14.7. Spain

- 14.8. United Arab Emirates

- 14.9. Saudi Arabia

- 14.10. South Africa

- 14.11. Denmark

- 14.12. Netherlands

- 14.13. Qatar

- 14.14. Finland

- 14.15. Sweden

- 14.16. Nigeria

- 14.17. Egypt

- 14.18. Turkey

- 14.19. Israel

- 14.20. Norway

- 14.21. Poland

- 14.22. Switzerland

15. Asia-Pacific Vacuum Components Market

- 15.1. Introduction

- 15.2. China

- 15.3. India

- 15.4. Japan

- 15.5. Australia

- 15.6. South Korea

- 15.7. Indonesia

- 15.8. Thailand

- 15.9. Philippines

- 15.10. Malaysia

- 15.11. Singapore

- 15.12. Vietnam

- 15.13. Taiwan

16. Competitive Landscape

- 16.1. Market Share Analysis, 2024

- 16.2. FPNV Positioning Matrix, 2024

- 16.3. Competitive Analysis

- 16.3.1. Atlas Copco AB

- 16.3.2. ULVAC, Inc.

- 16.3.3. Pfeiffer Vacuum Technology AG

- 16.3.4. Oerlikon Leybold Vacuum GmbH

- 16.3.5. MKS Instruments, Inc.

- 16.3.6. VAT Group AG

- 16.3.7. AMETEK, Inc.

- 16.3.8. Agilent Technologies, Inc.

- 16.3.9. Ebara Corporation

- 16.3.10. Shimadzu Corporation

- 16.3.11. Ingersoll Rand Inc.

- 16.3.12. Thermo Fisher Scientific Inc.

- 16.3.13. Oxford Instruments plc

- 16.3.14. Nikkiso Co., Ltd.

- 16.3.15. Piab AB

- 16.3.16. Shin Nippon Machinery Co., Ltd.