|

|

市場調査レポート

商品コード

1459325

HSS(高張力鋼)の世界市場-2024-2031年Global High Strength Steel Market - 2024-2031 |

||||||

カスタマイズ可能

適宜更新あり

|

|||||||

| HSS(高張力鋼)の世界市場-2024-2031年 |

|

出版日: 2024年04月03日

発行: DataM Intelligence

ページ情報: 英文 184 Pages

納期: 即日から翌営業日

|

- 全表示

- 概要

- 目次

概要

世界のHSS(高張力鋼)市場は2023年に325億米ドルに達し、2031年には611億米ドルに達すると予測され、予測期間2024-2031年のCAGRは8.2%で成長します。

温室効果ガスの排出による大気汚染の増加により、業界参加者は環境への影響を軽減するよう世界的に求められています。鉄鋼メーカーは、CO2排出量、エネルギー使用量、廃液発生量、廃棄物残渣を削減することで、環境の持続可能性を向上させたいと考えています。

HSSの製造には、炭素鋼の製造よりも少ないエネルギーしか必要としません。自動車部門は、特に軽量で低燃費の自動車製造において、HSSの主要ユーザーです。排ガス規制の厳格化と、より安全で燃費の良い車を求める消費者の需要が、自動車製造におけるHSSの使用を促進しています。

輸送車両の需要増がHSS産業を後押ししています。米国は世界第2位の自動車販売・生産市場です。例えばOICAによると、米国の自動車生産台数は2022年に1億60万339台に達し、2021年から10%増加します。その結果、自動車生産台数の増加が燃料添加剤市場の需要増につながると予測されます。

2023年には、北米が世界のHSS市場の約25%を占め、2番目に優位な地域になると予想されます。北米では、自動車の軽量化と高強度化に対する需要の高まりから、軽量鋼、特にHSSの普及が著しいです。例えば、米国の企業平均燃費基準は、米国自動車市場の燃費向上を促進することを目的としています。

ダイナミクス

自動車部門の大幅拡大

世界の自動車生産の増加は、HSS市場の成長を促進する重要な要素です。自動車ボディパネルにHSSを適用することで、製品の軽量化により燃費が向上します。さらに、電気自動車やハイブリッド車に対する世界の需要の増加は、予測期間中のHSS市場の成長を促進すると予測されています。

India Energy Storage Allianceの報告書によると、インドのEV市場は2026年まで36%のCAGRで成長すると予測されています。さらに、国際自動車工業会の発表によると、世界の乗用車生産台数は2020年の5,583万4,456台から2021年には5,705万4,295台に増加します。自動車生産台数の増加と成長の可能性により、HSSのニーズは自動車分野で拡大しています。

建築・建設業界からの需要増加

HSSは建築・建設業界で幅広く利用されています。HSSは、製品の厚みを薄くし、低温での靭性を高め、高い降伏強度を可能にするため、建設業界におけるHSSの需要を高めています。HSSは溶接が容易で機械加工が可能なため、橋や柱の設計、巨大な建築プロジェクトの建設に使用され、建築・建設業界におけるHSSの市場成長を促進しています。

国際貿易局によると、中国の建設部門は2022年から2031年まで平均8.6%増加すると予想されています。Oxford Economicsが述べているように、世界の建設生産高は2020年に10兆7,000億米ドルであり、2020年から2031年の間に42%、4兆5,000億米ドル増加し、15兆2,000億米ドルに達すると予測されています。世界の建築・建設プロジェクトの増加に伴い、様々な用途でHSSの需要が高まることが予想され、これが市場の成長を促進すると推測されます。

鋼種の進歩

鉄鋼や鋼種は時代とともに改良され続けています。強靭で安全性が高く、インパクトのある鋼は常に求められています。その結果、従来型鋼、HSS、AHSS、UHSS、ギガ鋼など、高度な品質を持つ新しい鋼種が開発されました。自動車メーカーは、優れた強度を持つ軽量素材を常に探しており、その中でもアルミニウムがトップランナーとなっているようです。

アルミニウムベースの構造は、その高い効率性、機能性、成形性、性能向上により、メーカーの間で幅広い関心を呼んでおり、HSS市場の成長を妨げると予測されています。その結果、様々な鋼種や代替製品の進歩がHSSの世界市場の成長を妨げると予想されます。

目次

第1章 調査手法と調査範囲

第2章 定義と概要

第3章 エグゼクティブサマリー

第4章 市場力学

- 影響要因

- 促進要因

- 自動車産業の大幅な拡大

- 建築・建設業界からの需要増加

- 抑制要因

- グレードの進歩

- 機会

- 影響分析

- 促進要因

第5章 産業分析

- ポーターのファイブフォース分析

- サプライチェーン分析

- 価格分析

- 規制分析

- ロシア・ウクライナ戦争の影響分析

- DMIの見解

第6章 COVID-19分析

第7章 タイプ別

- HSLA

- AHSS

- DP

- TRIP

- UHSS

第8章 用途別

- 自動車

- 建築・建設

- 航空宇宙

- その他

第9章 地域別

- 北米

- 米国

- カナダ

- メキシコ

- 欧州

- ドイツ

- 英国

- フランス

- イタリア

- ロシア

- その他欧州

- 南米

- ブラジル

- アルゼンチン

- その他南米

- アジア太平洋

- 中国

- インド

- 日本

- オーストラリア

- その他アジア太平洋地域

- 中東・アフリカ

第10章 競合情勢

- 競合シナリオ

- 市況/シェア分析

- M&A分析

第11章 企業プロファイル

- U.S. Steel Corporation

- 会社概要

- 製品ポートフォリオと説明

- 財務概要

- 主な発展

- Voestalpine

- Nippon Steel & Sumitomo Metal Corporation

- ArcelorMittal

- Tata Steel

- SSAB

- POSCO

- Ansteel Group Corporation

- Baosteel Group Corporation

- AK Steel

第12章 付録

Overview

Global High Strength Steel Market reached US$ 32.5 billion in 2023 and is expected to reach US$ 61.1 billion by 2031, growing with a CAGR of 8.2% during the forecast period 2024-2031.

Increasing levels of air pollution due to greenhouse gas emissions have prompted industry participants globally to lessen their environmental impact. Steel manufacturers hope to improve their environmental sustainability by reducing CO2 emissions, energy usage, liquid waste creation and waste residues.

High-strength steel manufacture takes less energy than carbon steel production. The automobile sector is a major user of high-strength steel, particularly in the manufacture of lightweight and fuel-efficient vehicles. Stricter emissions rules and consumer demand for safer and more fuel-efficient vehicles are driving the usage of high strength steel in automobile manufacture.

The increasing demand for transportation vehicles propels the high-strength steel industry. U.S. is the world's second largest car sales and production market. For example, according to OICA, vehicle production in U.S. will reach 1,00,60,339 units in 2022, a 10% increase from 2021. As a result, a growth in automotive production is predicted to create an upside demand in the fuel additives market.

In 2023, North America is expected to be the second-dominant region, holding about 25% of the global high strength steel market. North America has seen a significant penetration of lightweight steel, particularly high strength steel, due to rising demand for lighter and stronger automobiles. For example, the Corporate Average Fuel Economy standards from U.S. are aimed to drive incremental fuel economy gains in U.S. automobile market.

Dynamics

Huge Expansion in Automotive Sector

The increase in global vehicle production is a significant element driving the growth of the high strength steel market. The application of high-strength steel in automotive body panels improves fuel efficiency by reducing product weight. Furthermore, increased global demand for electric and hybrid vehicles is projected to fuel the growth of the high-strength steel market during the forecast period.

According to a report by the India Energy Storage Alliance, the EV market in India is predicted to grow at a 36% CAGR until 2026. Furthermore, the International Organization of Motor Vehicle Manufacturers said that global passenger car production increased from 5,58,34,456 in 2020 to 5,70,54,295 in 2021. With a rise in automotive vehicle production and growth possibilities, the need for high-strength steel is expanding in the automobile sector.

Rising Demand from the Building & Building and Construction Industry

High Strength Steel is extensively utilized in the building and construction industries. It raises the demand for high-strength steels in the construction industry since they allow for reduced product thickness, increased toughness at low temperatures and high yield strength. Owing to its easy weldability and machinability, high-strength steel is used in the design of bridges, pillars and the construction of enormous architectural projects, which promotes the market growth of high-strength steel in the building and construction industry.

In accordance to the International Trade Administration, China's construction sector is expected to increase by an average of 8.6% from 2022 to 2031. As stated by Oxford Economics, globally construction output was US$ 10.7 trillion in 2020 and is predicted to increase by 42% or US$ 4.5 trillion, between 2020 and 2031, reaching US$ 15.2 trillion. With the increase in building and construction projects in the globe, the demand for high-strength steel is expected to rise for various applications, which is estimated to fuel market growth.

Advancements in Grades

Steel or steel grades have continued to improve over time. Steels that are tough, secure and have a big impact are always in demand. It has resulted in the development of new steel grades with advanced qualities, such as conventional steels, high-strength steels, advanced high-strength steels, ultra-high-strength steels and Giga steels. Automobile makers are constantly searching for lightweight materials with excellent strength and aluminum appears to be the frontrunner among them.

Aluminum-based constructions have sparked broad interest among manufacturers due to their high efficiency, functionality, formability and performance enhancement, which is projected to impede high-strength steel market growth. As a result, it is expected that ongoing advances in various steel grades and alternative products will hinder the global market for high strength steel from growing.

Segment Analysis

The global high strength steel market is segmented based on type, application and region.

Rising Demand for High Strength Materials for Automotive Production Drives the Segment Growth

Automotive is expected to be the dominant segment with about 1/3rd of the market during the forecast period 2024-2031. High-strength steels are commonly utilized in the automobile sector to reduce overall vehicle weight while boosting stiffness and energy absorption in certain regions. Mechanical attributes, thickness and width capacities are just a few of the qualities that make high-strength steels so popular in the automobile sector.

Increased investment and developments in India's vehicle industry are likely to drive up demand for high-strength steel. For example, in April 2022, Tata Motors announced intentions to invest US$ 3.08 billion in its passenger vehicle industry over the next five years. It is likely to boost the high-strength steel market.

Geographical Penetration

Rising Automotive Production in Asia-Pacific

Asia-Pacific is the dominant region in the global high strength steel market covering over 35% of the market. The demand for high-strength steel is predicted to rise throughout the forecast period due to increased investment and construction activities in the country. China makes a significant contribution because it has been one of the world's leading infrastructure investors in recent years. According to the National Bureau of Statistics of China, the output value of building works in China in 2022 was US$ 4108.581 billion, a 6.6% increase over 2021.

Furthermore, automotive remains the country's largest sector and shows promising signals for the foreseeable future. For example, OICA forecasts that automotive production in the country would reach 2,70,20,615 units in 2022, up 3% from 2021. As a result, a good scenario in the country's vehicle production is predicted to provide an upward demand for the high strength steel market.

Competitive Landscape

The major global players in the market include U.S. Steel Corporation, Voestalpine, Nippon Steel & Sumitomo Metal Corporation, ArcelorMittal, Tata Steel, SSAB, POSCO, Ansteel Group Corporation, Baosteel Group Corporation and AK Steel.

COVID-19 Impact

The pandemic caused changes in demand for high-strength steel products across multiple industries. While the automobile, construction and infrastructure industries saw slowdowns owing to lockdowns and economic uncertainty, other industries, such as medical equipment, renewable energy and e-commerce, saw increased demand for high strength steel components.

The epidemic had a huge impact on the automobile and manufacturing sectors, both of which rely heavily on high strength steel. Plant closures, production shutdowns and supply chain disruptions reduced demand for high strength steel products, resulting in lower revenue and profitability for steel manufacturers and suppliers. Raw material price volatility, energy prices and currency changes all contributed to cost pressures for high strength steel manufacturers.

Russia-Ukraine War Impact

Russia and Ukraine are major manufacturers of steel and raw materials needed in steelmaking. Any delays in production or transit routes from these nations could result in raw material shortages for high-strength steel manufacturers globally. It might lead to production delays and higher expenses for industries who rely on Russian and Ukrainian steel.

The crisis might impact trade relations between Russia, Ukraine and other countries, potentially affecting steel imports and exports. Tariffs, trade restrictions and sanctions imposed by various governments may interrupt the flow of steel products and alter market dynamics. Uncertainty in energy prices could increase the cost of production for high strength steel manufacturers, affecting their competitiveness in the globally market.

By Type

- High Strength Low Alloys (HSLA)

- Advanced High Strength Steel (AHSS)

- Dual Phase (DP)

- Transformation Induced Plasticity (TRIP)

- Ultra-High Strength Steel (UHSS)

By Application

- Automotive

- Building and Construction

- Aerospace

- Others

By Region

- North America

- U.S.

- Canada

- Mexico

- Europe

- Germany

- UK

- France

- Italy

- Russia

- Rest of Europe

- South America

- Brazil

- Argentina

- Rest of South America

- Asia-Pacific

- China

- India

- Japan

- Australia

- Rest of Asia-Pacific

- Middle East and Africa

Key Developments

- In October 2022, the division of ArcelorMittal, AMNS India, has disclosed that it intends to provide high-strength special steel for the proposed bullet train project in India.

- In March 2022, AFV Beltrame Group has finalized the acquisition of the functional production assets of the Targoviste Special Steel Plant by finishing the transfer of ownership documents and full payment of the price of EUR 38.3 million.

- In December 2020, British Steel has launched a new high-strength structural steel grade, S460M. It is designed for multi-story, high-rise buildings and for various other commercial and industrial uses.

Why Purchase the Report?

- To visualize the global high strength steel market segmentation based on type, application and region, as well as understand key commercial assets and players.

- Identify commercial opportunities by analyzing trends and co-development.

- Excel data sheet with numerous data points of high strength steel market-level with all segments.

- PDF report consists of a comprehensive analysis after exhaustive qualitative interviews and an in-depth study.

- Product mapping available as excel consisting of key products of all the major players.

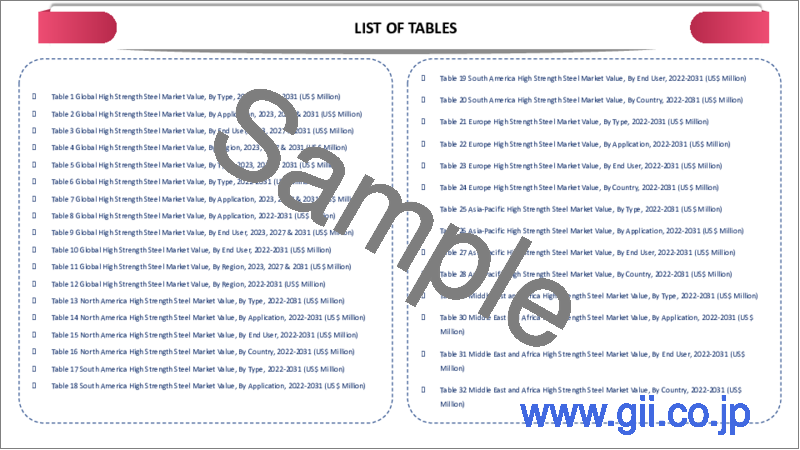

The global high strength steel market report would provide approximately 54 tables, 42 figures and 184 pages.

Target Audience 2024

- Manufacturers/ Buyers

- Industry Investors/Investment Bankers

- Research Professionals

- Emerging Companies

Table of Contents

1.Methodology and Scope

- 1.1.Research Methodology

- 1.2.Research Objective and Scope of the Report

2.Definition and Overview

3.Executive Summary

- 3.1.Snippet by Type

- 3.2.Snippet by Application

- 3.3.Snippet by Region

4.Dynamics

- 4.1.Impacting Factors

- 4.1.1.Drivers

- 4.1.1.1.Huge Expansion in Automotive Sector

- 4.1.1.2.Rising Demand from the Building & Building and Construction Industry

- 4.1.2.Restraints

- 4.1.2.1.Advancements in Grades

- 4.1.3.Opportunity

- 4.1.4.Impact Analysis

- 4.1.1.Drivers

5.Industry Analysis

- 5.1.Porter's Five Force Analysis

- 5.2.Supply Chain Analysis

- 5.3.Pricing Analysis

- 5.4.Regulatory Analysis

- 5.5.Russia-Ukraine War Impact Analysis

- 5.6.DMI Opinion

6.COVID-19 Analysis

- 6.1.Analysis of COVID-19

- 6.1.1.Scenario Before COVID

- 6.1.2.Scenario During COVID

- 6.1.3.Scenario Post COVID

- 6.2.Pricing Dynamics Amid COVID-19

- 6.3.Demand-Supply Spectrum

- 6.4.Government Initiatives Related to the Market During Pandemic

- 6.5.Manufacturers Strategic Initiatives

- 6.6.Conclusion

7.By Type

- 7.1.Introduction

- 7.1.1.Market Size Analysis and Y-o-Y Growth Analysis (%), By Type

- 7.1.2.Market Attractiveness Index, By Type

- 7.2.High Strength Low Alloys (HSLA)*

- 7.2.1.Introduction

- 7.2.2.Market Size Analysis and Y-o-Y Growth Analysis (%)

- 7.3.Advanced High Strength Steel (AHSS)

- 7.3.1.Dual Phase (DP)

- 7.3.2.Transformation Induced Plasticity (TRIP)

- 7.4.Ultra-High Strength Steel (UHSS)

8.By Application

- 8.1.Introduction

- 8.1.1.Market Size Analysis and Y-o-Y Growth Analysis (%), By Application

- 8.1.2.Market Attractiveness Index, By Application

- 8.2.Automotive*

- 8.2.1.Introduction

- 8.2.2.Market Size Analysis and Y-o-Y Growth Analysis (%)

- 8.3.Building and Construction

- 8.4.Aerospace

- 8.5.Others

9.By Region

- 9.1.Introduction

- 9.1.1.Market Size Analysis and Y-o-Y Growth Analysis (%), By Region

- 9.1.2.Market Attractiveness Index, By Region

- 9.2.North America

- 9.2.1.Introduction

- 9.2.2.Key Region-Specific Dynamics

- 9.2.3.Market Size Analysis and Y-o-Y Growth Analysis (%), By Type

- 9.2.4.Market Size Analysis and Y-o-Y Growth Analysis (%), By Application

- 9.2.5.Market Size Analysis and Y-o-Y Growth Analysis (%), By Country

- 9.2.5.1.U.S.

- 9.2.5.2.Canada

- 9.2.5.3.Mexico

- 9.3.Europe

- 9.3.1.Introduction

- 9.3.2.Key Region-Specific Dynamics

- 9.3.3.Market Size Analysis and Y-o-Y Growth Analysis (%), By Type

- 9.3.4.Market Size Analysis and Y-o-Y Growth Analysis (%), By Application

- 9.3.5.Market Size Analysis and Y-o-Y Growth Analysis (%), By Country

- 9.3.5.1.Germany

- 9.3.5.2.UK

- 9.3.5.3.France

- 9.3.5.4.Italy

- 9.3.5.5.Russia

- 9.3.5.6.Rest of Europe

- 9.4.South America

- 9.4.1.Introduction

- 9.4.2.Key Region-Specific Dynamics

- 9.4.3.Market Size Analysis and Y-o-Y Growth Analysis (%), By Type

- 9.4.4.Market Size Analysis and Y-o-Y Growth Analysis (%), By Application

- 9.4.5.Market Size Analysis and Y-o-Y Growth Analysis (%), By Country

- 9.4.5.1.Brazil

- 9.4.5.2.Argentina

- 9.4.5.3.Rest of South America

- 9.5.Asia-Pacific

- 9.5.1.Introduction

- 9.5.2.Key Region-Specific Dynamics

- 9.5.3.Market Size Analysis and Y-o-Y Growth Analysis (%), By Type

- 9.5.4.Market Size Analysis and Y-o-Y Growth Analysis (%), By Application

- 9.5.5.Market Size Analysis and Y-o-Y Growth Analysis (%), By Country

- 9.5.5.1.China

- 9.5.5.2.India

- 9.5.5.3.Japan

- 9.5.5.4.Australia

- 9.5.5.5.Rest of Asia-Pacific

- 9.6.Middle East and Africa

- 9.6.1.Introduction

- 9.6.2.Key Region-Specific Dynamics

- 9.6.3.Market Size Analysis and Y-o-Y Growth Analysis (%), By Type

- 9.6.4.Market Size Analysis and Y-o-Y Growth Analysis (%), By Application

10.Competitive Landscape

- 10.1.Competitive Scenario

- 10.2.Market Positioning/Share Analysis

- 10.3.Mergers and Acquisitions Analysis

11.Company Profiles

- 11.1.U.S. Steel Corporation*

- 11.1.1.Company Overview

- 11.1.2.Product Portfolio and Description

- 11.1.3.Financial Overview

- 11.1.4.Key Developments

- 11.2.Voestalpine

- 11.3.Nippon Steel & Sumitomo Metal Corporation

- 11.4.ArcelorMittal

- 11.5.Tata Steel

- 11.6.SSAB

- 11.7.POSCO

- 11.8.Ansteel Group Corporation

- 11.9.Baosteel Group Corporation

- 11.10.AK Steel

LIST NOT EXHAUSTIVE

12.Appendix

- 12.1.About Us and Services

- 12.2.Contact Us