|

|

市場調査レポート

商品コード

1532313

自動車用コンフォーマルコーティング市場- 世界と地域別分析:エンドユーザー別、車両タイプ別、推進タイプ別、車両部品別、材料別、技術別、地域別 - 分析と予測(2024年~2034年)Automotive Conformal Coatings Market - A Global and Regional Analysis: Focus on End User, Vehicle Type, Propulsion Type, Vehicle Component, Material, Technique, and Region - Analysis and Forecast, 2024-2034 |

||||||

カスタマイズ可能

|

|||||||

| 自動車用コンフォーマルコーティング市場- 世界と地域別分析:エンドユーザー別、車両タイプ別、推進タイプ別、車両部品別、材料別、技術別、地域別 - 分析と予測(2024年~2034年) |

|

出版日: 2024年08月13日

発行: BIS Research

ページ情報: 英文 110 Pages

納期: 1~5営業日

|

全表示

- 概要

- 目次

自動車用コンフォーマルコーティングの市場規模は、広範な自動車産業の中でも重要なセグメントであり、自動車に使用される電子部品の保護ソリューションに焦点を当てています。

楽観的シナリオでは、2024年の市場規模は22億米ドルと評価され、CAGR 8.9%で拡大し、2034年には51億6,000万米ドルに達すると予測されています。

| 主要市場統計 | |

|---|---|

| 予測期間 | 2024年~2034年 |

| 2024年の評価額 | 22億米ドル |

| 2034年の予測 | 51億6,000万米ドル |

| CAGR | 8.9% |

コンフォーマルコーティングは、繊細な電子部品を湿気、埃、温度変化などの環境要因から保護する上で非常に重要です。これらのコーティングは、自動車エレクトロニクスの寿命と信頼性を保証する保護層を提供します。

自動車が先進技術を取り入れて進化するにつれて、コンフォーマルコーティングの需要は高まっています。現代の自動車には、インフォテインメント・ユニット、電子制御ユニット(ECU)、バッテリー管理システム(特に電気自動車(EV))など、さまざまな電子システムが搭載されています。これらの電子システムの統合により、過酷な使用条件に耐え、長期にわたって信頼できる性能を確保できる高性能コンフォーマルコーティングのニーズが高まっています。

自動車用コンフォーマルコーティング市場は、材料の種類、車両部品、塗布技術、車両タイプなど、いくつかの要因に基づいて区分されます。コンフォーマルコーティングに使用される主な材料には、アクリル、シリコーン、エポキシ、パリレン、ポリウレタンなどがあります。それぞれの材料は、さまざまな用途や環境条件に適した明確な特性を備えています。例えば、シリコーンは高温耐性で知られ、アクリルは硬化が速く塗布が容易です。

当レポートでは、世界の自動車用コンフォーマルコーティング市場について調査し、市場の概要とともに、エンドユーザー別、車両タイプ別、推進タイプ別、車両部品別、材料別、地域別の動向、および市場に参入する企業のプロファイルなどを提供しています。

目次

エグゼクティブサマリー

第1章 市場:業界の展望

- 動向:現在および将来の影響評価

- サプライチェーンの概要

- R&Dレビュー

- 規制状況

- ステークホルダー分析

- 主要な世界的イベントの影響分析

- 市場力学の概要

第2章 自動車用コンフォーマルコーティング市場(用途別)

- 用途のセグメンテーション

- 用途の概要

- 自動車用コンフォーマルコーティング市場(エンドユーザー別)

- 自動車用コンフォーマルコーティング市場(車両タイプ別)

- 自動車用コンフォーマルコーティング市場(推進タイプ別)

- 自動車用コンフォーマルコーティング市場(車両部品別)

第3章 自動車用コンフォーマルコーティング市場(製品別)

- 製品セグメンテーション

- 製品概要

- 自動車用コンフォーマルコーティング市場(材料別)

- 自動車用コンフォーマルコーティング市場(技術別)

第4章 自動車用コンフォーマルコーティング市場(地域別)

- 自動車用コンフォーマルコーティング市場(地域別)

- 北米

- 欧州

- アジア太平洋

- その他の地域

第5章 企業プロファイル

- 今後の見通し

- 地理的評価

- 企業プロファイル

- Dow

- Henkel

- Chase Corporation

- H.B. Fuller

- Electrolube

- Dymax

- Illinois Tool Works Inc.

- KISCO LTD.

- Shin-Etsu Chemical Co. Ltd.

- MG Chemicals

- Panacol-Elosol GmbH

- CHT Germany GmbH

- ELANTAS GmbH

- Vertical Solutions, Inc.

- Plasma Ruggedized Solutions

- その他の主要参入企業

第6章 調査手法

Introduction to Automotive Conformal Coatings Market

The automotive conformal coatings market is an essential segment within the broader automotive industry, focusing on protective solutions for electronic components used in vehicles. In an optimistic scenario, the market is evaluated at a valuation of $2.20 billion in 2024 and is projected to expand at a CAGR of 8.9% to reach $5.16 billion by 2034.

| KEY MARKET STATISTICS | |

|---|---|

| Forecast Period | 2024 - 2034 |

| 2024 Evaluation | $2.20 Billion |

| 2034 Forecast | $5.16 Billion |

| CAGR | 8.9% |

Conformal coatings are critical in safeguarding sensitive electronic parts from environmental factors such as moisture, dust, and temperature variations. These coatings provide a protective layer that ensures the longevity and reliability of automotive electronics, which are increasingly integral to modern vehicle design and functionality.

As vehicles evolve to incorporate advanced technologies, the demand for conformal coatings has grown. Modern vehicles are equipped with a variety of electronic systems, including infotainment units, electronic control units (ECUs), and battery management systems, particularly in electric vehicles (EVs). The integration of these electronic systems is driving the need for high-performance conformal coatings that can withstand harsh operating conditions and ensure reliable performance over time.

The automotive conformal coatings market is segmented based on several factors, including material types, vehicle components, application techniques, and vehicle types. The primary materials used in conformal coatings include acrylics, silicones, epoxies, parylenes, and polyurethanes. Each material offers distinct properties suited to various applications and environmental conditions. For instance, silicones are known for their high-temperature resistance, while acrylics provide fast curing and ease of application.

The market is segmented across several dimensions, including end users, vehicle types, propulsion types, vehicle components, materials, application techniques, and regions. Based on end user, the market is divided into original equipment manufacturers (OEMs) and the aftermarket. OEMs apply coatings during vehicle production, while aftermarket applications involve coatings for vehicle maintenance and repair.

In terms of vehicle components, conformal coatings are applied to critical parts such as electronic control units (ECUs), printed circuit boards (PCBs), battery casings, sensors, infotainment systems, and light-emitting diodes (LEDs). These components require protection to maintain their functionality and reliability in the face of environmental stressors. Application techniques for these coatings include brush coating, dipping, selective coating, spray coating, and vapor deposition, each chosen based on the specific requirements of the component and application environment.

In terms of vehicle type, the market is segmented into passenger vehicles, commercial vehicles, light commercial vehicles (LCVs), and heavy commercial vehicles (HCVs). Passenger vehicles represent the largest segment, driven by consumer demand for advanced electronics and safety features. Commercial vehicles, including LCVs and HCVs, are significant due to their reliance on complex electronic systems for operational efficiency and safety.

The propulsion type segmentation includes internal combustion engine (ICE) vehicles, electric vehicles, and their subcategories, i.e., battery electric vehicles (BEVs), plug-in hybrid electric vehicles (PHEVs), and hybrid electric vehicles (HEVs). This segmentation reflects the diverse range of vehicles adopting various propulsion technologies and the corresponding demand for conformal coatings.

Regional dynamics play a crucial role in shaping the automotive conformal coatings market. Asia-Pacific is the largest market, driven by the region's dominant automotive manufacturing base and rapid technological advancements. North America and Europe also contribute significantly, reflecting their established automotive industries and stringent regulatory standards. Rest-of-the-World, including emerging markets, presents growth opportunities as automotive production and technological adoption expand.

Overall, the automotive conformal coatings market is poised for continued growth as the automotive industry advances toward more sophisticated and electronics-intensive vehicles. The ongoing evolution of vehicle technology, coupled with increasing environmental and performance requirements, underscores the critical role of conformal coatings in ensuring the durability and reliability of modern automotive electronics.

Market Segmentation:

Segmentation 1: by End User

- Original Equipment Manufacturers (OEMs)

- Aftermarket

Segmentation 2: by Vehicle Type

- Passenger Vehicles

- Commercial Vehicles

- Light Commercial Vehicles (LCVs)

- Heavy Commercial Vehicles (HCVs)

Segmentation 3: by Propulsion Type

- Internal Combustion Engine (ICE) Vehicles

- Electric Vehicles

- Battery Electric Vehicles (BEVs)

- Plug-in Hybrid Electric Vehicles (PHEVs)

- Hybrid Electric Vehicles (HEVs)

Segmentation 4: by Vehicle Component

- Electronic Control Unit (ECU)

- Printed Circuit Board (PCB)

- Battery Casing

- Sensors

- Infotainment System

- Light Emitting Diode (LED)

- Others

Segmentation 5: by Material

- Acrylic

- Silicone

- Epoxy

- Parylene

- Polyurethane

- Others

Segmentation 6: by Technique

- Brush Coating

- Dipping

- Selective Coating

- Spray Coating

- Vapor Deposition

- Others

Segmentation 7: by Region

- North America

- Europe

- Asia-Pacific

- Rest-of-the-World

How can this report add value to an organization?

Product/Innovation Strategy: The global automotive conformal coatings market has been extensively segmented based on various categories, such as end user, vehicle type, propulsion type, vehicle component, material, and technique. This can help readers get a clear overview of which segments account for the largest share and which ones are well-positioned to grow in the coming years.

Competitive Strategy: A detailed competitive benchmarking of the players operating in the global automotive conformal coatings market has been done to help the reader understand how players stack against each other, presenting a clear market landscape. Additionally, comprehensive competitive strategies such as partnerships, agreements, and collaborations will aid the reader in understanding the untapped revenue pockets in the market.

Key Market Players and Competition Synopsis

The companies that are profiled have been selected based on thorough secondary research, which includes analyzing company coverage, product portfolio, market penetration, and insights gathered from primary experts.

Some of the prominent companies in this market are:

- Dow

- Henkel

- Chase Corporation

- H.B. Fuller

- Electrolube

- Dymax

- Shin-Etsu Chemical Co. Ltd.

Key Questions Answered in this Report:

- What are the main factors driving the demand for the automotive conformal coatings?

- What are the major patents filed by the companies active in the automotive conformal coatings market?

- Which are the key players in the automotive conformal coatings market, and what are their respective market shares?

- What partnerships or collaborations are prominent among stakeholders in the automotive conformal coatings market?

- What are the strategies adopted by the key companies to gain a competitive edge in automotive conformal coatings market?

- What is the futuristic outlook for the automotive conformal coatings market in terms of growth potential?

- What is the current estimation of the automotive conformal coatings market and what growth trajectory is projected from 2024 to 2034?

- Which application and product segments are expected to lead the market over the forecast period 2024-2034?

- Which regions demonstrate the highest adoption rates for automotive conformal coatings market, and what factors contribute to their leadership?

Table of Contents

Executive Summary

Scope and Definition

Market/Product Definition

Key Questions Answered

Analysis and Forecast Note

1. Markets: Industry Outlook

- 1.1 Trends: Current and Future Impact Assessment

- 1.2 Supply Chain Overview

- 1.2.1 Value Chain Analysis

- 1.2.2 Pricing Forecast

- 1.3 R&D Review

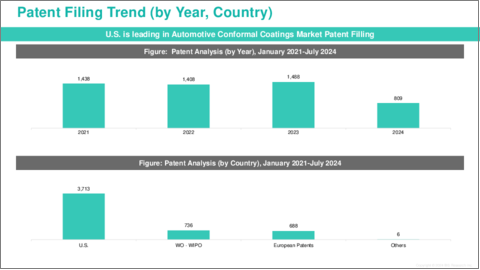

- 1.3.1 Patent Filing Trend by Country, by Company

- 1.4 Regulatory Landscape

- 1.5 Stakeholder Analysis

- 1.5.1 Use Case

- 1.5.2 End User and Buying Criteria

- 1.6 Impact Analysis for Key Global Events

- 1.7 Market Dynamics Overview

- 1.7.1 Market Drivers

- 1.7.2 Market Restraints

- 1.7.3 Market Opportunities

2. Automotive Conformal Coatings Market (by Application)

- 2.1 Application Segmentation

- 2.2 Application Summary

- 2.3 Automotive Conformal Coatings Market (by End User)

- 2.3.1 Original Equipment Manufacturers (OEMs)

- 2.3.2 Aftermarket

- 2.4 Automotive Conformal Coatings Market (by Vehicle Type)

- 2.4.1 Passenger Vehicles

- 2.4.2 Commercial Vehicles

- 2.4.2.1 Light Commercial Vehicles (LCVs)

- 2.4.2.2 Heavy Commercial Vehicles (HCVs)

- 2.5 Automotive Conformal Coatings Market (by Propulsion Type)

- 2.5.1 Internal Combustion Engine (ICE) Vehicles

- 2.5.2 Electric Vehicles

- 2.5.2.1 Battery Electric Vehicles (BEVs)

- 2.5.2.2 Plug-in Hybrid Electric Vehicles (PHEVs)

- 2.5.2.3 Hybrid Electric Vehicles (HEVs)

- 2.6 Automotive Conformal Coatings Market (by Vehicle Component)

- 2.6.1 Electronic Control Unit (ECU)

- 2.6.2 Printed Circuit Board (PCB)

- 2.6.3 Battery Casing

- 2.6.4 Sensors

- 2.6.5 Infotainment System

- 2.6.6 Light Emitting Diode (LED)

- 2.6.7 Others

3. Automotive Conformal Coatings Market (by Product)

- 3.1 Product Segmentation

- 3.2 Product Summary

- 3.3 Automotive Conformal Coatings Market (by Material)

- 3.3.1 Acrylic

- 3.3.2 Silicone

- 3.3.3 Epoxy

- 3.3.4 Parylene

- 3.3.5 Polyurethane

- 3.3.6 Others

Note: These segments are tentative, based on primary and secondary research outcomes, and may change during the course of the project. The client has the flexibility to suggest changes.

- 3.4 Automotive Conformal Coatings Market (by Technique)

- 3.4.1 Brush Coating

- 3.4.2 Dipping

- 3.4.3 Selective Coating

- 3.4.4 Spray Coating

- 3.4.5 Vapor Deposition

- 3.4.6 Others

4. Automotive Conformal Coatings Market (by Region)

- 4.1 Automotive Conformal Coatings Market (by Region)

- 4.2 North America

- 4.2.1 Regional Overview

- 4.2.2 Driving Factors for Market Growth

- 4.2.3 Factors Challenging the Market

- 4.2.4 Application

- 4.2.5 Product

- 4.2.5.1 U.S.

- 4.2.5.1.1 Market by Application

- 4.2.5.1.2 Market by Product

- 4.2.5.2 Canada

- 4.2.5.2.1 Market by Application

- 4.2.5.2.2 Market by Product

- 4.2.5.3 Mexico

- 4.2.5.3.1 Market by Application

- 4.2.5.3.2 Market by Product

- 4.2.5.1 U.S.

- 4.3 Europe

- 4.3.1 Regional Overview

- 4.3.2 Driving Factors for Market Growth

- 4.3.3 Factors Challenging the Market

- 4.3.4 Application

- 4.3.5 Product

- 4.3.5.1 Germany

- 4.3.5.1.1 Market by Application

- 4.3.5.1.2 Market by Product

- 4.3.5.2 France

- 4.3.5.2.1 Market by Application

- 4.3.5.2.2 Market by Product

- 4.3.5.3 U.K.

- 4.3.5.3.1 Market by Application

- 4.3.5.3.2 Market by Product

- 4.3.5.4 Italy

- 4.3.5.4.1 Market by Application

- 4.3.5.4.2 Market by Product

- 4.3.5.5 Rest-of-Europe

- 4.3.5.5.1 Market by Application

- 4.3.5.5.2 Market by Product

- 4.3.5.1 Germany

- 4.4 Asia-Pacific

- 4.4.1 Regional Overview

- 4.4.2 Driving Factors for Market Growth

- 4.4.3 Factors Challenging the Market

- 4.4.4 Application

- 4.4.5 Product

- 4.4.5.1 China

- 4.4.5.1.1 Market by Application

- 4.4.5.1.2 Market by Product

- 4.4.5.2 Japan

- 4.4.5.2.1 Market by Application

- 4.4.5.2.2 Market by Product

- 4.4.5.3 India

- 4.4.5.3.1 Market by Application

- 4.4.5.3.2 Market by Product

- 4.4.5.4 South Korea

- 4.4.5.4.1 Market by Application

- 4.4.5.4.2 Market by Product

- 4.4.5.5 Rest-of-Asia-Pacific

- 4.4.5.5.1 Market by Application

- 4.4.5.5.2 Market by Product

- 4.4.5.1 China

- 4.5 Rest-of-the-World

- 4.5.1 Regional Overview

- 4.5.2 Driving Factors for Market Growth

- 4.5.3 Factors Challenging the Market

- 4.5.4 Application

- 4.5.5 Product

- 4.5.5.1 South America

- 4.5.5.1.1 Market by Application

- 4.5.5.1.2 Market by Product

- 4.5.5.2 Middle East and Africa

- 4.5.5.2.1 Market by Application

- 4.5.5.2.2 Market by Product

- 4.5.5.1 South America

5. Companies Profiled

- 5.1 Next Frontiers

- 5.2 Geographic Assessment

- 5.3 Company Profiles

- 5.3.1 Dow

- 5.3.1.1 Overview

- 5.3.1.2 Top Products/Product Portfolio

- 5.3.1.3 Top Competitors

- 5.3.1.4 Target Customers

- 5.3.1.5 Key Personnel

- 5.3.1.6 Analyst View

- 5.3.1.7 Market Share

- 5.3.2 Henkel

- 5.3.2.1 Overview

- 5.3.2.2 Top Products/Product Portfolio

- 5.3.2.3 Top Competitors

- 5.3.2.4 Target Customers

- 5.3.2.5 Key Personnel

- 5.3.2.6 Analyst View

- 5.3.2.7 Market Share

- 5.3.3 Chase Corporation

- 5.3.3.1 Overview

- 5.3.3.2 Top Products/Product Portfolio

- 5.3.3.3 Top Competitors

- 5.3.3.4 Target Customers

- 5.3.3.5 Key Personnel

- 5.3.3.6 Analyst View

- 5.3.3.7 Market Share

- 5.3.4 H.B. Fuller

- 5.3.4.1 Overview

- 5.3.4.2 Top Products/Product Portfolio

- 5.3.4.3 Top Competitors

- 5.3.4.4 Target Customers

- 5.3.4.5 Key Personnel

- 5.3.4.6 Analyst View

- 5.3.4.7 Market Share

- 5.3.5 Electrolube

- 5.3.5.1 Overview

- 5.3.5.2 Top Products/Product Portfolio

- 5.3.5.3 Top Competitors

- 5.3.5.4 Target Customers

- 5.3.5.5 Key Personnel

- 5.3.5.6 Analyst View

- 5.3.5.7 Market Share

- 5.3.6 Dymax

- 5.3.6.1 Overview

- 5.3.6.2 Top Products/Product Portfolio

- 5.3.6.3 Top Competitors

- 5.3.6.4 Target Customers

- 5.3.6.5 Key Personnel

- 5.3.6.6 Analyst View

- 5.3.6.7 Market Share

- 5.3.7 Illinois Tool Works Inc.

- 5.3.7.1 Overview

- 5.3.7.2 Top Products/Product Portfolio

- 5.3.7.3 Top Competitors

- 5.3.7.4 Target Customers

- 5.3.7.5 Key Personnel

- 5.3.7.6 Analyst View

- 5.3.7.7 Market Share

- 5.3.8 KISCO LTD.

- 5.3.8.1 Overview

- 5.3.8.2 Top Products/Product Portfolio

- 5.3.8.3 Top Competitors

- 5.3.8.4 Target Customers

- 5.3.8.5 Key Personnel

- 5.3.8.6 Analyst View

- 5.3.8.7 Market Share

- 5.3.9 Shin-Etsu Chemical Co. Ltd.

- 5.3.9.1 Overview

- 5.3.9.2 Top Products/Product Portfolio

- 5.3.9.3 Top Competitors

- 5.3.9.4 Target Customers

- 5.3.9.5 Key Personnel

- 5.3.9.6 Analyst View

- 5.3.9.7 Market Share

- 5.3.10 MG Chemicals

- 5.3.10.1 Overview

- 5.3.10.2 Top Products/Product Portfolio

- 5.3.10.3 Top Competitors

- 5.3.10.4 Target Customers

- 5.3.10.5 Key Personnel

- 5.3.10.6 Analyst View

- 5.3.10.7 Market Share

- 5.3.11 Panacol-Elosol GmbH

- 5.3.11.1 Overview

- 5.3.11.2 Top Products/Product Portfolio

- 5.3.11.3 Top Competitors

- 5.3.11.4 Target Customers

- 5.3.11.5 Key Personnel

- 5.3.11.6 Analyst View

- 5.3.11.7 Market Share

- 5.3.12 CHT Germany GmbH

- 5.3.12.1 Overview

- 5.3.12.2 Top Products/Product Portfolio

- 5.3.12.3 Top Competitors

- 5.3.12.4 Target Customers

- 5.3.12.5 Key Personnel

- 5.3.12.6 Analyst View

- 5.3.12.7 Market Share

- 5.3.13 ELANTAS GmbH

- 5.3.13.1 Overview

- 5.3.13.2 Top Products/Product Portfolio

- 5.3.13.3 Top Competitors

- 5.3.13.4 Target Customers

- 5.3.13.5 Key Personnel

- 5.3.13.6 Analyst View

- 5.3.13.7 Market Share

- 5.3.14 Vertical Solutions, Inc.

- 5.3.14.1 Overview

- 5.3.14.2 Top Products/Product Portfolio

- 5.3.14.3 Top Competitors

- 5.3.14.4 Target Customers

- 5.3.14.5 Key Personnel

- 5.3.14.6 Analyst View

- 5.3.14.7 Market Share

- 5.3.15 Plasma Ruggedized Solutions

- 5.3.15.1 Overview

- 5.3.15.2 Top Products/Product Portfolio

- 5.3.15.3 Top Competitors

- 5.3.15.4 Target Customers

- 5.3.15.5 Key Personnel

- 5.3.15.6 Analyst View

- 5.3.15.7 Market Share

- 5.3.16 Other Key Players

- 5.3.1 Dow