|

|

市場調査レポート

商品コード

1676727

磁気浮上式回転システム市場:部品、技術、動作速度、用途、最終用途産業、販売チャネル別-2025-2030年世界予測Magnetic Levitation Rotation System Market by Components, Technology, Operational Speed, Application, End-Use Industry, Sales Channel - Global Forecast 2025-2030 |

||||||

カスタマイズ可能

適宜更新あり

|

|||||||

| 磁気浮上式回転システム市場:部品、技術、動作速度、用途、最終用途産業、販売チャネル別-2025-2030年世界予測 |

|

出版日: 2025年03月09日

発行: 360iResearch

ページ情報: 英文 186 Pages

納期: 即日から翌営業日

|

全表示

- 概要

- 図表

- 目次

磁気浮上式回転システム市場は、2023年に17億2,000万米ドルと評価され、2024年には18億8,000万米ドル、CAGR 9.57%で成長し、2030年には32億7,000万米ドルに達すると予測されています。

| 主な市場の統計 | |

|---|---|

| 基準年 2023 | 17億2,000万米ドル |

| 推定年 2024 | 18億8,000万米ドル |

| 予測年 2030 | 32億7,000万米ドル |

| CAGR(%) | 9.57% |

磁気浮上回転システムは画期的な技術革新として登場し、輸送やエネルギー生産から産業オートメーションに至るまで、さまざまな産業分野を再構築しています。このエグゼクティブサマリーでは、磁力を活用して物理的な接触なしに回転を可能にする革新的なメカニズムを紹介し、その結果、効率が向上するだけでなく、比類のない精度と耐久性を備えたシステムを実現しています。この技術は、摩擦を大幅に減らし、メンテナンスの必要性を最小限に抑え、さまざまな用途の機械の全体的な寿命を延ばす可能性を秘めています。

過去10年間で、材料科学、制御システム、センサー技術の開発が集結し、磁気浮上における急速な発展の時代に拍車がかかりました。このシステムの核心は、従来の機械システムの限界に課題する安定した高速回転を達成するために、細かく調整された磁気制御と堅牢な電力供給機構に依存しています。センサーとアクチュエーターを高度なフィードバック・ループとともに統合することで、これらのシステムは厳しい条件下でも確実に作動します。

この導入により、この革新的技術の世界の普及を後押ししている主要市場動向、セグメンテーションの洞察、地域ダイナミクスの包括的な概要が明らかになります。このテーマをさらに掘り下げると、磁気浮上回転システムが単なる技術的驚異ではなく、自動化とデジタル変革の態勢を整えた産業にとっての戦略的資産であることが明確になります。

磁気浮上式回転システム市場の変革

磁気浮上技術における最近のイノベーションは、いくつかの主要な市場セクターの業務パラダイムに劇的な変化をもたらしました。技術革新の収束と、エネルギー効率に優れ、メンテナンスの少ないソリューションに対する需要の高まりが、業界全体に大きな変化をもたらしました。制御システムとセンサーの統合における技術革新のペースは劇的に増加し、最新のシステムが俊敏かつ変動する運用要件に適応できるようになっています。

メーカー各社は、従来の機械的設計から、デジタル制御と予知保全を重視するシステムへの移行を目の当たりにしています。製造業者もエンドユーザーも同様に、摩擦を多用するシステムから非接触動作を提供するシステムへの移行を受け入れています。この進化は性能を向上させるだけでなく、物理的な磨耗や損傷を最小限に抑えることでダウンタイムを大幅に削減します。信頼性の向上と業務効率の改善により、さまざまな分野の主要企業が研究開発に多額の投資を行うようになり、これらのシステムが常に上昇し続ける性能ベンチマークに対応できるようになっています。

磁気浮上式回転システムの採用を加速させる上で、技術的な改良と並んで重要な役割を果たしているのが、規制と環境要因です。二酸化炭素排出量の削減とエネルギー効率の向上を目的とした政府の規制は、さまざまな用途への磁気システムの組み込みを間接的に促進しています。企業が厳しい環境基準を満たそうと努力する中、磁気浮上回転システムは、より環境に優しい産業慣行への移行に不可欠なツールと見なされるようになっています。

最後に、技術開発者と学術研究機関との間の戦略的パートナーシップや協力関係は、理論的進歩と実用的応用との間のギャップを埋めるのに役立っています。このような提携により、技術革新の商業化が加速され、従来は従来の工学的手法に頼っていた産業界でも利用できるようになりました。その結果、アイデアの相互受粉が、技術展望を再定義しつつある現在進行中の変革の礎となっています。

市場戦略を推進する包括的なセグメンテーション洞察

磁気浮上回転システム市場は、この業界を定義する多様なアプリケーションと技術的なニュアンスに対応するため、さまざまな洗練された方法でセグメント化されています。コンポーネントに基づいて詳細に分析すると、市場は制御システム、磁石、電源ユニット、センサー&アクチュエーター、構造要素などの重要な部分に体系的に分割されていることがわかります。制御システムの側面では、フィードバックシステムと安定化システムを区別することで、操作のニュアンスまで正確に捉えられるように、より深い考察が行われています。一方、磁石の分野では、電磁石、永久磁石、超電導磁石をさらに細分化しています。構造要素についても、ハウジングと支持構造、浮遊軌道の研究が追加されており、このように細分化することで、独自の設計と性能パラメータを理解するのに役立ちます。

技術面では、市場は電磁システム、ハイブリッド・システム、空気圧システム、超電導システムに分類されます。特にハイブリッド・システムは、電磁-空気圧、電磁-超電導にさらに細分化されており、利害関係者はシステム性能の向上をもたらすさまざまなメカニズムの融合を理解することができます。このデュアル・テクノロジー・アプローチは、性能の差別化に対応するだけでなく、さまざまな運転条件に適応する柔軟性の向上も可能にします。

運転速度はもう一つの重要なセグメンテーション・パラメーターであり、市場は高速システム、中速システム、低速システムに分けられます。この3分類は、超高速の技術プロセスから、低速ではあるが同様に重要な業務シナリオまで、幅広いアプリケーションを区分するのに役立ちます。こうすることで、顧客もメーカーも同様に、特定の運用ニーズを満たすソリューションをカスタマイズすることができます。

アプリケーションの観点からこのシステムを検証すると、エネルギー・システム、産業オートメーション、輸送システムに関連性があることがわかる。エネルギー・システムは、水力発電ダムや風力タービンのようなサブセクターに分類され、それぞれ独自のインフラや運用上の要求があります。同様に、産業オートメーションは、組立ラインや自動倉庫システムなど、さらに専門化されています。一方、輸送システムは、貨物システム、高速鉄道、都市交通など、さまざまな構成にまたがっており、さまざまな輸送様式における技術の多用途性を浮き彫りにしています。

セグメンテーションはさらに最終用途産業の領域にも及び、この技術の幅広い応用可能性を反映しています。具体的には、航空宇宙、コンシューマー・エレクトロニクス、ヘルスケア、産業・製造、運輸などのサブセクターが、磁気浮上システムの広範囲に及ぶ影響を強調しています。最後に、販売チャネルに基づく市場セグメンテーションでは、直販、販売代理店、オンラインプラットフォームといったチャネルを重視しており、これらは製品流通と顧客エンゲージメントの経路を明らかにする上で重要です。この全体的なセグメンテーションの枠組みは、ミクロ経済とマクロ経済の両方の要因に対応する市場戦略を設計し、的を絞ったイノベーションと賢明な意思決定への道を開く鍵となります。

目次

第1章 序文

第2章 調査手法

第3章 エグゼクティブサマリー

第4章 市場の概要

第5章 市場洞察

- 市場力学

- 促進要因

- 磁気浮上(マグレブ)技術の採用増加により、産業オートメーションと精密エンジニアリング市場が変革

- 効率的で省エネな輸送ソリューションに対する需要の高まり

- 磁気浮上回転技術の開発に向けた研究開発活動を世界的に拡大

- 抑制要因

- 磁気浮上システムに関連する技術およびメンテナンスの問題

- 機会

- 磁気浮上技術の進歩に向けた投資と資金の急増

- よりスムーズで効率的な公共交通ソリューションを実現する磁気浮上のイノベーション

- 課題

- さまざまな地域における磁気浮上技術の規制とコンプライアンスのハードル

- 促進要因

- 市場セグメンテーション分析

- 動作速度:高度な製造プロセスにおける高速システムの好感度が高まっています

- 技術:精密制御と高速輸送における有効性が確立されているため、電磁システムの使用が増加しています。

- コンポーネント:精度と応答性を高める磁気浮上回転システムの制御システムの需要が増加

- 用途:産業オートメーションにおける磁気浮上回転システムの使用拡大

- 最終用途産業:多様な産業における磁気浮上回転システムの進歩

- 販売チャネル:産業オートメーションと精密工学における直接販売の急増

- ポーターのファイブフォース分析

- PESTEL分析

- 政治的

- 経済

- 社会

- 技術的

- 法律上

- 環境

第6章 磁気浮上式回転システム市場:コンポーネント別

- 制御システム

- フィードバックシステム

- 安定化システム

- 磁石

- 電磁石

- 永久磁石

- 超伝導磁石

- 電源ユニット

- センサーとアクチュエータ

- 構造要素

- 住宅とサポート構造

- 浮遊トラック

第7章 磁気浮上式回転システム市場:技術別

- 電磁

- ハイブリッドシステム

- 電磁空気圧

- 電磁超伝導

- 空気圧

- 超伝導

第8章 磁気浮上式回転システム市場運用速度別

- 高速システム

- 低速システム

- 中速システム

第9章 磁気浮上式回転システム市場:用途別

- エネルギーシステム

- 水力発電ダム

- 風力タービン

- 産業オートメーション

- 組立ライン

- 自動保管システム

- 交通システム

- 貨物システム

- 高速鉄道

- 都市交通

第10章 磁気浮上式回転システム市場:最終用途産業別

- 航空宇宙

- 家電

- エネルギー

- ヘルスケア

- 工業・製造業

- 交通機関

第11章 磁気浮上式回転システム市場:販売チャネル別

- 直接販売

- 販売代理店

- オンラインプラットフォーム

第12章 南北アメリカの磁気浮上式回転システム市場

- アルゼンチン

- ブラジル

- カナダ

- メキシコ

- 米国

第13章 アジア太平洋地域の磁気浮上式回転システム市場

- オーストラリア

- 中国

- インド

- インドネシア

- 日本

- マレーシア

- フィリピン

- シンガポール

- 韓国

- 台湾

- タイ

- ベトナム

第14章 欧州・中東・アフリカの磁気浮上式回転システム市場

- デンマーク

- エジプト

- フィンランド

- フランス

- ドイツ

- イスラエル

- イタリア

- オランダ

- ナイジェリア

- ノルウェー

- ポーランド

- カタール

- ロシア

- サウジアラビア

- 南アフリカ

- スペイン

- スウェーデン

- スイス

- トルコ

- アラブ首長国連邦

- 英国

第15章 競合情勢

- 市場シェア分析, 2023

- FPNVポジショニングマトリックス, 2023

- 競合シナリオ分析

- 戦略分析と提言

企業一覧

- AB SKF

- ABB Ltd.

- AMT, Inc.

- BiVACOR Inc.

- Calnetix Technologies, LLC.

- Central Japan Railway Company

- Crealev BV by Appear Inc.

- CRRC Corporation Limited

- Evico GmbH

- General Atomics

- Hitachi, Ltd.

- Hyundai Rotem Co.

- IronLev by IronBox srl

- Kawasaki Heavy Industries, Ltd.

- Levitronix GmbH

- MagLev Aero Inc.

- Mitsubishi Electric Corporation

- Nevomos by JMR Technologies

- Physik Instrumente(PI)SE & Co. KG

- Rockwell Automation, Inc.

- Siemens AG

- SpinDrive Oy.

- Suzhou Supermag Intelligent Technology Co., Ltd.

- The Boeing Company

- The China Aerospace Science and Industry Corporation(CASIC)

LIST OF FIGURES

- FIGURE 1. MAGNETIC LEVITATION ROTATION SYSTEM MARKET MULTI-CURRENCY

- FIGURE 2. MAGNETIC LEVITATION ROTATION SYSTEM MARKET MULTI-LANGUAGE

- FIGURE 3. MAGNETIC LEVITATION ROTATION SYSTEM MARKET RESEARCH PROCESS

- FIGURE 4. MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, 2023 VS 2030

- FIGURE 5. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, 2018-2030 (USD MILLION)

- FIGURE 6. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY REGION, 2023 VS 2024 VS 2030 (USD MILLION)

- FIGURE 7. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY COUNTRY, 2023 VS 2024 VS 2030 (USD MILLION)

- FIGURE 8. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY COMPONENTS, 2023 VS 2030 (%)

- FIGURE 9. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY COMPONENTS, 2023 VS 2024 VS 2030 (USD MILLION)

- FIGURE 10. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY TECHNOLOGY, 2023 VS 2030 (%)

- FIGURE 11. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY TECHNOLOGY, 2023 VS 2024 VS 2030 (USD MILLION)

- FIGURE 12. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY OPERATIONAL SPEED, 2023 VS 2030 (%)

- FIGURE 13. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY OPERATIONAL SPEED, 2023 VS 2024 VS 2030 (USD MILLION)

- FIGURE 14. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY APPLICATION, 2023 VS 2030 (%)

- FIGURE 15. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY APPLICATION, 2023 VS 2024 VS 2030 (USD MILLION)

- FIGURE 16. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY END-USE INDUSTRY, 2023 VS 2030 (%)

- FIGURE 17. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY END-USE INDUSTRY, 2023 VS 2024 VS 2030 (USD MILLION)

- FIGURE 18. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY SALES CHANNEL, 2023 VS 2030 (%)

- FIGURE 19. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY SALES CHANNEL, 2023 VS 2024 VS 2030 (USD MILLION)

- FIGURE 20. AMERICAS MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY COUNTRY, 2023 VS 2030 (%)

- FIGURE 21. AMERICAS MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY COUNTRY, 2023 VS 2024 VS 2030 (USD MILLION)

- FIGURE 22. UNITED STATES MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY STATE, 2023 VS 2030 (%)

- FIGURE 23. UNITED STATES MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY STATE, 2023 VS 2024 VS 2030 (USD MILLION)

- FIGURE 24. ASIA-PACIFIC MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY COUNTRY, 2023 VS 2030 (%)

- FIGURE 25. ASIA-PACIFIC MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY COUNTRY, 2023 VS 2024 VS 2030 (USD MILLION)

- FIGURE 26. EUROPE, MIDDLE EAST & AFRICA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY COUNTRY, 2023 VS 2030 (%)

- FIGURE 27. EUROPE, MIDDLE EAST & AFRICA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY COUNTRY, 2023 VS 2024 VS 2030 (USD MILLION)

- FIGURE 28. MAGNETIC LEVITATION ROTATION SYSTEM MARKET SHARE, BY KEY PLAYER, 2023

- FIGURE 29. MAGNETIC LEVITATION ROTATION SYSTEM MARKET, FPNV POSITIONING MATRIX, 2023

LIST OF TABLES

- TABLE 1. MAGNETIC LEVITATION ROTATION SYSTEM MARKET SEGMENTATION & COVERAGE

- TABLE 2. UNITED STATES DOLLAR EXCHANGE RATE, 2018-2023

- TABLE 3. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, 2018-2030 (USD MILLION)

- TABLE 4. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY REGION, 2018-2030 (USD MILLION)

- TABLE 5. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY COUNTRY, 2018-2030 (USD MILLION)

- TABLE 6. MAGNETIC LEVITATION ROTATION SYSTEM MARKET DYNAMICS

- TABLE 7. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY COMPONENTS, 2018-2030 (USD MILLION)

- TABLE 8. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY CONTROL SYSTEMS, BY REGION, 2018-2030 (USD MILLION)

- TABLE 9. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY FEEDBACK SYSTEMS, BY REGION, 2018-2030 (USD MILLION)

- TABLE 10. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY STABILIZATION SYSTEMS, BY REGION, 2018-2030 (USD MILLION)

- TABLE 11. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY CONTROL SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 12. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY MAGNETS, BY REGION, 2018-2030 (USD MILLION)

- TABLE 13. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY ELECTROMAGNETS, BY REGION, 2018-2030 (USD MILLION)

- TABLE 14. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY PERMANENT MAGNETS, BY REGION, 2018-2030 (USD MILLION)

- TABLE 15. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY SUPERCONDUCTING MAGNETS, BY REGION, 2018-2030 (USD MILLION)

- TABLE 16. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY MAGNETS, 2018-2030 (USD MILLION)

- TABLE 17. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY POWER SUPPLY UNITS, BY REGION, 2018-2030 (USD MILLION)

- TABLE 18. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY SENSORS & ACTUATORS, BY REGION, 2018-2030 (USD MILLION)

- TABLE 19. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY STRUCTURAL ELEMENTS, BY REGION, 2018-2030 (USD MILLION)

- TABLE 20. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY HOUSING & SUPPORT STRUCTURES, BY REGION, 2018-2030 (USD MILLION)

- TABLE 21. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY LEVITATION TRACKS, BY REGION, 2018-2030 (USD MILLION)

- TABLE 22. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY STRUCTURAL ELEMENTS, 2018-2030 (USD MILLION)

- TABLE 23. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY TECHNOLOGY, 2018-2030 (USD MILLION)

- TABLE 24. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY ELECTROMAGNETIC, BY REGION, 2018-2030 (USD MILLION)

- TABLE 25. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY HYBRID SYSTEMS, BY REGION, 2018-2030 (USD MILLION)

- TABLE 26. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY ELECTROMAGNETIC-PNEUMATIC, BY REGION, 2018-2030 (USD MILLION)

- TABLE 27. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY ELECTROMAGNETIC-SUPERCONDUCTING, BY REGION, 2018-2030 (USD MILLION)

- TABLE 28. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY HYBRID SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 29. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY PNEUMATIC, BY REGION, 2018-2030 (USD MILLION)

- TABLE 30. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY SUPERCONDUCTING, BY REGION, 2018-2030 (USD MILLION)

- TABLE 31. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY OPERATIONAL SPEED, 2018-2030 (USD MILLION)

- TABLE 32. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY HIGH-SPEED SYSTEMS, BY REGION, 2018-2030 (USD MILLION)

- TABLE 33. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY LOW-SPEED SYSTEMS, BY REGION, 2018-2030 (USD MILLION)

- TABLE 34. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY MEDIUM-SPEED SYSTEMS, BY REGION, 2018-2030 (USD MILLION)

- TABLE 35. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY APPLICATION, 2018-2030 (USD MILLION)

- TABLE 36. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY ENERGY SYSTEMS, BY REGION, 2018-2030 (USD MILLION)

- TABLE 37. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY HYDROELECTRIC DAMS, BY REGION, 2018-2030 (USD MILLION)

- TABLE 38. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY WIND TURBINES, BY REGION, 2018-2030 (USD MILLION)

- TABLE 39. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY ENERGY SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 40. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY INDUSTRIAL AUTOMATION, BY REGION, 2018-2030 (USD MILLION)

- TABLE 41. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY ASSEMBLY LINES, BY REGION, 2018-2030 (USD MILLION)

- TABLE 42. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY AUTOMATED STORAGE SYSTEMS, BY REGION, 2018-2030 (USD MILLION)

- TABLE 43. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY INDUSTRIAL AUTOMATION, 2018-2030 (USD MILLION)

- TABLE 44. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY TRANSPORTATION SYSTEMS, BY REGION, 2018-2030 (USD MILLION)

- TABLE 45. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY CARGO SYSTEMS, BY REGION, 2018-2030 (USD MILLION)

- TABLE 46. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY HIGH-SPEED TRAINS, BY REGION, 2018-2030 (USD MILLION)

- TABLE 47. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY URBAN TRANSIT, BY REGION, 2018-2030 (USD MILLION)

- TABLE 48. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY TRANSPORTATION SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 49. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY END-USE INDUSTRY, 2018-2030 (USD MILLION)

- TABLE 50. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY AEROSPACE, BY REGION, 2018-2030 (USD MILLION)

- TABLE 51. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY CONSUMER ELECTRONICS, BY REGION, 2018-2030 (USD MILLION)

- TABLE 52. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY ENERGY, BY REGION, 2018-2030 (USD MILLION)

- TABLE 53. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY HEALTHCARE, BY REGION, 2018-2030 (USD MILLION)

- TABLE 54. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY INDUSTRIAL & MANUFACTURING, BY REGION, 2018-2030 (USD MILLION)

- TABLE 55. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY TRANSPORTATION, BY REGION, 2018-2030 (USD MILLION)

- TABLE 56. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY SALES CHANNEL, 2018-2030 (USD MILLION)

- TABLE 57. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY DIRECT SALES, BY REGION, 2018-2030 (USD MILLION)

- TABLE 58. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY DISTRIBUTORS, BY REGION, 2018-2030 (USD MILLION)

- TABLE 59. GLOBAL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY ONLINE PLATFORMS, BY REGION, 2018-2030 (USD MILLION)

- TABLE 60. AMERICAS MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY COMPONENTS, 2018-2030 (USD MILLION)

- TABLE 61. AMERICAS MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY CONTROL SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 62. AMERICAS MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY MAGNETS, 2018-2030 (USD MILLION)

- TABLE 63. AMERICAS MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY STRUCTURAL ELEMENTS, 2018-2030 (USD MILLION)

- TABLE 64. AMERICAS MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY TECHNOLOGY, 2018-2030 (USD MILLION)

- TABLE 65. AMERICAS MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY HYBRID SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 66. AMERICAS MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY OPERATIONAL SPEED, 2018-2030 (USD MILLION)

- TABLE 67. AMERICAS MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY APPLICATION, 2018-2030 (USD MILLION)

- TABLE 68. AMERICAS MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY ENERGY SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 69. AMERICAS MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY INDUSTRIAL AUTOMATION, 2018-2030 (USD MILLION)

- TABLE 70. AMERICAS MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY TRANSPORTATION SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 71. AMERICAS MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY END-USE INDUSTRY, 2018-2030 (USD MILLION)

- TABLE 72. AMERICAS MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY SALES CHANNEL, 2018-2030 (USD MILLION)

- TABLE 73. AMERICAS MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY COUNTRY, 2018-2030 (USD MILLION)

- TABLE 74. ARGENTINA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY COMPONENTS, 2018-2030 (USD MILLION)

- TABLE 75. ARGENTINA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY CONTROL SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 76. ARGENTINA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY MAGNETS, 2018-2030 (USD MILLION)

- TABLE 77. ARGENTINA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY STRUCTURAL ELEMENTS, 2018-2030 (USD MILLION)

- TABLE 78. ARGENTINA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY TECHNOLOGY, 2018-2030 (USD MILLION)

- TABLE 79. ARGENTINA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY HYBRID SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 80. ARGENTINA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY OPERATIONAL SPEED, 2018-2030 (USD MILLION)

- TABLE 81. ARGENTINA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY APPLICATION, 2018-2030 (USD MILLION)

- TABLE 82. ARGENTINA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY ENERGY SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 83. ARGENTINA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY INDUSTRIAL AUTOMATION, 2018-2030 (USD MILLION)

- TABLE 84. ARGENTINA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY TRANSPORTATION SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 85. ARGENTINA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY END-USE INDUSTRY, 2018-2030 (USD MILLION)

- TABLE 86. ARGENTINA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY SALES CHANNEL, 2018-2030 (USD MILLION)

- TABLE 87. BRAZIL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY COMPONENTS, 2018-2030 (USD MILLION)

- TABLE 88. BRAZIL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY CONTROL SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 89. BRAZIL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY MAGNETS, 2018-2030 (USD MILLION)

- TABLE 90. BRAZIL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY STRUCTURAL ELEMENTS, 2018-2030 (USD MILLION)

- TABLE 91. BRAZIL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY TECHNOLOGY, 2018-2030 (USD MILLION)

- TABLE 92. BRAZIL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY HYBRID SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 93. BRAZIL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY OPERATIONAL SPEED, 2018-2030 (USD MILLION)

- TABLE 94. BRAZIL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY APPLICATION, 2018-2030 (USD MILLION)

- TABLE 95. BRAZIL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY ENERGY SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 96. BRAZIL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY INDUSTRIAL AUTOMATION, 2018-2030 (USD MILLION)

- TABLE 97. BRAZIL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY TRANSPORTATION SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 98. BRAZIL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY END-USE INDUSTRY, 2018-2030 (USD MILLION)

- TABLE 99. BRAZIL MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY SALES CHANNEL, 2018-2030 (USD MILLION)

- TABLE 100. CANADA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY COMPONENTS, 2018-2030 (USD MILLION)

- TABLE 101. CANADA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY CONTROL SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 102. CANADA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY MAGNETS, 2018-2030 (USD MILLION)

- TABLE 103. CANADA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY STRUCTURAL ELEMENTS, 2018-2030 (USD MILLION)

- TABLE 104. CANADA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY TECHNOLOGY, 2018-2030 (USD MILLION)

- TABLE 105. CANADA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY HYBRID SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 106. CANADA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY OPERATIONAL SPEED, 2018-2030 (USD MILLION)

- TABLE 107. CANADA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY APPLICATION, 2018-2030 (USD MILLION)

- TABLE 108. CANADA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY ENERGY SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 109. CANADA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY INDUSTRIAL AUTOMATION, 2018-2030 (USD MILLION)

- TABLE 110. CANADA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY TRANSPORTATION SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 111. CANADA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY END-USE INDUSTRY, 2018-2030 (USD MILLION)

- TABLE 112. CANADA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY SALES CHANNEL, 2018-2030 (USD MILLION)

- TABLE 113. MEXICO MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY COMPONENTS, 2018-2030 (USD MILLION)

- TABLE 114. MEXICO MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY CONTROL SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 115. MEXICO MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY MAGNETS, 2018-2030 (USD MILLION)

- TABLE 116. MEXICO MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY STRUCTURAL ELEMENTS, 2018-2030 (USD MILLION)

- TABLE 117. MEXICO MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY TECHNOLOGY, 2018-2030 (USD MILLION)

- TABLE 118. MEXICO MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY HYBRID SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 119. MEXICO MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY OPERATIONAL SPEED, 2018-2030 (USD MILLION)

- TABLE 120. MEXICO MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY APPLICATION, 2018-2030 (USD MILLION)

- TABLE 121. MEXICO MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY ENERGY SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 122. MEXICO MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY INDUSTRIAL AUTOMATION, 2018-2030 (USD MILLION)

- TABLE 123. MEXICO MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY TRANSPORTATION SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 124. MEXICO MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY END-USE INDUSTRY, 2018-2030 (USD MILLION)

- TABLE 125. MEXICO MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY SALES CHANNEL, 2018-2030 (USD MILLION)

- TABLE 126. UNITED STATES MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY COMPONENTS, 2018-2030 (USD MILLION)

- TABLE 127. UNITED STATES MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY CONTROL SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 128. UNITED STATES MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY MAGNETS, 2018-2030 (USD MILLION)

- TABLE 129. UNITED STATES MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY STRUCTURAL ELEMENTS, 2018-2030 (USD MILLION)

- TABLE 130. UNITED STATES MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY TECHNOLOGY, 2018-2030 (USD MILLION)

- TABLE 131. UNITED STATES MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY HYBRID SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 132. UNITED STATES MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY OPERATIONAL SPEED, 2018-2030 (USD MILLION)

- TABLE 133. UNITED STATES MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY APPLICATION, 2018-2030 (USD MILLION)

- TABLE 134. UNITED STATES MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY ENERGY SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 135. UNITED STATES MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY INDUSTRIAL AUTOMATION, 2018-2030 (USD MILLION)

- TABLE 136. UNITED STATES MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY TRANSPORTATION SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 137. UNITED STATES MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY END-USE INDUSTRY, 2018-2030 (USD MILLION)

- TABLE 138. UNITED STATES MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY SALES CHANNEL, 2018-2030 (USD MILLION)

- TABLE 139. UNITED STATES MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY STATE, 2018-2030 (USD MILLION)

- TABLE 140. ASIA-PACIFIC MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY COMPONENTS, 2018-2030 (USD MILLION)

- TABLE 141. ASIA-PACIFIC MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY CONTROL SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 142. ASIA-PACIFIC MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY MAGNETS, 2018-2030 (USD MILLION)

- TABLE 143. ASIA-PACIFIC MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY STRUCTURAL ELEMENTS, 2018-2030 (USD MILLION)

- TABLE 144. ASIA-PACIFIC MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY TECHNOLOGY, 2018-2030 (USD MILLION)

- TABLE 145. ASIA-PACIFIC MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY HYBRID SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 146. ASIA-PACIFIC MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY OPERATIONAL SPEED, 2018-2030 (USD MILLION)

- TABLE 147. ASIA-PACIFIC MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY APPLICATION, 2018-2030 (USD MILLION)

- TABLE 148. ASIA-PACIFIC MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY ENERGY SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 149. ASIA-PACIFIC MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY INDUSTRIAL AUTOMATION, 2018-2030 (USD MILLION)

- TABLE 150. ASIA-PACIFIC MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY TRANSPORTATION SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 151. ASIA-PACIFIC MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY END-USE INDUSTRY, 2018-2030 (USD MILLION)

- TABLE 152. ASIA-PACIFIC MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY SALES CHANNEL, 2018-2030 (USD MILLION)

- TABLE 153. ASIA-PACIFIC MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY COUNTRY, 2018-2030 (USD MILLION)

- TABLE 154. AUSTRALIA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY COMPONENTS, 2018-2030 (USD MILLION)

- TABLE 155. AUSTRALIA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY CONTROL SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 156. AUSTRALIA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY MAGNETS, 2018-2030 (USD MILLION)

- TABLE 157. AUSTRALIA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY STRUCTURAL ELEMENTS, 2018-2030 (USD MILLION)

- TABLE 158. AUSTRALIA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY TECHNOLOGY, 2018-2030 (USD MILLION)

- TABLE 159. AUSTRALIA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY HYBRID SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 160. AUSTRALIA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY OPERATIONAL SPEED, 2018-2030 (USD MILLION)

- TABLE 161. AUSTRALIA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY APPLICATION, 2018-2030 (USD MILLION)

- TABLE 162. AUSTRALIA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY ENERGY SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 163. AUSTRALIA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY INDUSTRIAL AUTOMATION, 2018-2030 (USD MILLION)

- TABLE 164. AUSTRALIA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY TRANSPORTATION SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 165. AUSTRALIA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY END-USE INDUSTRY, 2018-2030 (USD MILLION)

- TABLE 166. AUSTRALIA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY SALES CHANNEL, 2018-2030 (USD MILLION)

- TABLE 167. CHINA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY COMPONENTS, 2018-2030 (USD MILLION)

- TABLE 168. CHINA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY CONTROL SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 169. CHINA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY MAGNETS, 2018-2030 (USD MILLION)

- TABLE 170. CHINA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY STRUCTURAL ELEMENTS, 2018-2030 (USD MILLION)

- TABLE 171. CHINA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY TECHNOLOGY, 2018-2030 (USD MILLION)

- TABLE 172. CHINA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY HYBRID SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 173. CHINA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY OPERATIONAL SPEED, 2018-2030 (USD MILLION)

- TABLE 174. CHINA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY APPLICATION, 2018-2030 (USD MILLION)

- TABLE 175. CHINA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY ENERGY SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 176. CHINA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY INDUSTRIAL AUTOMATION, 2018-2030 (USD MILLION)

- TABLE 177. CHINA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY TRANSPORTATION SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 178. CHINA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY END-USE INDUSTRY, 2018-2030 (USD MILLION)

- TABLE 179. CHINA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY SALES CHANNEL, 2018-2030 (USD MILLION)

- TABLE 180. INDIA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY COMPONENTS, 2018-2030 (USD MILLION)

- TABLE 181. INDIA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY CONTROL SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 182. INDIA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY MAGNETS, 2018-2030 (USD MILLION)

- TABLE 183. INDIA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY STRUCTURAL ELEMENTS, 2018-2030 (USD MILLION)

- TABLE 184. INDIA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY TECHNOLOGY, 2018-2030 (USD MILLION)

- TABLE 185. INDIA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY HYBRID SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 186. INDIA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY OPERATIONAL SPEED, 2018-2030 (USD MILLION)

- TABLE 187. INDIA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY APPLICATION, 2018-2030 (USD MILLION)

- TABLE 188. INDIA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY ENERGY SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 189. INDIA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY INDUSTRIAL AUTOMATION, 2018-2030 (USD MILLION)

- TABLE 190. INDIA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY TRANSPORTATION SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 191. INDIA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY END-USE INDUSTRY, 2018-2030 (USD MILLION)

- TABLE 192. INDIA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY SALES CHANNEL, 2018-2030 (USD MILLION)

- TABLE 193. INDONESIA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY COMPONENTS, 2018-2030 (USD MILLION)

- TABLE 194. INDONESIA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY CONTROL SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 195. INDONESIA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY MAGNETS, 2018-2030 (USD MILLION)

- TABLE 196. INDONESIA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY STRUCTURAL ELEMENTS, 2018-2030 (USD MILLION)

- TABLE 197. INDONESIA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY TECHNOLOGY, 2018-2030 (USD MILLION)

- TABLE 198. INDONESIA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY HYBRID SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 199. INDONESIA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY OPERATIONAL SPEED, 2018-2030 (USD MILLION)

- TABLE 200. INDONESIA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY APPLICATION, 2018-2030 (USD MILLION)

- TABLE 201. INDONESIA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY ENERGY SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 202. INDONESIA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY INDUSTRIAL AUTOMATION, 2018-2030 (USD MILLION)

- TABLE 203. INDONESIA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY TRANSPORTATION SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 204. INDONESIA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY END-USE INDUSTRY, 2018-2030 (USD MILLION)

- TABLE 205. INDONESIA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY SALES CHANNEL, 2018-2030 (USD MILLION)

- TABLE 206. JAPAN MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY COMPONENTS, 2018-2030 (USD MILLION)

- TABLE 207. JAPAN MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY CONTROL SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 208. JAPAN MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY MAGNETS, 2018-2030 (USD MILLION)

- TABLE 209. JAPAN MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY STRUCTURAL ELEMENTS, 2018-2030 (USD MILLION)

- TABLE 210. JAPAN MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY TECHNOLOGY, 2018-2030 (USD MILLION)

- TABLE 211. JAPAN MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY HYBRID SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 212. JAPAN MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY OPERATIONAL SPEED, 2018-2030 (USD MILLION)

- TABLE 213. JAPAN MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY APPLICATION, 2018-2030 (USD MILLION)

- TABLE 214. JAPAN MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY ENERGY SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 215. JAPAN MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY INDUSTRIAL AUTOMATION, 2018-2030 (USD MILLION)

- TABLE 216. JAPAN MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY TRANSPORTATION SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 217. JAPAN MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY END-USE INDUSTRY, 2018-2030 (USD MILLION)

- TABLE 218. JAPAN MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY SALES CHANNEL, 2018-2030 (USD MILLION)

- TABLE 219. MALAYSIA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY COMPONENTS, 2018-2030 (USD MILLION)

- TABLE 220. MALAYSIA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY CONTROL SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 221. MALAYSIA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY MAGNETS, 2018-2030 (USD MILLION)

- TABLE 222. MALAYSIA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY STRUCTURAL ELEMENTS, 2018-2030 (USD MILLION)

- TABLE 223. MALAYSIA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY TECHNOLOGY, 2018-2030 (USD MILLION)

- TABLE 224. MALAYSIA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY HYBRID SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 225. MALAYSIA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY OPERATIONAL SPEED, 2018-2030 (USD MILLION)

- TABLE 226. MALAYSIA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY APPLICATION, 2018-2030 (USD MILLION)

- TABLE 227. MALAYSIA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY ENERGY SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 228. MALAYSIA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY INDUSTRIAL AUTOMATION, 2018-2030 (USD MILLION)

- TABLE 229. MALAYSIA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY TRANSPORTATION SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 230. MALAYSIA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY END-USE INDUSTRY, 2018-2030 (USD MILLION)

- TABLE 231. MALAYSIA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY SALES CHANNEL, 2018-2030 (USD MILLION)

- TABLE 232. PHILIPPINES MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY COMPONENTS, 2018-2030 (USD MILLION)

- TABLE 233. PHILIPPINES MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY CONTROL SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 234. PHILIPPINES MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY MAGNETS, 2018-2030 (USD MILLION)

- TABLE 235. PHILIPPINES MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY STRUCTURAL ELEMENTS, 2018-2030 (USD MILLION)

- TABLE 236. PHILIPPINES MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY TECHNOLOGY, 2018-2030 (USD MILLION)

- TABLE 237. PHILIPPINES MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY HYBRID SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 238. PHILIPPINES MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY OPERATIONAL SPEED, 2018-2030 (USD MILLION)

- TABLE 239. PHILIPPINES MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY APPLICATION, 2018-2030 (USD MILLION)

- TABLE 240. PHILIPPINES MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY ENERGY SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 241. PHILIPPINES MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY INDUSTRIAL AUTOMATION, 2018-2030 (USD MILLION)

- TABLE 242. PHILIPPINES MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY TRANSPORTATION SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 243. PHILIPPINES MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY END-USE INDUSTRY, 2018-2030 (USD MILLION)

- TABLE 244. PHILIPPINES MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY SALES CHANNEL, 2018-2030 (USD MILLION)

- TABLE 245. SINGAPORE MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY COMPONENTS, 2018-2030 (USD MILLION)

- TABLE 246. SINGAPORE MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY CONTROL SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 247. SINGAPORE MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY MAGNETS, 2018-2030 (USD MILLION)

- TABLE 248. SINGAPORE MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY STRUCTURAL ELEMENTS, 2018-2030 (USD MILLION)

- TABLE 249. SINGAPORE MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY TECHNOLOGY, 2018-2030 (USD MILLION)

- TABLE 250. SINGAPORE MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY HYBRID SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 251. SINGAPORE MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY OPERATIONAL SPEED, 2018-2030 (USD MILLION)

- TABLE 252. SINGAPORE MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY APPLICATION, 2018-2030 (USD MILLION)

- TABLE 253. SINGAPORE MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY ENERGY SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 254. SINGAPORE MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY INDUSTRIAL AUTOMATION, 2018-2030 (USD MILLION)

- TABLE 255. SINGAPORE MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY TRANSPORTATION SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 256. SINGAPORE MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY END-USE INDUSTRY, 2018-2030 (USD MILLION)

- TABLE 257. SINGAPORE MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY SALES CHANNEL, 2018-2030 (USD MILLION)

- TABLE 258. SOUTH KOREA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY COMPONENTS, 2018-2030 (USD MILLION)

- TABLE 259. SOUTH KOREA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY CONTROL SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 260. SOUTH KOREA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY MAGNETS, 2018-2030 (USD MILLION)

- TABLE 261. SOUTH KOREA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY STRUCTURAL ELEMENTS, 2018-2030 (USD MILLION)

- TABLE 262. SOUTH KOREA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY TECHNOLOGY, 2018-2030 (USD MILLION)

- TABLE 263. SOUTH KOREA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY HYBRID SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 264. SOUTH KOREA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY OPERATIONAL SPEED, 2018-2030 (USD MILLION)

- TABLE 265. SOUTH KOREA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY APPLICATION, 2018-2030 (USD MILLION)

- TABLE 266. SOUTH KOREA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY ENERGY SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 267. SOUTH KOREA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY INDUSTRIAL AUTOMATION, 2018-2030 (USD MILLION)

- TABLE 268. SOUTH KOREA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY TRANSPORTATION SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 269. SOUTH KOREA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY END-USE INDUSTRY, 2018-2030 (USD MILLION)

- TABLE 270. SOUTH KOREA MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY SALES CHANNEL, 2018-2030 (USD MILLION)

- TABLE 271. TAIWAN MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY COMPONENTS, 2018-2030 (USD MILLION)

- TABLE 272. TAIWAN MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY CONTROL SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 273. TAIWAN MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY MAGNETS, 2018-2030 (USD MILLION)

- TABLE 274. TAIWAN MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY STRUCTURAL ELEMENTS, 2018-2030 (USD MILLION)

- TABLE 275. TAIWAN MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY TECHNOLOGY, 2018-2030 (USD MILLION)

- TABLE 276. TAIWAN MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY HYBRID SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 277. TAIWAN MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY OPERATIONAL SPEED, 2018-2030 (USD MILLION)

- TABLE 278. TAIWAN MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY APPLICATION, 2018-2030 (USD MILLION)

- TABLE 279. TAIWAN MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY ENERGY SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 280. TAIWAN MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY INDUSTRIAL AUTOMATION, 2018-2030 (USD MILLION)

- TABLE 281. TAIWAN MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY TRANSPORTATION SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 282. TAIWAN MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY END-USE INDUSTRY, 2018-2030 (USD MILLION)

- TABLE 283. TAIWAN MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY SALES CHANNEL, 2018-2030 (USD MILLION)

- TABLE 284. THAILAND MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY COMPONENTS, 2018-2030 (USD MILLION)

- TABLE 285. THAILAND MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY CONTROL SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 286. THAILAND MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY MAGNETS, 2018-2030 (USD MILLION)

- TABLE 287. THAILAND MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY STRUCTURAL ELEMENTS, 2018-2030 (USD MILLION)

- TABLE 288. THAILAND MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY TECHNOLOGY, 2018-2030 (USD MILLION)

- TABLE 289. THAILAND MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY HYBRID SYSTEMS, 2018-2030 (USD MILLION)

- TABLE 290. THAILAND MAGNETIC LEVITATION ROTATION SYSTEM MARKET SIZE, BY OPERATIONAL SPEED, 2018-2030 (USD M

The Magnetic Levitation Rotation System Market was valued at USD 1.72 billion in 2023 and is projected to grow to USD 1.88 billion in 2024, with a CAGR of 9.57%, reaching USD 3.27 billion by 2030.

| KEY MARKET STATISTICS | |

|---|---|

| Base Year [2023] | USD 1.72 billion |

| Estimated Year [2024] | USD 1.88 billion |

| Forecast Year [2030] | USD 3.27 billion |

| CAGR (%) | 9.57% |

Magnetic Levitation Rotation Systems have emerged as a groundbreaking technological innovation that is reshaping multiple industrial sectors, from transportation and energy production to industrial automation and beyond. This executive summary introduces the innovative mechanism that leverages magnetic forces to enable rotation without physical contact, resulting in systems that are not only more efficient but also offer unparalleled precision and durability. The technology has the potential to drastically reduce friction, minimize maintenance requirements, and extend the overall lifespan of machinery across various applications.

Over the past decade, advances in materials science, control systems, and sensor technologies have converged to spur an era of rapid development in magnetic levitation. At its core, the system relies on finely tuned magnetic controls and robust power supply mechanisms to achieve stable and high-speed rotations that challenge the limitations of traditional mechanical systems. The integration of sensors and actuators along with sophisticated feedback loops ensures that these systems operate reliably even under demanding conditions.

This introduction sets the stage for a comprehensive overview of key market trends, segmentation insights, and regional dynamics that are driving the global adoption of this transformative technology. As we delve deeper into the subject, the discussion provides clarity on how the magnetic levitation rotation system is not just a technical marvel but also a strategic asset for industries poised for automation and digital transformation.

Transformative Shifts in the Technological Landscape

Recent innovations in magnetic levitation technology have led to dramatic shifts in the operational paradigms of several key market sectors. A convergence of technological breakthroughs and rising demand for energy-efficient, low-maintenance solutions has catalyzed major changes across industries. The pace of innovation in control systems and sensor integration has increased dramatically, ensuring that modern systems are both agile and adaptable to fluctuating operational requirements.

Manufacturers are witnessing a shift from traditional mechanical designs to systems that emphasize digital control and predictive maintenance. Manufacturers and end-users alike are embracing the transition from friction-intensive systems to those that offer contactless movement. This evolution not only improves performance but also significantly reduces downtime by minimizing physical wear and tear. Enhanced reliability and operational efficiencies are prompting key players in myriad sectors to invest heavily in research and development, ensuring these systems keep pace with ever-rising performance benchmarks.

Alongside technological refinements, regulatory and environmental factors have played a pivotal role in accelerating the adoption of magnetic levitation rotation systems. Government regulations aimed at reducing carbon emissions and improving energy efficiency have indirectly promoted the incorporation of magnetic systems in various applications. As companies strive to meet stringent environmental standards, these systems are increasingly seen as vital tools in the transition toward greener industrial practices.

Finally, strategic partnerships and collaborations between technology developers and academic research institutions have helped to bridge the gap between theoretical advances and practical applications. Such alliances have accelerated the commercialization of these innovations, making them accessible even to industries that traditionally relied on conventional engineering methods. The resulting cross-pollination of ideas has been the cornerstone of the ongoing transformation that is redefining the technology landscape.

Comprehensive Segmentation Insights Driving Market Strategies

The magnetic levitation rotation system market has been segmented in various sophisticated ways to address the diverse range of applications and technological nuances that define the industry. A detailed analysis based on components reveals that the market is systematically divided into vital parts such as Control Systems, Magnets, Power Supply Units, Sensors & Actuators, and Structural Elements. The Control Systems aspect receives a deeper look by distinguishing between Feedback Systems and Stabilization Systems, ensuring that even operational nuances are captured accurately. Meanwhile, the Magnets segment dissects its scope further to cover Electromagnets, Permanent Magnets, and Superconducting Magnets. Structural Elements are not left behind, with additional study into Housing & Support Structures and Levitation Tracks; this finer segmentation helps in understanding unique design and performance parameters.

In terms of technology, the market is dissected into Electromagnetic, Hybrid, Pneumatic, and Superconducting systems. Notably, Hybrid Systems, which have been further broken down into Electromagnetic-Pneumatic and Electromagnetic-Superconducting, allow stakeholders to appreciate the blend of different mechanisms that bring about enhanced system performance. This dual-technology approach not only caters to performance differentiation but also enables improved flexibility in adapting to varied operational conditions.

Operational speed is another key segmentation parameter, where the market is divided among High-Speed Systems, Medium-Speed Systems, and Low-Speed Systems. This tripartite categorization helps in demarcating applications that range from ultra-fast technological processes to slower, yet equally critical, operational scenarios. In this manner, customers and manufacturers alike are able to tailor solutions that meet specific operational needs.

Examining the system from an application standpoint reveals that it finds relevance in Energy Systems, Industrial Automation, and Transportation Systems. Energy Systems undergo an additional breakdown into subsectors like Hydroelectric Dams and Wind Turbines, each with unique infrastructural and operational demands. Similarly, Industrial Automation features further specialization that considers Assembly Lines and Automated Storage Systems, while Transportation Systems span an array of configurations such as Cargo Systems, High-Speed Trains, and Urban Transit, highlighting the technology's versatility across different transport modalities.

The segmentation extends further into the realm of End-Use Industries, reflecting the technology's broad applicability. Specifically, subsectors such as Aerospace, Consumer Electronics, Energy, Healthcare, Industrial & Manufacturing, and Transportation underscore the far-reaching impact of magnetic levitation systems. Lastly, market segmentation based on Sales Channel emphasizes the channels of Direct Sales, Distributors, and Online Platforms, which are critical in illuminating the pathways for product distribution and customer engagement. This holistic segmentation framework is key to designing market strategies that address both micro and macroeconomic factors, paving the way for targeted innovation and smart decision-making.

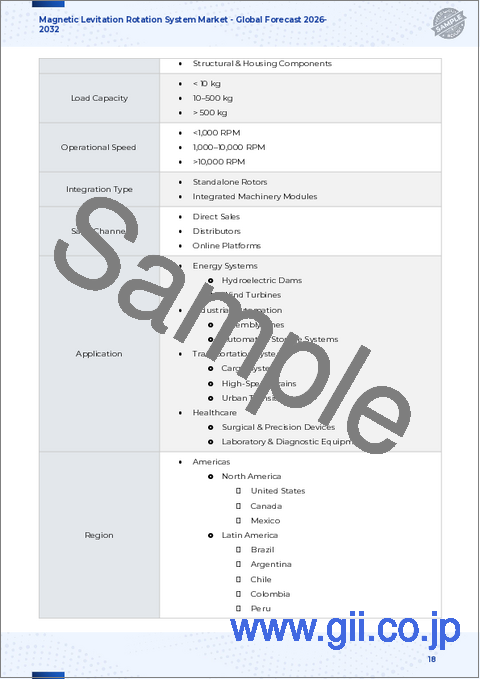

Based on Components, market is studied across Control Systems, Magnets, Power Supply Units, Sensors & Actuators, and Structural Elements. The Control Systems is further studied across Feedback Systems and Stabilization Systems. The Magnets is further studied across Electromagnets, Permanent Magnets, and Superconducting Magnets. The Structural Elements is further studied across Housing & Support Structures and Levitation Tracks.

Based on Technology, market is studied across Electromagnetic, Hybrid Systems, Pneumatic, and Superconducting. The Hybrid Systems is further studied across Electromagnetic-Pneumatic and Electromagnetic-Superconducting.

Based on Operational Speed, market is studied across High-Speed Systems, Low-Speed Systems, and Medium-Speed Systems.

Based on Application, market is studied across Energy Systems, Industrial Automation, and Transportation Systems. The Energy Systems is further studied across Hydroelectric Dams and Wind Turbines. The Industrial Automation is further studied across Assembly Lines and Automated Storage Systems. The Transportation Systems is further studied across Cargo Systems, High-Speed Trains, and Urban Transit.

Based on End-Use Industry, market is studied across Aerospace, Consumer Electronics, Energy, Healthcare, Industrial & Manufacturing, and Transportation.

Based on Sales Channel, market is studied across Direct Sales, Distributors, and Online Platforms.

Dynamic Regional Insights Shaping Global Adoption

Regional dynamics play an instrumental role in shaping the market for magnetic levitation rotation systems. In the context of the Americas, strong industrial bases and concentrated efforts towards innovation in technology provide an environment ripe for rapid adoption. The emphasis on high-speed transit solutions and energy-efficient systems in North America and South America has led to significant investments in these transformative technologies.

Shifting focus to a broader international stage, regions spanning Europe, the Middle East, and Africa continue to prioritize modernization in manufacturing and transportation. The established industrial ecosystems across Europe are embracing these technologies to remain at the forefront of automation and smart control systems. Meanwhile, emerging markets in the Middle East and Africa are seeking to leverage magnetic levitation for sustainable development and infrastructural upgrades, ensuring that innovation is not confined to traditionally dominant economies.

The Asia-Pacific region represents a unique confluence of rapid industrial expansion and high technological adoption rates. Driven by robust manufacturing sectors in countries such as China, Japan, and South Korea, this region exhibits dynamic growth patterns and an increasing appetite for high-performance engineering solutions. As urbanization and technological transformation accelerate, the appetite for magnetic levitation systems continues to grow, backed by governmental support for research and development as well as strategic public-private partnerships. This diverse regional landscape underlines how market conditions, development priorities, and infrastructural capabilities collectively determine the pace and scope of technology integration globally.

Based on Region, market is studied across Americas, Asia-Pacific, and Europe, Middle East & Africa. The Americas is further studied across Argentina, Brazil, Canada, Mexico, and United States. The United States is further studied across California, Florida, Illinois, New York, Ohio, Pennsylvania, and Texas. The Asia-Pacific is further studied across Australia, China, India, Indonesia, Japan, Malaysia, Philippines, Singapore, South Korea, Taiwan, Thailand, and Vietnam. The Europe, Middle East & Africa is further studied across Denmark, Egypt, Finland, France, Germany, Israel, Italy, Netherlands, Nigeria, Norway, Poland, Qatar, Russia, Saudi Arabia, South Africa, Spain, Sweden, Switzerland, Turkey, United Arab Emirates, and United Kingdom.

Influential Companies Setting Industry Benchmarks

Several key companies have risen to prominence as leaders in the domain of magnetic levitation rotation systems, each contributing significantly to technological advancement and market expansion. Esteemed organizations such as AB SKF, ABB Ltd., and AMT, Inc. have played crucial roles in setting high benchmarks in terms of reliability and performance. Companies like BiVACOR Inc. and Calnetix Technologies, LLC. have advanced specialized components, while Central Japan Railway Company and Crealev BV by Appear Inc. have been at the forefront of integrating these systems into high-speed transportation and industrial operations.

Other influential market players include CRRC Corporation Limited, Evico GmbH, and General Atomics, whose innovations have stimulated significant improvements in component efficiency and system durability. The industry has also seen profound contributions from Hitachi, Ltd. and Hyundai Rotem Co., which have optimized control systems and dynamic stability in high-speed applications. IronLev by IronBox srl and Kawasaki Heavy Industries, Ltd. have further contributed by refining the hardware engineering aspects, ensuring that the physical components set new standards of longevity and performance.

Moreover, pioneering companies such as Levitronix GmbH and MagLev Aero Inc. have been instrumental in driving research initiatives and facilitating cross-disciplinary collaborations that merge commercial viability with academic research insights. This progress is echoed by industry giants like Mitsubishi Electric Corporation, Nevomos by JMR Technologies, and Physik Instrumente (PI) SE & Co. KG, who have consistently pushed the boundaries of what magnetic levitation systems can achieve. Rockwell Automation, Inc., Siemens AG, SpinDrive Oy., Suzhou Supermag Intelligent Technology Co., Ltd., The Boeing Company, and The China Aerospace Science and Industry Corporation (CASIC) round out the competitive landscape, demonstrating how collaborative innovation and rigorous performance standards have become the hallmarks of the market. The combined expertise of these organizations underpins the relentless drive towards systems that are not only efficient but also capable of adapting to the most challenging industrial environments.

The report delves into recent significant developments in the Magnetic Levitation Rotation System Market, highlighting leading vendors and their innovative profiles. These include AB SKF, ABB Ltd., AMT, Inc., BiVACOR Inc., Calnetix Technologies, LLC., Central Japan Railway Company, Crealev BV by Appear Inc., CRRC Corporation Limited, Evico GmbH, General Atomics, Hitachi, Ltd., Hyundai Rotem Co., IronLev by IronBox srl, Kawasaki Heavy Industries, Ltd., Levitronix GmbH, MagLev Aero Inc., Mitsubishi Electric Corporation, Nevomos by JMR Technologies, Physik Instrumente (PI) SE & Co. KG, Rockwell Automation, Inc., Siemens AG, SpinDrive Oy., Suzhou Supermag Intelligent Technology Co., Ltd., The Boeing Company, and The China Aerospace Science and Industry Corporation (CASIC). Actionable Recommendations for Industry Leaders to Excel

For industry leaders aiming to maintain a competitive edge in the rapidly evolving landscape of magnetic levitation rotation systems, several actionable strategies are worth considering. Investing in next-generation research and development is paramount. Continuous innovation, especially in the fields of control system integration and smart sensor technologies, creates substantial value by enhancing system resilience, performance, and adaptability. Allocating resources to experimental projects can uncover novel applications that align with emerging market trends.

Furthermore, collaboration is a key driver of sustained success. Building strategic alliances with academic institutions and technology incubators fosters a vibrant ecosystem of ideas that support the transition from proof-of-concept to mass-market deployment. Such partnerships not only stimulate innovation, but they also help in shaping industry standards by merging theoretical insights with practical engineering expertise.

Adopting a customer-centric approach throughout the innovation process is equally critical. Leaders should actively engage with end-users to acquire real-time feedback that informs iterative product enhancements. This approach ensures that the technology remains attuned to market needs, while also paving the way for customized solutions that address specific operational challenges.

In addition, diversifying sales and distribution channels can significantly broaden market reach. In today's interconnected world, leveraging both traditional and digital platforms is essential to meet the diverse demands of globally dispersed customer bases. This tactic promises not only improved market penetration but also a more resilient supply chain that can adapt to fluctuating market conditions.

Lastly, leaders are encouraged to adopt an integrated approach to sustainability. As environmental concerns continue to gain prominence, ensuring that technological advancements align with global sustainability goals can enhance brand reputation and open doors to new, eco-conscious market segments. In summary, a forward-thinking strategy that emphasizes R&D, collaboration, customer engagement, diversified marketing, and sustainability will be critical for industry players striving to excel in this dynamic field.

Conclusion: Embracing the Future of Magnetic Levitation

The evolution of magnetic levitation rotation systems marks a pivotal moment in the history of technology-driven industrial innovation. This comprehensive review of market segmentation, technological advances, and regional dynamics illustrates that the shift towards contactless, high-performance mechanisms is not merely a temporary trend but an enduring transformation poised to redefine operational benchmarks across multiple sectors.

In synthesizing the rich insights from component-based, technological, operational, application, and sales channel perspectives, it becomes evident that the future of this industry is both expansive and multifaceted. Diverse market segments-from high-speed transportation and energy systems to industrial automation-are converging towards a paradigm that prioritizes efficiency, reliability, and environmental sustainability. This multi-pronged approach not only augments operational efficiency but also provides a solid foundation for predictive maintenance and long-term cost benefits.

Furthermore, it is clear that regional nuances and the presence of influential companies have been instrumental in driving the innovation curve. With strong contributions from leading corporations, pioneering research initiatives, and the adoption of sustainable practices, the groundwork has been laid for further advancements. As organizations continue to invest in and adopt magnetic levitation technologies, they pave the way for an era of enhanced productivity and smarter infrastructure design.

In summary, the magnetic levitation rotation system represents a transformational leap forward. Leaders across sectors must recognize the importance of embracing these innovations to secure a competitive edge. The future calls for not only technical excellence but also an integrated approach that harmonizes technological, environmental, and operational strategies.

Table of Contents

1. Preface

- 1.1. Objectives of the Study

- 1.2. Market Segmentation & Coverage

- 1.3. Years Considered for the Study

- 1.4. Currency & Pricing

- 1.5. Language

- 1.6. Stakeholders

2. Research Methodology

- 2.1. Define: Research Objective

- 2.2. Determine: Research Design

- 2.3. Prepare: Research Instrument

- 2.4. Collect: Data Source

- 2.5. Analyze: Data Interpretation

- 2.6. Formulate: Data Verification

- 2.7. Publish: Research Report

- 2.8. Repeat: Report Update

3. Executive Summary

4. Market Overview

5. Market Insights

- 5.1. Market Dynamics

- 5.1.1. Drivers

- 5.1.1.1. Rising adoption of magnetic levitation (maglev) technologies transforming industrial automation and precision engineering markets

- 5.1.1.2. Surging demand for efficient and energy-saving transportation solutions

- 5.1.1.3. Increasing research and development activities for development of magnetic levitation rotation technology globally

- 5.1.2. Restraints

- 5.1.2.1. Technical and maintenance issues associated with magnetic levitation systems

- 5.1.3. Opportunities

- 5.1.3.1. Surging investments & funding for the advancement of magnetic levitation technology

- 5.1.3.2. Innovations in magnetic levitation for smoother and efficient public transportation solutions

- 5.1.4. Challenges

- 5.1.4.1. Regulatory and compliance hurdles for magnetic levitation technology in various regions

- 5.1.1. Drivers

- 5.2. Market Segmentation Analysis

- 5.2.1. Operational Speed: Increasing preference for high-speed systems in advanced manufacturing processes

- 5.2.2. Technology: Growing usage of electromagnetic systems owing to the established efficacy in precision control and high-speed transportation

- 5.2.3. Components: Rising demand for control systems in magnetic levitation rotation systems for enhancing precision and responsiveness

- 5.2.4. Application: Expanding usage of magnetic levitation rotation systems in industrial automation

- 5.2.5. End-Use Industry: Advancements in magnetic levitation rotation systems across diverse industries

- 5.2.6. Sales Channel: Surge of direct sales in industrial automation and precision engineering

- 5.3. Porter's Five Forces Analysis

- 5.3.1. Threat of New Entrants

- 5.3.2. Threat of Substitutes

- 5.3.3. Bargaining Power of Customers

- 5.3.4. Bargaining Power of Suppliers

- 5.3.5. Industry Rivalry

- 5.4. PESTLE Analysis

- 5.4.1. Political

- 5.4.2. Economic

- 5.4.3. Social

- 5.4.4. Technological

- 5.4.5. Legal

- 5.4.6. Environmental

6. Magnetic Levitation Rotation System Market, by Components

- 6.1. Introduction

- 6.2. Control Systems

- 6.2.1. Feedback Systems

- 6.2.2. Stabilization Systems

- 6.3. Magnets

- 6.3.1. Electromagnets

- 6.3.2. Permanent Magnets

- 6.3.3. Superconducting Magnets

- 6.4. Power Supply Units

- 6.5. Sensors & Actuators

- 6.6. Structural Elements

- 6.6.1. Housing & Support Structures

- 6.6.2. Levitation Tracks

7. Magnetic Levitation Rotation System Market, by Technology

- 7.1. Introduction

- 7.2. Electromagnetic

- 7.3. Hybrid Systems

- 7.3.1. Electromagnetic-Pneumatic

- 7.3.2. Electromagnetic-Superconducting

- 7.4. Pneumatic

- 7.5. Superconducting

8. Magnetic Levitation Rotation System Market, by Operational Speed

- 8.1. Introduction

- 8.2. High-Speed Systems

- 8.3. Low-Speed Systems

- 8.4. Medium-Speed Systems

9. Magnetic Levitation Rotation System Market, by Application

- 9.1. Introduction

- 9.2. Energy Systems

- 9.2.1. Hydroelectric Dams

- 9.2.2. Wind Turbines

- 9.3. Industrial Automation

- 9.3.1. Assembly Lines

- 9.3.2. Automated Storage Systems

- 9.4. Transportation Systems

- 9.4.1. Cargo Systems

- 9.4.2. High-Speed Trains

- 9.4.3. Urban Transit

10. Magnetic Levitation Rotation System Market, by End-Use Industry

- 10.1. Introduction

- 10.2. Aerospace

- 10.3. Consumer Electronics

- 10.4. Energy

- 10.5. Healthcare

- 10.6. Industrial & Manufacturing

- 10.7. Transportation

11. Magnetic Levitation Rotation System Market, by Sales Channel

- 11.1. Introduction

- 11.2. Direct Sales

- 11.3. Distributors

- 11.4. Online Platforms

12. Americas Magnetic Levitation Rotation System Market

- 12.1. Introduction

- 12.2. Argentina

- 12.3. Brazil

- 12.4. Canada

- 12.5. Mexico

- 12.6. United States

13. Asia-Pacific Magnetic Levitation Rotation System Market

- 13.1. Introduction

- 13.2. Australia

- 13.3. China

- 13.4. India

- 13.5. Indonesia

- 13.6. Japan

- 13.7. Malaysia

- 13.8. Philippines

- 13.9. Singapore

- 13.10. South Korea

- 13.11. Taiwan

- 13.12. Thailand

- 13.13. Vietnam

14. Europe, Middle East & Africa Magnetic Levitation Rotation System Market

- 14.1. Introduction

- 14.2. Denmark

- 14.3. Egypt

- 14.4. Finland

- 14.5. France

- 14.6. Germany

- 14.7. Israel

- 14.8. Italy

- 14.9. Netherlands

- 14.10. Nigeria

- 14.11. Norway

- 14.12. Poland

- 14.13. Qatar

- 14.14. Russia

- 14.15. Saudi Arabia

- 14.16. South Africa

- 14.17. Spain

- 14.18. Sweden

- 14.19. Switzerland

- 14.20. Turkey

- 14.21. United Arab Emirates

- 14.22. United Kingdom

15. Competitive Landscape

- 15.1. Market Share Analysis, 2023

- 15.2. FPNV Positioning Matrix, 2023

- 15.3. Competitive Scenario Analysis

- 15.3.1. China proposes innovative magnetic levitation rotation system

- 15.3.2. Breakthrough magnetic levitation technology used in first successful artificial heart transplant

- 15.3.3. Swisspod raises EUR 7 Million to transform high-speed global transportation

- 15.3.4. IronLev unveils revolutionary magnetic levitation vehicle at LetExpo 2024

- 15.3.5. SpinDrive secures USD 4.1 million in funding to transform industrial efficiency with advanced magnetic bearings

- 15.3.6. BiVACOR advances total artificial heart with MAGLEV technology and new funding

- 15.3.7. China's maglev train advances with new speed record and technological breakthroughs

- 15.3.8. Supermag secures significant investment for magnetic levitation expansion

- 15.4. Strategy Analysis & Recommendation

- 15.4.1. MagLev Aero Inc.

- 15.4.2. Siemens AG

- 15.4.3. SpinDrive Oy.

- 15.4.4. Central Japan Railway Company

Companies Mentioned

- 1. AB SKF

- 2. ABB Ltd.

- 3. AMT, Inc.

- 4. BiVACOR Inc.

- 5. Calnetix Technologies, LLC.

- 6. Central Japan Railway Company

- 7. Crealev BV by Appear Inc.

- 8. CRRC Corporation Limited

- 9. Evico GmbH

- 10. General Atomics

- 11. Hitachi, Ltd.

- 12. Hyundai Rotem Co.

- 13. IronLev by IronBox srl

- 14. Kawasaki Heavy Industries, Ltd.

- 15. Levitronix GmbH

- 16. MagLev Aero Inc.

- 17. Mitsubishi Electric Corporation

- 18. Nevomos by JMR Technologies

- 19. Physik Instrumente (PI) SE & Co. KG

- 20. Rockwell Automation, Inc.

- 21. Siemens AG

- 22. SpinDrive Oy.

- 23. Suzhou Supermag Intelligent Technology Co., Ltd.

- 24. The Boeing Company

- 25. The China Aerospace Science and Industry Corporation (CASIC)