|

|

市場調査レポート

商品コード

1316225

燃料電池自動車(FCV)用熱交換器の世界市場-2023年~2030年Global Fuel Cell Vehicle Heat Exchangers Market - 2023-2030 |

||||||

カスタマイズ可能

適宜更新あり

|

|||||||

| 燃料電池自動車(FCV)用熱交換器の世界市場-2023年~2030年 |

|

出版日: 2023年07月27日

発行: DataM Intelligence

ページ情報: 英文 185 Pages

納期: 即日から翌営業日

|

- 全表示

- 概要

- 目次

市場概要

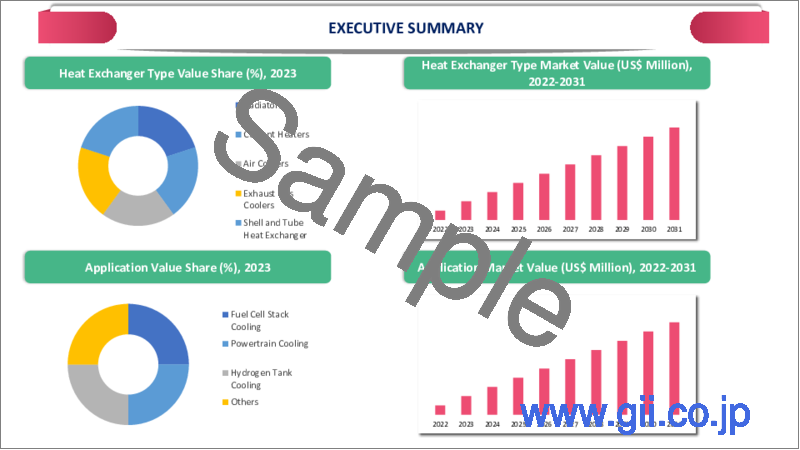

燃料電池自動車(FCV)用熱交換器の世界市場は、2022年に8億6,550万米ドルに達し、2030年には13億7,900万米ドルに達すると予測され、予測期間2023年~2030年のCAGRは6.0%で成長すると予測されています。さまざまな業種の運輸会社では、持続可能性と企業の社会的責任を優先する傾向が強まっています。そのため、多くの企業が二酸化炭素排出量とカーボンフットプリントを削減するため、燃料電池自動車(FCV)を車両に採用しています。燃料電池自動車(FCV)に対する企業需要の増加に伴い、燃料電池自動車(FCV)用熱交換器に対する需要も増加しています。

現在の研究の焦点は、燃料電池自動車(FCV)の使用条件に適した新しいタイプの熱交換器の開発です。例えば、2023年1月には、イランのイスファハン大学の科学者が、蛇行流路を利用した膜式熱交換器の使用法を詳述した論文を発表しています。

市場力学

政府の支援とインセンティブ

政府は、燃料電池自動車(FCV)や熱交換器のような関連部品の採用を促進するため、財政的なインセンティブを提供しています。インセンティブには、補助金、助成金、税額控除、リベートなどがあり、燃料電池自動車(FCV)の購入にかかる初期費用を軽減します。経済的インセンティブが利用できるため、消費者や企業は燃料電池自動車(FCV)への投資を促し、燃料電池用熱交換器の需要を促進します。

各国政府は、燃料電池技術の進歩に焦点を当てた研究開発プログラムに資金を割り当てています。例えば、米国政府は2022年8月にインフレ削減法(IRA)を可決し、燃料電池のような新しいクリーンエネルギー技術の研究に多額の資金を割り当てた。このプログラムは、熱交換器技術を含む革新的なソリューションを開発する研究機関、大学、非公開会社を支援しています。研究開発資金は、技術の進歩、性能の向上、燃料電池熱交換器のコスト削減を促進します。

熱交換器設計の進歩

熱交換器設計の進歩により熱効率が改善され、燃料電池システム内の異なる流体ストリーム間の効果的な熱伝達が確保されています。熱伝達プロセスを最適化することで、先進の熱交換器は望ましい動作温度を維持し、燃料電池システムの全体的な効率を最大化するのに役立ちます。熱効率の向上は、燃料電池自動車(FCV)の性能向上と燃費向上につながります。

熱交換器の設計に高性能合金や複合材料などの先端材料を使用することで、熱伝達効率、耐腐食性、耐久性が向上しています。この材料は、燃料電池システムの厳しい運転条件に耐える熱交換器の設計を可能にします。先進材料はまた、熱伝導率の向上と圧力損失の低減を実現し、より効率的な熱伝達とエネルギー損失の最小化を可能にします。

熱交換器設計の進歩は、燃料電池自動車(FCV)の進化するニーズに対応する上で重要な役割を果たします。効率的な熱管理を可能にし、システムのサイズと重量を軽減し、全体的な性能を向上させ、燃料電池自動車(FCV)の普及に貢献するため、燃料電池自動車(FCV)用熱交換器の需要が増加します。

高い製造・生産コスト

燃料電池自動車(FCV)用熱交換器の製造プロセスには、複雑な手順と特殊な設備が必要です。精密工学と厳しい公差で熱交換器を製造するには、高度な製造技術が必要です。この複雑さが製造コストを上昇させ、燃料電池用熱交換器を他の用途で使用される従来の熱交換器に比べ高価なものにしています。

燃料電池自動車(FCV)用熱交換器には、固有の運転条件に合わせた特定の材料と部品が必要です。耐腐食性や高い熱伝導性など、特殊な特性を持つ材料はコストが高くなることが多いです。チタンや先端合金などの高価な材料の使用は、燃料電池用熱交換器の全体的な製造コストの一因となっています。

燃料電池自動車(FCV)用熱交換器の市場需要が限られているため、生産における規模の経済の達成が妨げられます。顧客ベースが小さいと、メーカーはより多くの生産量を達成できなくなりますが、これは通常、規模の経済によって単価を下げるのに役立ちます。規模の経済の欠如により、燃料電池熱交換器の単位あたりのコストが増加し、代替熱交換技術と比較して競争力が低下します。

COVID-19影響分析

COVID-19の大流行により、自動車セクターの多くの研究開発活動が遅延または停止しました。このため、熱交換器の進歩を含め、市場成長にとって有益となりうる革新的な燃料電池自動車(FCV)技術の開発が鈍化しました。さらに、前年にこの分野で頭角を現した新興企業の多くが、パンデミック中に資金が枯渇したために閉鎖せざるを得なくなっています。

一部の政府は、パンデミックの余波を受け、クリーンエネルギー技術に重点を置いた景気刺激策を実施しました。こうしたパッケージの中には、電気自動車や水素燃料電池自動車(FCV)に対する奨励金や補助金も含まれていました。こうしたイニシアチブは、クリーンエネルギー車の導入を促進し、間接的に燃料電池自動車(FCV)産業に利益をもたらすことを目的としていました。

AIの影響分析

AI主導の自律走行車技術の出現は、熱交換器の設計と機能性に影響を与える可能性があります。自律走行車は演算能力の向上により大量の熱を発生するため、熱交換器はこの熱を効率的に放散する必要があります。AIアルゴリズムは、自律走行型燃料電池自動車(FCV)における熱交換器の配置、サイズ、熱管理戦略の最適化を支援することができます。

AIを搭載したアルゴリズムは膨大な量のデータを分析し、熱交換器のサプライチェーンを最適化することができます。需要予測、在庫管理、輸送ロジスティクスなどの要素を考慮することで、AIはコスト削減、リードタイムの最小化、サプライチェーン全体の効率化に貢献することができます。

ウクライナ・ロシア戦争の影響分析

ロシアとウクライナの紛争は世界の商品取引に混乱をもたらし、主要な商品供給国であるロシアが西側諸国から制裁を受けたため、価格の上昇につながっています。短期的な重要商品価格の上昇は、投入コストの増加による燃料電池の生産中断につながっています。その結果、燃料電池用熱交換器の需要が短期的に減少しました。

さらに、紛争はEU(欧州連合)諸国がグリーンエネルギー技術への投資を大幅に増やすきっかけとなっています。これは、自動車産業における燃料電池の開発と採用に弾みをつけました。政府の政策の変化は、中長期的に欧州における燃料電池用熱交換器の需要を増大させる可能性が高いです。

目次

第1章 調査手法と調査範囲

第2章 定義と概要

第3章 エグゼクティブサマリー

第4章 市場力学

- 影響要因

- 促進要因

- 燃料電池技術の進歩

- 水素インフラの開発

- 政府の支援とインセンティブ

- 熱交換器設計の進歩

- 抑制要因

- 燃料電池自動車(FCV)の限定的な普及

- 高い製造・生産コスト

- 機会

- 影響分析

- 促進要因

第5章 産業分析

- ポーターのファイブフォース分析

- サプライチェーン分析

- 価格分析

- 規制分析

第6章 COVID-19分析

第7章 タイプ別

- シェル&チューブ式熱交換器

- プレート式熱交換器

- 空冷式熱交換器

第8章 用途別

- 乗用車

- 小型商用車(LCV)

- 大型商用車(HCV)

第9章 地域別

- 北米

- 米国

- カナダ

- メキシコ

- 欧州

- ドイツ

- 英国

- フランス

- イタリア

- ロシア

- その他欧州

- 南米

- ブラジル

- アルゼンチン

- その他南米

- アジア太平洋

- 中国

- インド

- 日本

- オーストラリア

- その他アジア太平洋地域

- 中東・アフリカ

第10章 競合情勢

- 競合シナリオ

- 市況/シェア分析

- M&A分析

第11章 企業プロファイル

- Hanon Systems

- 会社概要

- 製品ポートフォリオと概要

- 財務概要

- 最近の動向

- Valeo

- Denso Corporation

- Nippon Light Metal Co., Ltd

- Alfa Laval

- T.RAD Co., Ltd.

- Thermogym Ltd.

- MAHLE GmBH

- Tempco Srl

- Tianjin Botai Heat-Exchanger Equipment Co., Ltd.

第12章 付録

Market Overview

Global Fuel Cell Vehicle Heat Exchangers Market reached US$ 865.5 million in 2022 and is expected to reach US$ 1,379 million by 2030, growing with a CAGR of 6.0% during the forecast period 2023-2030. Transportation companies across various industries are increasingly prioritizing sustainability and corporate social responsibility. Therefore, many companies are adopting fuel cell vehicles as part of the fleet to reduce carbon emissions and the carbon footprint of their operations. With rise in corporate demand for fuel cell vehicles, there is a corresponding rise in the demand for fuel cell vehicle heat exchangers.

The current focus of research is on developing new types of heat exchangers, better suited to the working conditions of fuel cell vehicles. For example, in January 2023, scientists from the University of Isfahan in Iran published a paper detailing the usage of a membrane-based heat exchanger utilizing serpentine flow channels

Market Dynamics

Government Support and Incentives

Governments provide financial incentives to promote the adoption of fuel cell vehicles and associated components like heat exchangers. The incentives include subsidies, grants, tax credits and rebates, which reduce the upfront cost of purchasing fuel cell vehicles. The availability of financial incentives encourages consumers and businesses to invest in fuel cell vehicles, driving the demand for fuel cell heat exchangers.

Governments allocate funds for research and development programs focused on advancing fuel cell technology. For instance, the U.S. government passed the inflation reduction act (IRA) in August 2022, which allocated significant sums for research into new clean energy technologies such as fuel cells. The programs support research institutions, universities and private companies in developing innovative solutions, including heat exchanger technologies. Research and development funding foster technological advancements, improve performance and reduce the cost of fuel cell heat exchangers.

Advances in Heat Exchanger Design

Advances in heat exchanger design have led to improved thermal efficiency, ensuring effective heat transfer between different fluid streams within the fuel cell system. By optimizing the heat transfer process, advanced heat exchangers help maintain the desired operating temperatures and maximize the overall efficiency of fuel cell systems. Higher thermal efficiency translates to better performance and increased fuel economy for fuel cell vehicles.

The use of advanced materials, such as high-performance alloys and composites, in heat exchanger design has enhanced heat transfer efficiency, corrosion resistance and durability. The materials allow for the design of heat exchangers that can withstand the demanding operating conditions of fuel cell systems. Advanced materials also offer improved thermal conductivity and reduced pressure drops, enabling more efficient heat transfer and minimizing energy losses.

The advances in heat exchanger design are instrumental in meeting the evolving needs of fuel cell vehicles. enable efficient thermal management, reduce system size and weight, improve overall performance and contribute to the wider adoption of fuel cell vehicles, thus generating increased demand for fuel cell vehicle heat exchangers.

High Manufacturing and Production Costs

The manufacturing process of fuel cell vehicle heat exchangers involves intricate procedures and specialized equipment. Fabricating heat exchangers with precision engineering and tight tolerances requires advanced manufacturing techniques. The complexities increase production costs, making fuel cell heat exchangers more expensive compared to conventional heat exchangers used in other applications.

Fuel cell vehicle heat exchangers require specific materials and components that are tailored for their unique operating conditions. The materials often come at a higher cost due to their specialized properties, such as corrosion resistance and high thermal conductivity. The use of expensive materials, such as titanium or advanced alloys, contributes to the overall manufacturing cost of fuel cell heat exchangers.

The limited market demand for fuel cell vehicle heat exchangers hinders the achievement of economies of scale in production. With a smaller customer base, manufacturers are unable to achieve higher production volumes, which typically help drive down unit costs through economies of scale. The lack of economies of scale increases the per-unit cost of fuel cell heat exchangers, making them less competitive compared to alternative heat exchange technologies.

COVID-19 Impact Analysis

Many research and development activities in the automotive sector were delayed or halted due to the COVID-19 pandemic. It slowed down the development of innovative fuel cell vehicle technologies, including advancements in heat exchangers, which could have beneficial for market growth. Furthermore, many startups that had emerged in the field in previous years had to shut down during the pandemic due to drying up of funding.

Some governments implemented stimulus packages to revive the economy in the aftermath of the pandemic with a strong emphasis on clean energy technologies. Some of these packages included incentives and subsidies for electric and hydrogen fuel cell vehicles. Such initiatives aimed to promote the adoption of clean energy vehicles, indirectly benefiting the the fuel cell vehicle industry.

AI Impact Analysis

The emergence of AI-driven autonomous vehicle technology has the potential to impact the design and functionality of heat exchangers. As autonomous vehicles generate significant amounts of heat due to increased computing power heat exchangers need to efficiently dissipate this heat. AI algorithms can assist in optimizing the placement, size and thermal management strategies of heat exchangers in autonomous fuel cell vehicles.

AI-powered algorithms can analyze vast amounts of data to optimize the supply chain of heat exchangers. By considering factors such as demand forecasting, inventory management and transportation logistics, AI can help reduce costs, minimize lead times and improve the overall efficiency of the supply chain.

Ukraine-Russia War Impact Analysis

The conflict between Russia and Ukraine has led to disruption in global commodity trade and has led to increased prices, as Russia, a major commodities suppliers was sanctioned by western countries. A short-term increase in critical commodity prices has led to disruption in the production of fuel cells due to increased input costs. It in turn, led to a short-term decline in demand for fuel cell heat exchangers.

Furthermore, the conflict has led countries of the EU (European Union) to drastically increase investments in green energy technologies. It has given a boost to the development and adoption of fuel cells in the automotive industry. The change in governmental policies is likely to augment demand for fuel cell heat exchangers in Europe over the medium and long-term.

Segment Analysis

The global fuel cell vehicle heat exchangers market is segmented based on type, application and region.

Lightweight and Compact Design makes Plate Heat Exchangers Widely Preferred

Plate heat exchangers have a compact design that allows for efficient heat transfer in a small footprint. It is particularly important in the limited space available in fuel cell vehicles, where compactness is essential for optimizing system integration. The use of thin metal plates in plate heat exchangers makes them lightweight compared to other types of heat exchangers. The lightweight nature of plate heat exchangers aligns with the need for weight reduction in fuel cell vehicles, contributing to improved vehicle efficiency and range.

Plate heat exchangers provide a large heat transfer surface area due to their design, which consists of multiple thin metal plates with corrugated patterns. The corrugations enhance heat transfer efficiency by creating turbulent flow and increasing the surface area for heat exchange. It results in effective thermal management within the fuel cell system.

Geographical Analysis

Expanding Adoption of Fuel Cell Vehicles Makes North America a Key Region in The Global Market

North America accounts for a third of the global market. U.S. is one of the key markets for fuel cell vehicles in North America. The country has been actively supporting the development and deployment of fuel cell technology through various initiatives and funding programs. Several automakers, including Toyota, Honda and General Motors, have introduced fuel cell vehicles in the U.S. market.

The U.S. state of California, in particular, has been a leader in promoting fuel cell vehicles, with a comprehensive set of policies such as green subsidies, tax credits and infrastructure investments to support their adoption. In fact, many carmakers exclusively launch fuel cell vehicles in California due to the ready availability of infrastructure.

In addition to passenger vehicles, there is a growing focus on the use of fuel cells in commercial applications such as buses, trucks and material handling equipment. The potential for zero-emission transportation solutions in these sectors has prompted industry stakeholders to explore the benefits of fuel cell technology. Furthermore, pilot projects and deployments of fuel cell-powered commercial vehicles are taking place in various regions of North America.

Competitive Landscape

The major global players include: Hanon Systems, Valeo, Denso Corporation, Nippon Light Metal Co.,Ltd, Alfa Laval, T.RAD Co., Ltd., Thermogym Ltd., MAHLE GmBH, Tempco Srl and Tianjin Botai Heat-Exchanger Equipment Co., Ltd.

Why Purchase the Report?

- To visualize the global fuel cell vehicle heat exchangers market segmentation based on type, application and region, as well as understand key commercial assets and players.

- Identify commercial opportunities by analyzing trends and co-development.

- Excel data sheet with numerous data points of fuel cell vehicle heat exchangers market-level with all segments.

- PDF report consists of a comprehensive analysis after exhaustive qualitative interviews and an in-depth study.

- Product mapping available as Excel consisting of key products of all the major players.

The global fuel cell vehicle heat exchangers market report would provide approximately 53 tables, 47 figures and 185 Pages.

Target Audience 2023

- Fuel Cell Vehicle Manufacturers

- Fuel Cell Component Manufacturers

- Industry Investors/Investment Bankers

- Research Professionals

- Emerging Companies

Table of Contents

1. Methodology and Scope

- 1.1. Research Methodology

- 1.2. Research Objective and Scope of the Report

2. Definition and Overview

3. Executive Summary

- 3.1. Snippet by Type

- 3.2. Snippet by Application

- 3.3. Snippet by Region

4. Dynamics

- 4.1. Impacting Factors

- 4.1.1. Drivers

- 4.1.1.1. Advancements in Fuel Cell Technology

- 4.1.1.2. Development of Hydrogen Infrastructure

- 4.1.1.3. Government Support and Incentives

- 4.1.1.4. Advances in Heat Exchanger Design

- 4.1.2. Restraints

- 4.1.2.1. Limited Adoption of Fuel Cell Vehicles

- 4.1.2.2. High Manufacturing and Production Costs

- 4.1.3. Opportunity

- 4.1.4. Impact Analysis

- 4.1.1. Drivers

5. Industry Analysis

- 5.1. Porter's Five Force Analysis

- 5.2. Supply Chain Analysis

- 5.3. Pricing Analysis

- 5.4. Regulatory Analysis

6. COVID-19 Analysis

- 6.1. Analysis of COVID-19

- 6.1.1. Scenario Before COVID

- 6.1.2. Scenario During COVID

- 6.1.3. Scenario Post COVID

- 6.2. Pricing Dynamics Amid COVID-19

- 6.3. Demand-Supply Spectrum

- 6.4. Government Initiatives Related to the Market During Pandemic

- 6.5. Manufacturers Strategic Initiatives

- 6.6. Conclusion

7. By Type

- 7.1. Introduction

- 7.1.1. Market Size Analysis and Y-o-Y Growth Analysis (%), By Type

- 7.1.2. Market Attractiveness Index, By Type

- 7.2. Shell & Tube Heat Exchanger*

- 7.2.1. Introduction

- 7.2.2. Market Size Analysis and Y-o-Y Growth Analysis (%)

- 7.3. Plate Heat Exchanger

- 7.4. Air Cooled Heat Exchanger

8. By Application

- 8.1. Introduction

- 8.1.1. Market Size Analysis and Y-o-Y Growth Analysis (%), By Application

- 8.1.2. Market Attractiveness Index, By Application

- 8.2. Passenger Vehicle*

- 8.2.1. Introduction

- 8.2.2. Market Size Analysis and Y-o-Y Growth Analysis (%)

- 8.3. Light Commercial Vehicle (LCV)

- 8.4. Heavy Commercial Vehicle (HCV)

9. By Region

- 9.1. Introduction

- 9.1.1. Market Size Analysis and Y-o-Y Growth Analysis (%), By Region

- 9.1.2. Market Attractiveness Index, By Region

- 9.2. North America

- 9.2.1. Introduction

- 9.2.2. Key Region-Specific Dynamics

- 9.2.3. Market Size Analysis and Y-o-Y Growth Analysis (%), By Type

- 9.2.4. Market Size Analysis and Y-o-Y Growth Analysis (%), By Application

- 9.2.5. Market Size Analysis and Y-o-Y Growth Analysis (%), By Country

- 9.2.5.1. U.S.

- 9.2.5.2. Canada

- 9.2.5.3. Mexico

- 9.3. Europe

- 9.3.1. Introduction

- 9.3.2. Key Region-Specific Dynamics

- 9.3.3. Market Size Analysis and Y-o-Y Growth Analysis (%), By Type

- 9.3.4. Market Size Analysis and Y-o-Y Growth Analysis (%), By Application

- 9.3.5. Market Size Analysis and Y-o-Y Growth Analysis (%), By Country

- 9.3.5.1. Germany

- 9.3.5.2. UK

- 9.3.5.3. France

- 9.3.5.4. Italy

- 9.3.5.5. Russia

- 9.3.5.6. Rest of Europe

- 9.4. South America

- 9.4.1. Introduction

- 9.4.2. Key Region-Specific Dynamics

- 9.4.3. Market Size Analysis and Y-o-Y Growth Analysis (%), By Type

- 9.4.4. Market Size Analysis and Y-o-Y Growth Analysis (%), By Application

- 9.4.5. Market Size Analysis and Y-o-Y Growth Analysis (%), By Country

- 9.4.5.1. Brazil

- 9.4.5.2. Argentina

- 9.4.5.3. Rest of South America

- 9.5. Asia-Pacific

- 9.5.1. Introduction

- 9.5.2. Key Region-Specific Dynamics

- 9.5.3. Market Size Analysis and Y-o-Y Growth Analysis (%), By Type

- 9.5.4. Market Size Analysis and Y-o-Y Growth Analysis (%), By Application

- 9.5.5. Market Size Analysis and Y-o-Y Growth Analysis (%), By Country

- 9.5.5.1. China

- 9.5.5.2. India

- 9.5.5.3. Japan

- 9.5.5.4. Australia

- 9.5.5.5. Rest of Asia-Pacific

- 9.6. Middle East and Africa

- 9.6.1. Introduction

- 9.6.2. Key Region-Specific Dynamics

- 9.6.3. Market Size Analysis and Y-o-Y Growth Analysis (%), By Type

- 9.6.4. Market Size Analysis and Y-o-Y Growth Analysis (%), By Application

10. Competitive Landscape

- 10.1. Competitive Scenario

- 10.2. Market Positioning/Share Analysis

- 10.3. Mergers and Acquisitions Analysis

11. Company Profiles

- 11.1. Hanon Systems*

- 11.1.1. Company Overview

- 11.1.2. Type Portfolio and Description

- 11.1.3. Financial Overview

- 11.1.4. Recent Developments

- 11.2. Valeo

- 11.3. Denso Corporation

- 11.4. Nippon Light Metal Co., Ltd

- 11.5. Alfa Laval

- 11.6. T.RAD Co., Ltd.

- 11.7. Thermogym Ltd.

- 11.8. MAHLE GmBH

- 11.9. Tempco Srl

- 11.10. Tianjin Botai Heat-Exchanger Equipment Co., Ltd.

LIST NOT EXHAUSTIVE

12. Appendix

- 12.1. About Us and Services

- 12.2. Contact Us