|

|

市場調査レポート

商品コード

1625345

低炭素アルミニウムの世界市場:用途・製品・地域別の分析・予測 (2024-2034年)Low-Carbon Aluminum Market - A Global and Regional Analysis: Focus on Application, Product, and Regional Analysis - Analysis and Forecast, 2024-2034 |

||||||

カスタマイズ可能

|

|||||||

| 低炭素アルミニウムの世界市場:用途・製品・地域別の分析・予測 (2024-2034年) |

|

出版日: 2025年01月08日

発行: BIS Research

ページ情報: 英文 192 Pages

納期: 1~5営業日

|

全表示

- 概要

- 図表

- 目次

世界の低炭素アルミニウムの市場規模は、2023年の907億5,000万米ドルから、予測期間中はCAGR 5.97%で推移し、2034年には1,711億8,000万米ドルに達すると予測されています。

同市場の成長は、政府や企業がネットゼロエミッション目標を重視する中、自動車、建設、包装などの業界全体で持続可能な材料に対する需要が増加していることが背景にあります。主な促進要因には、カーボンフリー製錬や再生可能エネルギー統合などの生産技術の進歩があり、一次生産に比べ消費エネルギーが大幅に少ない再生アルミニウムの採用が増加しています。EUのCBAM (Carbon Border Adjustment Mechanism) などの規制上の取り組みや、環境に優しい素材に対する消費者の意識の高まりが、市場をさらに後押ししています。

同市場の成長は、生産性を維持しながら炭素排出量を削減することに焦点を当てた、強力な技術革新と戦略的パートナーシップによっても支えられています。業界の主要企業は、カーボンフリー製錬のためにELYSISなどの画期的な技術を採用しており、自動車メーカーは軽量の電気自動車 (EV) 向けに低炭素アルミニウムの利用を増やしています。しかし、生産コストの高さ、再生可能エネルギーへのアクセスの制限、コストの高い代替品への抵抗といった課題は依然として残っています。このような障壁にもかかわらず、低炭素アルミニウム市場は持続可能な産業慣行への重要な一歩であり、気候変動と闘いながら循環経済を支える可能性を示しています。

| 主要市場統計 | |

|---|---|

| 予測期間 | 2024-2034年 |

| 2024年評価 | 958億9,000万米ドル |

| 2034年予測 | 1,711億8,000万米ドル |

| CAGR | 5.97% |

市場セグメンテーション

セグメンテーション1:エンドユーザー別

- 輸送

- 建築・建設

- 電気

- 消費財

- フォイル・包装

- 機械・設備

- その他

セグメンテーション2:製錬所レベルでの生産経路別

- 一次アルミニウム生産

- 再生可能エネルギーによる電解 (再生可能エネルギーを利用した従来のホールヒールプロセス)

- 太陽エネルギー

- 風力エネルギー

- 水力エネルギー

- 水素電解

- CCUSの統合によるプロセス排出量の削減

- 不活性陽極技術

- 水抜き正極セル

- 再生可能エネルギーによる電解 (再生可能エネルギーを利用した従来のホールヒールプロセス)

- リサイクルまたは二次アルミニウム生産

セグメンテーション3:地域別

- 北米

- 欧州

- アジア太平洋

- その他の地域

市場促進要因

世界各国政府は、アルミニウム部門を含め、温室効果ガス排出に大きく寄与する産業における炭素排出削減に注力しています。炭素税、排出権取引制度、環境基準の厳格化などの規制政策が、低炭素アルミニウム生産へのシフトを後押ししています。グリーン技術や再生可能エネルギーを採用するメーカーに対する奨励金や補助金も市場をさらに後押ししています。例えば、EUのグリーンディールや米国のインフレ削減法のようなイニシアチブは、産業の脱炭素化を優先し、低炭素アルミニウムの採用に有利な状況を作り出しています。

市場抑制要因

特定の産業におけるアルミニウムのリサイクル率の低さは、低炭素アルミニウム市場の成長にとって大きな課題となっています。アルミニウムは本来リサイクル可能ですが、建設や航空宇宙などの分野では、使用済みアルミニウム製品をリサイクルする際に、しばしば物流や技術的な障壁に直面します。こうした課題には、標準化されたリサイクルインフラの欠如、スクラップ材料の汚染、混合アルミニウムや低品質のアルミニウム廃棄物の処理に伴う高コストなどがあります。さらに、建築業や運輸業など、製品のライフサイクルが長い業界では、スクラップの入手が遅れ、再生アルミニウムの供給が制限されます。こうしたリサイクルの非効率性に対処することは、世界の持続可能性目標を達成し、低炭素アルミニウムの利用可能性を高めるために不可欠です。

市場機会

超低CO2アルミニウムグレードに対する需要の高まりは、低炭素アルミニウム市場のニッチセグメントで大きな機会を示します。航空宇宙、電気自動車、高級パッケージングなどの業界では、持続可能性の目標や規制遵守に沿うため、環境への影響を最小限に抑えた材料を求める傾向が強まっています。再生可能エネルギーを利用した製錬やリサイクル率の高い素材など、先進技術を駆使して生産される超低CO2アルミニウムは、こうした用途に適した素材として人気を集めています。このような特殊なアルミニウム等級の開発と生産拡大に投資する企業は、二酸化炭素排出量の削減に取り組む顧客層の拡大に対応することができ、その結果、利益率の高い環境重視の市場セグメントで価値を獲得することができます。

当レポートでは、世界の低炭素アルミニウムの市場を調査し、主要動向、市場影響因子の分析、法規制環境、技術開発・特許の動向、ケーススタディ、市場規模の推移・予測、各種区分・地域/主要国別の詳細分析、競合情勢、主要企業のプロファイルなどをまとめています。

目次

エグゼクティブサマリー

範囲と定義

第1章 市場:業界の展望

- 動向:現在および将来の影響評価

- 低炭素アルミニウムへの投資増加

- 低炭素インフラ整備に向けた政府の取り組み

- サプライチェーンの概要

- 低炭素アルミニウム市場のエコシステム

- コンソーシアムと協会

- 規制機関/認証機関

- 政府プログラム

- 研究機関・大学による別プログラム

- 市場力学の概要

- 市場促進要因

- 市場の課題

- 事業戦略

- 企業戦略

- 市場機会

- スタートアップの情勢

- エコシステム内の主要なスタートアップ

- 特許分析

- 特許出願動向 (特許件数別、年別、国別)

- 平均価格分析:世界および地域レベル

- アルミニウム生産における炭素排出

- アルミニウム貿易分析:2021-2023年

- 2023年の主な稼働アルミニウム工場

第2章 用途

- 用途のセグメンテーション

- 用途の概要

- 低炭素アルミニウム市場 (エンドユーザー別)

- 輸送

- 建築・建設

- 電気産業

- 消費財

- フォイル・包装

- 機械設備

- その他

第3章 製品

- 製品セグメンテーション

- 製品概要

- 低炭素アルミニウム市場 (製錬所レベルでの生産経路別)

- 一次アルミニウム生産

- リサイクルまたは二次アルミニウム製品

- 低炭素アルミニウム市場 (非商業化経路別)

- アルミニウム炭素熱還元

- アルミナ直接還元 (水素電気分解)

- アルミナ由来の中間体を使用した処理

第4章 地域

- 地域別概要

- 北米

- 地域概要

- 市場成長の原動力

- 市場課題

- 米国

- カナダ

- メキシコ

- 欧州

- 地域概要

- 市場成長の原動力

- 市場課題

- ドイツ

- フランス

- ロシア

- イタリア

- スペイン

- 英国

- その他

- アジア太平洋

- 地域概要

- 市場成長の原動力

- 市場課題

- 中国

- 日本

- インド

- 韓国

- ASEAN諸国

- その他

- その他の地域

- 地域概要

- 市場成長の原動力

- 市場課題

- 南米

- 中東・アフリカ

第5章 市場:競合ベンチマーキングと企業プロファイル

- 次なるフロンティア

- 地理的評価

- Vedanta Aluminium & Power

- Century Aluminum Company

- RUSAL

- Norsk Hydro ASA

- Alcoa Corporation

- China Hongqiao Group Limited

- Emirates Global Aluminum PJSC

- Capral Limited

- Constellium SE

- Aluar Aluminio Argentino S.A.I.C.

- Volta Aluminium Company Limited

- Runaya

- Rio Tinto

- CBA

- South32

- PT Indonesia Asahan Aluminium

- Novelis

- Eti Aluminyum

- Speira GmbH

- Aluminium Dunkerque

第6章 調査手法

List of Figures

- Figure 1: Low-Carbon Aluminum Market (by Scenario), $Billion, 2024, 2028, and 2034

- Figure 2: Low-Carbon Aluminum Market (by Region), $Billion, 2023, 2028, and 2034

- Figure 3: Low-Carbon Aluminum Market (by End User), $Billion, 2023, 2028, and 2034

- Figure 4: Low-Carbon Aluminum Market (by Production Pathway at Smelter Level), $Billion, 2023, 2028, and 2034

- Figure 5: Key Events

- Figure 6: Sector-Wide Emissions Reduction Trajectory

- Figure 7: Primary Electricity-Related Emissions, in Ton CO2 per Ton Aluminum Produced, 2020-2050

- Figure 8: Primary All Other Emissions, in Ton CO2 per Ton Aluminum Produced, 2020-2025

- Figure 9: Production Volumes in Europe, Metric Tons, 2015 and 2021

- Figure 10: European GHG Emissions, Per Ton of Aluminum Ingot and Type of Emissions, 2023

- Figure 11: GHG Footprint of the Aluminum Sector, 2023

- Figure 12: Reductions by Decade Compared to 2021

- Figure 13: Global End-Use of Aluminum, 2019

- Figure 14: Impact Analysis of Low-Carbon Aluminum Market Navigating Factors, 2024-2034

- Figure 15: Process-Wise Greenhouse Gas Emissions, Tons of Carbon Dioxide per Ton of Primary Aluminum Produced, 2023

- Figure 16: Patent Analysis (by Year), January 2021-December 2024

- Figure 17: Patent Analysis (by Country), January 2021-December 2024

- Figure 18: Aluminum Trade Analysis - Net Trade (by Region), $Billion, 2021-2023

- Figure 19: Aluminum Trade Analysis - Net Trade (by Region), $Billion, 2021-2023

- Figure 20: U.S. Low-Carbon Aluminum Market, $Billion, 2023-2034

- Figure 21: Canada Low-Carbon Aluminum Market, $Billion, 2023-2034

- Figure 22: Mexico Low-Carbon Aluminum Market, $Billion, 2023-2034

- Figure 23: Germany Low-Carbon Aluminum Market, $Billion, 2023-2034

- Figure 24: France Low-Carbon Aluminum Market, $Billion, 2023-2034

- Figure 25: Russia Low-Carbon Aluminum Market, $Billion, 2023-2034

- Figure 26: Italy Low-Carbon Aluminum Market, $Billion, 2023-2034

- Figure 27: Spain Low-Carbon Aluminum Market, $Billion, 2023-2034

- Figure 28: U.K. Low-Carbon Aluminum Market, $Billion, 2023-2034

- Figure 29: Rest-of-Europe Low-Carbon Aluminum Market, $Billion, 2023-2034

- Figure 30: China Low-Carbon Aluminum Market, $Billion, 2023-2034

- Figure 31: Japan Low-Carbon Aluminum Market, $Billion, 2023-2034

- Figure 32: India Low-Carbon Aluminum Market, $Billion, 2023-2034

- Figure 33: South Korea Low-Carbon Aluminum Market, $Billion, 2023-2034

- Figure 34: ASEAN Low-Carbon Aluminum Market, $Billion, 2023-2034

- Figure 35: Rest-of-Asia-Pacific Low-Carbon Aluminum Market, $Billion, 2023-2034

- Figure 36: South America Low-Carbon Aluminum Market, $Billion, 2023-2034

- Figure 37: Middle East and Africa Low-Carbon Aluminum Market, $Billion, 2023-2034

- Figure 38: Strategic Initiatives, January 2021-December 2024

- Figure 39: Data Triangulation

- Figure 40: Top-Down and Bottom-Up Approach

- Figure 41: Assumptions and Limitations

List of Tables

- Table 1: Market Snapshot

- Table 2: Opportunities across Regions

- Table 3: Competitive Landscape Snapshot

- Table 4: Recent Investments in Low-Carbon Aluminum

- Table 5: Recent Government Activities toward Low-Carbon Infrastructure

- Table 6: Timeline of the ASI-Endorsed Method

- Table 7: Scenario-Based Forecasted Electricity Grid Developments

- Table 8: Regulatory/Certification Bodies in Low-Carbon Aluminum Market

- Table 9: Recent Government Programs in Low-Carbon Aluminum Market

- Table 10: Key Research Institutes and University Programs in Low-Carbon Aluminum Market

- Table 11: Recent R&D Initiatives in Low-Carbon Aluminum Market

- Table 12: Start-ups and Investment Landscape

- Table 13: Low-Carbon Aluminum Market (by Region), $/Ton, 2023-2034

- Table 14: Greenhouse Gas Emissions Intensity - Primary Aluminum, Tons of CO2e per Ton of Primary Aluminum, 2023

- Table 15: Greenhouse Gas Emissions - Aluminum Sector, Overall CO2 Emissions, Million Tons of CO2e, 2023

- Table 16: List of Key Operating Aluminum Plants, 2023

- Table 17: Application Summary

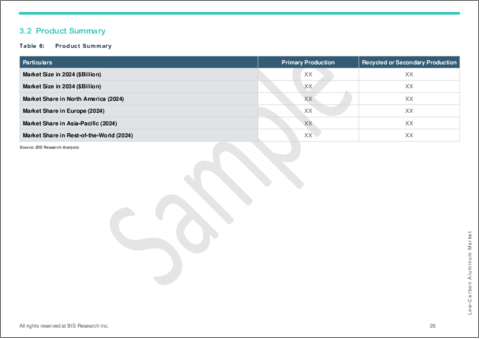

- Table 18: Product Summary

- Table 19: Low-Carbon Aluminum Market (by Region), $Billion, 2023-2034

- Table 20: North America Low-Carbon Aluminum Market (by End User), $Billion, 2023-2034

- Table 21: North America Low-Carbon Aluminum Market (by Production Pathway at Smelter Level), $Billion, 2023-2034

- Table 22: U.S. Low-Carbon Aluminum Market (by End User), $Billion, 2023-2034

- Table 23: U.S. Low-Carbon Aluminum Market (by Production Pathway at Smelter Level), $Billion, 2023-2034

- Table 24: Canada Low-Carbon Aluminum Market (by End User), $Billion, 2023-2034

- Table 25: Canada Low-Carbon Aluminum Market (by Production Pathway at Smelter Level), $Billion, 2023-2034

- Table 26: Mexico Low-Carbon Aluminum Market (by End User), $Billion, 2023-2034

- Table 27: Mexico Low-Carbon Aluminum Market (by Production Pathway at Smelter Level), $Billion, 2023-2034

- Table 28: Europe Low-Carbon Aluminum Market (by End User), $Billion, 2023-2034

- Table 29: Europe Low-Carbon Aluminum Market (by Production Pathway at Smelter Level), $Billion, 2023-2034

- Table 30: Germany Low-Carbon Aluminum Market (by End User), $Billion, 2023-2034

- Table 31: Germany Low-Carbon Aluminum Market (by Production Pathway at Smelter Level), $Billion, 2023-2034

- Table 32: France Low-Carbon Aluminum Market (by End User), $Billion, 2023-2034

- Table 33: France Low-Carbon Aluminum Market (by Production Pathway at Smelter Level), $Billion, 2023-2034

- Table 34: Russia Low-Carbon Aluminum Market (by End User), $Billion, 2023-2034

- Table 35: Russia Low-Carbon Aluminum Market (by Production Pathway at Smelter Level), $Billion, 2023-2034

- Table 36: Italy Low-Carbon Aluminum Market (by End User), $Billion, 2023-2034

- Table 37: Italy Low-Carbon Aluminum Market (by Production Pathway at Smelter Level), $Billion, 2023-2034

- Table 38: Spain Low-Carbon Aluminum Market (by End User), $Billion, 2023-2034

- Table 39: Spain Low-Carbon Aluminum Market (by Production Pathway at Smelter Level), $Billion, 2023-2034

- Table 40: U.K. Low-Carbon Aluminum Market (by End User), $Billion, 2023-2034

- Table 41: U.K. Low-Carbon Aluminum Market (by Production Pathway at Smelter Level), $Billion, 2023-2034

- Table 42: Rest-of-Europe Low-Carbon Aluminum Market (by End User), $Billion, 2023-2034

- Table 43: Rest-of-Europe Low-Carbon Aluminum Market (by Production Pathway at Smelter Level), $Billion, 2023-2034

- Table 44: Asia-Pacific Low-Carbon Aluminum Market (by End User), $Billion, 2023-2034

- Table 45: Asia-Pacific Low-Carbon Aluminum Market (by Production Pathway at Smelter Level), $Billion, 2023-2034

- Table 46: China Low-Carbon Aluminum Market (by End User), $Billion, 2023-2034

- Table 47: China Low-Carbon Aluminum Market (by Production Pathway at Smelter Level), $Billion, 2023-2034

- Table 48: Japan Low-Carbon Aluminum Market (by End User), $Billion, 2023-2034

- Table 49: Japan Low-Carbon Aluminum Market (by Production Pathway at Smelter Level), $Billion, 2023-2034

- Table 50: India Low-Carbon Aluminum Market (by End User), $Billion, 2023-2034

- Table 51: India Low-Carbon Aluminum Market (by Production Pathway at Smelter Level), $Billion, 2023-2034

- Table 52: South Korea Low-Carbon Aluminum Market (by End User), $Billion, 2023-2034

- Table 53: South Korea Low-Carbon Aluminum Market (by Production Pathway at Smelter Level), $Billion, 2023-2034

- Table 54: ASEAN Low-Carbon Aluminum Market (by End User), $Billion, 2023-2034

- Table 55: ASEAN Low-Carbon Aluminum Market (by Production Pathway at Smelter Level), $Billion, 2023-2034

- Table 56: Rest-of-Asia-Pacific Low-Carbon Aluminum Market (by End User), $Billion, 2023-2034

- Table 57: Rest-of-Asia-Pacific Low-Carbon Aluminum Market (by Production Pathway at Smelter Level), $Billion, 2023-2034

- Table 58: Rest-of-the-World Low-Carbon Aluminum Market (by End User), $Billion, 2023-2034

- Table 59: Rest-of-the-World Low-Carbon Aluminum Market (by Production Pathway at Smelter Level), $Billion, 2023-2034

- Table 60: South America Low-Carbon Aluminum Market (by End User), $Billion, 2023-2034

- Table 61: South America Low-Carbon Aluminum Market (by Production Pathway at Smelter Level), $Billion, 2023-2034

- Table 62: Middle East and Africa Low-Carbon Aluminum Market (by End User), $Billion, 2023-2034

- Table 63: Middle East and Africa Low-Carbon Aluminum Market (by Production Pathway at Smelter Level), $Billion, 2023-2034

- Table 64: Global Market Share, 2023

Low-Carbon Aluminum Market Overview

The global low-carbon aluminum market is projected to reach $171.18 billion by 2034 from $90.75 billion in 2023, growing at a CAGR of 5.97% during the forecast period 2024-2034. This growth is driven by increasing demand for sustainable materials across industries like automotive, construction, and packaging, as governments and corporations emphasize net-zero emissions goals. Key drivers include advancements in production technologies, such as carbon-free smelting and renewable energy integration, alongside the rising adoption of recycled aluminum, which consumes significantly less energy compared to primary production. Regulatory initiatives like the European Union's Carbon Border Adjustment Mechanism (CBAM) and growing consumer awareness of eco-friendly materials further bolster the market.

The market's growth is underpinned by strong innovation and strategic partnerships focused on reducing carbon emissions while maintaining productivity. Major industry players are adopting breakthrough technologies like ELYSIS for carbon-free smelting, while automakers are increasingly utilizing low-carbon aluminum for lightweight electric vehicles (EVs). However, challenges such as high production costs, limited access to renewable energy, and resistance to costlier alternatives remain. Despite these hurdles, the low-carbon aluminum market represents a critical step toward sustainable industrial practices, reflecting its potential to combat climate change while supporting a circular economy.

| KEY MARKET STATISTICS | |

|---|---|

| Forecast Period | 2024 - 2034 |

| 2024 Evaluation | $95.89 Billion |

| 2034 Forecast | $171.18 Billion |

| CAGR | 5.97% |

Introduction to the Low-Carbon Aluminum Market

The low-carbon aluminum market is growing rapidly, driven by increasing global efforts to reduce industrial carbon footprints and achieve sustainability goals. Governments and organizations are implementing policies and offering incentives to encourage industries to adopt low-carbon materials and production processes, such as renewable energy integration, recycling, and carbon-free smelting technologies. The rising demand for sustainable materials, fueled by corporate net-zero commitments and consumer pressure for eco-friendly products, is creating new opportunities for aluminum producers. Advancements in technology, including carbon-free smelting, energy-efficient recycling methods, and blockchain-enabled supply chain transparency, are enhancing the production and tracking of low-carbon aluminum. Additionally, collaborations among manufacturers, technology providers, and environmental organizations are accelerating innovation and driving widespread adoption. These factors, combined with the need to transition toward a circular economy, highlight the immense growth potential of the low-carbon aluminum market.

Market Introduction

The low-carbon aluminum market represents a critical shift toward sustainable industrial practices by producing aluminum with a significantly lower carbon footprint. The market is gaining momentum due to growing corporate net-zero commitments, increasing demand for sustainable materials, and supportive government policies offering subsidies and incentives for low-carbon technologies. Technological advancements, such as carbon-free smelting processes, renewable energy-powered production, and enhanced aluminum recycling methods, are boosting market credibility and adoption. As industries aim to meet stricter environmental standards, improve energy efficiency, and address consumer demands for sustainability, the low-carbon aluminum market is positioned for substantial growth. This evolution reflects a larger global trend of decarbonization and resource optimization across industries.

Industrial Impact

The low-carbon aluminum market is emerging as a transformative force with significant industrial impacts, particularly for sectors focused on reducing their carbon footprints. Low-carbon aluminum, produced using renewable energy sources and advanced recycling technologies, provides sustainable solutions for industries such as automotive, aerospace, construction, and packaging. By integrating low-carbon aluminum into their supply chains, industries can significantly lower emissions, meet sustainability goals, and enhance their environmental credentials.

The industrial impact of low-carbon aluminum has been bolstered by regulatory frameworks such as the European Union's Carbon Border Adjustment Mechanism (CBAM), which incentivizes the use of greener materials, and initiatives like the U.S. Inflation Reduction Act, which promotes decarbonization in heavy industries. These policies encourage industries to adopt low-carbon aluminum as a key component in meeting global climate targets under the Paris Agreement.

Furthermore, low-carbon aluminum supports the transition toward a circular economy by integrating recycled materials and reducing the energy-intensive nature of primary aluminum production. The use of low-carbon aluminum in value-added applications such as electric vehicles, renewable energy infrastructure, and lightweight packaging solutions not only strengthens supply chain sustainability but also aligns businesses with growing consumer demand for eco-friendly products. With ongoing technological advancements and investments in renewable energy integration, the low-carbon aluminum market is poised to become a cornerstone of sustainable industrial practices across diverse sectors.

Market Segmentation:

Segmentation 1: by End-User

- Transportation

- Building and Construction

- Electrical Industry

- Consumer Goods

- Foil and Packaging

- Machinery and Equipment

- Others

Transportation to Lead the Market (by End-User)

The transportation sector is the leading market for low-carbon aluminum due to its critical need for lightweight, durable, and sustainable materials. Aluminum's unique properties, such as its high strength-to-weight ratio, corrosion resistance, and recyclability, make it an ideal choice for reducing vehicle weight, which is directly linked to improved fuel efficiency and reduced greenhouse gas (GHG) emissions. In particular, the rise of electric vehicles (EVs) has further amplified the demand for low-carbon aluminum, as automakers aim to offset the weight of batteries and enhance overall energy efficiency. Additionally, regulatory pressures, such as the European Union's stringent emission reduction targets and Corporate Average Fuel Economy (CAFE) standards in the U.S., have compelled automakers to adopt sustainable materials, making low-carbon aluminum a preferred option.

The shift toward sustainability across the aviation, rail, and shipping industries is also driving the demand for low-carbon aluminum. Airlines, for example, are increasingly using aluminum alloys in aircraft manufacturing to reduce weight, lower fuel consumption, and comply with carbon-neutral aviation goals. Similarly, rail and shipping companies are integrating low-carbon aluminum into train cars, freight containers, and marine vessels to improve energy efficiency and reduce operational emissions. These trends, combined with growing consumer expectations for environmentally responsible transportation options, have positioned the sector as a key driver of the low-carbon aluminum market. By adopting this material, transportation companies not only address environmental concerns but also achieve operational benefits, creating a win-win scenario that fuels market growth.

Segmentation 2: by Production Pathway at Smelter Level

- Primary Aluminum Production

- Renewable-Powered Electrolysis (Traditional Hall-Heroult Process with Renewable Energy)

Solar Energy

Wind Energy

Hydro Energy

Hydrogen Powered Electrolysis

- CCUS Integration to Reduce Process Emissions

- Inert Anode Technology

- Drained Cathode Cell

- Recycled or Secondary Aluminum Production

Recycled or Secondary Aluminum Production to Lead the Market (by Production Pathway at Smelter Level)

Recycled or secondary aluminum production is leading the low-carbon aluminum market because it significantly reduces energy consumption and carbon emissions compared to primary aluminum production. Recycling aluminum requires only about 5% of the energy needed to produce primary aluminum from bauxite, which makes it an inherently low-carbon process. This drastic reduction in energy use translates into a smaller carbon footprint, positioning recycled aluminum as the preferred choice for industries aiming to meet sustainability goals and reduce operational emissions. With growing corporate commitments to net-zero emissions and the global push for a circular economy, the demand for secondary aluminum continues to grow.

Additionally, the recyclability of aluminum-where nearly 100% of the material can be reused without losing its quality-makes it a key component in sustainable manufacturing practices. Industries such as automotive, construction, and packaging are increasingly adopting recycled aluminum to meet stricter environmental regulations and consumer expectations for eco-friendly products. The rising availability of scrap aluminum and advancements in recycling technologies, such as closed-loop systems and AI-driven sorting processes, have enhanced the efficiency and scalability of secondary aluminum production. As a result, recycled aluminum not only offers environmental benefits but also supports cost efficiency, making it a leading driver in the low-carbon aluminum market.

Segmentation 3: by Region

- North America

- Europe

- Asia-Pacific

- Rest-of-the-World

Asia-Pacific Region to Lead the Market

The Asia-Pacific region is leading the market for low-carbon aluminum due to its massive industrial base, rapid urbanization, and growing focus on sustainable development. Countries such as China, India, and Japan are major producers and consumers of aluminum, with China accounting for over half of the world's aluminum production. The region's dominance in manufacturing and construction drives significant demand for low-carbon aluminum, as industries aim to reduce their carbon footprint and comply with tightening environmental regulations. China's commitment to achieving carbon neutrality by 2060 has spurred investments in renewable energy-powered aluminum production, recycling infrastructure, and advanced smelting technologies.

Another critical factor is the rising adoption of low-carbon aluminum in key industries like automotive, electronics, and construction within Asia-Pacific. The increasing production of electric vehicles (EVs) in China and other regional markets has further boosted demand for lightweight, sustainable materials like low-carbon aluminum. Additionally, government policies and incentives, such as carbon pricing mechanisms, subsidies for green technologies, and renewable energy initiatives, have accelerated the transition toward low-carbon aluminum production. The availability of cost-competitive labor, technological innovation, and the region's focus on building a circular economy solidify Asia-Pacific's leadership in the global low-carbon aluminum market.

Recent developments in the low-carbon aluminum market:

- On August 2, 2021, Vedanta Aluminium announced that it has become India's largest green power purchaser, sourcing over 3 billion units of renewable energy. This milestone aligns with Vedanta's commitment to reducing its carbon footprint and supporting India's transition to renewable energy.

- On September 23, 2024, Novelis announced its 3x30 sustainability initiative, which aims to reduce carbon emissions by 30%, increase recycled content to 30%, and achieve 30% improvement in water usage efficiency by 2030. This initiative highlights Novelis' commitment to sustainability and its leadership in producing low-carbon aluminum.

- Alcoa and Rio Tinto launch new joint venture, ELYSIS, for larger scale development and commercialisation of the process, with a technology package planned for sale beginning in 2024.

Demand - Drivers, Limitations, and Opportunities

Market Drivers

Governments worldwide are focusing on reducing carbon emissions in industries that significantly contribute to greenhouse gas emissions, including the aluminum sector. Regulatory policies such as carbon taxation, emissions trading systems, and stricter environmental standards are driving the shift toward low-carbon aluminum production. Incentives and subsidies for manufacturers adopting green technologies and renewable energy further propel the market. For instance, initiatives like the European Union's Green Deal and the U.S. Inflation Reduction Act prioritize decarbonizing industries, creating a favorable landscape for low-carbon aluminum adoption.

Market Restraints

The low recycling rates of aluminum in certain industries pose a significant challenge to the growth of the low-carbon aluminum market. While aluminum is inherently recyclable, sectors like construction and aerospace often face logistical and technical barriers in recycling end-of-life aluminum products. These challenges include the lack of standardized recycling infrastructure, contamination of scrap materials, and high costs associated with processing mixed or low-quality aluminum waste. Additionally, industries with long product lifecycles, such as building and transportation, contribute to delayed scrap availability, limiting the supply of recycled aluminum. Addressing these recycling inefficiencies is critical to meeting global sustainability goals and enhancing the availability of low-carbon aluminum.

Market Opportunities

The rising demand for ultra-low-CO2 aluminum grades presents a significant opportunity within niche segments of the low-carbon aluminum market. Industries such as aerospace, electric vehicles, and premium packaging increasingly seek materials with minimal environmental impact to align with sustainability goals and regulatory compliance. Ultra-low-CO2 aluminum, produced using advanced technologies like renewable energy-powered smelting and high-recycled content, is gaining traction as a preferred material for these applications. Companies investing in developing and scaling the production of these specialized aluminum grades can cater to a growing customer base committed to reducing their carbon footprints, thereby capturing value in high-margin, environmentally focused market segments.

How can this report add value to an organization?

Product/Innovation Strategy: This report provides a comprehensive product and innovation strategy for the low-carbon aluminum market, highlighting opportunities for market entry, technological advancements, and sustainable practices. It offers actionable insights that enable organizations to meet carbon reduction goals, and capitalize on the increasing demand for low-carbon aluminum across various sectors.

Growth/Marketing Strategy: This report outlines a robust growth and marketing strategy specifically tailored for the low-carbon aluminum market. It emphasizes a targeted approach to identifying niche market segments, establishing competitive advantages, and implementing innovative marketing initiatives to optimize market share and financial performance. By leveraging these strategic recommendations, organizations can strengthen their market presence, exploit emerging opportunities, and drive revenue growth effectively.

Competitive Strategy: This report formulates a strong competitive strategy designed for the low-carbon aluminum market. It assesses key market players, suggests differentiation tactics, and provides guidance for maintaining a competitive edge. By following these strategic directives, companies can effectively position themselves against competitors, ensuring long-term success and profitability in a rapidly evolving market.

Research Methodology

The section exhibits the standard assumptions and limitations followed throughout the research study named low-carbon aluminum market:

- The scope of this report has been focused on applications and types of products.

- The base currency considered for the market analysis is US$. Currencies other than the US$ have been converted to the US$ for all statistical calculations, considering the average conversion rate for that particular year.

- The currency conversion rate has been taken from the historical exchange rate of the Oanda website.

- All the recent developments from January 2021 to December 2024 have been considered in this research study.

- The information rendered in the report is a result of in-depth primary interviews, surveys, and secondary analysis.

- Where relevant information was not available, proxy indicators and extrapolation were employed.

- Any economic downturn in the future has not been taken into consideration for the market estimation and forecast.

- Technologies currently used are expected to persist through the forecast with no major technological breakthroughs.

Market Estimation and Forecast

This research study employs extensive secondary sources, including certified publications, articles from recognized experts, white papers, annual reports from relevant companies, industry directories, and major databases, to gather valuable and actionable information for a comprehensive, technical, and market-oriented analysis of the low-carbon aluminum market.

The market engineering process encompasses the calculation of market statistics, estimation of market size, forecasting trends, and conducting data triangulation (the methodology for these quantitative data processes is detailed in subsequent sections). Primary research has been conducted to collect information and validate market figures related to segmentation types and industry trends among key players in the low-carbon aluminum sector.

Primary Research

The primary sources involve industry experts from the low-carbon aluminum market and various stakeholders in the ecosystem. Respondents such as CEOs, vice presidents, marketing directors, and technology and innovation directors have been interviewed to obtain and verify both qualitative and quantitative aspects of this research study.

The key data points taken from primary sources include:

- validation and triangulation of all the numbers and graphs

- validation of reports segmentation and key qualitative findings

- understanding the competitive landscape

- validation of the numbers of various markets for market type

- percentage split of individual markets for geographical analysis

Secondary Research

This research study of the low-carbon aluminum market involves extensive secondary research, directories, company websites, and annual reports. It also makes use of databases, such as ITU, Hoovers, Bloomberg, Businessweek, and Factiva, to collect useful and effective information for an extensive, technical, market-oriented, and commercial study of the global market.

Secondary research was done to obtain crucial information about the industry's value chain, revenue models, the market's monetary chain, the total pool of key players, and the current and potential use cases and applications.

The key data points taken from secondary research include:

- segmentations and percentage shares

- data for market value

- key industry trends of the top players of the market

- qualitative insights into various aspects of the market, key trends, and emerging areas of innovation

- quantitative data for mathematical and statistical calculations

Key Market Players and Competition Synopsis

The companies that are profiled in the low-carbon aluminum market have been selected based on input gathered from primary experts and analyzing company coverage, project portfolio, and market penetration.

Some of the prominent companies in this market are:

- Vedanta Aluminium & Power

- Century Aluminum Company

- RUSAL

- Norsk Hydro ASA

- Alcoa Corporation

- China Hongqiao Group Limited

- Emirates Global Aluminum PJSC

- Capral Limited

- Constellium SE

- Aluar Aluminio Argentino S.A.I.C.

- Volta Aluminium Company Limited

- Runaya

- Rio Tinto

- CBA

- South32

- PT Indonesia Asahan Aluminium

- Novelis

- Eti Aluminyum

- Speira GmbH

- Aluminium Dunkerque

Companies not part of the pool have been well represented across different sections of the report (wherever applicable).

Table of Contents

Executive Summary

Scope and Definition

1 Market: Industry Outlook

- 1.1 Trends: Current and Future Impact Assessment

- 1.1.1 Increasing Investments in Low-Carbon Aluminum

- 1.1.2 Government Activities Toward the Establishment of Low-Carbon Infrastructure

- 1.2 Supply Chain Overview

- 1.3 Ecosystem of the Low-Carbon Aluminum Market

- 1.3.1 Consortiums and Associations

- 1.3.1.1 Analysis of ASI GHG Production Pathway

- 1.3.1.2 Analysis of European Aluminium Association Science-Based Decarbonization Pathways

- 1.3.1.3 Analysis of Pathway Set by World Economic Forum

- 1.3.2 Regulatory/Certification Bodies

- 1.3.3 Government Programs

- 1.3.4 Programs by Research Institutions and Universities

- 1.3.1 Consortiums and Associations

- 1.4 Market Dynamics Overview

- 1.4.1 Market Drivers

- 1.4.1.1 Increasing Attention of Governments toward Decarbonization of Core Contributing Commodities

- 1.4.1.2 Growing Research and Development Activities to Achieve Near Zero Emissions

- 1.4.2 Market Challenges

- 1.4.2.1 Lower Recycling Rates for Aluminum in Various Industries

- 1.4.2.2 Volatile Low-Carbon Aluminum Prices

- 1.4.3 Business Strategies

- 1.4.3.1 Product Developments

- 1.4.3.2 Market Developments

- 1.4.4 Corporate Strategies

- 1.4.4.1 Partnerships and Joint Ventures

- 1.4.5 Market Opportunities

- 1.4.5.1 Low-Carbon Aluminum in Niche Segments such as Ultra-Low-CO2 Grades

- 1.4.5.2 Climate Mitigation Initiatives to Increase Demand for Sustainably Sourced Aluminum

- 1.4.1 Market Drivers

- 1.5 Start-Ups Landscape

- 1.5.1 Key Start-Ups in the Ecosystem

- 1.6 Patent Analysis

- 1.6.1 Patent Filing Trend (by Number of Patents, by Year and by Country)

- 1.7 Average Pricing Analysis: Global and Regional Level, Low-Carbon Aluminum

- 1.8 Embedded Carbon Emissions in Aluminum Production

- 1.9 Trade Analysis: Aluminum, 2021-2023

- 1.1 Key Operating Aluminum Plants, 2023

2 Application

- 2.1 Application Segmentation

- 2.2 Application Summary

- 2.3 Low-Carbon Aluminum Market (by End-User)

- 2.3.1 Transportation

- 2.3.2 Building and Construction

- 2.3.3 Electrical Industry

- 2.3.4 Consumer Goods

- 2.3.5 Foil and Packaging

- 2.3.6 Machinery and Equipment

- 2.3.7 Others

3 Products

- 3.1 Product Segmentation

- 3.2 Product Summary

- 3.3 Low-Carbon Aluminum Market (by Production Pathway at Smelter Level)

- 3.3.1 Primary Aluminum Production

- 3.3.1.1 Renewable-Powered Electrolysis (Traditional Hall Heroult Process with Renewable Energy)

- 3.3.1.1.1 Solar Energy

- 3.3.1.1.2 Wind Energy

- 3.3.1.1.3 Hydro Energy

- 3.3.1.1.4 Hydrogen Powered Electrolysis

- 3.3.1.2 CCUS Integration to Reduce Process Emissions

- 3.3.1.3 Inert Anode Technology

- 3.3.1.4 Drained Cathode Cell

- 3.3.1.1 Renewable-Powered Electrolysis (Traditional Hall Heroult Process with Renewable Energy)

- 3.3.2 Recycled or Secondary Aluminum Productions

- 3.3.1 Primary Aluminum Production

- 3.4 Low-Carbon Aluminum Market (by Non-Commercialized Pathways)

- 3.4.1 Aluminum Carbothermic Reduction

- 3.4.2 Direct Reduction of Alumina (Hydrogen-Based Electrolysis)

- 3.4.3 Processing Using Intermediates Derived from Alumina

- 3.4.3.1 Sulfide and Chloride Processing

4 Region

- 4.1 Regional Summary

- 4.2 North America

- 4.2.1 Regional Overview

- 4.2.2 Driving Factors for Market Growth

- 4.2.3 Factors Challenging the Market

- 4.2.3.1 Application

- 4.2.3.2 Product

- 4.2.4 U.S.

- 4.2.4.1 Application

- 4.2.4.2 Product

- 4.2.5 Canada

- 4.2.5.1 Application

- 4.2.5.2 Product

- 4.2.6 Mexico

- 4.2.6.1 Application

- 4.2.6.2 Product

- 4.3 Europe

- 4.3.1 Regional Overview

- 4.3.2 Driving Factors for Market Growth

- 4.3.3 Factors Challenging the Market

- 4.3.3.1 Application

- 4.3.3.2 Product

- 4.3.4 Germany

- 4.3.4.1 Application

- 4.3.4.2 Product

- 4.3.5 France

- 4.3.5.1 Application

- 4.3.5.2 Product

- 4.3.6 Russia

- 4.3.6.1 Application

- 4.3.6.2 Product

- 4.3.7 Italy

- 4.3.7.1 Application

- 4.3.7.2 Product

- 4.3.8 Spain

- 4.3.8.1 Application

- 4.3.8.2 Product

- 4.3.9 U.K.

- 4.3.9.1 Application

- 4.3.9.2 Product

- 4.3.10 Rest-of-Europe

- 4.3.10.1 Application

- 4.3.10.2 Product

- 4.4 Asia-Pacific

- 4.4.1 Regional Overview

- 4.4.2 Driving Factors for Market Growth

- 4.4.3 Factors Challenging the Market

- 4.4.3.1 Application

- 4.4.3.2 Product

- 4.4.4 China

- 4.4.4.1 Application

- 4.4.4.2 Product

- 4.4.5 Japan

- 4.4.5.1 Application

- 4.4.5.2 Product

- 4.4.6 India

- 4.4.6.1 Application

- 4.4.6.2 Product

- 4.4.7 South Korea

- 4.4.7.1 Application

- 4.4.7.2 Product

- 4.4.8 ASEAN

- 4.4.8.1 Application

- 4.4.8.2 Product

- 4.4.9 Rest-of-Asia-Pacific

- 4.4.9.1 Application

- 4.4.9.2 Product

- 4.5 Rest-of-the-World

- 4.5.1 Regional Overview

- 4.5.2 Driving Factors for Market Growth

- 4.5.3 Factors Challenging the Market

- 4.5.3.1 Application

- 4.5.3.2 Product

- 4.5.4 South America

- 4.5.4.1 Application

- 4.5.4.2 Product

- 4.5.5 Middle East and Africa

- 4.5.5.1 Application

- 4.5.5.2 Product

5 Markets - Competitive Benchmarking & Company Profiles

- 5.1 Next Frontiers

- 5.2 Geographic Assessment

- 5.2.1 Vedanta Aluminium & Power

- 5.2.1.1 Overview

- 5.2.1.2 Top Competitors

- 5.2.1.3 Top Products/Product Portfolio

- 5.2.1.4 Target Customers/End-Use Industries

- 5.2.1.5 Key Personnel

- 5.2.1.6 Analyst View

- 5.2.1.7 Market Share, 2023

- 5.2.2 Century Aluminum Company

- 5.2.2.1 Overview

- 5.2.2.2 Top Competitors

- 5.2.2.3 Top Products/Product Portfolio

- 5.2.2.4 Target Customers/End-Use Industries

- 5.2.2.5 Key Personnel

- 5.2.2.6 Analyst View

- 5.2.2.7 Market Share, 2023

- 5.2.3 RUSAL

- 5.2.3.1 Overview

- 5.2.3.2 Top Competitors

- 5.2.3.3 Top Products/Product Portfolio

- 5.2.3.4 Target Customers/End-Use Industries

- 5.2.3.5 Key Personnel

- 5.2.3.6 Analyst View

- 5.2.3.7 Market Share, 2023

- 5.2.4 Norsk Hydro ASA

- 5.2.4.1 Overview

- 5.2.4.2 Top Competitors

- 5.2.4.3 Top Products/Product Portfolio

- 5.2.4.4 Target Customers/End-Use Industries

- 5.2.4.5 Key Personnel

- 5.2.4.6 Analyst View

- 5.2.4.7 Market Share, 2023

- 5.2.5 Alcoa Corporation

- 5.2.5.1 Overview

- 5.2.5.2 Top Competitors

- 5.2.5.3 Top Products/Product Portfolio

- 5.2.5.4 Target Customers/End-Use Industries

- 5.2.5.5 Key Personnel

- 5.2.5.6 Analyst View

- 5.2.5.7 Market Share, 2023

- 5.2.6 China Hongqiao Group Limited

- 5.2.6.1 Overview

- 5.2.6.2 Top Competitors

- 5.2.6.3 Top Products/Product Portfolio

- 5.2.6.4 Target Customers/End-Use Industries

- 5.2.6.5 Key Personnel

- 5.2.6.6 Analyst View

- 5.2.6.7 Market Share, 2023

- 5.2.7 Emirates Global Aluminum PJSC

- 5.2.7.1 Overview

- 5.2.7.2 Top Competitors

- 5.2.7.3 Top Products/Product Portfolio

- 5.2.7.4 Target Customers/End-Use Industries

- 5.2.7.5 Key Personnel

- 5.2.7.6 Analyst View

- 5.2.7.7 Market Share, 2023

- 5.2.8 Capral Limited

- 5.2.8.1 Overview

- 5.2.8.2 Top Competitors

- 5.2.8.3 Top Products/Product Portfolio

- 5.2.8.4 Target Customers/End-Use Industries

- 5.2.8.5 Key Personnel

- 5.2.8.6 Analyst View

- 5.2.8.7 Market Share, 2023

- 5.2.9 Constellium SE

- 5.2.9.1 Overview

- 5.2.9.2 Top Competitors

- 5.2.9.3 Top Products/Product Portfolio

- 5.2.9.4 Target Customers/End-Use Industries

- 5.2.9.5 Key Personnel

- 5.2.9.6 Analyst View

- 5.2.9.7 Market Share, 2023

- 5.2.10 Aluar Aluminio Argentino S.A.I.C.

- 5.2.10.1 Overview

- 5.2.10.2 Top Competitors

- 5.2.10.3 Top Products/Product Portfolio

- 5.2.10.4 Target Customers/End-Use Industries

- 5.2.10.5 Key Personnel

- 5.2.10.6 Analyst View

- 5.2.10.7 Market Share, 2023

- 5.2.11 Volta Aluminium Company Limited

- 5.2.11.1 Overview

- 5.2.11.2 Top Competitors

- 5.2.11.3 Top Products/Product Portfolio

- 5.2.11.4 Target Customers/End-Use Industries

- 5.2.11.5 Key Personnel

- 5.2.11.6 Analyst View

- 5.2.11.7 Market Share, 2023

- 5.2.12 Runaya

- 5.2.12.1 Overview

- 5.2.12.2 Top Competitors

- 5.2.12.3 Top Products/Product Portfolio

- 5.2.12.4 Target Customers/End-Use Industries

- 5.2.12.5 Key Personnel

- 5.2.12.6 Analyst View

- 5.2.12.7 Market Share, 2023

- 5.2.13 Rio Tinto

- 5.2.13.1 Overview

- 5.2.13.2 Top Competitors

- 5.2.13.3 Top Products/Product Portfolio

- 5.2.13.4 Target Customers/End-Use Industries

- 5.2.13.5 Key Personnel

- 5.2.13.6 Analyst View

- 5.2.13.7 Market Share, 2023

- 5.2.14 CBA

- 5.2.14.1 Overview

- 5.2.14.2 Top Competitors

- 5.2.14.3 Top Products/Product Portfolio

- 5.2.14.4 Target Customers/End-Use Industries

- 5.2.14.5 Key Personnel

- 5.2.14.6 Analyst View

- 5.2.14.7 Market Share, 2023

- 5.2.15 South32

- 5.2.15.1 Overview

- 5.2.15.2 Top Competitors

- 5.2.15.3 Top Products/Product Portfolio

- 5.2.15.4 Target Customers/End-Use Industries

- 5.2.15.5 Key Personnel

- 5.2.15.6 Analyst View

- 5.2.15.7 Market Share, 2023

- 5.2.16 PT Indonesia Asahan Aluminium

- 5.2.16.1 Overview

- 5.2.16.2 Top Competitors

- 5.2.16.3 Top Products/Product Portfolio

- 5.2.16.4 Target Customers/End-Use Industries

- 5.2.16.5 Key Personnel

- 5.2.16.6 Analyst View

- 5.2.16.7 Market Share, 2023

- 5.2.17 Novelis

- 5.2.17.1 Overview

- 5.2.17.2 Top Competitors

- 5.2.17.3 Top Products/Product Portfolio

- 5.2.17.4 Target Customers/End-Use Industries

- 5.2.17.5 Key Personnel

- 5.2.17.6 Analyst View

- 5.2.17.7 Market Share, 2023

- 5.2.18 Eti Aluminyum

- 5.2.18.1 Overview

- 5.2.18.2 Top Competitors

- 5.2.18.3 Top Products/Product Portfolio

- 5.2.18.4 Target Customers/End-Use Industries

- 5.2.18.5 Key Personnel

- 5.2.18.6 Analyst View

- 5.2.18.7 Market Share, 2023

- 5.2.19 Speira GmbH

- 5.2.19.1 Overview

- 5.2.19.2 Top Competitors

- 5.2.19.3 Top Products/Product Portfolio

- 5.2.19.4 Target Customers/End-Use Industries

- 5.2.19.5 Key Personnel

- 5.2.19.6 Analyst View

- 5.2.19.7 Market Share, 2023

- 5.2.20 Aluminium Dunkerque

- 5.2.20.1 Overview

- 5.2.20.2 Top Competitors

- 5.2.20.3 Top Products/Product Portfolio

- 5.2.20.4 Target Customers/End-Use Industries

- 5.2.20.5 Key Personnel

- 5.2.20.6 Analyst View

- 5.2.20.7 Market Share, 2023

- 5.2.1 Vedanta Aluminium & Power

6 Research Methodology

- 6.1 Data Sources

- 6.1.1 Primary Data Sources

- 6.1.2 Secondary Data Sources

- 6.1.3 Data Triangulation

- 6.2 Market Estimation and Forecast