|

市場調査レポート

商品コード

1273364

工業用塗料市場- 成長、動向、予測(2023年-2028年)Industrial Coatings Market - Growth, Trends, and Forecasts (2023 - 2028) |

||||||

● お客様のご希望に応じて、既存データの加工や未掲載情報(例:国別セグメント)の追加などの対応が可能です。 詳細はお問い合わせください。

| 工業用塗料市場- 成長、動向、予測(2023年-2028年) |

|

出版日: 2023年04月14日

発行: Mordor Intelligence

ページ情報: 英文 110 Pages

納期: 2~3営業日

|

- 全表示

- 概要

- 目次

予測期間中、工業用塗料市場は4%以上のCAGRで成長すると予想されます。

COVID-19は、2020年までの世界の工業用塗料の産業の成長に中程度の影響を与えます。しかし、石油・ガス、化学、鉱業などさまざまな産業分野で工業用塗料の需要が急増しています、

主なハイライト

- 工業用塗料市場は、長持ちする製品への需要の高まりや粉体塗料の使用増加などの要因によって、さまざまな形で成長すると予想されます。

- 溶剤系塗料が環境に与える有害な影響は、市場の成長を妨げると考えられます。

- 将来的には、長持ちする製品への需要の高まりから、市場も恩恵を受けるチャンスがあると思われます。

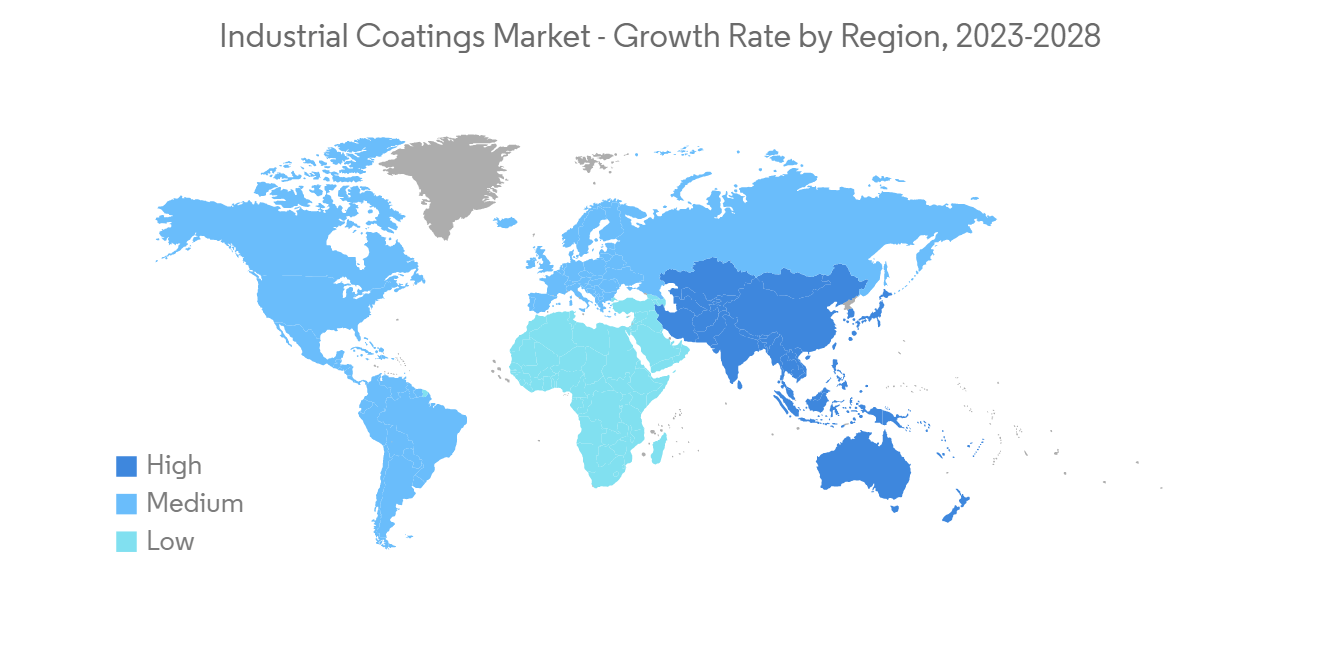

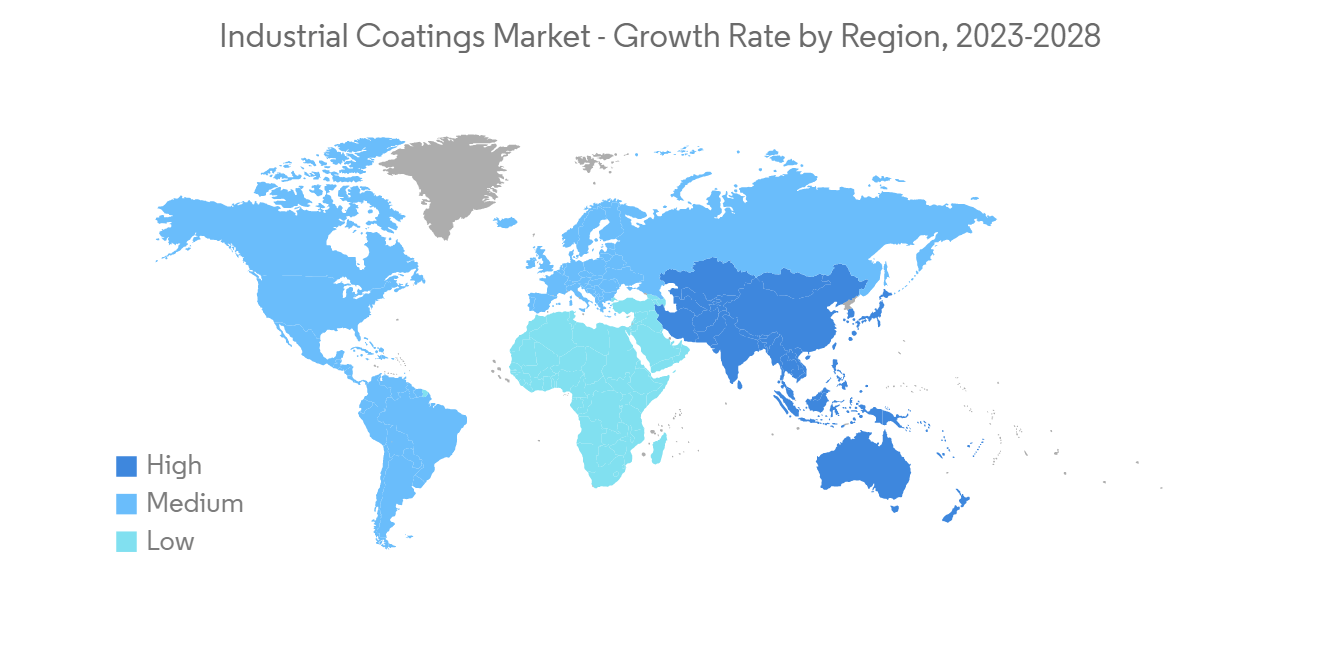

アジア太平洋が工業用塗料の世界市場をリードしているのは、インドや中国などの新興国での使用が急増しているためです。

工業用塗料の市場動向

石油・ガス産業での用途拡大

- 石油・ガス産業には、石油・ガスの探査、生産、精製用の海上および陸上プラットフォーム、精製所、パイプライン、ガスパイプライン、石油化学装置、貯蔵ターミナルが含まれます。石油・ガス産業では、精製所に向かって石油・ガスを移動するために、上流および下流の両方で保護塗料が使用されています。この業界では、腐食防止、耐熱、耐摩耗、耐火など、さまざまな種類の保護膜が使用されています。

- この業界では、資本金を削減する方法を模索しています。これに加えて、厳しい環境規制を遵守する必要があるため、資産の保護に効果的な長寿命のコーティングシステムが求められているのです。

- さらに、オフショアでの石油・ガス生産は、最も過酷な条件下にあります。そのため、そこで使用されるコーティングシステムにも同様の設備が必要です。オフショアでは、紫外線に長時間さらされ、荒い海水と常に接触するため、保護膜の必要性が高くなります。また、パイプラインにも保護膜が施されます。パイプラインの防食がなければ、生産時間の損失や設備の故障による石油・ガスの腐食被害の年間コストは、星の数ほどにもなります。

- また、米国、サウジアラビア、ロシア、中国、カナダなどは、石油・ガス産業の成長を支える大国です。

- COVID-19のパンデミックにより、米国のエネルギー使用量は2020年に減少したが、2021年には再び増加しました。2021年末、米国の原油とリースコンデンセートの確認埋蔵量は382億バレルから444億バレルへと62億バレル(16%)増加しました。

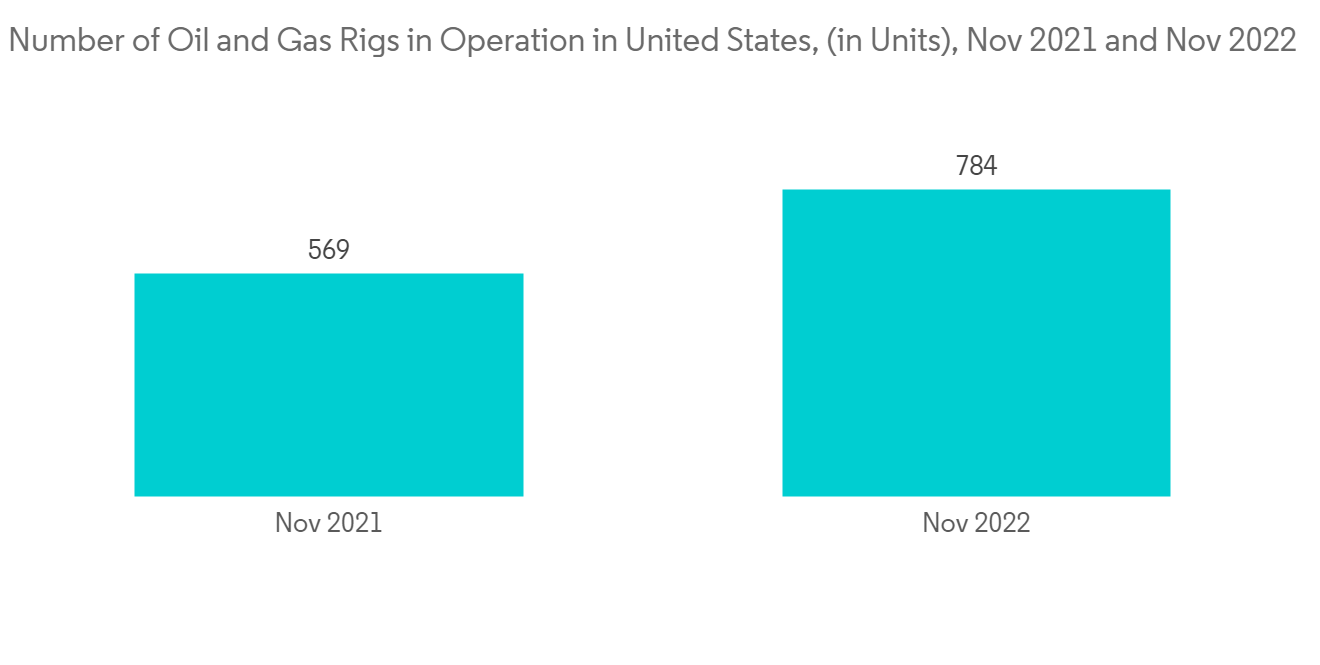

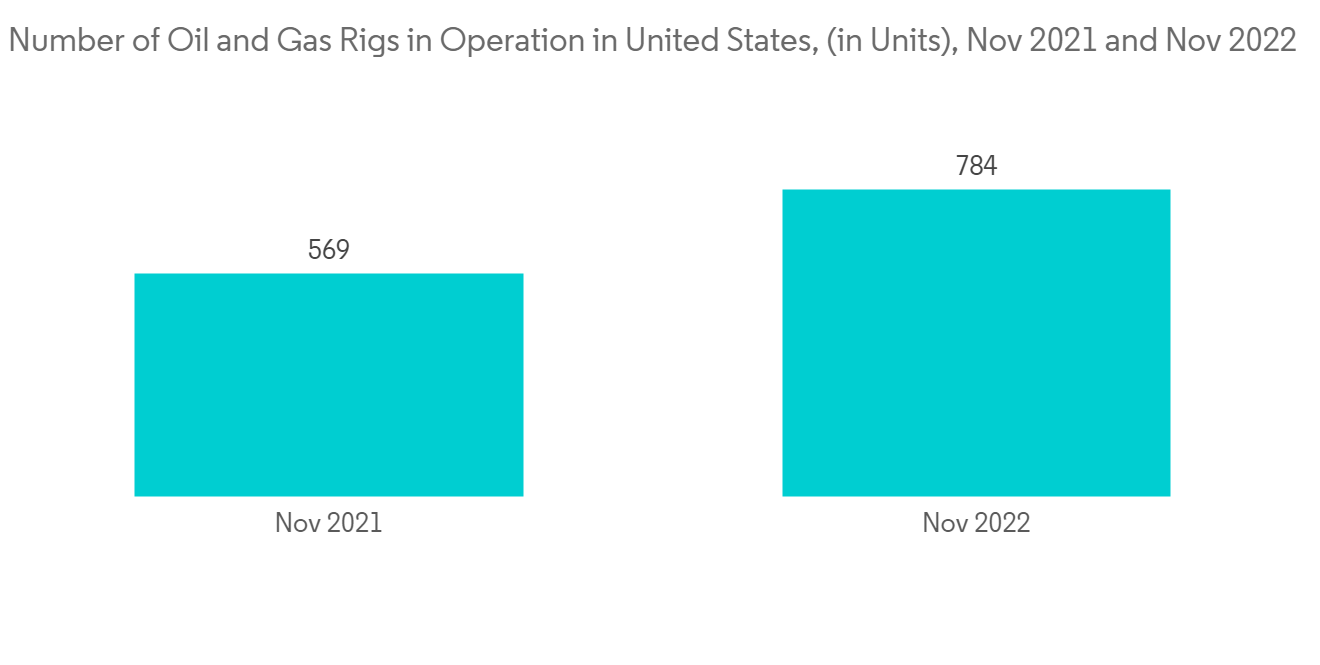

- 2021年、石油と天然ガスの需要は2020年から5%増加し、価格は上昇し、両燃料で確認埋蔵量は増加し、天然ガスでは米国の新記録を樹立しました。石油リグは米国で最も多いリグです。2021年末時点で、稼働中の石油リグは約480基であるのに対し、ガスリグはおよそ106基でした。

- 中国では、Sulige油田で1,204本の天然ガス井が新たに開発され、2022年には1日の生産量が1,625万立方メートルに急増しました。国家統計局によると、中国は今年最初の10カ月間に1,785億立方メートルの天然ガスを生産し、前年同期比で6%増加しました。

- 予測期間中、工業用塗料の世界市場は、上記のすべての要因によって牽引されると思われます。

アジア太平洋地域が工業用塗料市場を独占する

- アジア太平洋地域では、インドが支配的な国の1つです。安価な労働力の確保、原材料費の安さ、同地域の都市人口の拡大が市場促進要因となっています。

- また、インドではインフラ整備のための政府投資に支えられ、建設部門の増加速度が速くなっています。メトロ、橋、ビルなどの新しいプロジェクトが国中に建設されています。

- インドの建設産業は同国で2番目に大きく、GDPに大きな貢献をしています。パンデミックの蔓延期には、インドの建設産業は成長が大きく落ち込みました。しかし、2021年には、同部門への公共投資と民間投資の両方が急成長しました。同国では、今後6~7年間で住宅への投資が約1兆3,000億米ドルに達し、 6,000万戸の新しい住宅の建設が示されるとみられ、これが調査対象市場の大きな押し上げ要因になっています。

- 政府の「Make in India」政策により、同国の製造業への外国直接投資(FDI)が増加しています。これにより、多くの産業が成長・向上し、同国の工業用塗料市場が活性化しました。

- インドは、発電部門の改革計画の一環として、エネルギーインフラを更新し、新しい技術を使用して電力供給の信頼性と回復力を向上させたいと考えています。これには、予測期間中に約2兆5,000億インドルピー(350億米ドル)の費用がかかる可能性があります。発電部門における新しい設備の製造と投資は、同国における保護膜市場の需要に貢献すると予想されます。

- また、電気を得る人が増えること、一人当たりの電気使用量が増えること、そして人口が増えることは、いずれも経済を活性化させます。2022年10月現在、インドの電力設備容量は408.71GWでした。これにより、世界第3位の電力生産・消費国となりました。

- 電力省は、2026年までに石炭の使用を止め、代わりに再生可能エネルギーの使用を開始する81の火力発電所を発見しました。これにより、インドは再生可能エネルギー500GWという目標を達成し、石炭の供給が毎年需要を満たさないという問題を解決することができます。さらに、インドが2030年までに再生可能エネルギー450GWという目標を達成するために、英国政府は2021年9月、グリーンプロジェクトと再生可能エネルギーに公的投資と民間投資を通じて12億米ドルを投資すると発表しました。

- したがって、前述の要因が保護膜の需要を促進しています。これがひいては、同国における塗料・コーティング市場の需要を高めています。

工業用塗料業界の概要

工業用塗料の世界市場は、トップ企業が大きなシェアを占める統合市場です。主要企業には、Jotun、Akzo Nobel NV、PPG Industries、The Sherwin-Williams Company、Axalta Coating Systems、日本ペイント(NIPSEA GROUP)などがあります(順序は不同)。

その他の特典:

- エクセル形式の市場予測(ME)シート

- 3ヶ月間のアナリストサポート

目次

第1章 イントロダクション

- 調査の成果

- 本調査の前提条件

- 本調査の対象範囲

第2章 調査手法

第3章 エグゼクティブサマリー

第4章 市場力学

- 促進要因

- 保護膜の需要拡大

- 石油・ガス産業におけるアプリケーションの増加

- 抑制要因

- 溶剤系塗料による環境への悪影響

- COVID-19の発生による影響

- 産業バリューチェーン分析

- ポーターのファイブフォース分析

- 供給企業の交渉力

- 消費者の交渉力

- 新規参入業者の脅威

- 代替品の脅威

- 競合の度合い

第5章 市場セグメンテーション

- 樹脂

- エポキシ

- ポリウレタン

- アクリル

- ポリエステル

- その他の樹脂

- 技術情報

- 水系コーティング

- 溶剤型コーティング

- その他の技術

- エンドユーザー業界

- 一般産業用

- 保護塗料

- 石油・ガス分野

- 鉱業

- 電力

- インフラストラクチャー

- その他の保護膜

- 地域

- アジア太平洋地域

- 中国

- インド

- 日本

- 韓国

- その他アジア太平洋地域

- 北米

- 米国

- カナダ

- メキシコ

- 欧州

- ドイツ

- 英国

- イタリア

- フランス

- ロシア

- その他欧州

- 南米

- ブラジル

- アルゼンチン

- その他南米地域

- 中東・アフリカ地域

- サウジアラビア

- 南アフリカ

- その他中東とアフリカ

- アジア太平洋地域

第6章 競合情勢

- M&A、ジョイントベンチャー、コラボレーション、契約など

- 市場シェア/ランキング分析

- 主要企業が採用した戦略

- 企業プロファイル

- AkzoNobel N.V.

- Axalta Coating Systems

- BASF SE

- Beckers Group

- Chugoku Marine Paints, Ltd.

- Hempel A/S

- Jotun

- Kansai Paint Co.,Ltd.

- Nippon Paint(NIPSEA GROUP)

- PPG Industries

- RPM International, Inc.

- Sika AG

- The Sherwin-Williams Company

- Wacker Chemie AG

第7章 市場機会および将来動向

- 高耐久性製品への需要の高まり

During the time frame of the forecast, the industrial coatings market is expected to grow at a CAGR of more than 4%.

COVID-19 had a moderate impact on the global industrial coatings industry's growth by 2020. However, there is an upsurge in demand for industrial coatings in various industrial sectors, including oil and gas, chemical, and mining industries,

Key Highlights

- The industrial coatings market is expected to grow in many ways, thanks to factors like the growing demand for products that last a long time and the increased use of powder coatings.

- The harmful environmental impact of solvent-borne coatings is likely to hinder the market's growth.

- In the future, the market is likely to have a chance to benefit from the rising demand for products that last a long time.

Asia-Pacific led the world market for industrial coatings because their use in developing countries like India and China is growing quickly.

Industrial Coatings Market Trends

Increasing Applications in Oil and Gas Industry

- The oil and gas segment includes offshore and onshore platforms for oil and gas exploration, production, and refining, as well as refineries, pipelines, gas pipelines, petrochemical units, and storage terminals.The oil and gas industry uses protective coatings in both the upstream and downstream segments for the movement of oil and gas toward the refineries. In this industry, different kinds of protective coatings are used, such as those that stop corrosion, resist heat, wear, and fire, among others.

- The industry has been trying to find ways to cut capital charges. This, along with the need to adhere to strict environmental regulations, has led to a demand for a coating system with a long life that will be effective in the protection of the assets.

- Furthermore, offshore oil and gas production has some of the most demanding conditions. As a result, the coating systems used there must be similarly outfitted. Offshore, there is prolonged exposure to penetrating UV rays and constant contact with rough seawater, which increases the need for protective coatings. Also, protective coatings are applied to pipelines. Without pipeline corrosion protection, the annual cost of oil and gas corrosion damages, due to lost production time and equipment failure, can be stellar.

- Also, the United States, Saudi Arabia, Russia, China, and Canada, among others, are some of the biggest countries that help the oil and gas industry grow.

- The COVID-19 pandemic caused energy use in the United States to drop in 2020, but it went back up in 2021.At year's end 2021, proved reserves of U.S. crude oil and lease condensate increased by 6.2 billion barrels (16%), from 38.2 billion barrels to 44.4 billion barrels.

- In 2021, demand for petroleum and natural gas increased by 5% from 2020, prices rose, and proved reserves increased for both fuels, setting a new U.S. record for natural gas. Oil rigs are the most common rigs in the United States. At the end of 2021, there were some 480 active oil rigs, compared with roughly 106 gas rigs.

- In China, 1,204 new natural gas wells were developed in the Sulige field, ramping up daily output by 16.25 million cubic meters in 2022. According to the National Bureau of Statistics, China produced 178.5 billion cubic meters of natural gas in the first 10 months of this year, up 6 percent year-on-year.

- During the forecast period, the global market for industrial coatings is likely to be driven by all of the above factors.

Asia Pacific Dominates the Industrial Coatings Market

- In the Asia-Pacific region, India is one of the dominant countries. The availability of inexpensive labor, low raw material costs, and the expanding urban population in the area are the main market drivers.

- The construction sector has also been increasing in India at a faster rate, supported by government investments for infrastructure development; new projects like metros, bridges, and buildings are being constructed across the country.

- The construction industry in India is the second largest in the country and makes a big contribution to its GDP.During the spread of the pandemic, the Indian construction industry saw a big drop in growth. However, in 2021, both public and private investments in the sector grew sharply.The country is likely to witness around USD 1.3 trillion of investment in housing over the next six to seven years and is likely to witness the construction of 60 million new homes in the country, which is a major boosting factor for the market studied.

- The "Make in India" policy of the government has led to more foreign direct investment (FDI) in the manufacturing sector of the country. This has helped many industries grow and improve.This in turn has boosted the market for industrial coatings in the country.

- India wants to update its energy infrastructure and use new technology to improve the reliability and resilience of its electricity supply as part of its plan to reform its power generation sector. This could cost almost INR 2.5 trillion (USD 35 billion) over the forecast period. The manufacturing and investment of new facilities in the power generation sector are expected to contribute to the demand for the protective coatings market in the country.

- Also, more people getting electricity, more people using electricity per person, and more people will all give the economy a boost.As of October 2022, India had 408.71 GW of installed power capacity. This made it the third-largest electricity producer and consumer in the world.

- The Ministry of Power has found 81 thermal units that will stop using coal and start using renewable energy instead by 2026. This will help India reach its goal of 500 GW of renewable energy and fix the problem of coal supply not meeting demand every year. Additionally, in order to help India reach its goal of 450 GW of renewable energy by 2030, the United Kingdom government announced in September 2021 that it would invest USD 1.2 billion through public and private investments in green projects and renewable energy.

- Hence, the aforementioned factors are driving the demand for protective coatings. This, in turn, is increasing the demand for the paint and coatings market in the country.

Industrial Coatings Industry Overview

The global market for industrial coatings segment is a consolidated market among the top players accounting for a major share of the market. Major Players include Jotun, Akzo Nobel NV, PPG Industries, The Sherwin-Williams Company, Axalta Coating Systems, and Nippon Paint ( NIPSEA GROUP) among others (not in any particular order).

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Deliverables

- 1.2 Study Assumptions

- 1.3 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Drivers

- 4.1.1 Rising Demand for Protective Coatings

- 4.1.2 Increasing Applications in Oil and Gas Industry

- 4.2 Restraints

- 4.2.1 Harmful Environmental Impact Of Solvent-borne Coatings

- 4.2.2 Impact of COVID-19 Outbreak

- 4.3 Industry Value-Chain Analysis

- 4.4 Porter's Five Forces Analysis

- 4.4.1 Bargaining Power of Suppliers

- 4.4.2 Bargaining Power of Consumers

- 4.4.3 Threat of New Entrants

- 4.4.4 Threat of Substitute Products and Services

- 4.4.5 Degree of Competition

5 MARKET SEGMENTATION (Market Size in Value)

- 5.1 Resin

- 5.1.1 Epoxy

- 5.1.2 Polyurethane

- 5.1.3 Acrylic

- 5.1.4 Polyester

- 5.1.5 Other Resins

- 5.2 Technology

- 5.2.1 Water-borne Coatings

- 5.2.2 Solvent-borne Coatings

- 5.2.3 Other Technologies

- 5.3 End-user Industry

- 5.3.1 General Industrial

- 5.3.2 Protective Coatings

- 5.3.2.1 Oil and Gas

- 5.3.2.2 Mining

- 5.3.2.3 Power

- 5.3.2.4 Infrastructure

- 5.3.2.5 Other Protective Coatings

- 5.4 Geography

- 5.4.1 Asia-Pacific

- 5.4.1.1 China

- 5.4.1.2 India

- 5.4.1.3 Japan

- 5.4.1.4 South Korea

- 5.4.1.5 Rest of Asia-Pacific

- 5.4.2 North America

- 5.4.2.1 United States

- 5.4.2.2 Canada

- 5.4.2.3 Mexico

- 5.4.3 Europe

- 5.4.3.1 Germany

- 5.4.3.2 United Kingdom

- 5.4.3.3 Italy

- 5.4.3.4 France

- 5.4.3.5 Russia

- 5.4.3.6 Rest of Europe

- 5.4.4 South America

- 5.4.4.1 Brazil

- 5.4.4.2 Argentina

- 5.4.4.3 Rest of South America

- 5.4.5 Middle East & Africa

- 5.4.5.1 Saudi Arabia

- 5.4.5.2 South Africa

- 5.4.5.3 Rest of Middle East & Africa

- 5.4.1 Asia-Pacific

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers & Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Market Share**/Ranking Analysis

- 6.3 Strategies Adopted by Leading Players

- 6.4 Company Profiles

- 6.4.1 AkzoNobel N.V.

- 6.4.2 Axalta Coating Systems

- 6.4.3 BASF SE

- 6.4.4 Beckers Group

- 6.4.5 Chugoku Marine Paints, Ltd.

- 6.4.6 Hempel A/S

- 6.4.7 Jotun

- 6.4.8 Kansai Paint Co.,Ltd.

- 6.4.9 Nippon Paint ( NIPSEA GROUP)

- 6.4.10 PPG Industries

- 6.4.11 RPM International, Inc.

- 6.4.12 Sika AG

- 6.4.13 The Sherwin-Williams Company

- 6.4.14 Wacker Chemie AG

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Increasing Demand For High Durable Products