|

|

市場調査レポート

商品コード

1664179

ヒートガンの世界市場:2025-2030年Global Heat Gun Market - Focused Insights 2025-2030 |

||||||

|

|||||||

| ヒートガンの世界市場:2025-2030年 |

|

出版日: 2025年02月25日

発行: Arizton Advisory & Intelligence

ページ情報: 英文 137 Pages

納期: 即納可能

|

全表示

- 概要

- 図表

- 目次

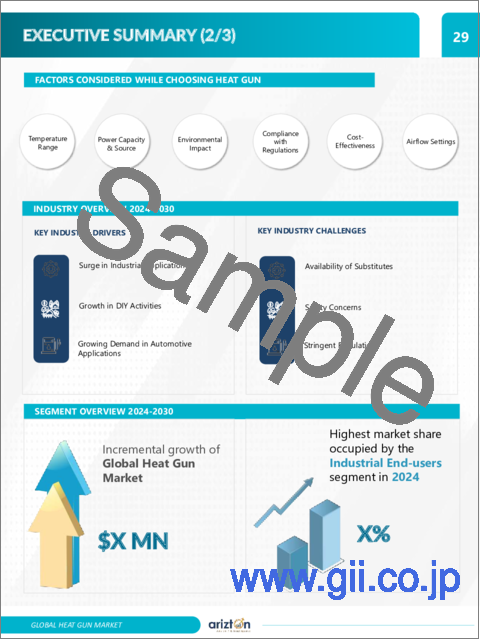

世界のヒートガンの市場規模は、2024年から2030年にかけてCAGR 4.32%で成長すると予測されています。

主な発展

- 製品タイプ別:温度可変ヒートガンは4.46%の高成長を示しており、これはユーザーが特定の要件に応じて熱出力を調整できる汎用性が推進因子となっています。

- 電源タイプ別:電気コード式が58%超で最大シェアを占めています。このセグメントは、産業用途や大規模なDIYプロジェクトなど、持続的な操作が必要な作業により便利であることから成長しています。

- エンドユーザー別:電子機器の組み立て、プラスチック成形、接着剤によるボンディングなど、さまざまな作業を容易にする能力により、産業セグメントが最大のシェアを示しています。

- 流通チャネル別:幅広い選択肢を提供し、価格や機能を比較できる利便性から、オンラインセグメントが最も高い成長を示しています。

- 地域別:建設、自動車、エレクトロニクスなど様々な分野での需要の高まりにより、北米が世界の市場シェアを独占しています。

- 成長要因:世界のヒートガン市場は、産業用途の急増と自動車用途の需要拡大により成長する見通しです。

市場動向と促進要因

技術の進歩

ヒートガン市場は、特に温度制御、人間工学に基づいた設計、エネルギー効率、安全機能などの分野における技術の進歩により、著しい成長を遂げています。これらの技術革新は、機能性とユーザーエクスペリエンスを向上させただけでなく、様々な産業におけるヒートガンの応用範囲を広げています。先進的なヒートガンは精密な温度制御システムを装備しており、ユーザーは作業の特定の要件に合わせて熱出力を調整することができます。最近のヒートガンの多くは、リアルタイムの温度設定を表示するLCDまたはLEDスクリーンを備えており、正確さを保証しています。複数の熱レベルにより、専門家はシュリンク包装や繊細な電子機器のようなデリケートな用途でも、損傷のリスクを冒すことなくツールを使用することができます。メーカーは、性能を損なうことなく消費電力を削減するために、省エネ技術を統合しています。これは、環境意識の高い消費者や企業が持続可能性の目標に沿ったツールを求める中で、特に重要です。自動シャットオフシステム、クールダウンモード、過熱保護などの機能は、高品質のヒートガンに標準装備されており、ユーザーの安全を確保し、製品の寿命を延ばします。これらの技術革新は、都市化や持続可能性といった世界の動向と相まって、ヒートガン市場を新たな高みへと押し上げています。

他のツールとの統合

最近のヒートガンは、ドリル、ノコギリ、サンダーなどの他の工具と連動するように設計されることが増えており、機能性と効率性が向上しています。このような技術革新は、プロやDIY愛好家のニーズを満たし、需要を牽引しています。統合されたシステムにより、ユーザーは複数の作業をシームレスに行うことができます。例えば、塗料スクレーパーと一体化したヒートガンは、塗料を軟化させ、同時に除去することを可能にし、時間と労力を節約します。製造業や建設業では、ヒートガンとカッティングツールや接着剤塗布ツールを組み合わせることで、複雑な工程を合理化し、より迅速かつ効率的に行うことができます。高度な統合により、操作の同期が可能になり、精度が向上します。例えば、レーザーガイドまたはセンサーツールと統合されたヒートガンは、はんだ付けやシュリンク包装などの作業で一貫した加熱を保証します。自動車や電子機器などの業界では、溶接や部品配置のための精密ツールと組み合わせたヒートガンが、最小限の誤差で高品質の結果を保証します。一体型ヒートガンは汎用性があり、溶接、乾燥、表面処理など多様な用途に適しています。この汎用性は、工業の専門家から趣味の愛好家まで、より幅広い顧客層にアピールしています。このように、統合化の動向は、その用途とユーザーベースを拡大することによって、ヒートガン市場を変革しています。

産業用途の急増

ヒートガン市場は、産業用途の拡大が大きな原動力となり、大きな盛り上がりを見せています。ヒートガンは、はんだ付け、溶接、塗装剥離、シュリンク包装、プラスチック曲げ加工などの作業を行うために熱風を供給する多用途ツールです。様々な産業に適応できるため、製造、自動車、建設、エレクトロニクスの分野で欠かせないものとなっています。効率的な生産方法への需要が高まる中、ヒートガンは様々な産業ニーズに対して費用対効果が高く、正確なソリューションを提供します。ヒートガンは、古い塗料の除去、接着剤の軟化、表面の乾燥など、建築において極めて重要です。世界のインフラプロジェクトの増加により、このような多用途のツールに対する需要が生まれています。電子機器では、ヒートガンははんだ付け、はんだ除去、熱収縮チューブの収縮に不可欠です。CE製品市場の成長に伴い、この分野でのヒートガンの需要は増加傾向にあります。ヒートガンを使用したシュリンク包装は、製品保護や改ざん防止のために包装業界では不可欠です。eコマースが拡大を続ける中、効率的なパッケージングソリューションへの需要が高まっています。

当レポートでは、世界のヒートガンの市場を調査し、市場概要、市場への各種影響因子の分析、市場規模の推移・予測、各種区分・地域/主要国別の詳細分析、競合情勢、主要企業のプロファイルなどをまとめています。

主要ベンダー

- Apex Tool Group

- J. Wagner

- Koki Holdings

- Makita

- Master Appliance

- Robert Bosch

- Stanley Black & Decker

- Techtronic Industries

その他のベンダー

- Aegon Power

- Jiangsu Dongcheng M&E Tools

- Enertwist

- FirstRate

- Forsthoff

- Jinhua Galaxia Tech

- Genesis Power Tools

- KYNKO

- Leister

- Poniie

- SEEKONE Technology

- SparkFun Electronics

- STEINEL

- TackLife

- TECCPO

- ZHEJIANG PRULDE ELECTRIC APPLIANCE

目次

第1章:世界のヒートガン市場:概要

- エグゼクティブサマリー

- 主な調査結果

第2章:世界のヒートガン市場

- 世界のヒートガン市場の予測収益

第3章:世界のヒートガン市場の見通しと機会

- 世界のヒートガン市場の機会と動向

- 世界のヒートガン市場の促進要因

- 世界のヒートガン市場の抑制要因

第4章:世界のヒートガン市場:セグメンテーションデータ

- 予測収益:製品タイプ別

- 可変温度

- デュアル温度

- 予測収益:電力タイプ別

- 電気コード付き

- コードレス

- ガス

- 予測収益:エンドユーザー別

- 産業

- 自動車

- 建設・改修

- 電子機器メーカー

- 航空宇宙

- その他の産業

- 商業

- 住宅

- 予測収益:流通チャネル別

- オフライン

- オンライン

第5章 主要地域の概要

- 世界のヒートガン市場の予測収益:北米

- 米国

- カナダ

- 世界のヒートガン市場の予測収益:欧州

- 英国

- ドイツ

- フランス

- イタリア

- スペイン

- 世界のヒートガン市場の予測収益:アジア太平洋

- 中国

- 日本

- インド

- 韓国

- オーストラリア

- 世界のヒートガン市場の予測収益:ラテンアメリカ

- ブラジル

- メキシコ

- 世界のヒートガン市場の予測収益:中東・アフリカ

- トルコ

- サウジアラビア

- UAE

- 南アフリカ

第6章:世界のヒートガン市場業界の概要

- 競合情勢

- 主要ベンダーのプロファイル

- その他の主要ベンダー

- 主要な戦略的推奨事項

第7章付録

LIST OF EXHIBITS

- Exhibit 1: Global Heat Gun Market 2021-2030 ($ million)

- Exhibit 2: Global Heat Gun Market by Product Type 2021-2030 ($ million)

- Exhibit 3: Market by Variable Temperature 2021-2030 ($ million)

- Exhibit 4: Market by Dual Temperature 2021-2030 ($ million)

- Exhibit 5: Global Heat Gun Market by Power Type 2021-2030 ($ million)

- Exhibit 6: Market by Electric Corded 2021-2030 ($ million)

- Exhibit 7: Market by Electric Cordless 2021-2030 ($ million)

- Exhibit 8: Market by Gas Powered 2021-2030 ($ million)

- Exhibit 9: Global Heat Gun Market by End-users 2021-2030 ($ million)

- Exhibit 10: Market by Industrial 2021-2030 ($ million)

- Exhibit 11: Global Heat Gun Market by Industrial End-Users 2021-2030 ($ million)

- Exhibit 12: Market by Automotive Industry 2021-2030 ($ million)

- Exhibit 13: Market by Construction & Refurbishment Industry 2021-2030 ($ million)

- Exhibit 14: Market by Electronic Equipment Manufacturers 2021-2030 ($ million)

- Exhibit 15: Market by Aerospace Industry 2021-2030 ($ million)

- Exhibit 16: Market by Others 2021-2030 ($ million)

- Exhibit 17: Market by Commercial 2021-2030 ($ million)

- Exhibit 18: Market by Residential 2021-2030 ($ million)

- Exhibit 19: Global Heat Gun Market by Distribution Channel 2021-2030 ($ million)

- Exhibit 20: Market by Offline 2021-2030 ($ million)

- Exhibit 21: Market by Online 2021-2030 ($ million)

- Exhibit 22: Global Heat Gun Market by Geography 2021-2030 ($ million)

- Exhibit 23: North America Heat Gun Market 2021-2030 ($ million)

- Exhibit 24: US Heat Gun Market 2021-2030 ($ million)

- Exhibit 25: Canada Heat Gun Market 2021-2030 ($ million)

- Exhibit 26: Europe Heat Gun Market 2021-2030 ($ million)

- Exhibit 27: UK Heat Gun Market 2021-2030 ($ million)

- Exhibit 28: Germany Heat Gun Market 2021-2030 ($ million)

- Exhibit 29: France Heat Gun Market 2021-2030 ($ million)

- Exhibit 30: Italy Heat Gun Market 2021-2030 ($ million)

- Exhibit 31: Spain Heat Gun Market 2021-2030 ($ million)

- Exhibit 32: APAC Heat Gun Market 2021-2030 ($ million)

- Exhibit 33: China Heat Gun Market 2021-2030 ($ million)

- Exhibit 34: Japan Heat Gun Market 2021-2030 ($ million)

- Exhibit 35: India Heat Gun Market 2021-2030 ($ million)

- Exhibit 36: South Korea Heat Gun Market 2021-2030 ($ million)

- Exhibit 37: Australia Heat Gun Market 2021-2030 ($ million)

- Exhibit 38: Latin America Heat Gun Market 2021-2030 ($ million)

- Exhibit 39: Brazil Heat Gun Market 2021-2030 ($ million)

- Exhibit 40: Mexico Heat Gun Market 2021-2030 ($ million)

- Exhibit 41: Middle East & Africa Heat Gun Market 2021-2030 ($ million)

- Exhibit 42: Turkey Heat Gun Market 2021-2030 ($ million)

- Exhibit 43: Saudi Arabia Heat Gun Market 2021-2030 ($ million)

- Exhibit 44: UAE Heat Gun Market 2021-2030 ($ million)

- Exhibit 45: South Africa Heat Gun Market 2021-2030 ($ million)

LIST OF TABLES

- Table 1: Global Heat Gun Market 2021-2030 ($ million)

- Table 2: Global Heat Gun Market by Product Type Segment 2021-2030 ($ million)

- Table 3: Global Heat Gun Market by Power Type Segment 2021-2030 ($ million)

- Table 4: Global Heat Gun Market by End-users Segment 2021-2030 ($ million)

- Table 5: Global Heat Gun Market by Industrial End-users Sub-segment 2021-2030 ($ million)

- Table 6: Global Heat Gun Market by Distribution Channel 2021-2030 ($ million)

- Table 7: Global Heat Gun Market by Geography 2021-2030 ($ million)

The global heat gun market is expected to grow at a CAGR of 4.32% from 2024 to 2030.

RECENT VENDOR ACTIVITIES

- In 2024, the U.S. Census Bureau reported that construction spending for October 2024 was estimated at a seasonally adjusted annual rate of $2,174.0 million. This represents a 0.4 percent increase compared to the revised September estimate of $2,164.7 million. Heat guns are widely used for applications such as paint removal, softening adhesives, and heat-shrinking tubing in the construction industry. As global construction and renovation activities grow, the demand for tools like heat guns increases.

- In 2023, Robert Bosch unveiled a series of innovative tools, including an 18V concrete nailer and a heat gun, further expanding its cordless tool portfolio to cater to the needs of trade professionals. Alongside these new offerings, Bosch Power Tools introduced an enhanced 18V Limited Warranty, providing extended coverage for its 18V tools, chargers, and batteries, reinforcing its commitment to quality and customer satisfaction.

- In 2022, Makita, a manufacturer of professional tools and accessories, introduced two new cordless heat guns to its expanding LXT system. The additions include the 18V LXT Heat Gun (XGH01) and the 18V LXT Variable Temperature Heat Gun (XGH02). These tools are designed to offer versatile solutions for a wide range of applications and professional needs.

KEY DEVELOPMENT

- By Product Type: The variable temperature segment shows the highest growth of 4.46%, driven by its versatility which allows users to adjust the heat output according to specific requirements.

- By Power Type: The electric corded segment holds the largest market share of over 58%. The segment is growing as they are more convenient for tasks requiring sustained operation, such as industrial applications or extensive DIY projects.

- By End-Users: The industrial segment holds the largest market share, driven by its ability to facilitate a range of tasks, including electronic assembly, plastic molding, and adhesive bonding.

- By Distribution Channel: The online segment shows the highest growth due to its convenience, offering a wide range of options and the ability to compare prices and features.

- By Geography: North America dominates the global heat gun market share, driven by the growing demand across various sectors such as construction, automotive, and electronics.

- Growth Factor: The global heat gun market is set to grow due to a surge in industrial applications and growing demand for automotive applications.

MARKET TRENDS & DRIVERS

Technological Advancements

The heat gun market is witnessing significant growth due to advancements in technology, particularly in areas such as temperature control, ergonomic design, energy efficiency, and safety features. These innovations have not only improved the functionality and user experience but have also broadened the range of applications for heat guns across various industries. Advanced heat guns are equipped with precise temperature control systems, allowing users to adjust the heat output to match the specific requirements of their tasks. Many modern heat guns feature LCD or LED screens that show real-time temperature settings, ensuring accuracy. Multiple heat levels enable professionals to use the tool for delicate applications like shrink wrapping or sensitive electronics without risking damage. Manufacturers are integrating energy-saving technologies to reduce power consumption without compromising performance. This is especially significant as eco-conscious consumers and businesses seek tools that align with sustainability goals. Features such as automatic shut-off systems, cool-down modes, and overheat protection are standard in high-quality heat guns, ensuring user safety and prolonging product lifespan. These innovations, combined with global trends like urbanization and sustainability, are propelling the heat gun market to new heights.

Integration With Other Tools

Modern heat guns are increasingly being designed to work in tandem with other tools, such as drills, saws, and sanders, offering enhanced functionality and efficiency. These innovations are driving demand by meeting the needs of professionals and DIY enthusiasts alike. Integrated systems allow users to perform multiple tasks seamlessly. For example, a heat gun integrated with a paint scraper enables users to simultaneously soften and remove paint, saving time and effort. In manufacturing and construction, heat guns paired with cutting or adhesive applicator tools streamline complex processes, making them faster and more efficient. Advanced integration allows for synchronized operations, enhancing precision. For instance, a heat gun integrated with a laser guide or sensor tool ensures consistent heating for tasks such as soldering or shrink-wrapping. In industries like automotive and electronics, heat guns paired with precision tools for welding or component placement ensure high-quality outcomes with minimal errors. Integrated heat guns offer versatility, making them suitable for diverse applications such as welding, drying, and surface preparation. This versatility appeals to a broader customer base, from industrial professionals to hobbyists. Thus, the integration trend is transforming the heat gun market by expanding its applications and user base.

Surge In Industrial Applications

The heat gun market is experiencing a significant surge, largely driven by the expansion of its industrial applications. Heat guns are versatile tools that deliver a stream of hot air to perform tasks such as soldering, welding, paint stripping, shrink wrapping, and plastic bending. Their adaptability across a range of industries makes them indispensable in the manufacturing, automotive, construction, and electronics sectors. Heat guns are widely used in manufacturing processes for tasks like plastic welding, bending, and curing adhesives. With the rise in demand for efficient production methods, heat guns offer a cost-effective and precise solution for various industrial needs. Heat guns are crucial in construction for activities like removing old paint, softening adhesives, and drying surfaces. The growth in infrastructure projects globally is creating demand for such versatile tools. In electronics, heat guns are indispensable for soldering, desoldering, and shrinking heat-shrink tubing. With the growing consumer electronics market, the demand for heat guns in this sector is on the rise. Shrinkwrapping using heat guns is vital in the packaging industry for product protection and tamper-proofing. As e-commerce continues to expand, the demand for efficient packaging solutions has increased.

INDUSTRY RESTRAINTS

Availability of Substitutes

The availability of substitutes, such as blowtorches and soldering irons, represents a significant challenge to the growth of the heat gun market. While heat guns are versatile and effective tools used in various industries, they face strong competition from other heat-producing devices that offer similar functionalities. Blowtorches and soldering irons are frequently used in industries where heat guns also find application, creating direct competition. While heat guns typically provide a broader range of heat, blowtorches and soldering irons can offer more concentrated and directed heat, making them suitable alternatives for certain tasks. Blowtorches are often used in industries like metalworking, plumbing, and automotive repair. In some cases, blowtorches can achieve faster results than heat guns, especially when dealing with high-temperature requirements like soldering or brazing metal parts. Soldering irons are used predominantly in the electronics and electrical industries, but their application overlaps with heat guns when it comes to tasks like soldering and desoldering electronic components. Blowtorches and soldering irons often come at lower costs compared to heat guns, especially when it comes to smaller-scale applications. Their lower purchase price and focused heat application make them an attractive alternative for consumers and businesses that do not require the broader, more diffused heat provided by heat guns.

SEGMENTATION INSIGHTS

INSIGHTS BY PRODUCT TYPE

The global heat gun market by product type is segmented into variable temperature and dual temperature. The variable temperature shows significant growth, with the fastest-growing CAGR of 4.46% during the forecast period. Variable temperature heat guns are versatile tools that allow users to adjust the heat output according to specific requirements. These tools are widely used in industries like automotive, construction, electronics, and DIY crafts due to their precision and adaptability. Heat guns are becoming indispensable in industries such as automotive, electronics, and construction. The demand for tasks like shrink-wrapping, de-soldering, paint removal, and thawing frozen pipes has significantly boosted the adoption of heat guns, particularly variable temperature models. The growing global DIY trend, fueled by online tutorials and social media platforms, has significantly boosted the demand for user-friendly tools like variable-temperature heat guns. This segment is further supported by the affordability and availability of compact, versatile heat gun models.

By Product Type

- Variable Temperature

- Dual Temperature

INSIGHTS BY POWER TYPE

The global heat gun market by power type is categorized into electric corded, electric cordless, and gas-powered. The electric corded segment holds the largest market share of over 58%. Electric corded heat guns are preferred over cordless models for tasks requiring sustained operation, such as industrial applications or extensive DIY projects. The continuous power supply ensures uninterrupted performance, making these tools reliable for heavy-duty tasks like paint stripping, plastic welding, and heat shrinking. Unlike battery-operated alternatives, corded models eliminate concerns about runtime, boosting their demand among professionals. Industries such as automotive, electronics, construction, and manufacturing heavily rely on corded heat guns for precision heating applications. The growth in these industries, particularly in developing economies such as China, India, Brazil, etc., has directly increased the demand for electric corded heat guns.

By Power Type

- Electric Corded

- Electric Cordless

- Gas Powered

INSIGHTS BY END-USERS

Based on the end-users, the industrial segment holds the largest share of the global heat gun market. Heat guns have become indispensable tools in the automotive industry, offering a wide range of applications that cater to both repair and customization needs. Automotive professionals and enthusiasts rely on heat guns for tasks that require precise temperature control and effective heat application, making them a versatile tool in this sector. Heat guns are crucial for shrink-wrapping electrical wires and cables in automotive applications. Shrink tubing is used to insulate and protect wiring, and heat guns ensure a secure fit by uniformly shrinking the tubing around the wires. This is especially critical in modern vehicles with extensive electrical systems. One of the most common applications of heat guns in the automotive sector is during the installation of window tints and vinyl wraps. Heat guns are used to evenly heat the material, ensuring it conforms smoothly to the contours of the vehicle without wrinkles or air bubbles. They also aid in activating adhesives, making the installation process more efficient.

By End-users Market

- Industrial

- Automotive Industry

- Construction & Refurbishment Industry

- Electronic Equipment Manufacturers

- Aerospace Industry

- Others

- Commercial

- Residential

INSIGHTS BY DISTRIBUTION CHANNEL

Based on the distribution channel, the online segment shows prominent growth, with the fastest-growing CAGR during the forecast period. The shift towards e-commerce has been a significant driver in the growth of online distribution channels for heat guns. Consumers are increasingly turning to online platforms for their convenience, offering a wide range of options and the ability to compare prices and features. Online platforms like Amazon, eBay, and dedicated tool retailers provide users with easy access to heat gun products without the need to visit physical stores. The convenience of ordering from home and receiving products delivered directly to the doorstep is a major advantage of online shopping. Consumers can browse heat gun products at their own pace, read reviews, and make informed decisions, which is particularly helpful when purchasing technical tools like heat guns.

By Distribution Channel

- Offline

- Online

GEOGRAPHICAL ANALYSIS

North America dominates and holds the largest share of the global heat gun market, driven by the growing demand across various sectors such as construction, automotive, and electronics. With advancements in technology, the region has witnessed an increasing adoption of energy-efficient and versatile heat guns, supported by favorable economic conditions and robust industrial activity. North America is a hub for the automotive industry, with the US and Canada contributing significantly to vehicle production and repair markets. Companies such as Ford, General Motors (GM), and Toyota have a significant presence in North America, thus it has led to higher heat gun usage. Heat guns play a critical role in the production and customization of medical devices, such as orthotics and prosthetics. The rising healthcare expenditure in the US has further driven the demand for specialized heat guns tailored for delicate applications.

By Geography

- North America

- US

- Canada

- Europe

- UK

- Germany

- France

- Italy

- Spain

- APAC

- China

- Japan

- India

- South Korea

- Australia

- Latin America

- Brazil

- Mexico

- Middle East & Africa

- Turkey

- Saudi Arabia

- UAE

- South Africa

COMPETITIVE LANDSCAPE

The global heat gun market report consists of exclusive data on 24 vendors. The market is fragmented and characterized by the presence of several major players, as well as numerous regional and local manufacturers. Apex Tool Group, J. Wagner, Koki Holdings, Makita, Master Appliance, Robert Bosch, Stanley Black & Decker, and Techtronic Industries are the key players in the global heat gun market. Key strategies include product innovation, mergers and acquisitions, and partnerships to enhance market presence and expand geographical reach. Collaborations with key industry stakeholders and partners to develop integrated solutions and enhance market reach.

Key Vendors

- Apex Tool Group

- J. Wagner

- Koki Holdings

- Makita

- Master Appliance

- Robert Bosch

- Stanley Black & Decker

- Techtronic Industries

Other Prominent Vendors

- Aegon Power

- Jiangsu Dongcheng M&E Tools

- Enertwist

- FirstRate

- Forsthoff

- Jinhua Galaxia Tech

- Genesis Power Tools

- KYNKO

- Leister

- Poniie

- SEEKONE Technology

- SparkFun Electronics

- STEINEL

- TackLife

- TECCPO

- ZHEJIANG PRULDE ELECTRIC APPLIANCE

KEY QUESTIONS ANSWERED:

1. How big is the global heat gun market?

2. What is the growth rate of the global heat gun market?

3. What are the factors driving the global heat gun market growth?

4. Which region dominates the global heat gun market growth share?

5. Who are the major players in the global heat gun market?

TABLE OF CONTENTS

CHAPTER - 1: Global Heat Gun Market Overview

- Executive Summary

- Key Findings

CHAPTER - 2: Global Heat Gun Market Market

- GLOBAL: Projected Revenue of Global Heat Gun Market (2021-2030; $ Millions)

CHAPTER - 3: Global Heat Gun Market Prospects & Opportunities

- Global Heat Gun Market Opportunities & Trends

- Global Heat Gun Market Drivers

- Global Heat Gun Market Constraints

CHAPTER - 4: Global Heat Gun Market Segmentation Data

- GLOBAL: Projected Revenue by Product Type (2021-2030; $ Millions)

- Variable Temperature

- Dual Temperature

- GLOBAL: Projected Revenue by Power Type (2021-2030; $ Millions)

- Electric Corded

- Electric Cordless

- Gas Powered

- GLOBAL: Projected Revenue by End-users (2021-2030; $ Millions)

- Industrial

- Automotive Industry

- Construction & Refurbishment Industry

- Electronic Equipment Manufacturers

- Aerospace Industry

- Others

- Commercial

- Residential

- GLOBAL: Projected Revenue by Distribution Channel (2021-2030; $ Millions)

- Offline

- Online

CHAPTER - 5: Key Regions Overview

- North America: Projected Revenue of Global Heat Gun Market (2021-2030; $ Millions)

- Projected Revenue of Global Heat Gun Market in US

- Projected Revenue of Global Heat Gun Market in Canada

- Europe: Projected Revenue of Global Heat Gun Market (2021-2030; $ Millions)

- Projected Revenue of Global Heat Gun Market in UK

- Projected Revenue of Global Heat Gun Market in Germany

- Projected Revenue of Global Heat Gun Market in France

- Projected Revenue of Global Heat Gun Market in Italy

- Projected Revenue of Global Heat Gun Market in Spain

- APAC: Projected Revenue of Global Heat Gun Market (2021-2030; $ Millions)

- Projected Revenue of Global Heat Gun Market in China

- Projected Revenue of Global Heat Gun Market in Japan

- Projected Revenue of Global Heat Gun Market in India

- Projected Revenue of Global Heat Gun Market in South Korea

- Projected Revenue of Global Heat Gun Market in Australia

- Latin America: Projected Revenue of Global Heat Gun Market (2021-2030; $ Millions)

- Projected Revenue of Global Heat Gun Market in Brazil

- Projected Revenue of Global Heat Gun Market in Mexico

- Middle East & Africa: Projected Revenue of Global Heat Gun Market (2021-2030; $ Millions)

- Projected Revenue of Global Heat Gun Market in Turkey

- Projected Revenue of Global Heat Gun Market in Saudi Arabia

- Projected Revenue of Global Heat Gun Market in UAE

- Projected Revenue of Global Heat Gun Market in South Africa

CHAPTER - 6: Global Heat Gun Market Industry Overview

- Global Heat Gun Market - Competitive Landscape

- Global Heat Gun Market- Key Vendor Profiles

- Global Heat Gun Market- Other Prominent Vendors

- Global Heat Gun Market - Key Strategic Recommendations

CHAPTER - 7: Appendix

- Research Methodology

- Abbreviations

- About Arizton