|

|

市場調査レポート

商品コード

1783022

産業用ロボットにおけるデジタル&AI:2025年Digital & AI in Industrial Robotics Insights Report 2025 |

||||||

|

|||||||

| 産業用ロボットにおけるデジタル&AI:2025年 |

|

出版日: 2025年08月04日

発行: IoT Analytics GmbH

ページ情報: 英文 58 Pages

納期: 即日から翌営業日

|

全表示

- 概要

- 目次

サンプルプレビュー

ソフトウェアプラットフォームとAIの進歩がオートメーション能力を再定義する中、産業用ロボットの情勢は大きな技術的変化を遂げつつあります。製造業、オートメーション、技術開発のリーダーにとって、これらの動向を正確かつ最新の形で把握することは、戦略的な計画や競争力の維持に不可欠です。

本レポートは、産業用IoTおよびAIに関する継続的な調査の一環として、ロボティクス分野におけるデジタルプラットフォームとAIの最新動向を分析したものです。本レポートは、2025年にドイツ・ミュンヘンで開催されたAutomaticaにおいて実施された50件以上のインタビューおよび一部の二次調査に基づいています。

サンプルプレビュー

レポート概要

- 58ページのPDFレポート:最新のロボティクストレンドを分析した詳細なドキュメントです。

- 10の主要トレンドの分析:ロボティクスにおけるデジタルプラットフォームおよびAIに関する最も重要な進展をレビューします。

- 3社のOEM詳細比較:主要ベンダーによるIoTプラットフォーム、AI構成、モバイルロボット製品の詳細な比較を行います。

- 50名以上の専門家インタビューからの洞察:Automatica 2025でロボティクスOEM、スタートアップ、インテグレーターから得た直接の視点を紹介します。

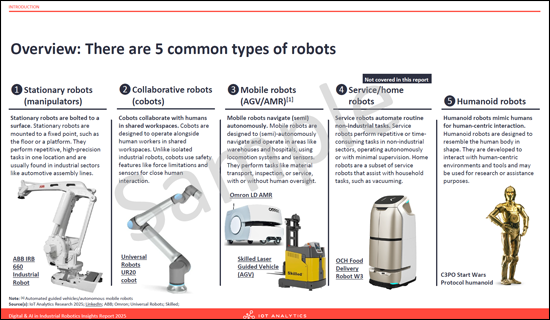

- 5タイプのロボット分類の内訳:据置型、協働型、モバイル型、サービスロボット、ヒューマノイドロボットの役割と市場状況を概観します。

サンプルプレビュー

言及された企業

本レポートで言及されている企業の一部:

|

|

目次

第1章 イントロダクション

第2章 産業用ロボットにおけるデジタルプラットフォーム

第3章 産業用ロボットにおけるAI

- 概要

- 据置型と協働型ロボットにおけるAI

- 移動ロボットにおけるAI

- サービスにおけるAIとヒューマノイドロボット

第4章 IoT Analyticsについて

A 58-page report analyzing the current state and future vision for software platforms and AI in industrial robotics - based on observations and 50+ expert interviews.

Sample preview

Introduction

The industrial robotics landscape is undergoing a significant technological shift as advancements in software platforms and artificial intelligence redefine automation capabilities. For leaders in manufacturing, automation, and technology development, a current and objective understanding of these trends is critical for strategic planning and maintaining a competitive edge.

As part of our ongoing coverage of industrial IoT and AI, this report presents a timely analysis of the state of digital platforms and AI in robotics. The insights are based on observations and over 50 interviews conducted at Automatica 2025 in Munich, Germany, supplemented by selected secondary research.

The result is a 58-page report compiled to help readers stay apprised of the newest trends in industrial robotics and the evolving market landscape. The report examines the software strategies of leading OEMs and provides a deep dive into the key use cases and technologies driving the next generation of industrial automation.

Sample preview

Report at a glance

- 58-page PDF report: A detailed document analyzing the latest robotics trends.

- Analysis of 10 key trends: A review of the most important developments in digital platforms and AI for robotics.

- 3 in-depth OEM comparisons: Detailed examinations of the IoT platforms, AI setups, and mobile robot offerings from leading vendors.

- Insights from 50+ expert interviews: Direct perspectives from robotics OEMs, startups, and integrators at Automatica 2025.

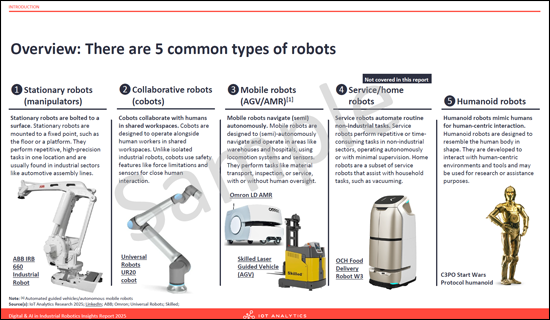

- Breakdown of 5 robot types: An overview of the roles and market status for stationary, collaborative, mobile, service, and humanoid robots.

Sample preview

Key areas of analysis:

The report's analysis includes an in-depth look at several key areas:

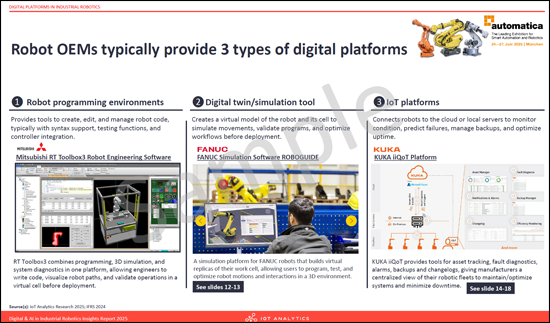

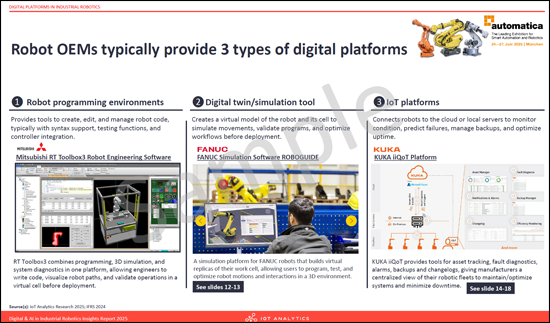

- OEM digital platform strategies: An examination of the three types of software platforms offered by robot OEMs: programming environments, digital twin/simulation tools, and IoT platforms. The analysis includes a detailed comparison of the IoT platform offerings of leading vendors.

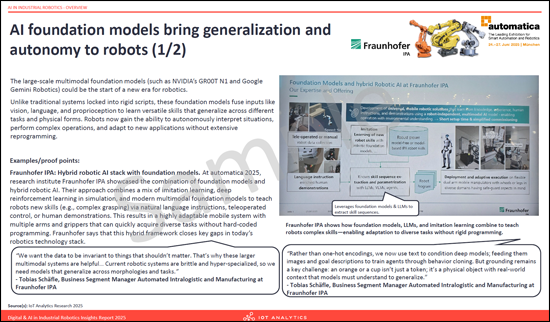

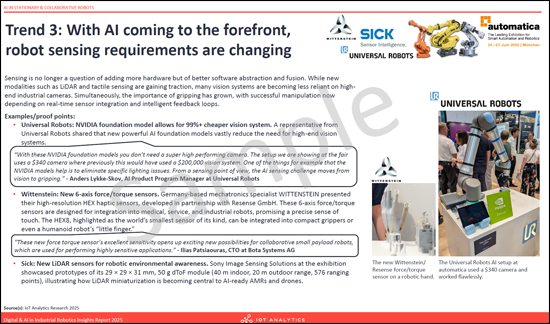

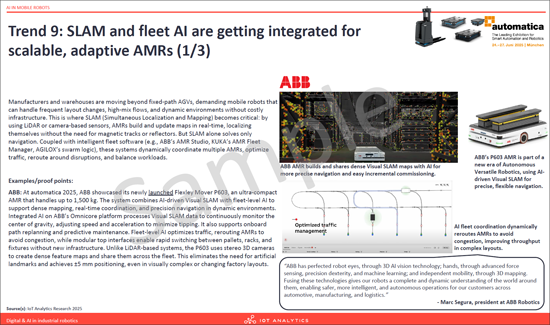

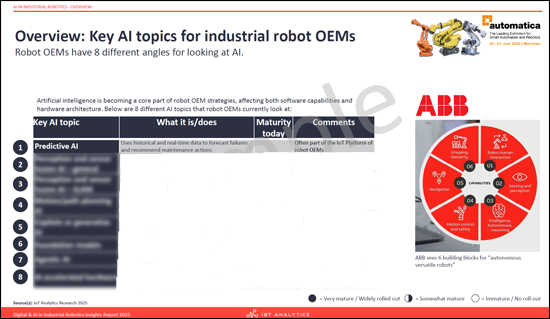

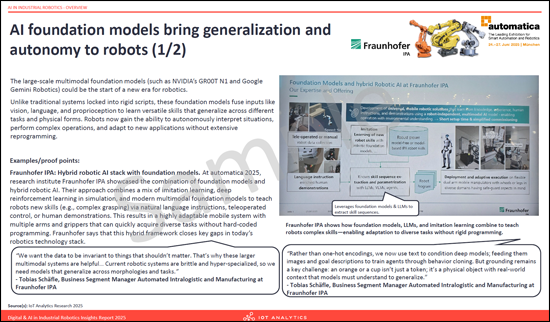

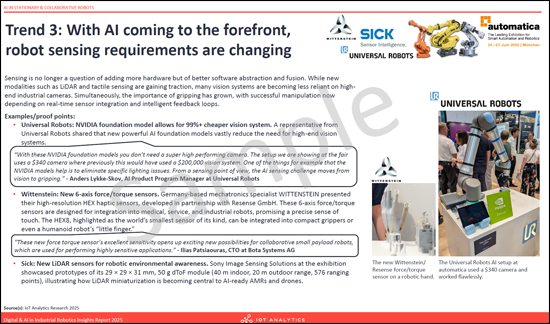

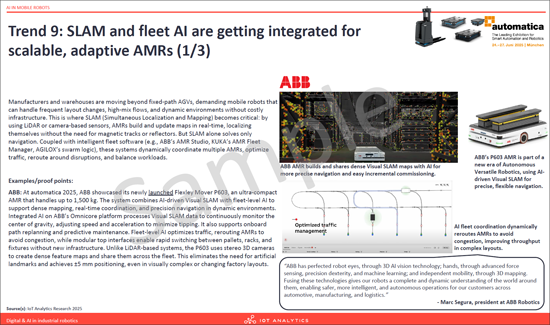

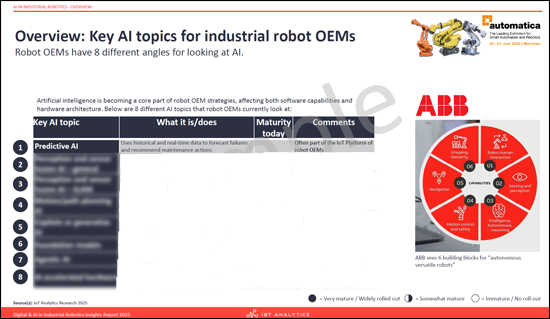

- The role of AI in robotics: A deep dive into the key AI topics for industrial robot OEMs, including perception, motion planning, and the emerging role of foundation models. The report includes detailed comparisons of the AI setups of leading stationary and mobile robot manufacturers.

- Emerging technology trends: An analysis of 10 key trends observed at Automatica 2025.

- Market overview and context: An analysis of the global industrial robotics market, including annual installation data by country, industry, and vendor.

A data-driven foundation for key business functions

This research is designed to provide a data-driven foundation for key business functions:

- For corporate strategy & product management: The report's analysis of OEM platform strategies and emerging technology trends provides the necessary intelligence to benchmark product roadmaps and identify new market opportunities.

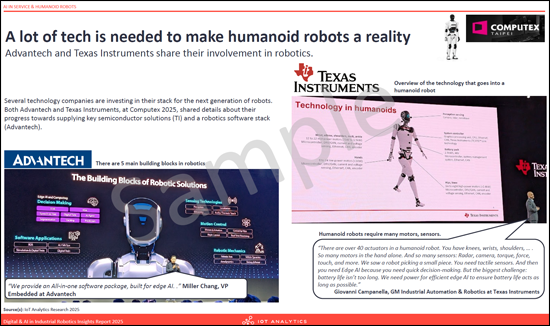

- For CTOs & engineering leadership: The deep dives into AI hardware and software architectures, including the role of AI compute and changing sensor requirements, offer a clear view of the technological trajectory of the industrial robotics market.

- For market intelligence & competitive analysis: The detailed comparisons of vendor offerings in IoT platforms and AI serve as a central, objective source of intelligence for assessing the competitive landscape.

- For automation & manufacturing leaders: The analysis of key use cases and trends provides a practical guide to the latest advancements in robotic automation, from virtual commissioning with digital twins to the adoption of AI-driven quality control.

Key concepts in industrial robotics

Types of robots

The report provides context on the five common types of robots in the market:

- Stationary robots: Robots mounted to a fixed point, typically used for repetitive, high-precision tasks in industrial settings.

- Collaborative robots (cobots): Robots designed to operate safely alongside human workers in shared workspaces.

- Mobile robots (AGV/AMR): Robots that navigate (semi)-autonomously to perform tasks like material transport and inspection.

- Service robots: Robots that automate routine, non-industrial tasks in sectors like healthcare and logistics.

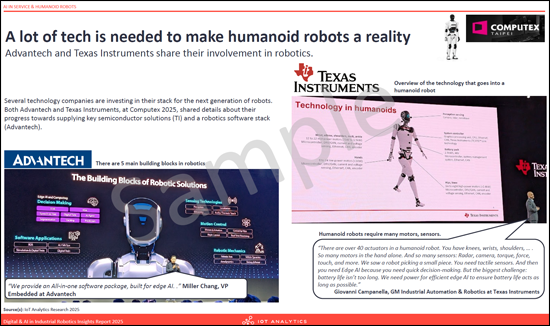

- Humanoid robots: Robots designed to resemble the human body for interaction in human-centric environments.

OEM software platforms

The analysis covers the three core types of digital platforms that robot OEMs typically provide:

- Robot programming environments: Tools to create, edit, and manage robot code.

- Digital twin/simulation tools: Software to create virtual models of robots and their work cells for offline programming and validation.

- IoT platforms: Software to connect robots to the cloud or local servers for condition monitoring, predictive maintenance, and fleet management.

Questions answered:

- What types of robots currently exist, and what are their roles?

- What types of software platforms do robotics OEMs provide?

- How many robots have been installed, and which industries and regions lead in these installations?

- What are key focus areas of AI in robotics and how do they differ among robotic OEMs?

- What are robotics executives saying about the current and future states of robotics?

- What are key use cases for AI in robotics?

- How do IoT platforms of different robotics OEM compare?

Companies mentioned:

A selection of companies mentioned in the report.

|

|

Table of Contents

1. Introduction

2. Digital platforms in industrial robotics

3. AI in industrial robotics

- Overview

- AI in stationary & collaborative robots

- AI in mobile robots

- AI in service & humanoid robots