|

|

市場調査レポート

商品コード

1176576

ファクトリーオートメーションの世界市場-2023-2030Global Factory Automation Market - 2023-2030 |

||||||

|

● お客様のご希望に応じて、既存データの加工や未掲載情報(例:国別セグメント)の追加などの対応が可能です。 詳細はお問い合わせください。 |

|||||||

| ファクトリーオートメーションの世界市場-2023-2030 |

|

出版日: 2022年12月26日

発行: DataM Intelligence

ページ情報: 英文 180 Pages

納期: 約2営業日

|

- 全表示

- 概要

- 目次

市場概要

ファクトリーオートメーションとは、エンドツーエンドの生産工程に自動化を取り入れることです。製造環境において、自動化は油圧システム、空気圧システム、ロボットアームなどの技術を活用し、より一貫性のある、無駄の少ない、生産性の向上、品質の向上、より安全な労働環境を提供します。

自動化によって製造プロセスを改善するためのコンポーネント、スマートシステム、機械、設備の採用が進み、サプライチェーンロジスティクス、プランニング、製品開発のためのスマート工場の需要を押し上げています。工場の自動化は、自動車、化学、医薬品、食品・飲料、鉱業・鉱物、石油・ガス、エネルギー・電力、紙・パルプなど、様々なエンドユーザー産業で採用されています。

DataM Intelligence社の調査レポートでは、世界のファクトリーオートメーション市場は、予測期間2023-2030年のCAGRは8.1%で成長するとされています。

市場力学

産業界における自動化利用の拡大が、世界のファクトリーオートメーション市場の主要な促進要因となっています

現代の製造業では、利益と収益を最大化するために、より高い効率性、スピード、コスト管理が求められています。オートメーションは、特にコンベヤベルトタイプのシステムにおいて、生産速度を大幅に向上させ、効率性を実現し、ダウンタイムを削減します。生産ラインは、最小限の人的介入で24時間365日稼働させることができます。オートメーションが提供する大きなメリットにより、自動車、食品加工、飲食品、医薬品など、さまざまな分野の産業で広く採用されています。さまざまな産業でオートメーションの利用が拡大していることは、予測期間中の世界市場の主要な促進要因になると考えられます。

自動化に伴う高い設備投資が、世界のファクトリーオートメーション市場の抑制要因になると予想されます

予測期間中、自動化に関連する高額な設備投資が、世界のファクトリーオートメーション市場の成長を妨げると予想されます。ファクトリーオートメーションは、高い支出を伴う資本集約的なプロセスです。ロボット機械はハイテクであるため、非常に高価です。複雑な機械のコストは、数十万米ドルから数百万米ドルにのぼります。したがって、工場の自動化には非常に高いコストがかかるのです。そのため、工場の自動化は多国籍企業や大企業に限られ、中小企業は自動化の恩恵を受けられないです。

統一された設計アーキテクチャの採用が、世界のファクトリーオートメーション市場に新たな機会をもたらします

現在使用されている自動化機械は、様々な企業によって設計・製造され、独自の設計アーキテクチャを使用しています。そのため、相互運用性が阻害され、自動化の成長を妨げています。単一の統一されたデザインアーキテクチャを採用することで、相互運用性を高め、自動化の普及に弾みをつけることができます。したがって、統一デザインアーキテクチャの採用は、予測期間中、世界のファクトリーオートメーション市場に新たな機会を生み出すと期待されています。

熟練労働者の不足は、世界のファクトリーオートメーション市場に課題をもたらすと予想されます

自動化された機械には、機械の操作とメンテナンスに精通した高度なスキルを持つ労働力が必要です。オートメーションの基礎を理解するためには、技術的な学位レベルの教育が必要です。熟練労働者の不足は、人手不足の工場に打撃を与え、増え続ける製品需要に対応するための生産規模を拡大することができません。その結果、オートメーションの普及を妨げることになります。熟練労働者の不足は、世界のファクトリーオートメーション市場の成長にとって大きな課題となることが予想されます。

COVID-19の影響分析

COVID-19のパンデミックは、世界のファクトリーオートメーション市場の衰退を招きました。パンデミックのロックダウンは、様々なエンドユーザー産業を混乱させました。多くの産業がパンデミックの影響により、設備投資の縮小、中断、延期を余儀なくされました。短期的な課題にもかかわらず、パンデミックは世界のファクトリーオートメーション市場の長期的な展望にプラスの影響を与えると予想されます。企業は最小限の人的資源で工場の効率を高めたいと考えているため、パンデミックは、バーチャルリアリティや人工知能などのスマートテクノロジーの採用拡大や工場ロボティクスへの統合につながると考えられます。

業界における最近の動向

1. 2021年10月、台湾の協働ロボット企業であるテックマンロボット社が、オムロン株式会社から出資を受けました。同社はテックマンへの出資により、同社の産業用オートメーション技術とテックマンの協働ロボットを融合させた斬新なロボットソリューションの共同開発を目指します

2. 2022年1月、ドイツの産業用ロボットメーカーKUKAは、フォードのトルコ子会社であるFord Otosanと、トルコのコチャエリにあるフォードの新EV生産施設向けに700台のロボットを供給する契約を締結しました

目次

第1章 ファクトリーオートメーションの世界市場の調査手法と範囲

- 調査手法

- 調査目的・調査範囲

第2章 ファクトリーオートメーションの世界市場-市場の定義と概要

第3章 ファクトリーオートメーションの世界市場- エグゼクティブサマリー

- タイプ別市場内訳

- コンポーネント別市場内訳

- ソリューション別市場内訳

- エンドユーザー別市場内訳

- 地域別市場内訳

第4章 ファクトリーオートメーションの世界市場-市場力学

- 市場影響要因

- 促進要因

- 産業界における自動化利用の拡大が、世界のファクトリーオートメーション市場の主要な促進要因となっている

- 抑制要因

- 自動化に伴う高い設備投資が、世界のファクトリーオートメーション市場の抑制要因となる見込み

- ビジネスチャンス

- 影響分析

- 促進要因

第5章 世界のファクトリーオートメーション市場-産業分析

- ポーターのファイブフォース分析

- サプライチェーン分析

- 価格設定分析

- 規制分析

第6章 ファクトリーオートメーションの世界市場-COVID-19分析

- COVID-19の市場分析

- COVID-19登場前の市場シナリオ

- COVID-19の現在の市場シナリオ

- COVID-19以降、または今後のシナリオ

- COVID-19の中での価格ダイナミクス

- 需要-供給スペクトラム

- パンデミック時の市場に関連する政府の取り組み

- メーカーの戦略的な取り組み

- まとめ

第7章 ファクトリーオートメーションの世界市場- タイプ別

- 固定式オートメーション

- プログラマブルオートメーション

- フレキシブルオートメーション

- 統合型オートメーション

- その他

第8章 ファクトリーオートメーションの世界市場- コンポーネント別

- ビジョンマシン

- 産業用ロボット

- 制御バルブ

- フィールド機器

- ヒューマンマシンインターフェース

- 産業用PC

- センサー

- その他

第9章 ファクトリーオートメーションの世界市場- ソリューション別

- 監視制御・データ収集(SCADA)

- プログラマブルロジックコントローラー(PLC)

- 分散型制御システム(DCS)

- 製造実行システム(MES)

- プロダクトライフサイクルマネジメント(PLM)

- 機能安全

- プラントアセットマネジメント(PAM)

- その他

第10章 ファクトリーオートメーションの世界市場- エンドユーザー別

- 石油・ガス

- 化学品

- 紙・パルプ

- 製薬

- 鉱業・金属

- 飲食品

- エネルギー・電力

- 自動車

- エレクトロニクス・半導体

- 航空宇宙・防衛

- 医療機器

- その他

第11章 ファクトリーオートメーションの世界市場- 地域別

- 北米

- 米国

- カナダ

- メキシコ

- 欧州

- ドイツ

- 英国

- フランス

- イタリア

- スペイン

- その他欧州

- 南米

- ブラジル

- アルゼンチン

- その他の南米地域

- アジア太平洋地域

- 中国

- インド

- 日本

- 韓国

- その他アジア太平洋地域

- 中東・アフリカ地域

第12章 ファクトリーオートメーションの世界市場- 競争情勢

- 競合シナリオ

- 市況/シェア分析

- M&A(合併・買収)分析

第13章 ファクトリーオートメーションの世界市場-企業プロファイル

- ABB

- 企業概要

- エンドユーザー向けポートフォリオと説明

- 主なハイライト

- 財務概要

- Rockwell Automation, Inc.

- Yokogawa Electric Corporation

- Hewlett Packard Enterprise Development LP

- OMRON Corporation

- Honeywell International Inc

- Mitsubishi Electric Corporation

- GE DIGITAL

- Schneider Electric

- Siemens AG

第14章 ファクトリーオートメーションの世界市場:重要考察

第15章 ファクトリーオートメーションの世界市場:DataM

Market Overview

Factory automation is the inclusion of automation from end-to-end production processes. In manufacturing environments, automation leverages technologies, such as hydraulic systems, pneumatic systems and robotic arms, to offer more consistency, reduce wastage, increase productivity, better quality and safer working conditions.

The increasing adoption of components, smart systems, machinery and equipment for improving manufacturing processes through automation has boosted the demand for smart factories for supply chain logistics, planning and product development. Factory automation has been adopted in various end-user industries, including automotive, chemicals, pharmaceuticals, food and beverages, mining & minerals, oil and gas, energy & power, paper & pulp and others.

As per the research report by DataM Intelligence, the global factory automation market was valued at US$ XX million in 2022; it is projected to reach US$ XX million by 2030, with growth at a CAGR of 8.1% over the forecast period 2023-2030.

Market Dynamics

The growing use of automation in industries is a major driver for the global factory automation market:

Modern-day manufacturing practices demand greater efficiency, speed and cost controls to maximize profits and revenues. Automation greatly increases production speed, especially in conveyor belt-type systems, while delivering efficiency and reducing downtime. The production lines can be run 24/7 with minimal human intervention. The significant benefits offered by automation have led to its widespread adoption by industries across various sectors, such as automotive, food processing, beverages and pharmaceuticals. The growing use of automation in various industries will be a major driver for the global market during the forecast period.

High capital investment associated with automation is expected to restrain the global factory automation market:

Over the forecast period, the high capital investment associated with automation is expected to prevent the growth of the global factory automation market. Factory automation is a capital-intensive process that involves high expenditure. The robotic machinery is high-tech and, therefore, very expensive. The cost of complex machinery runs into several hundred thousand or millions of dollars. Therefore, automating a factory incurs very high costs. The high costs involved mean factory automation is limited to multinational companies and large enterprises and deprives smaller companies of the advantages of automation.

The adoption of unified design architecture to generate new opportunities for the global factory automation market:

The automated machinery currently in use is designed and manufactured by various companies that use their proprietary design architecture. It prevents interoperability and hinders the growth of automation. The adoption of a single unified design architecture can enhance interoperability and provide a boost to the wider adoption of automation. Therefore, the adoption of unified design architecture is expected to create new opportunities for the global factory automation market during the forecast period.

The lack of a skilled workforce is expected to present challenges for the global factory automation market:

Automated machinery demands the usage of a highly skilled workforce that is well-versed in operation and maintenance of the machinery. Technical diploma-level education is required to grasp the fundamentals of automation. The lack of a skilled workforce hurts the factories since being understaffed; they cannot scale up production to meet the ever-growing demand for their goods. It ultimately prevents the wider adoption of automation in industry. The lack of a skilled workforce is expected to be a major challenge for the growth of the global factory automation market.

COVID-19 Impact Analysis

The COVID-19 pandemic caused a decline in the global factory automation market. The pandemic lockdowns disrupted various end-user industries. Many industries had to scale back, suspend or postpone capital investments due to the effects of the pandemic. Despite the short-term challenges, the pandemic is expected to positively impact the long-term outlook of the global factory automation market. The pandemic will lead to greater adoption of smart technologies such as virtual reality and artificial intelligence and their integration into factory robotics as companies are looking to boost factory efficiency with minimal human resources.

Recent Developments in the Industry:

- 1. In October 2021, Techman Robot Inc., a Taiwanese collaborative robot company, received an investment from OMRON Corporation. With its investment in Techman, the firm hopes to collaborate on novel robot solutions that integrate its industrial automation technology with Techman's collaborative robots.

- 2. In January 2022, KUKA, a German manufacturer of industrial robots, signed an agreement with Ford Otosan, the Turkish subsidiary of Ford, to supply 700 robots for Ford's new EV production facility in Kocaeli, Turkey.

Market Segmentation:

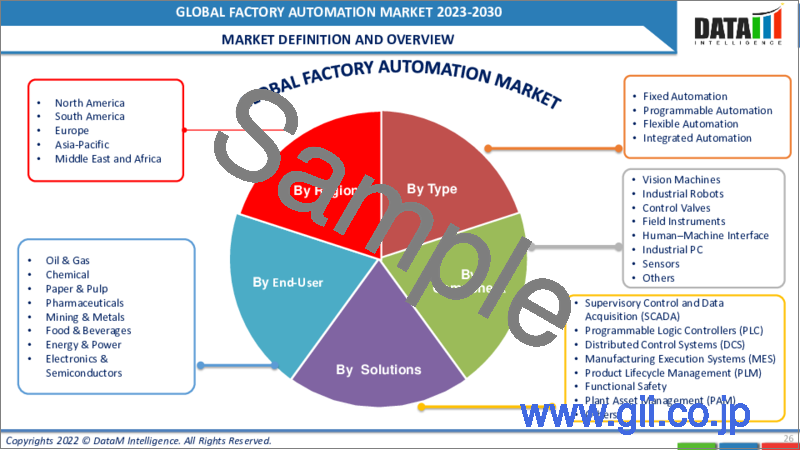

The scope of the report covers segmentation based on type, component, solutions, end-user and region. The global factory automation market is segmented by type into fixed automation, programmable automation, flexible automation, integrated automation and others. The global factory automation market is segmented by component into vision machines, industrial robots, control valves, field instruments, human-machine interface, industrial PC, sensors and others. The global factory automation market is segmented by solutions into supervisory control and data acquisition (SCADA), programmable logic controllers (PLC), distributed control systems (DCS), manufacturing execution systems (MES), product lifecycle management (PLM), functional safety, product lifecycle management (PLM) and others. The global factory automation market is segmented by end-user into oil & gas, chemicals, pulp & paper, pharmaceuticals, mining & metals, food & beverages, energy & power and automotive. The global factory automation market is segmented by region into North America, South America, Europe, Asia-Pacific, Middle East and Africa.

- 1. Fixed Automation: Fixed automation, sometimes known as "hard automation," refers to an automated manufacturing facility where the equipment setup determines the order of processing processes. In effect, the machine's programmed commands are stored in cams, gears, wires and other hardware that is difficult to modify from one product style to the next.

- 2. Programmable Automation: Programmable automation is a type of automation used to produce things in batches. The goods are manufactured in batches ranging from a few dozen to several thousand units. The production equipment must be reprogrammed and switched over for each new batch to accommodate the new product style.

- 3. Flexible Automation: Flexible automation is a manufacturing method that adapts and responds quickly to changes in production requirements, such as product kind and quantity. Flexible automation systems can produce many parts with minimal downtime during changeovers.

- 4. Integrated Automation: It is a complete manufacturing system integrated into a computer-controlled, digitally processed and coordinated system with integrated automation systems. A common production system database controls robotic bin-picking automation with conveyors-integrated automation systems. Its central automation control point integrates industrial and non-industrial processes and robot integration through automated production technologies.

- 5. Others: Numerically controlled machines, computer-aided manufacturing, industrial robots, automated production lines and automated assembly are other factory automation systems.

Regional Classification:

According to the DataM Intelligence market research report, the global factory automation market is divided into North America, South America, Europe, Asia-Pacific, Middle East and Africa.

North America is known for the early adoption of the latest technology and growing investments to save energy by adopting new technologies have led to the growth of factory automation in the region. The presence of key high-technology industries and a culture of innovation are expected to favor the growth of the North American factory automation market. Manufacturing units in Europe are compelled to implement newer technical advances and digital transformation solutions to make their business processes as effective as possible due to a rapid increase in competition and increasing end-user requirements. The increased use of robots and automation in the European automobile industry is predicted to bolster the European factory automation market. In addition, strict manufacturing and control regulations have made food and beverage manufacturers hesitant to adopt new technologies in Europe. Asia-Pacific holds the largest global factory automation market share, with China becoming the largest consumer. China is gradually building itself as one of the major automation markets in production and consumption.

Competitive Analysis:

The global factory automation market is slightly fragmented, with major players accounting for a significant market share. Technology launches, new projects, awards, acquisitions and R&D activities are key strategies adopted by players in the factory automation market. The companies compete based on price, product specifications, technologies and market presence.

Major Companies:

Some key companies contributing to the global factory automation market growth include ABB, Siemens, Schneider Electric, Mitsubishi Electric, General Electric, Honeywell, Rockwell Automation, Yokogawa Electric Corporation, HP and Omron Corporation, among others.

Additional Benefits Post Purchase:

- 1) Unlimited Analyst support for a period of 1 year.

- 2) Any query regarding the scope offered will be addressed within 24- 48 hours.

- 3) An excel sheet with market numbers will be provided separately.

The Full Report has the below insights.

The report offers a comprehensive evaluation of the market in terms of Market Value (US$) and Y-o-Y Growth Rates (%). It does so via in-depth qualitative insights, historical data (2020-2021) and verifiable projections about market size during the forecast period (2022-2029).

Visualize the composition of the global factory automation market segmentation by drone type, application and region, highlighting the key commercial assets and players.

- By Type: Fixed Automation, Programmable Automation, Flexible Automation, Integrated Automation and Others

- By Component: Vision Machines, Industrial Robots, Control Valves, Field Instruments, Human-Machine Interface, Industrial Pc, Sensors and Others

- By Solutions: Supervisory Control and Data Acquisition (SCADA), Programmable Logic Controllers (PLC), Distributed Control Systems (DCS), Manufacturing Execution Systems (MES), Product Lifecycle Management (PLM), Functional Safety, Product Lifecycle Management (PLM) and Others

- By End-User: Oil & Gas, Chemicals, Pulp & Paper, Pharmaceuticals, Mining & Metals, Food & Beverages, Energy & Power and Automotive

- By Region: North America, South America, Europe, Asia-Pacific, Middle East and Africa

- Identify commercial opportunities in the global factory automation market by analyzing trends and co-development deals.

- The report also covers data insights on various industry forces such as porter's five forces, regulations in each country, reimbursement scenario, technological advancements, PEST analysis and pricing analysis.

- Excel data sheet with thousands of global factory automation market-level 4/5 segmentation data points.

- PDF report with the most relevant analysis cogently put together after exhaustive qualitative interviews and in-depth market study.

- Product mapping in excel for the key product of all major market players

- The report will provide access to approximately 50+ market data tables, 40+ figures and close to 296 pages.

Table of Contents

1. Global Factory Automation Market Methodology and Scope

- 1.1. Research Methodology

- 1.2. Research Objective and Scope of the Report

2. Global Factory Automation Market - Market Definition and Overview

3. Global Factory Automation Market - Executive Summary

- 3.1. Market Snippet by Type

- 3.2. Market Snippet by Component

- 3.3. Market Snippet by Solutions

- 3.4. Market Snippet by End-User

- 3.5. Market Snippet by Region

4. Global Factory Automation Market-Market Dynamics

- 4.1. Market Impacting Factors

- 4.1.1. Drivers

- 4.1.1.1. The growing use of automation in industries is a major driver for the global factory automation market

- 4.1.1.2. XX

- 4.1.2. Restraints

- 4.1.2.1. High capital investment associated with automation is expected to restrain the global factory automation market

- 4.1.2.2. XX

- 4.1.3. Opportunity

- 4.1.3.1. XX

- 4.1.4. Impact Analysis

- 4.1.1. Drivers

5. Global Factory Automation Market - Industry Analysis

- 5.1. Porter's Five Forces Analysis

- 5.2. Supply Chain Analysis

- 5.3. Pricing Analysis

- 5.4. Regulatory Analysis

6. Global Factory Automation Market - COVID-19 Analysis

- 6.1. Analysis of COVID-19 on the Market

- 6.1.1. Before COVID-19 Market Scenario

- 6.1.2. Present COVID-19 Market Scenario

- 6.1.3. After COVID-19 or Future Scenario

- 6.2. Pricing Dynamics Amid COVID-19

- 6.3. Demand-Supply Spectrum

- 6.4. Government Initiatives Related to the Market During Pandemic

- 6.5. Manufacturers Strategic Initiatives

- 6.6. Conclusion

7. Global Factory Automation Market - By Type

- 7.1. Introduction

- 7.1.1. Market Size Analysis and Y-o-Y Growth Analysis (%), By Type

- 7.1.2. Market Attractiveness Index, By Type

- 7.2. Fixed Automation *

- 7.2.1. Introduction

- 7.2.2. Market Size Analysis and Y-o-Y Growth Analysis (%)

- 7.3. Programmable Automation

- 7.4. Flexible Automation

- 7.5. Integrated Automation

- 7.6. Others

8. Global Factory Automation Market - By Component

- 8.1. Introduction

- 8.1.1. Market Size Analysis and Y-o-Y Growth Analysis (%), By Component

- 8.1.2. Market Attractiveness Index, By Component

- 8.2. Vision Machines*

- 8.2.1. Introduction

- 8.2.2. Market Size Analysis and Y-o-Y Growth Analysis (%)

- 8.3. Industrial Robots

- 8.4. Control Valves

- 8.5. Field Instruments

- 8.6. Human-Machine Interface

- 8.7. Industrial PC

- 8.8. Sensors

- 8.9. Others

9. Global Factory Automation Market - By Solutions

- 9.1. Introduction

- 9.1.1. Market Size Analysis and Y-o-Y Growth Analysis (%), By Solutions

- 9.1.2. Market Attractiveness Index, By Solutions

- 9.2. Supervisory Control and Data Acquisition (SCADA)*

- 9.2.1. Introduction

- 9.2.2. Market Size Analysis and Y-o-Y Growth Analysis (%)

- 9.3. Programmable Logic Controllers (PLC)

- 9.4. Distributed Control Systems (DCS)

- 9.5. Manufacturing Execution Systems (MES)

- 9.6. Product Lifecycle Management (PLM)

- 9.7. Functional Safety

- 9.8. Plant Asset Management (PAM)

- 9.9. Others

10. Global Factory Automation Market - By End-User

- 10.1. Introduction

- 10.1.1. Market Size Analysis and Y-o-Y Growth Analysis (%), By End-User

- 10.1.2. Market Attractiveness Index, By End-User

- 10.2. Oil & Gas *

- 10.2.1. Introduction

- 10.2.2. Market Size Analysis and Y-o-Y Growth Analysis (%)

- 10.3. Chemicals

- 10.4. Paper & Pulp

- 10.5. Pharmaceuticals

- 10.6. Mining & Metals

- 10.7. Food & Beverages

- 10.8. Energy & Power

- 10.9. Automotive

- 10.10. Electronics & Semiconductors

- 10.11. Aerospace and Defense

- 10.12. Medical Devices

- 10.13. Others

11. Global Factory Automation Market - By Region

- 11.1. Introduction

- 11.1.1. Market Size Analysis and Y-o-Y Growth Analysis (%), By Region

- 11.1.2. Market Attractiveness Index, By Region

- 11.2. North America

- 11.2.1. Introduction

- 11.2.2. Key Region-Specific Dynamics

- 11.2.3. Market Size Analysis and Y-o-Y Growth Analysis (%), By Type

- 11.2.4. Market Size Analysis and Y-o-Y Growth Analysis (%), By Component

- 11.2.5. Market Size Analysis and Y-o-Y Growth Analysis (%), By Solutions

- 11.2.6. Market Size Analysis and Y-o-Y Growth Analysis (%), By End-User

- 11.2.7. Market Size Analysis and Y-o-Y Growth Analysis (%), By Country

- 11.2.7.1. U.S.

- 11.2.7.2. Canada

- 11.2.7.3. Mexico

- 11.3. Europe

- 11.3.1. Introduction

- 11.3.2. Key Region-Specific Dynamics

- 11.3.3. Market Size Analysis and Y-o-Y Growth Analysis (%), By Type

- 11.3.4. Market Size Analysis and Y-o-Y Growth Analysis (%), By Component

- 11.3.5. Market Size Analysis and Y-o-Y Growth Analysis (%), By Solutions

- 11.3.6. Market Size Analysis and Y-o-Y Growth Analysis (%), By End-User

- 11.3.7. Market Size Analysis and Y-o-Y Growth Analysis (%), By Country

- 11.3.7.1. Germany

- 11.3.7.2. UK

- 11.3.7.3. France

- 11.3.7.4. Italy

- 11.3.7.5. Spain

- 11.3.7.6. Rest of Europe

- 11.4. South America

- 11.4.1. Introduction

- 11.4.2. Key Region-Specific Dynamics

- 11.4.3. Market Size Analysis and Y-o-Y Growth Analysis (%), By Type

- 11.4.4. Market Size Analysis and Y-o-Y Growth Analysis (%), By Component

- 11.4.5. Market Size Analysis and Y-o-Y Growth Analysis (%), By Solutions

- 11.4.6. Market Size Analysis and Y-o-Y Growth Analysis (%), By End-User

- 11.4.7. Market Size Analysis and Y-o-Y Growth Analysis (%), By Country

- 11.4.7.1. Brazil

- 11.4.7.2. Argentina

- 11.4.7.3. Rest of South America

- 11.5. Asia-Pacific

- 11.5.1. Introduction

- 11.5.2. Key Region-Specific Dynamics

- 11.5.3. Market Size Analysis and Y-o-Y Growth Analysis (%), By Type

- 11.5.4. Market Size Analysis and Y-o-Y Growth Analysis (%), By Component

- 11.5.5. Market Size Analysis and Y-o-Y Growth Analysis (%), By Solutions

- 11.5.6. Market Size Analysis and Y-o-Y Growth Analysis (%), By End-User

- 11.5.7. Market Size Analysis and Y-o-Y Growth Analysis (%), By Country

- 11.5.7.1. China

- 11.5.7.2. India

- 11.5.7.3. Japan

- 11.5.7.4. South Korea

- 11.5.7.5. Rest of Asia-Pacific

- 11.6. Middle East and Africa

- 11.6.1. Introduction

- 11.6.2. Key Region-Specific Dynamics

- 11.6.3. Market Size Analysis and Y-o-Y Growth Analysis (%), By Type

- 11.6.4. Market Size Analysis and Y-o-Y Growth Analysis (%), By Component

- 11.6.5. Market Size Analysis and Y-o-Y Growth Analysis (%), By Solutions

- 11.6.6. Market Size Analysis and Y-o-Y Growth Analysis (%), By End-User

12. Global Factory Automation Market - Competitive Landscape

- 12.1. Competitive Scenario

- 12.2. Market Positioning/Share Analysis

- 12.3. Mergers and Acquisitions Analysis

13. Global Factory Automation Market- Company Profiles

- 13.1. ABB*

- 13.1.1. Company Overview

- 13.1.2. End-User Portfolio and Description

- 13.1.3. Key Highlights

- 13.1.4. Financial Overview

- 13.2. Rockwell Automation, Inc.

- 13.3. Yokogawa Electric Corporation

- 13.4. Hewlett Packard Enterprise Development LP

- 13.5. OMRON Corporation

- 13.6. Honeywell International Inc

- 13.7. Mitsubishi Electric Corporation

- 13.8. GE DIGITAL

- 13.9. Schneider Electric

- 13.10. Siemens AG

LIST NOT EXHAUSTIVE

14. Global Factory Automation Market - Premium Insights

15. Global Factory Automation Market - DataM

- 15.1. Appendix

- 15.2. About Us and Services

- 15.3. Contact Us